Leakage detecting device of high-temperature flange connecting system

A connection system, high temperature flange technology, used in flange connection, pipe/pipe joint/pipe fitting, through components, etc., can solve the problem that non-bolt connection can not be tested, affect the normal force of gaskets, and high equipment cost problem, to achieve the effect of low cost, simple structure and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

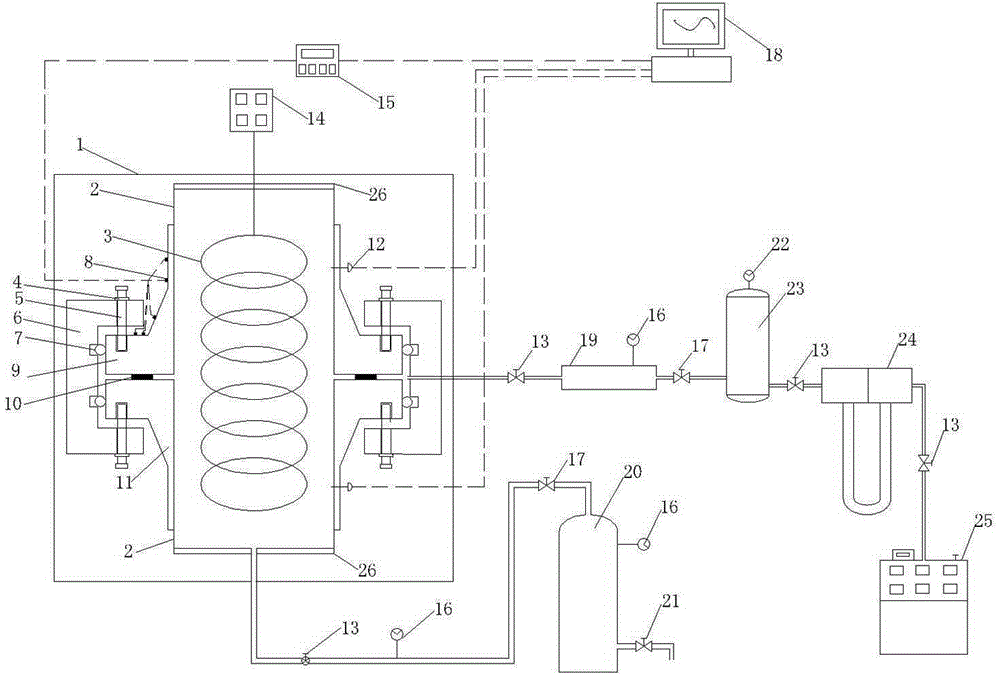

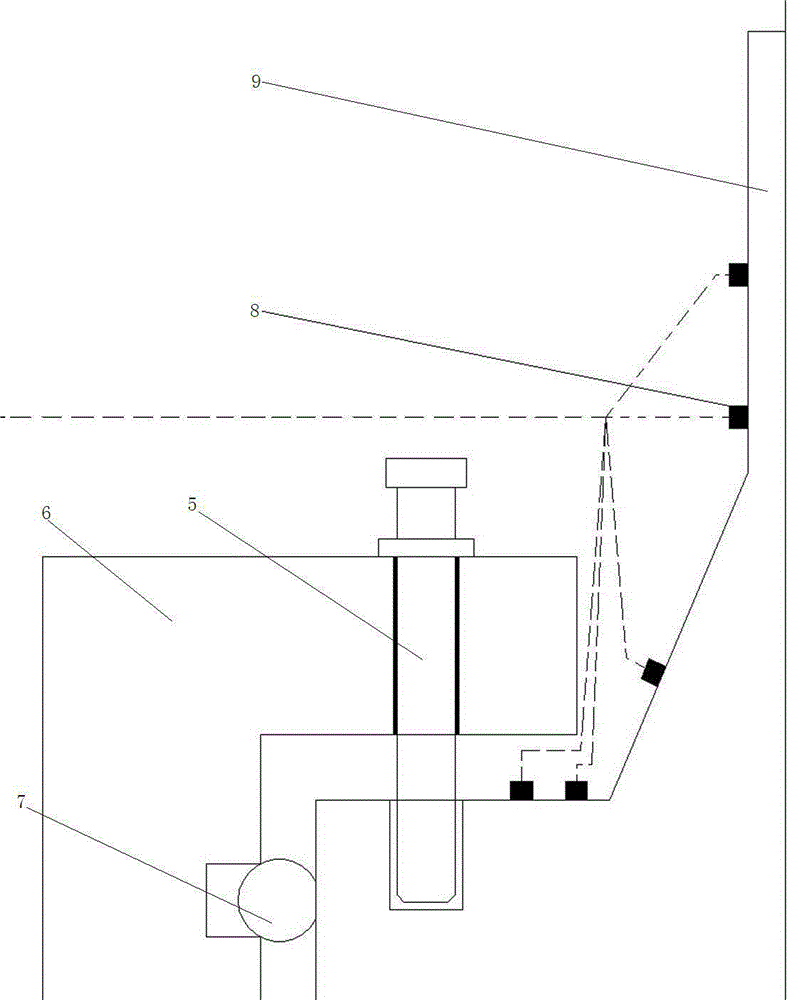

[0027] Such as figure 1 As shown, a leak detection device of a high temperature flange connection system includes two leak detection pipes 2, a first flange 9 and a second flange 11 connecting the two leak detection pipes 2, and a first flange 9 and the gasket 10 between the sealing surface of the second flange 11, the heating mechanism, the pressurizing mechanism, the non-connecting ends of the two leak detection pipes 2 are closed (through the blind plate 26) and a sealed cavity is formed inside, the heating mechanism Located in the sealed chamber, the pressurizing mechanism delivers gas to the sealed chamber; the outer side of the first flange 9 and the second flange 11 is covered with an annular rigid part 6, and the inner side of the rigid part 6 is provided with two annular grooves, and the annular concave Sealing rings 7 are provided in the groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com