Patents

Literature

32results about How to "Play a straightening role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

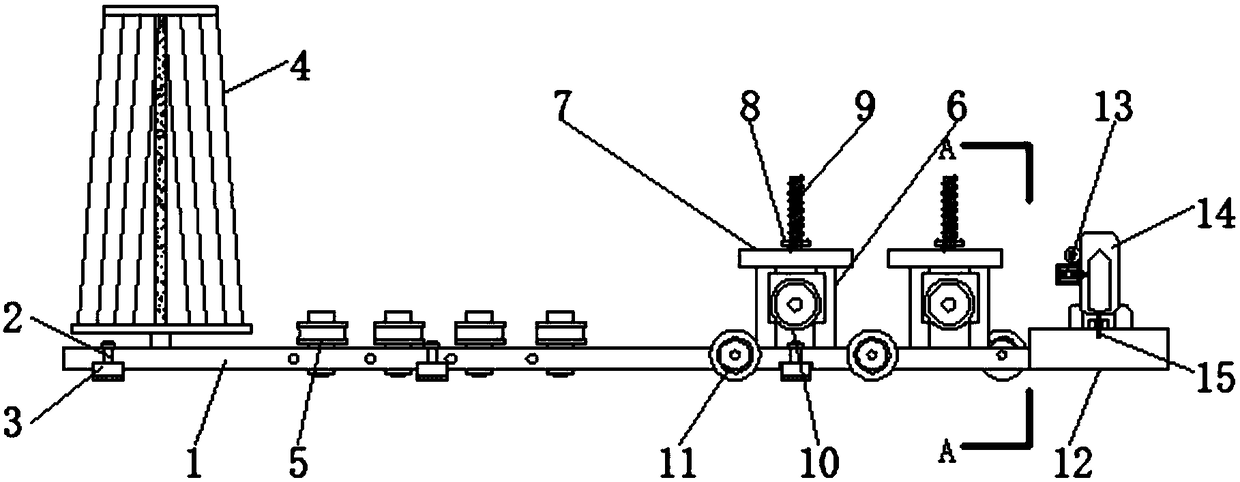

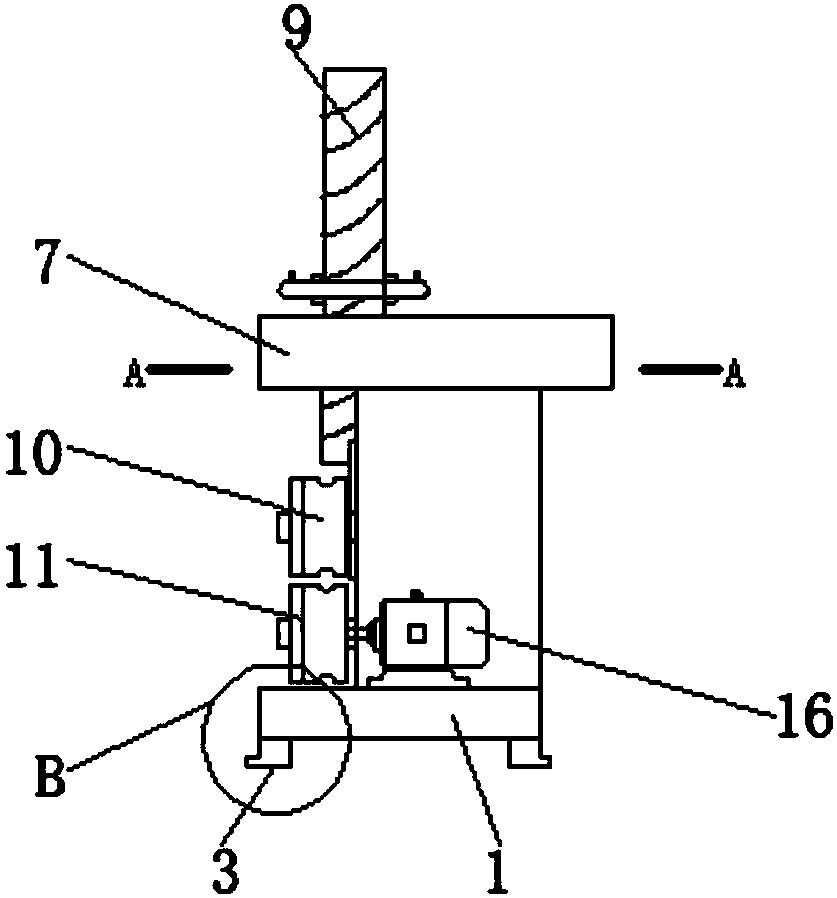

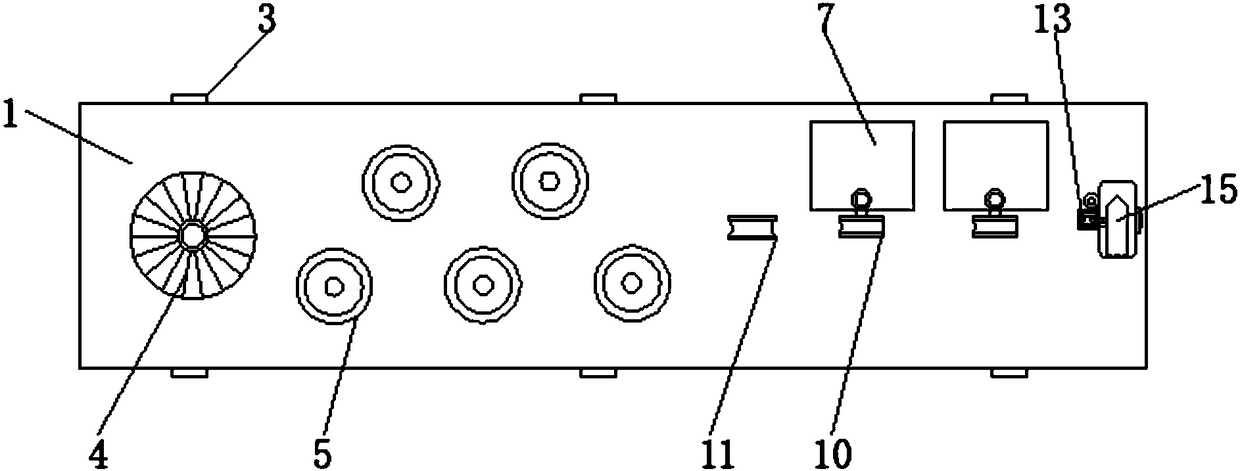

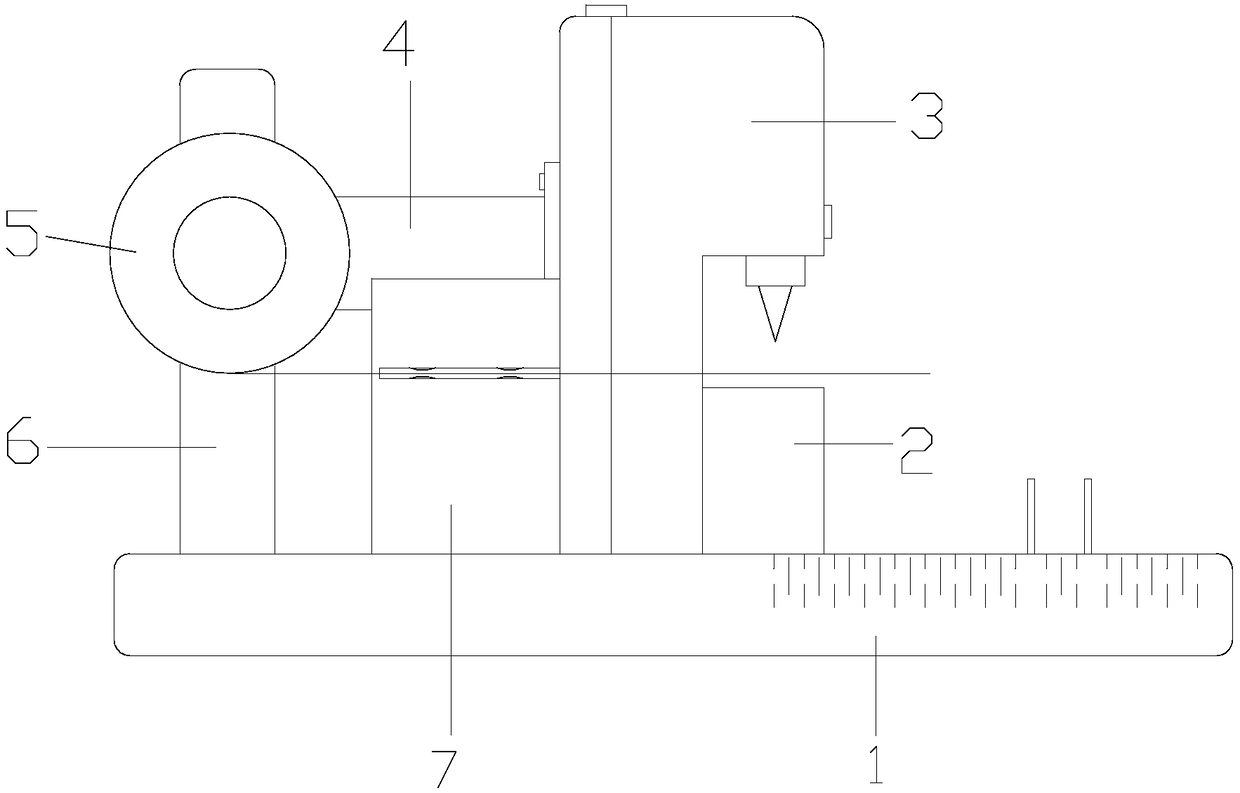

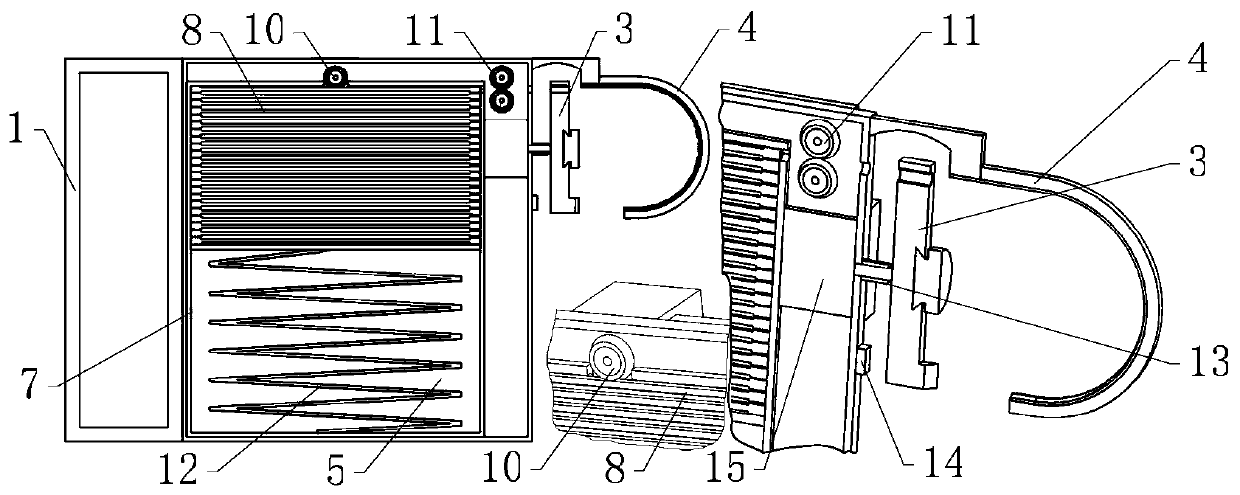

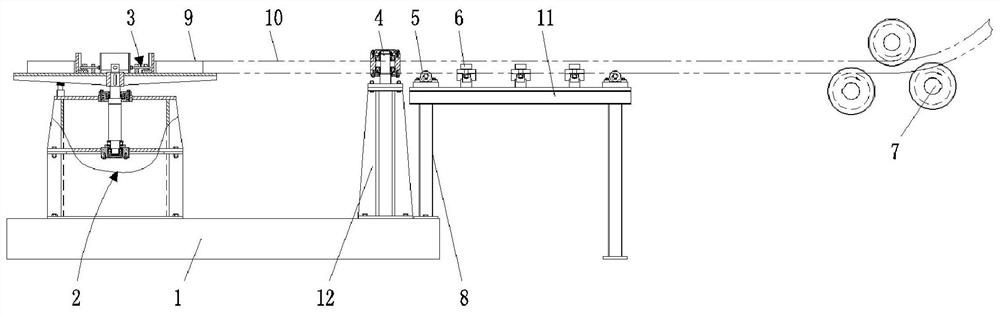

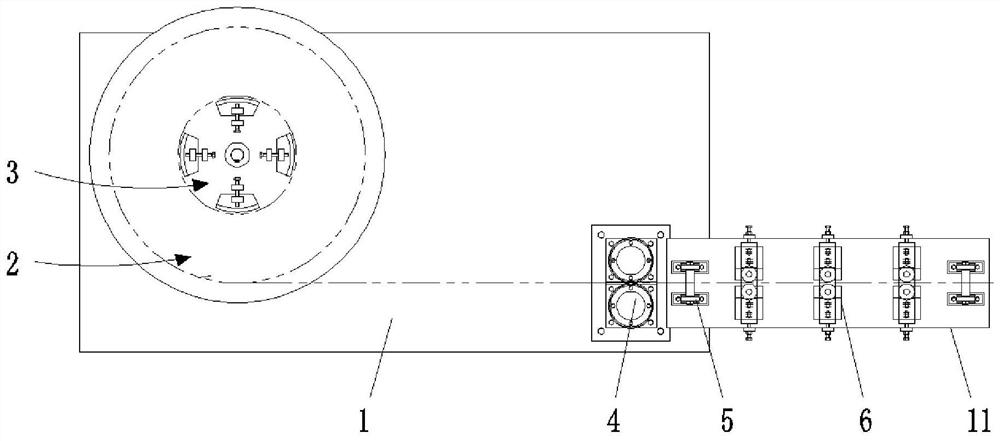

Reinforcing steel bar straightening and cutting all-in-one machine

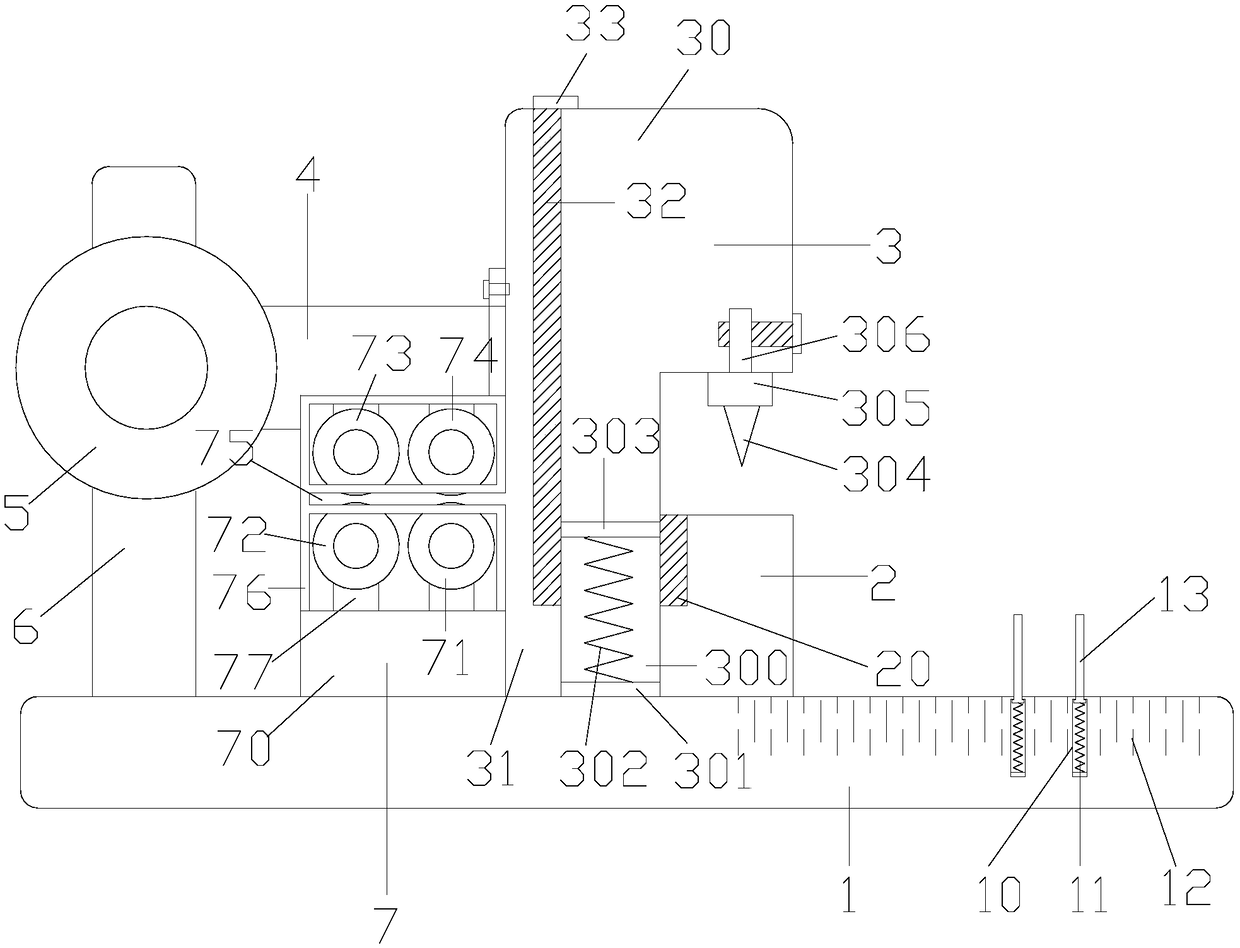

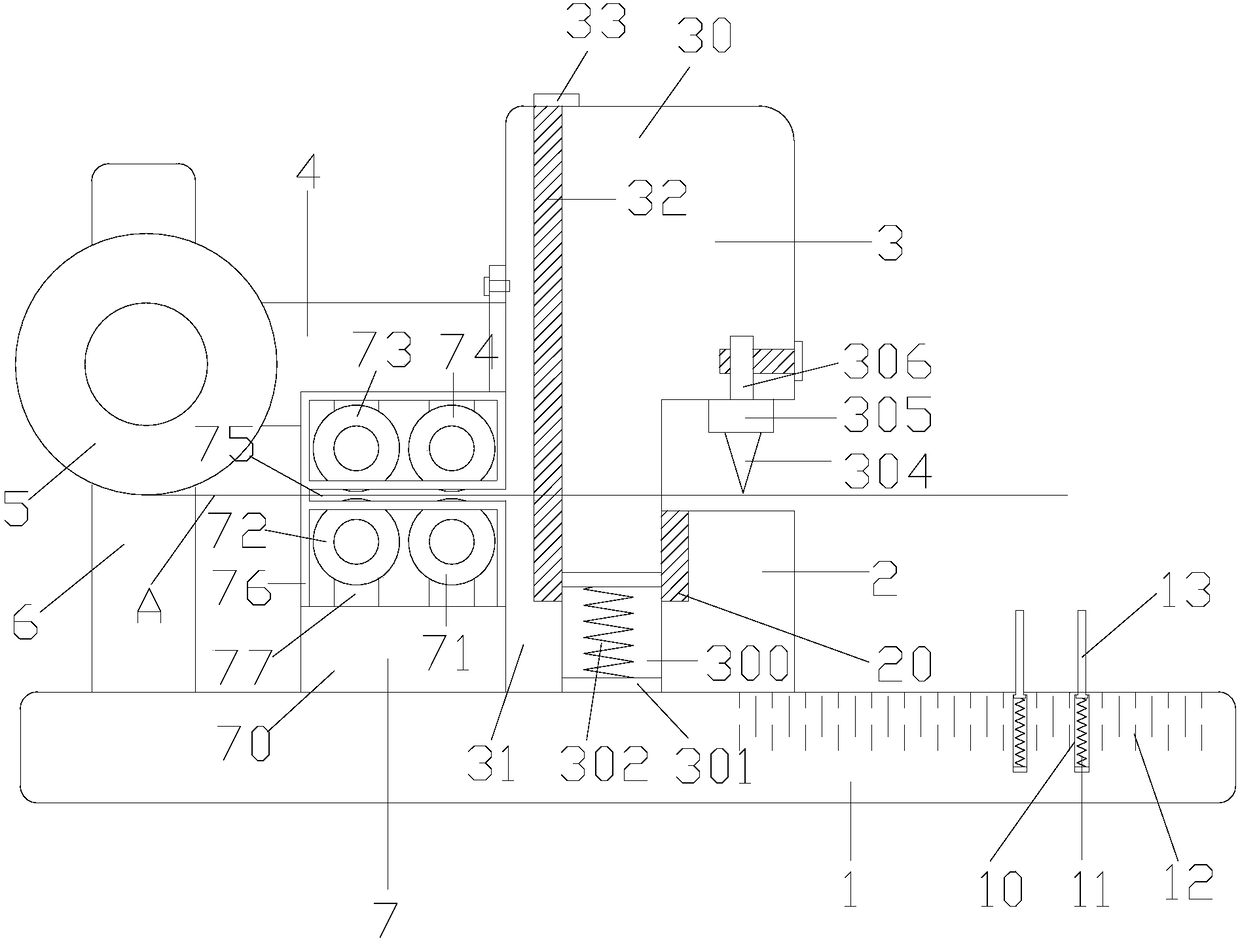

The invention relates to a reinforcing steel bar straightening and cutting all-in-one machine. The reinforcing steel bar straightening and cutting all-in-one machine comprises a bottom plate, a horizontal guide wheel, a straightening machine body and a driving straightening wheel; an adjusting mechanism is arranged in the bottom plate in a penetrating manner, the lower end of the adjusting mechanism is connected with a fixed frame, the fixed frame is arranged in the bottom plate, a paying-off cage is arranged at the upper end of the bottom plate, and the horizontal guide wheel is arranged above the bottom plate; the paying-off cage is arranged on one side of the horizontal guide wheel, the straightening machine body is arranged above the bottom plate, the horizontal guide wheel is arrangedon one side of the straightening machine body, a worktable is fixed to the upper end of the straightening machine body, a thread rod is arranged in the upper end of the worktable in a penetrating manner, the lower end of the thread rod is connected with the driven straightening wheel, the thread rod penetrates into the adjusting wheel, the driving straightening wheel is arranged on the outer sideof the bottom plate, one side of the driving straightening wheel is connected with a second motor, and a cutting table is arranged at one end of the bottom plate. The reinforcing steel bar straightening and cutting all-in-one machine can achieve straightening and cutting of reinforcing steel bars, and use is convenient.

