Negative pressure type embossing device capable of rapidly unfolding clothes

A negative pressure and embossing technology, which is applied in the field of garment processing, can solve problems affecting embossing quality, garment wrinkles, and garment embossing printing position offset, etc., to facilitate normal embossing operations, avoid wrinkles, and improve embossing. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

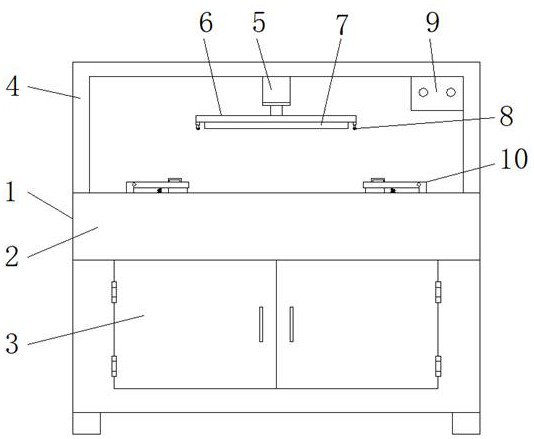

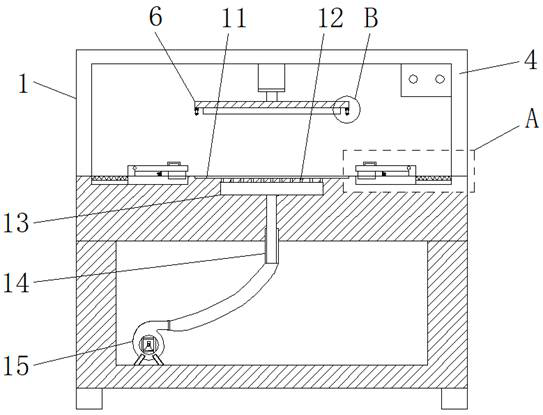

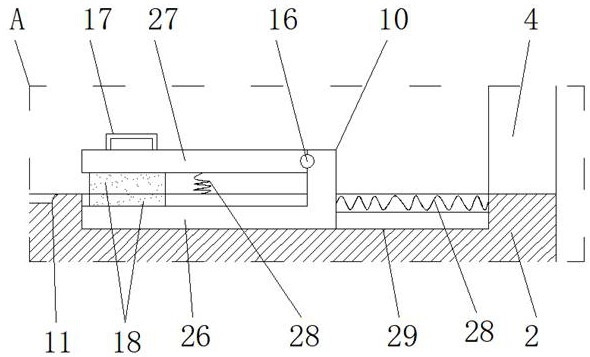

[0027] see Figure 1-8 , the present invention provides a technical solution: a negative pressure embossing device that can quickly deploy clothing, including an embossing device body 1, an operating table 2, a protective door 3, a support frame 4, a telescopic mechanism 5, and a support plate 6 , embossing plate 7, pressing wheel 8, control box 9, tensioning structure 10, pressing groove 11, negative pressure hole 12, communication cavity 13, connecting pipe 14, exhaust fan 15, reset rotating shaft 16, pulling frame 17, Pressing block 18, supporting column 19, connecting sleeve 20, lifting groove 21, mounting groove 22, fixing screw 23, embossing area 24, embossing part 25, sliding part 26, pressing part 27, spring 28 and sliding groove 29 , the embossing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com