Automated saw for splitting carcasses

A torso, livestock technology, applied in applications, meat holding devices, slaughter accessories, etc., can solve the problems of slow processing, limiting accurate positioning of saws, inaccurate meat processing industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

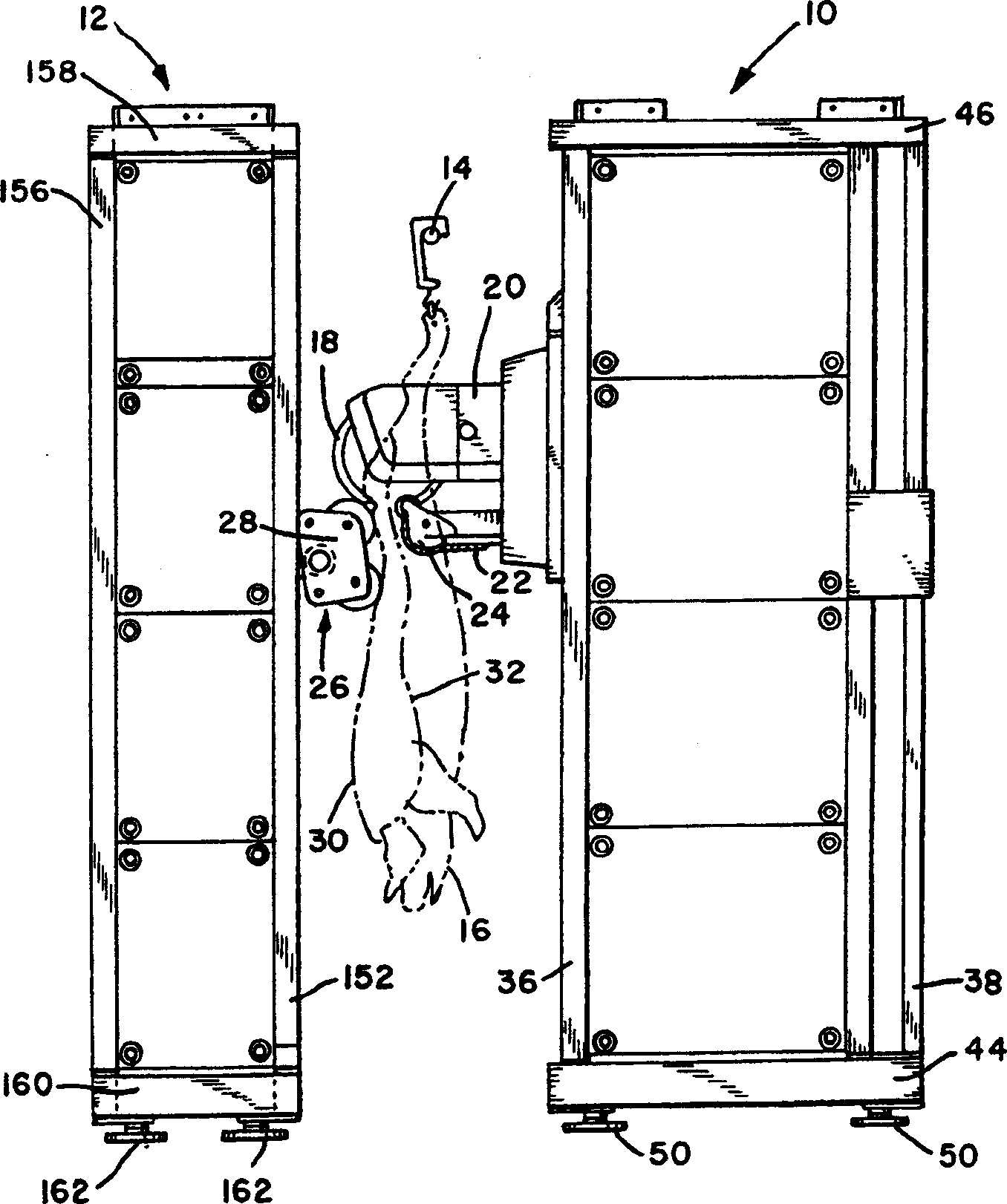

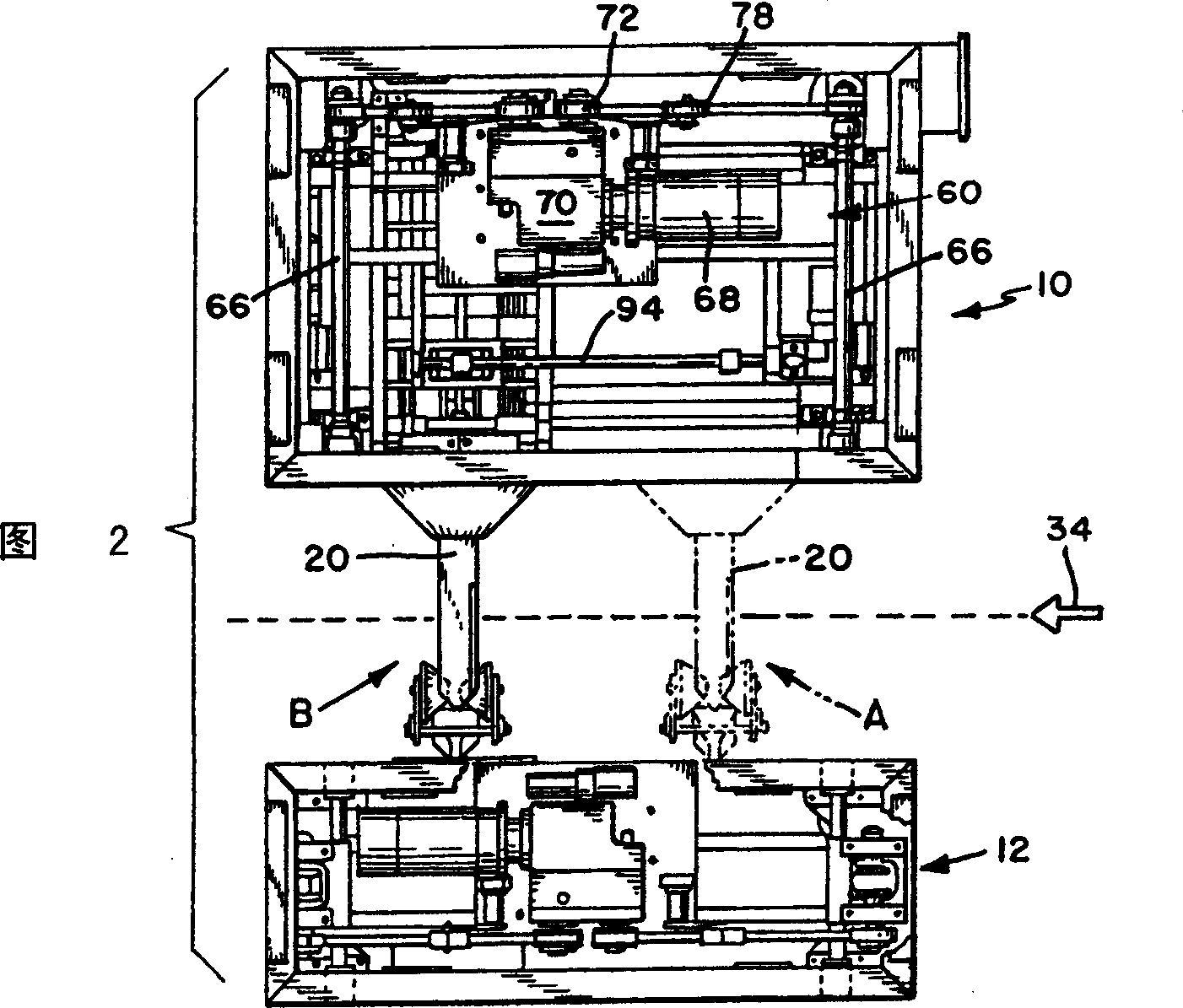

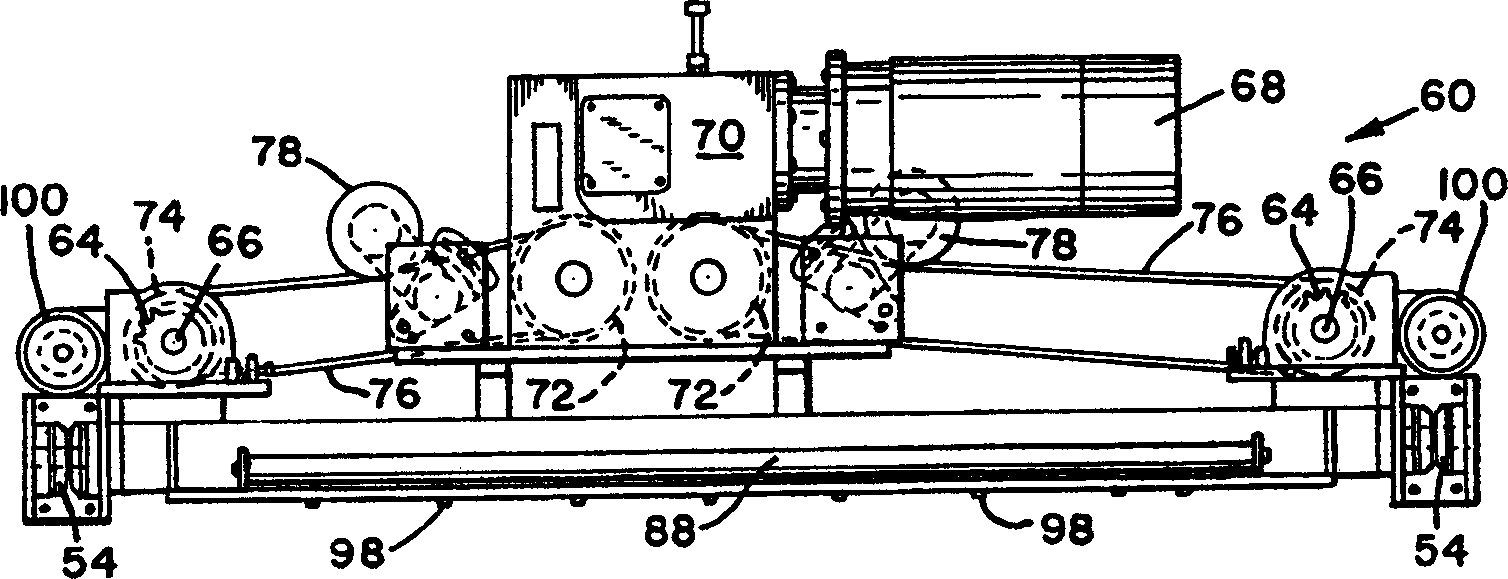

[0062] In describing the preferred embodiment of the invention reference is made to figure 1 -22, the same reference numerals in these figures denote the same features of the present invention.

[0063] see figure 1 , the present invention generally includes a splitting station 10 and a back roller station 12, which are located on opposite sides of a livestock trunk track 14. Livestock trunks 16 are suspended by rail cars on livestock trunk tracks 14 by their hind feet, and the livestock trunks are continuously driven between the splitting station 10 and the back roller station 12, in which case these trunks are cut with a saw 18. open.

[0064] The animal trunk is first positioned by extending the lead roller assembly 24 from the splitting station 10 and extending the back roller assembly 28 from the back roller station 12 . The saw 18 is then extended to cut vertically while the saw, guide rollers and back wheels all track the moving animal body. The rollers and saw are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com