Owner:冼辉

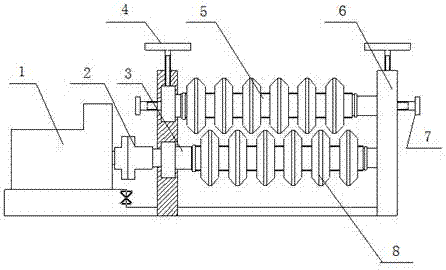

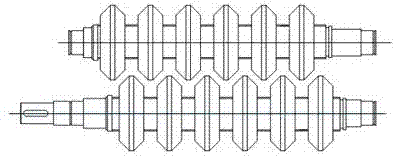

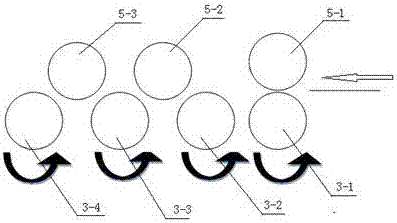

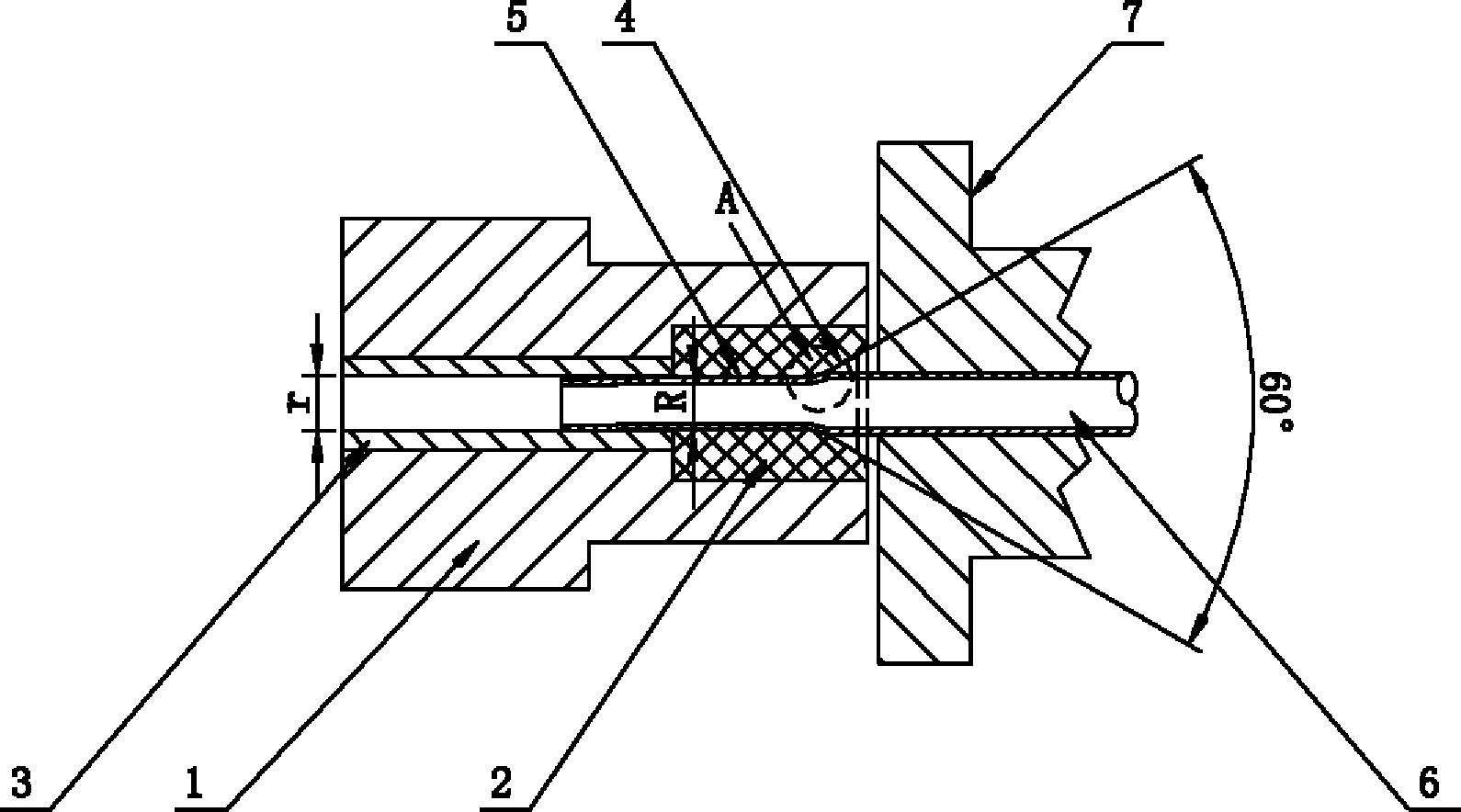

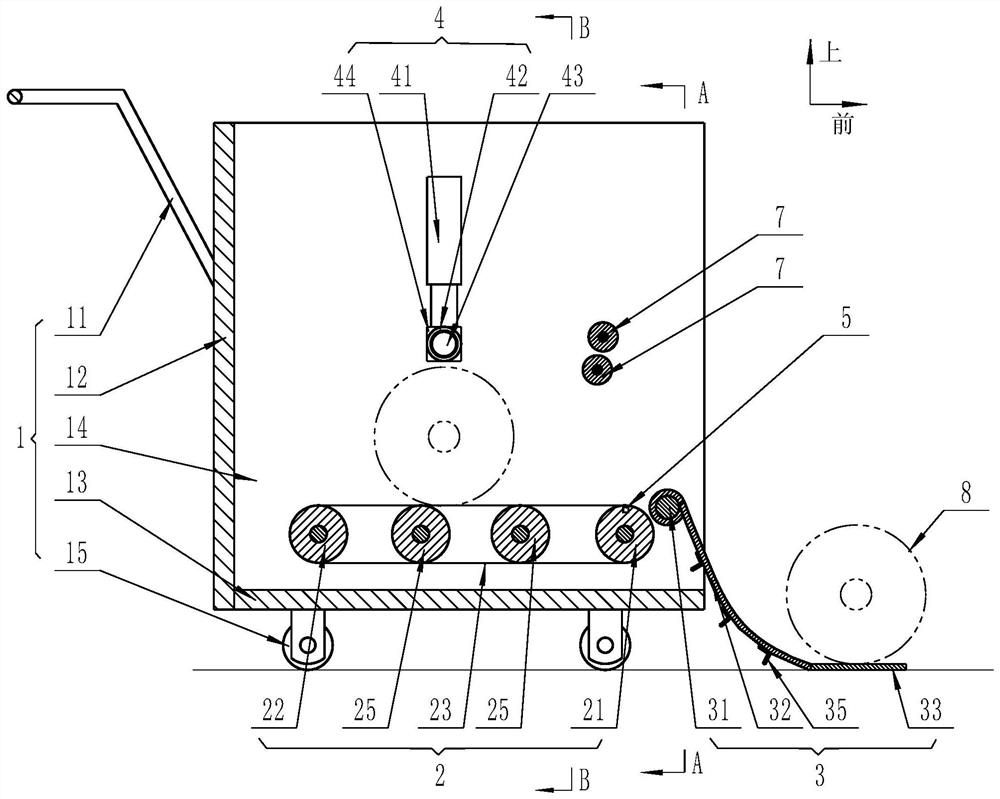

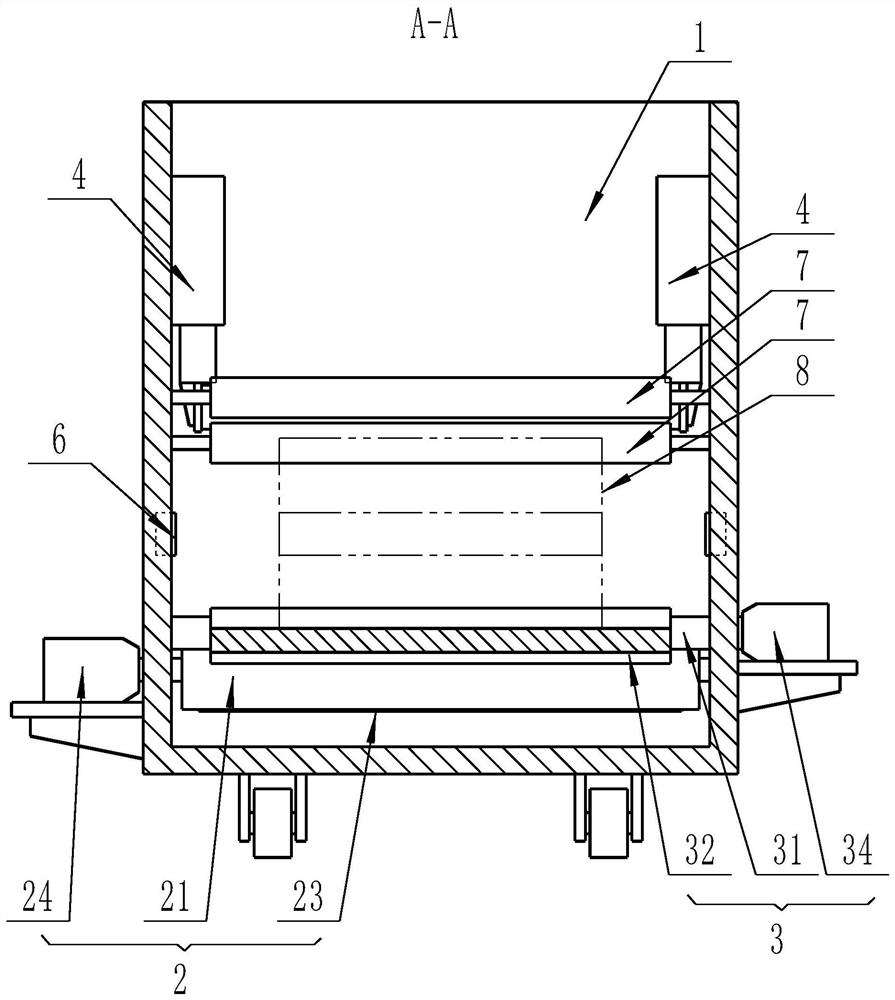

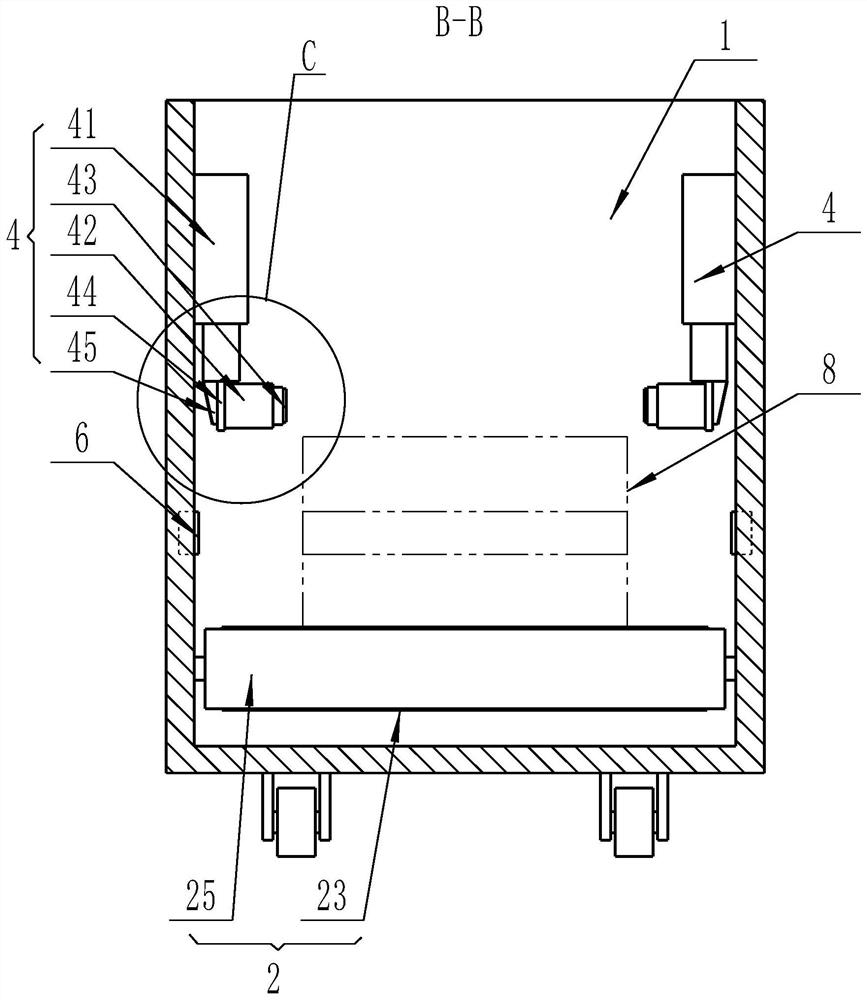

