Live pig splitting machine

A technology for pigs and pillars, applied in splitting tools, slaughtering accessories, slaughtering, etc., can solve the problems of pig bone slag submerged in pork, pig bone slag splashing everywhere, affecting meat quality, etc., shortening the splitting time by half, and simple structure , The effect of low equipment manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the purpose of the present invention and the advantages of the technical solution more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples.

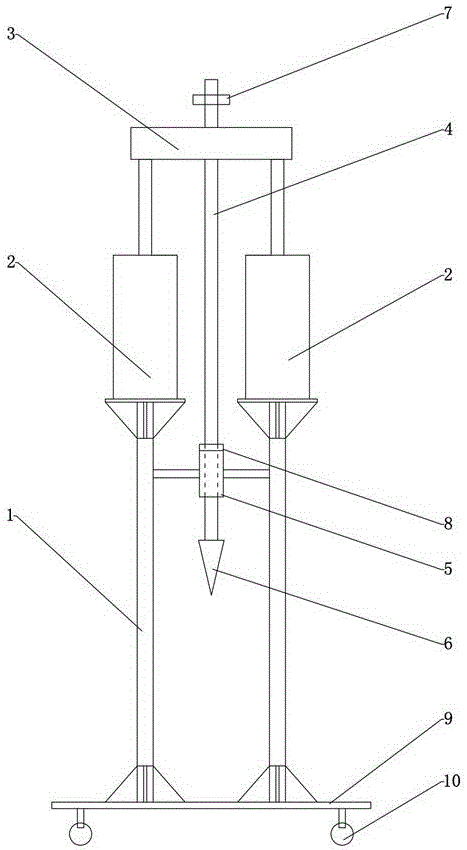

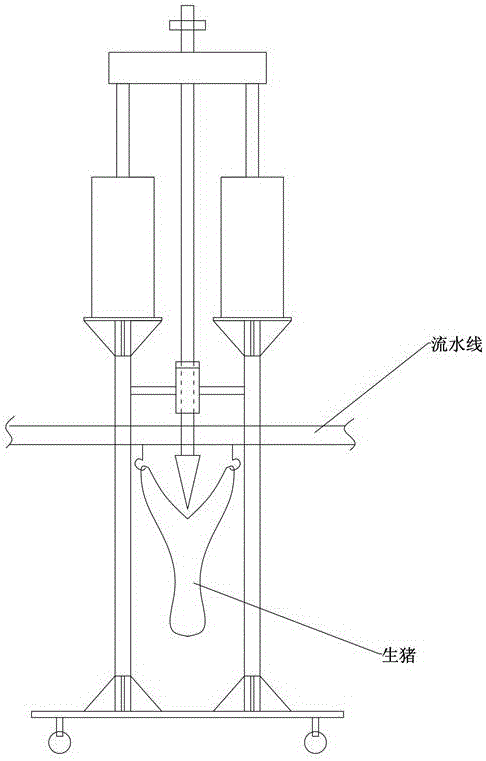

[0015] as attached figure 1 and 2 As shown, the pig splitting machine is characterized in that: it includes two pillars 1, and a cylinder 2 is respectively installed on the top of the two pillars 1, and the tops of the piston rods of the two cylinders 2 are connected with the electronic hoop 3, A straight rod-shaped knife handle 4 in the vertical direction at the central position between the two cylinders 2 is provided with a guide cylinder 5 on the two pillars 1 and the guide cylinder 5 is fixedly connected to the pillar 1, The knife handle 4 passes through the electronic hoop 3 and the guide cylinder 5 and a knife head 6 is connected to the bottom end of the knife handle 4 .

[0016] Further, a limit nut 7 is provided at the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com