Board material cutting device

A cutting device and plate technology, used in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of poor stability, severe wall panel vibration, low cutting accuracy, etc., to reduce cutting vibration, improve cutting accuracy, avoid The effect of accidental injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

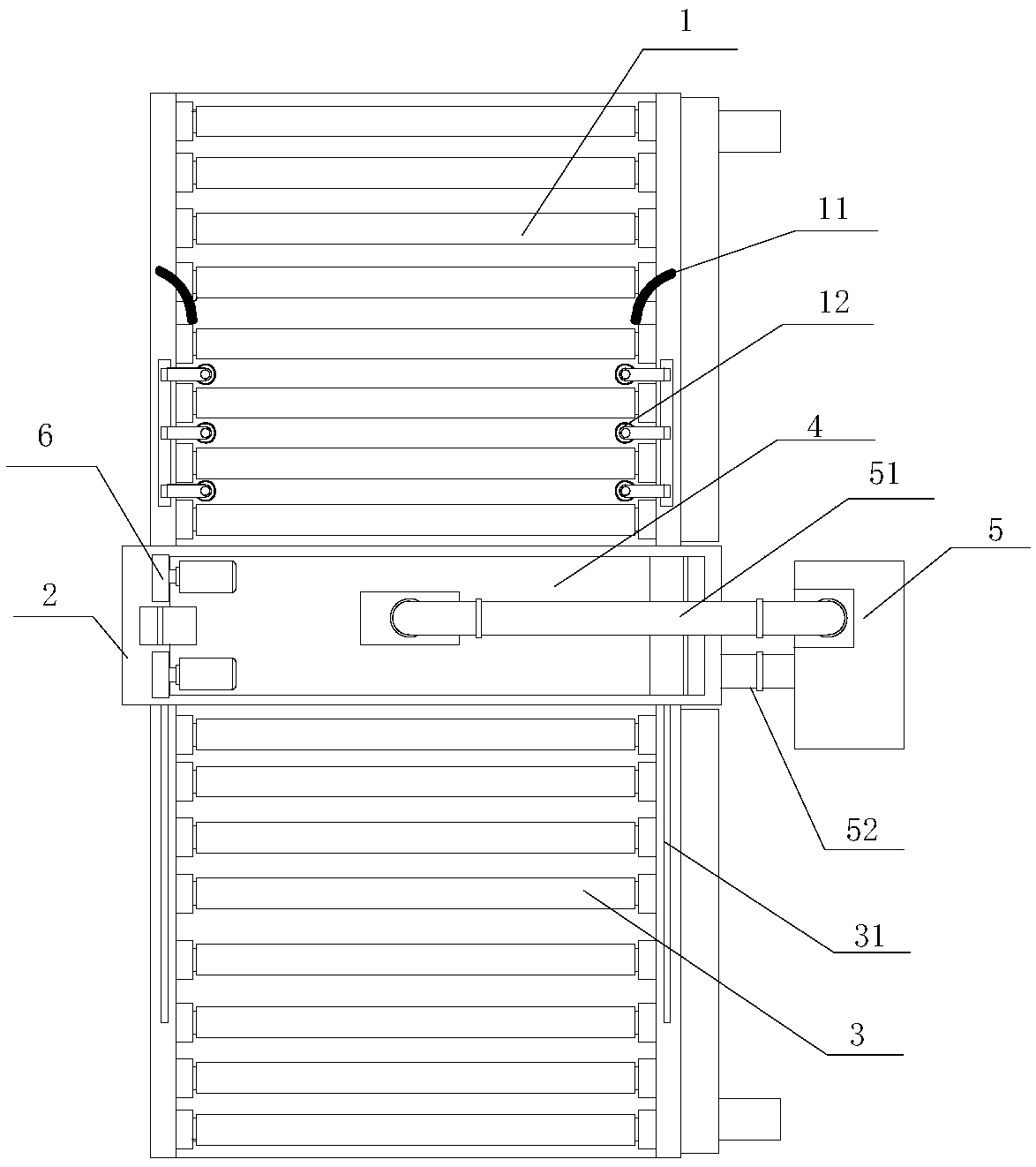

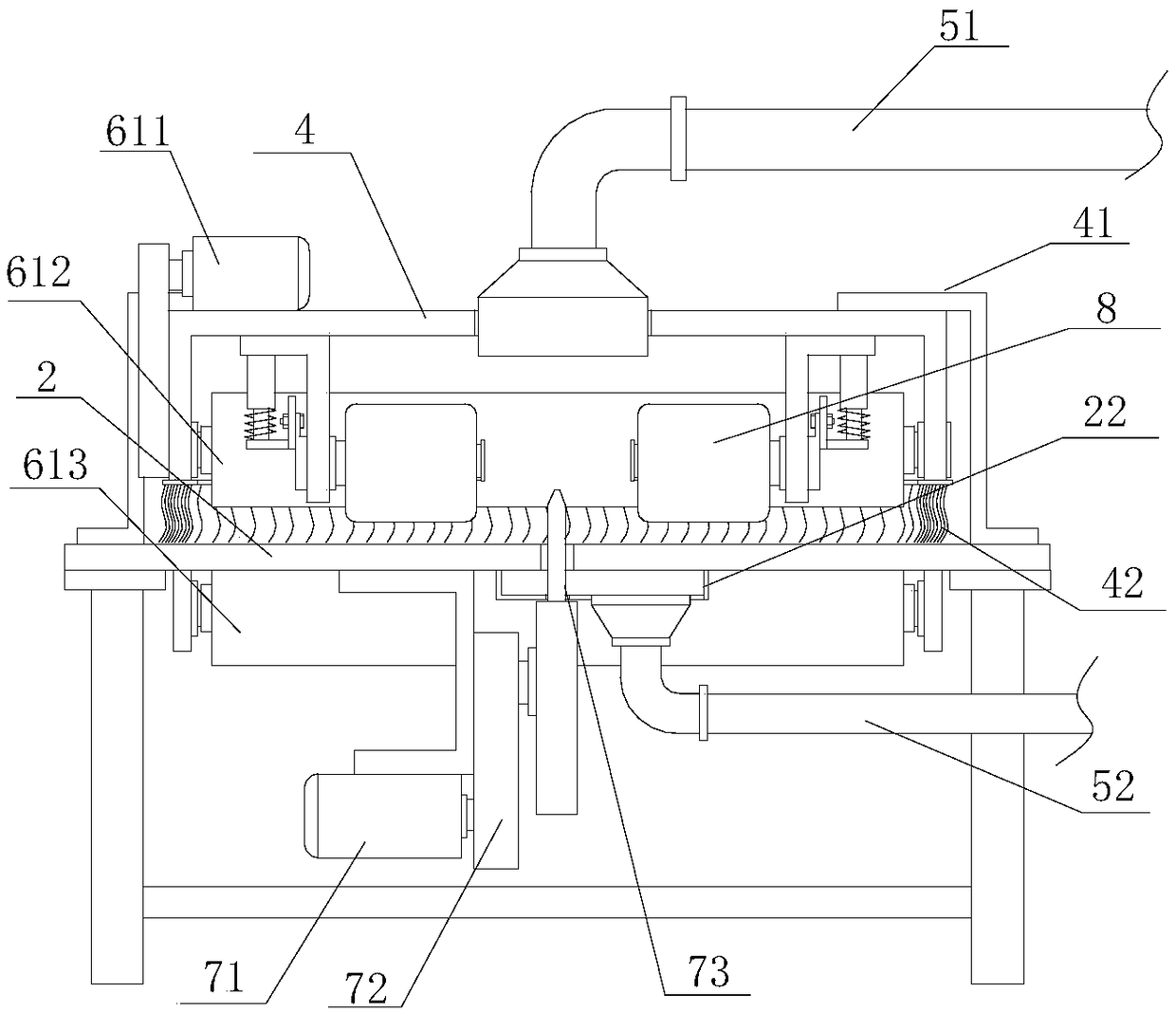

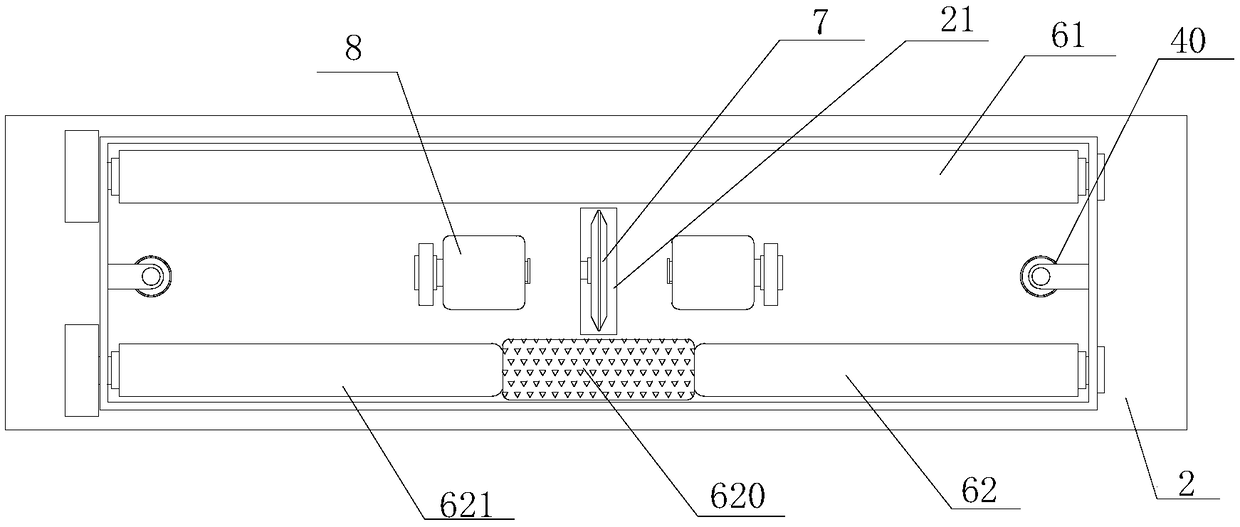

[0017] refer to Figure 1 to Figure 4 , a plate cutting device of the present invention, comprising a feeding roller device 1, a frame 2, a feeding roller device 3, a dust removal protective cover 4, a dust suction device 5, an auxiliary feeding roller device 6, a cutting device 7 and an auxiliary press Material roller mechanism 8, the two ends of described frame 2 are respectively provided with feeding conveying roller device 1 and unloading conveying roller device 3, and described dust removal protective cover 4 is installed on the top of frame 2, and described dust removal protective cover 4 The upper part of the upper side is connected with the dust suction device 5 through the first dust collection pipe 51. The dust removal protective cover 4 is provided with an auxiliary feeding roller device 6, a cutting device 7 and an auxiliary nip roller mechanism 8. The frame 2 is provided with There is a knife groove 21, the cutting device 7 is installed below the frame 2, the cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com