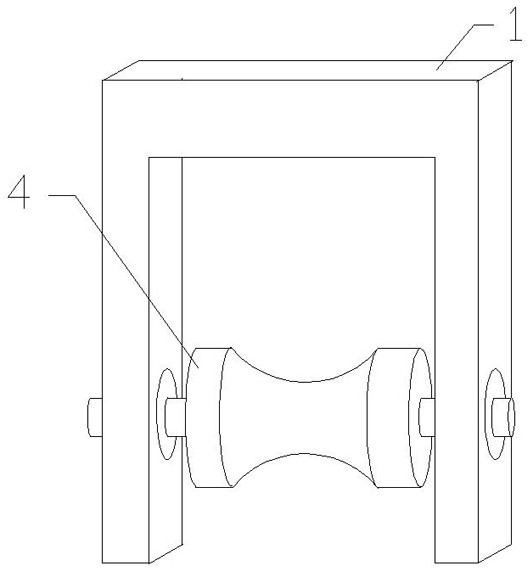

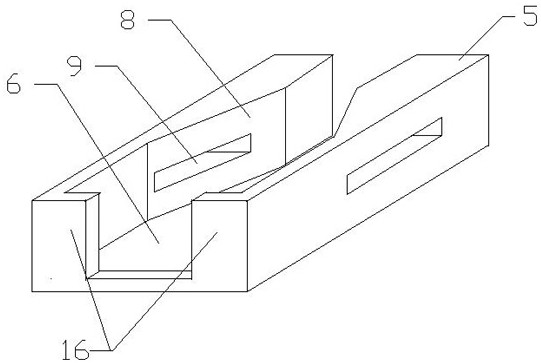

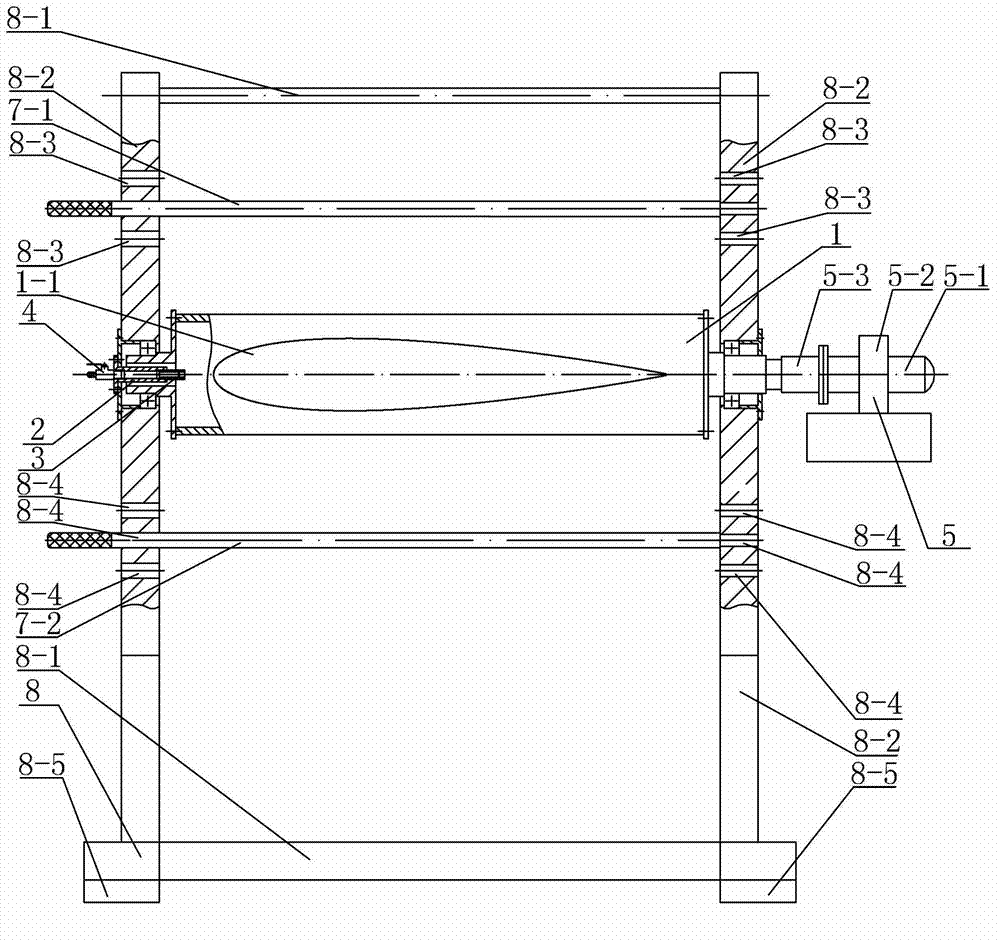

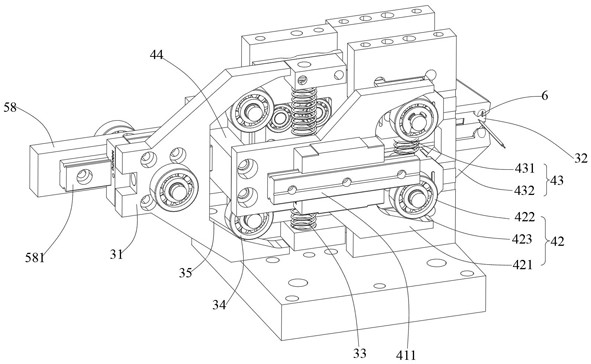

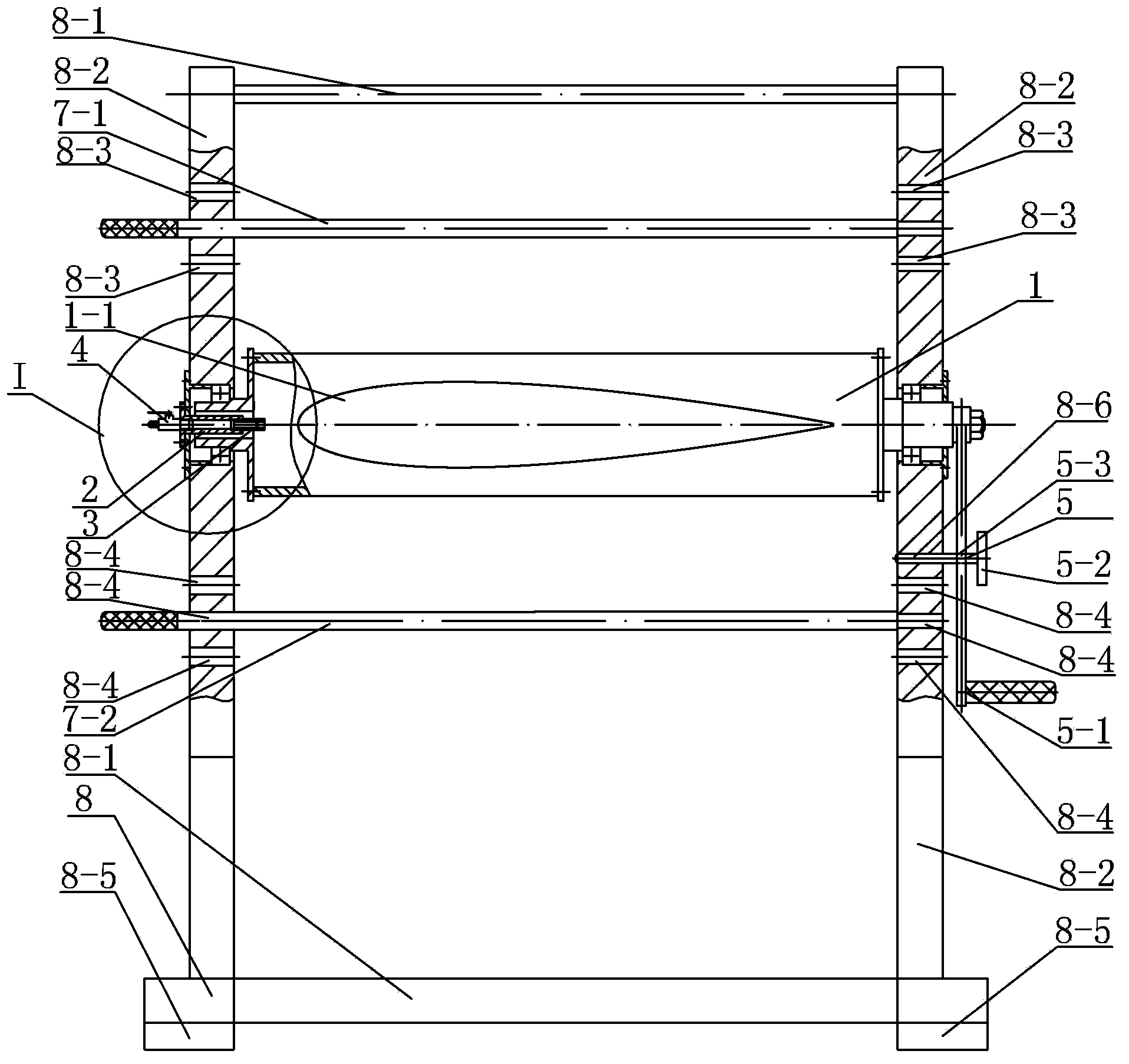

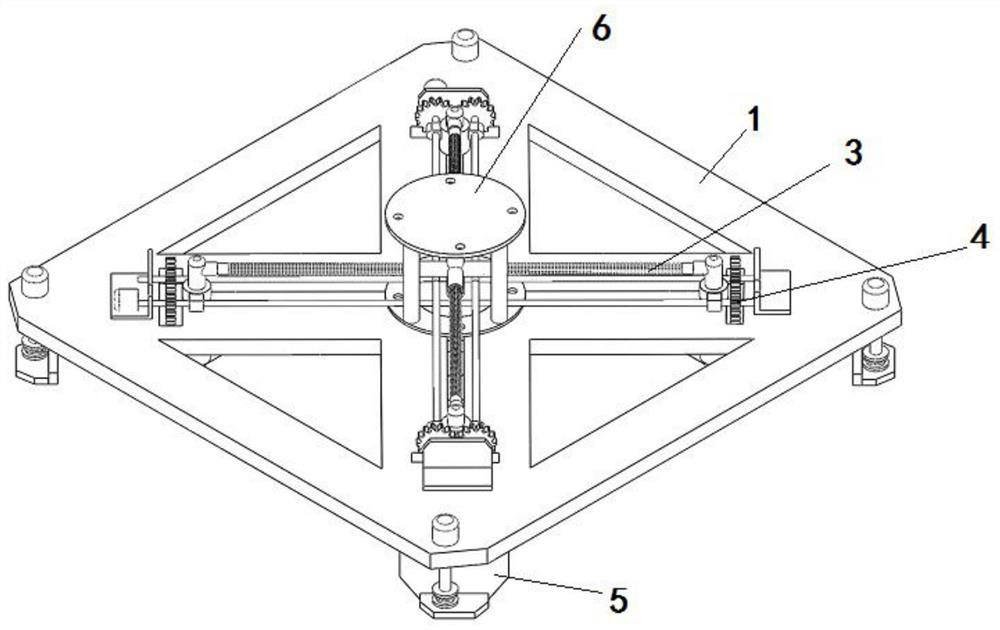

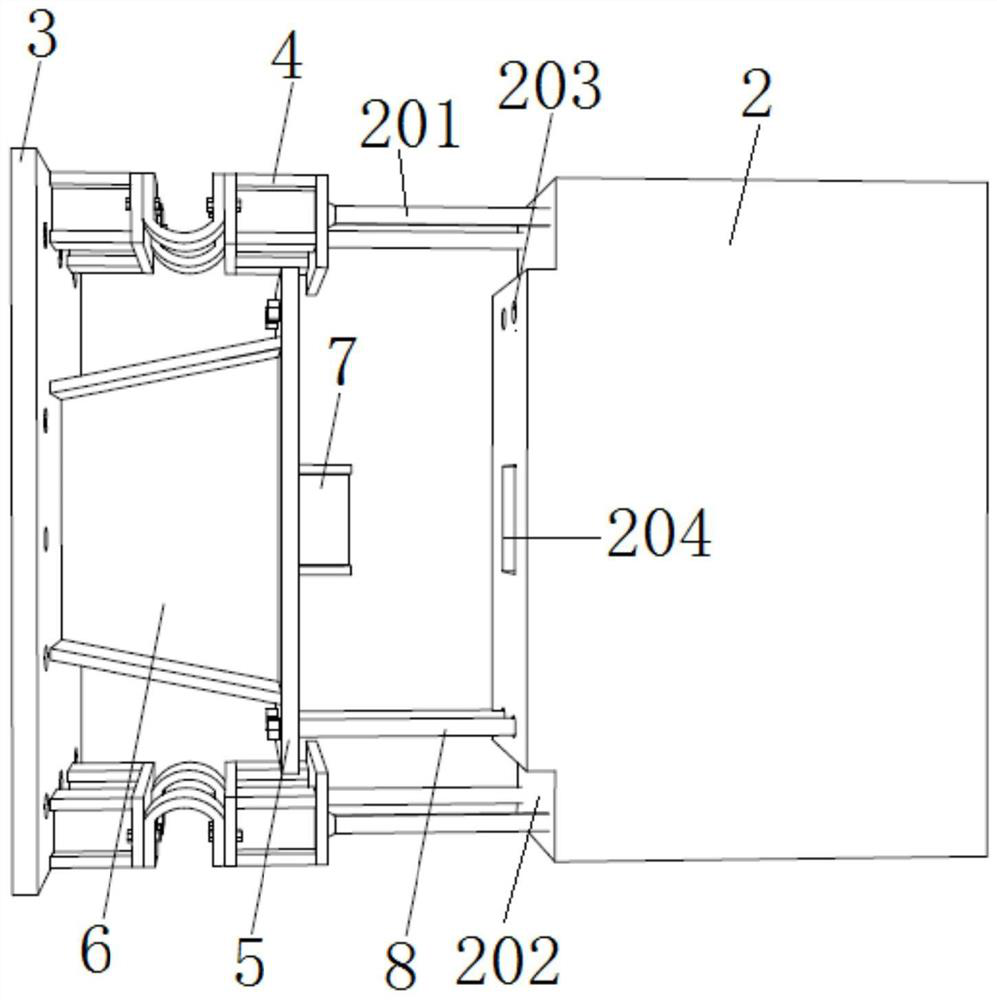

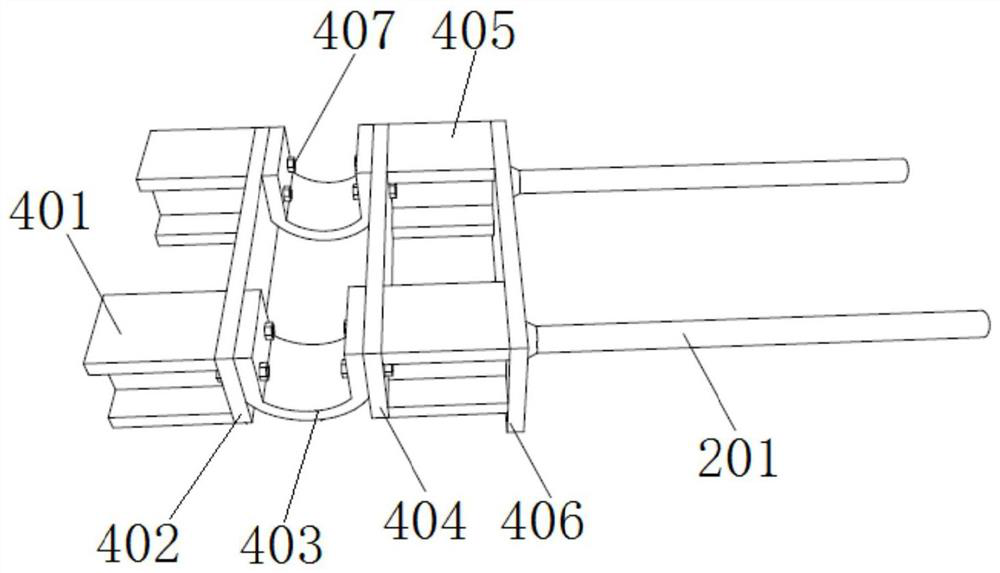

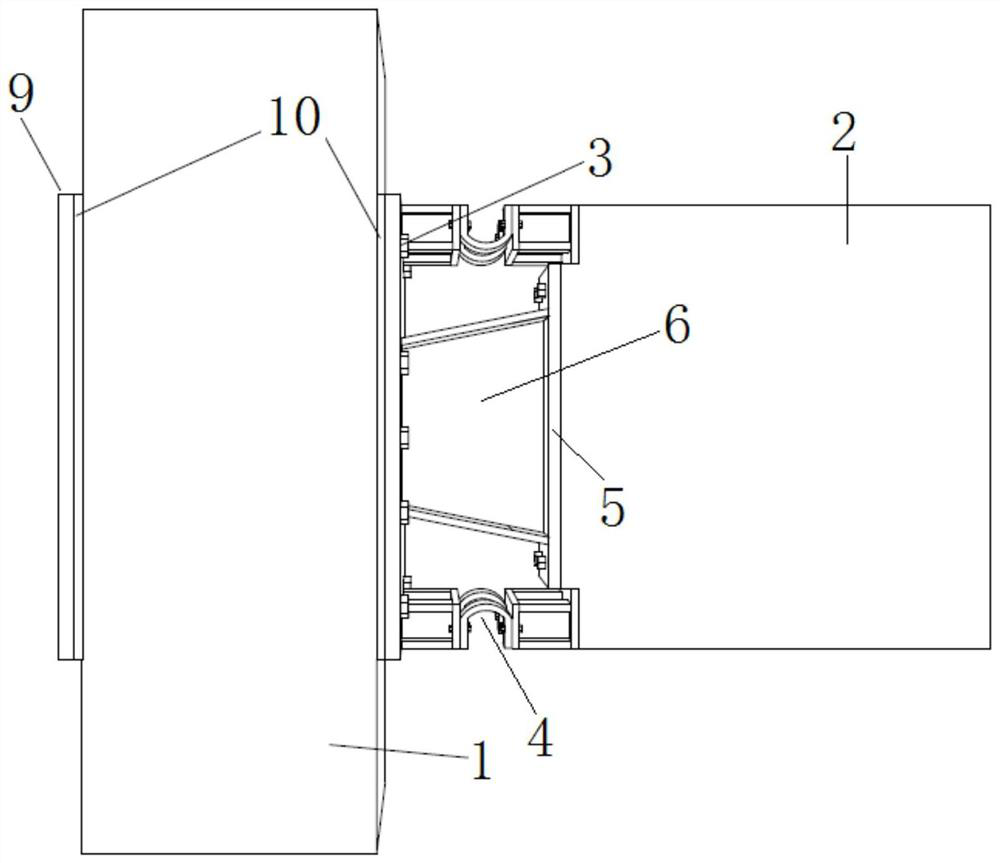

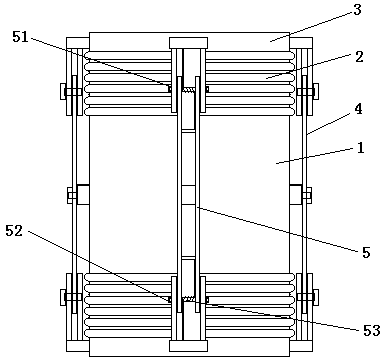

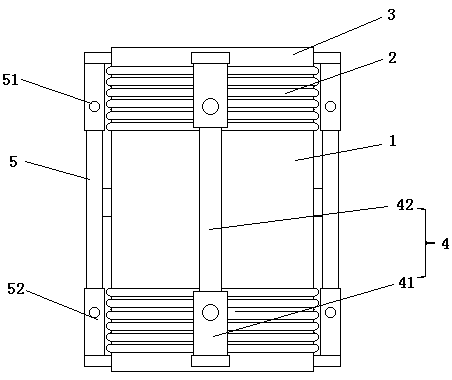

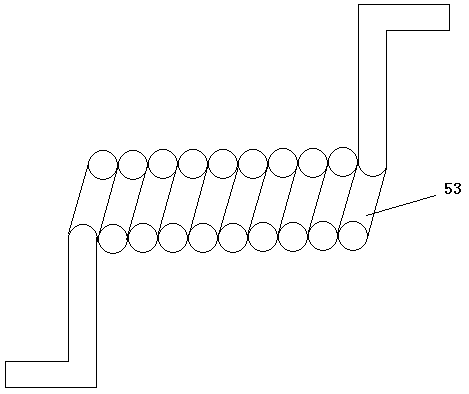

Angle steel pre-straightening device

InactiveCN106881354ARealize online pre-straighteningAchieve groomingMetal rolling arrangementsProduction lineCoupling

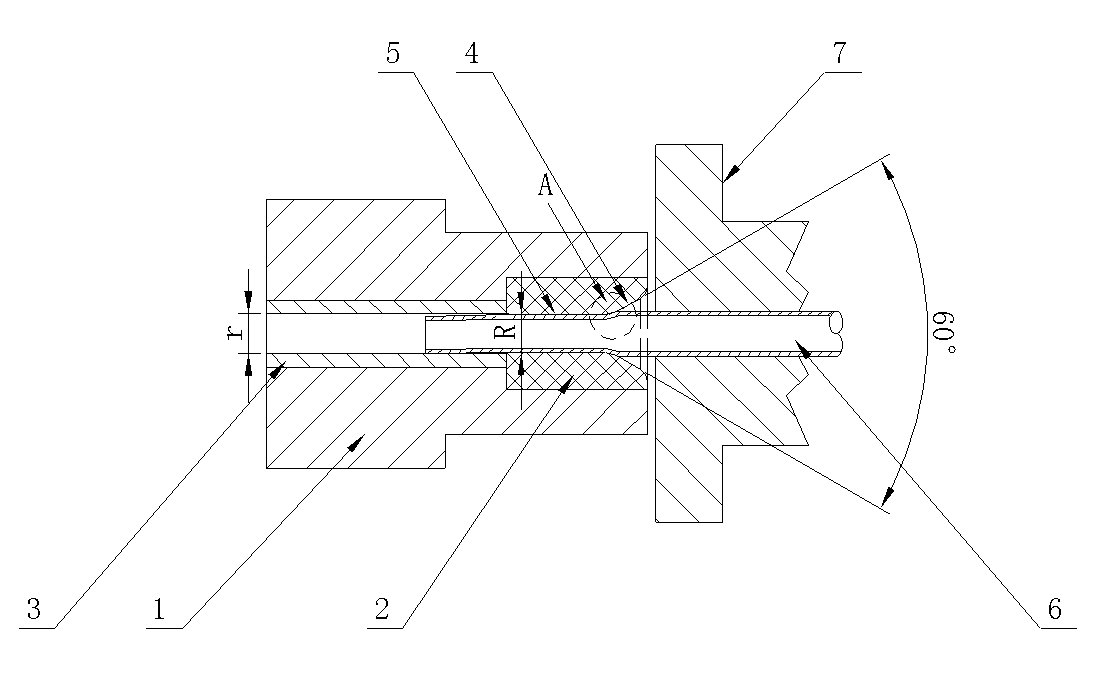

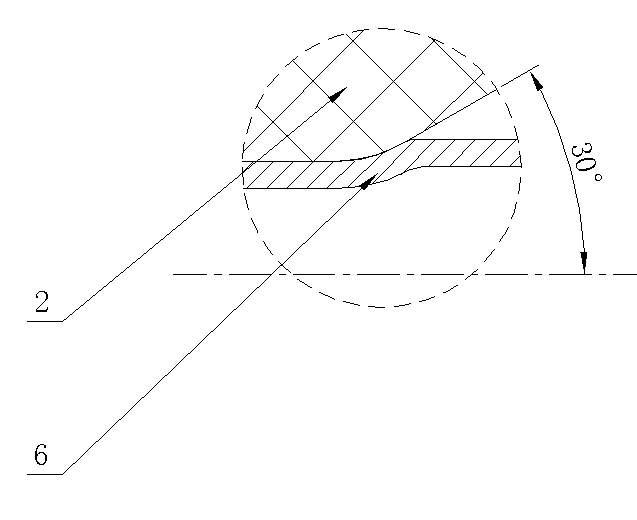

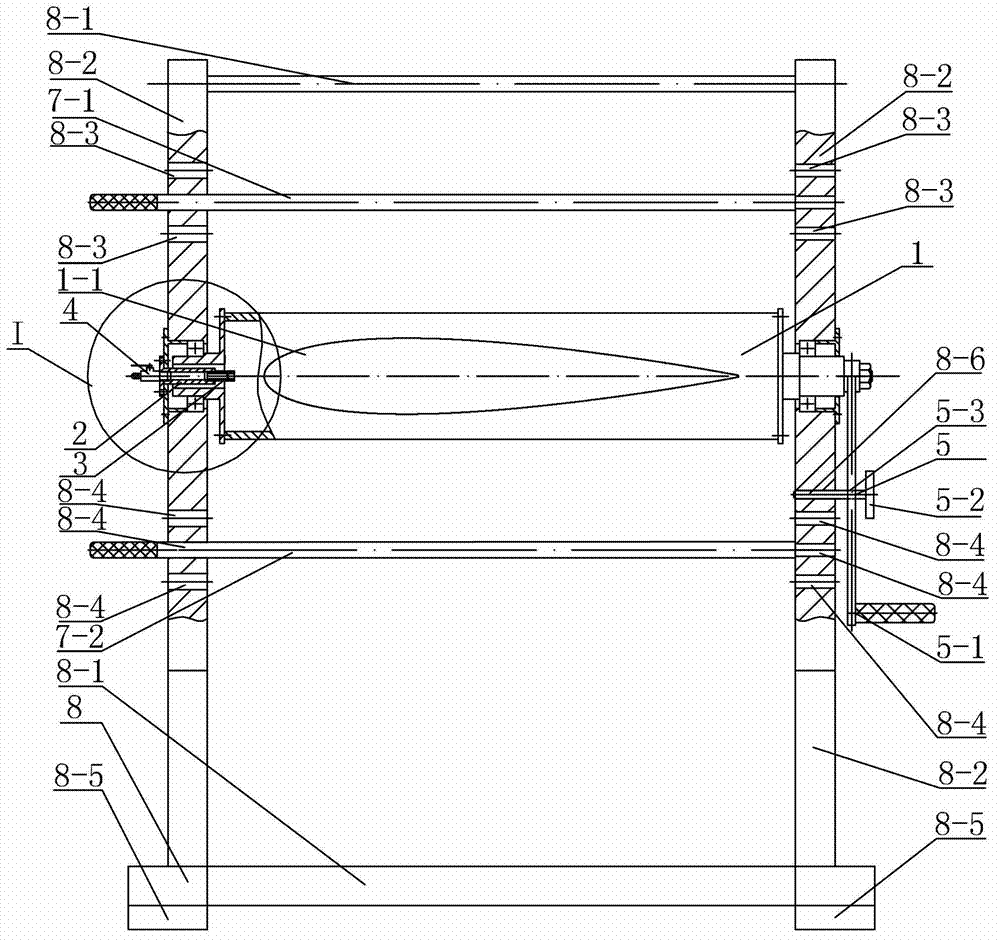

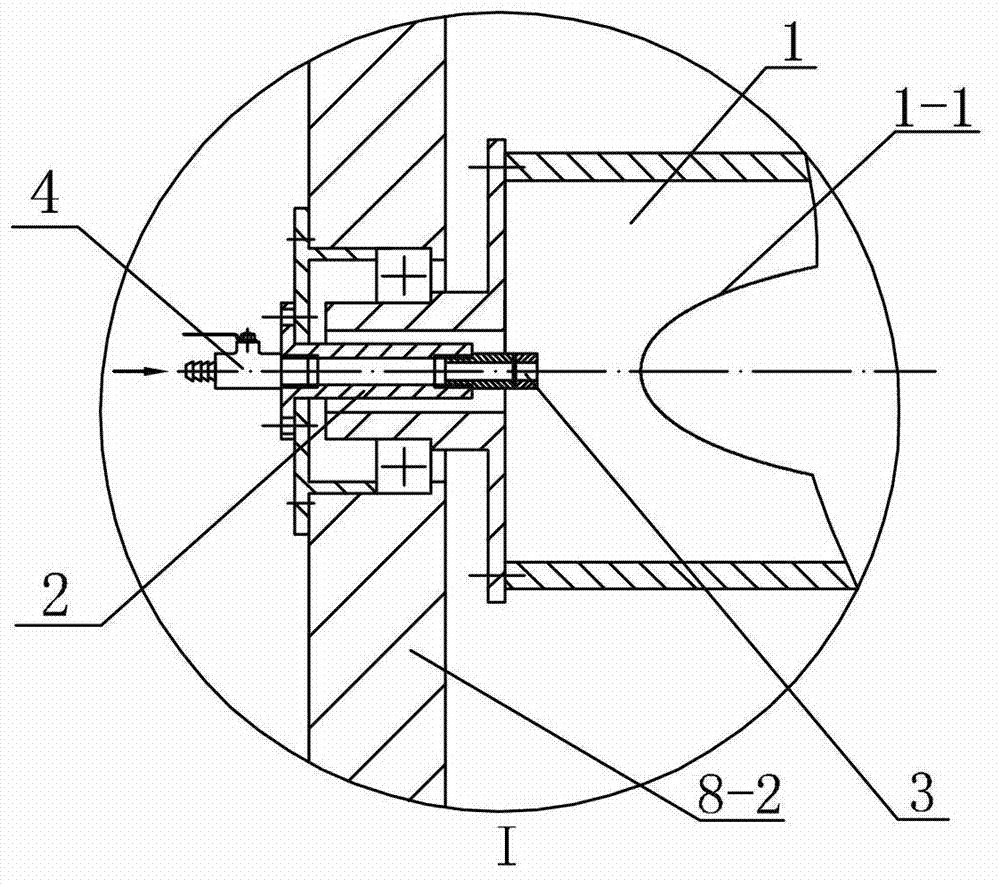

The invention relates to hot-rolled angle steel production line before-shearing straightening equipment, belongs to the technical field of hot-rolled angle steel straightening equipment, and discloses an angle steel pre-straightening device. According to the technical scheme, the angle steel pre-straightening device comprises a power assembly (1), a coupling (2), a lower straightening roller set (3), a press-down adjusting mechanism (4), an upper straightening roller set (5), a roller frame (6) and a horizontal adjusting mechanism (7). The upper straightening roller set (5) and the lower straightening roller set (3) are arranged in the roller frame (6) and are arranged in an up-and-down parallel manner. The lower straightening roller set (3) is in drive connection with the power assembly (1) through the coupling (2). The upper straightening roller set (5) is provided with the press-down adjusting mechanism (4) and the horizontal adjusting mechanism (7). The angle steel pre-straightening device has the beneficial effects that the functions of online pre-straightening, angle steel dredging and conveying before angle steel shearing are achieved; the labor intensity of staff is reduced; angle steel is flatly and precisely conveyed onto a cold shear blade; and the angle steel quality accidents of angle steel shear deformation and the like caused by angle disorderliness and inclination are eradicated.

Owner:宣化钢铁集团有限责任公司

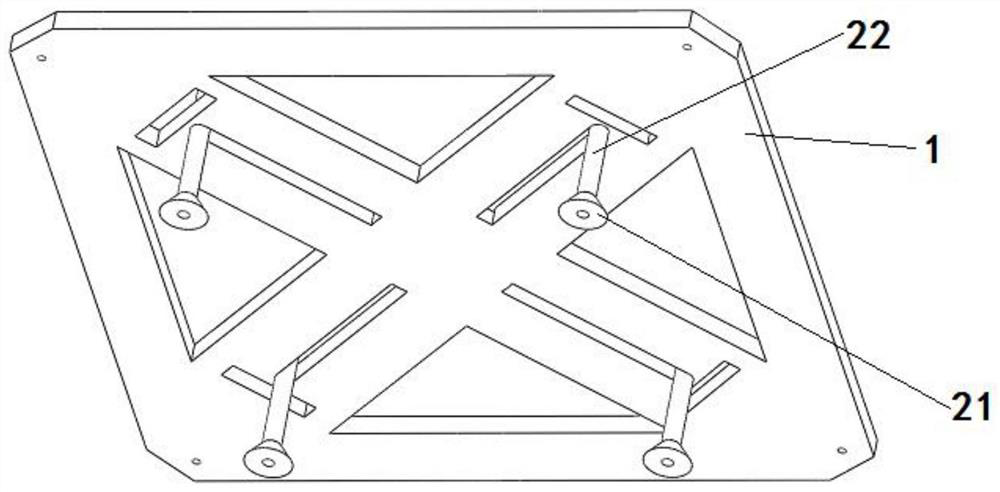

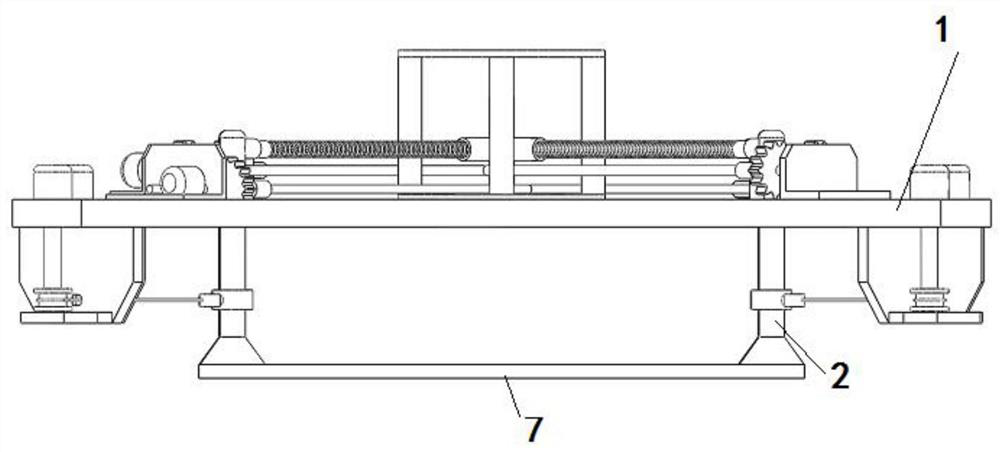

Substrate taking mechanism capable of preventing glass substrate from deforming

ActiveCN112193832AAvoid warpingAvoid dent deformationCharge manipulationConveyor partsEngineeringStructural engineering

The invention discloses a substrate taking mechanism capable of preventing a glass substrate from deforming. The substrate taking mechanism comprises a square mounting plate, wherein four suction cupassemblies distributed in a rectangle are mounted at the four vertex corners of the lower end of the square mounting plate, the upper ends of the four suction cup assemblies are jointly connected withan air exhaust connecting assembly, the upper ends of two suction cup assemblies located on the same diagonal line of the square mounting plate are jointly provided with a size adjusting assembly, the outer side of each suction cup assembly is connected with a traction assembly, and a mounting connecting piece is fixed to the center of the upper end of the square mounting plate. When the glass substrate is taken out, the four suction cup assemblies can suck the glass substrate from the four vertex corners, after the glass substrate is sucked, the traction assembles are started, supporting vertical pipes are pulled outwards, and the four supporting vertical pipes are pulled outwards at the same time, so that the glass substrate is straightened, buckling deformation of the periphery of theglass substrate can be prevented, and depressed deformation of the center of the glass substrate can be effectively avoided.

Owner:彩虹(合肥)液晶玻璃有限公司

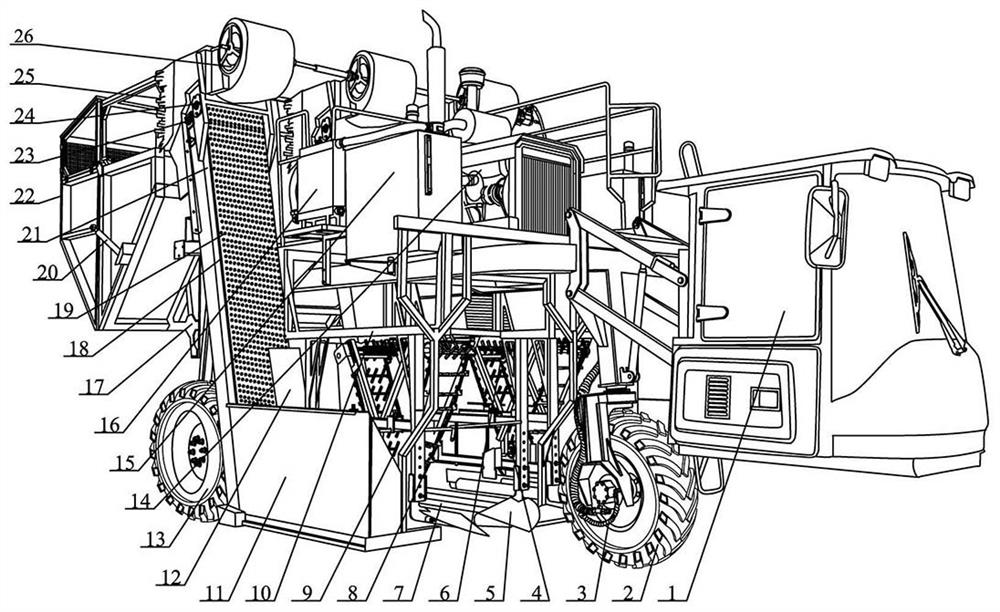

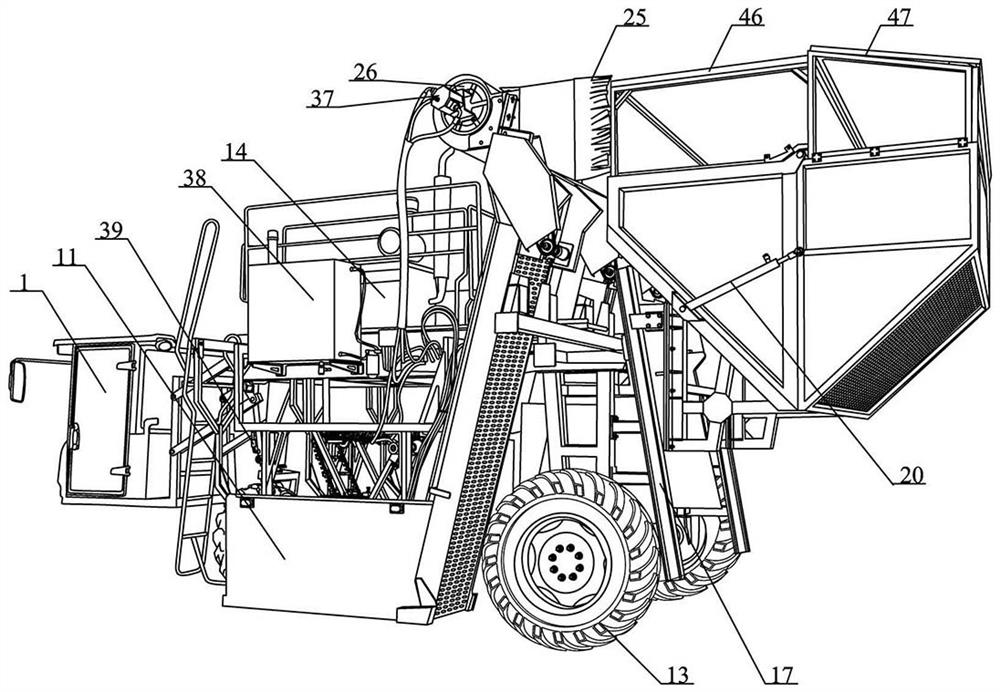

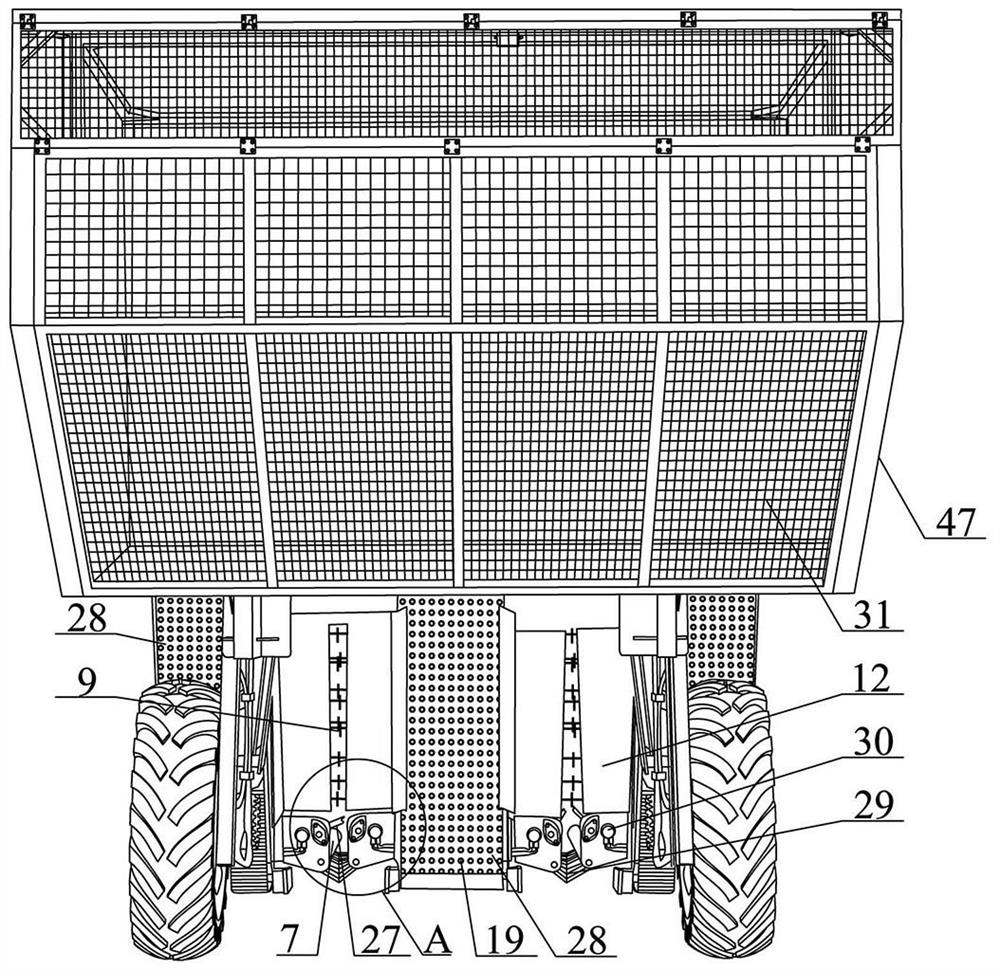

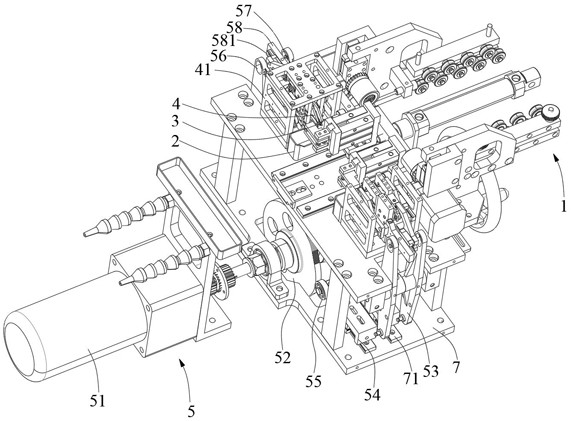

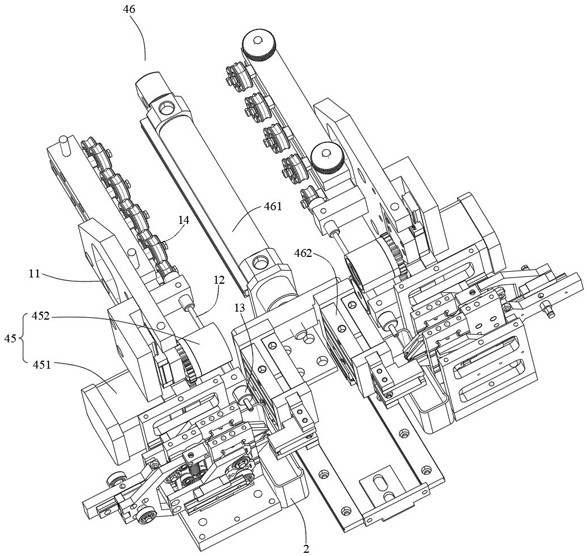

Flat pressing type upper tobacco leaf harvesting machine

ActiveCN113141865AImprove transmission efficiencyImprove work efficiencyHarvestersPower control systemAgricultural engineering

The invention belongs to the technical field of tobacco leaf harvesting, and particularly relates to a flat pressing type upper tobacco leaf harvesting machine for harvesting upper tobacco leaves by using a flat pressing type structure. The flat pressing type upper tobacco leaf harvesting machine comprises a rack, a power control system, a traveling system, harvesting systems, conveying systems and a boxing system; each harvesting system comprises a harvesting frame and a harvesting mechanism, the harvesting mechanism comprises two groups of chain transmission mechanisms which are of inverted triangular structures, and a plurality of flat pressing type manipulators are horizontally and uniformly distributed on transmission chains; each transmission system comprises a horizontal distribution mechanism, a horizontal conveying mechanism and a lifting conveying mechanism; the power control system is connected with and controls a manipulator hydraulic driver, a horizontal leaf pressing roller hydraulic driver and a lifting conveying crawler belt assembly hydraulic driver. and the tobacco leaves on the upper portion are harvested after being pressed downwards through the flat pressing type manipulators and are packed through the conveying systems and the boxing system in sequence. The flat pressing type manipulator system is adopted for harvesting so as to reduce the tobacco leaf breakage rate, and the multiple groups of conveying systems are adopted for improving the conveying efficiency.

Owner:河南省烟草公司三门峡市公司 +4

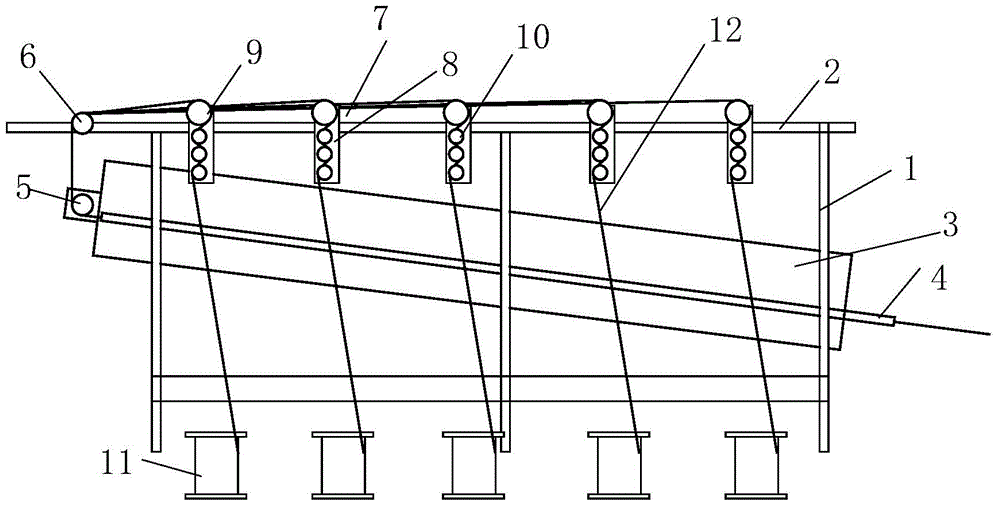

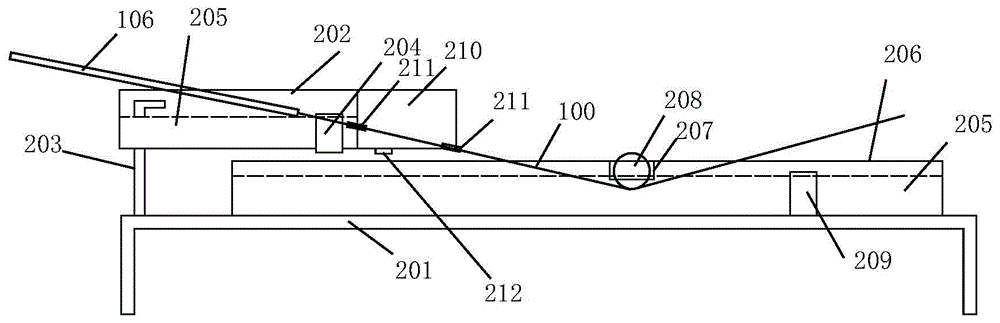

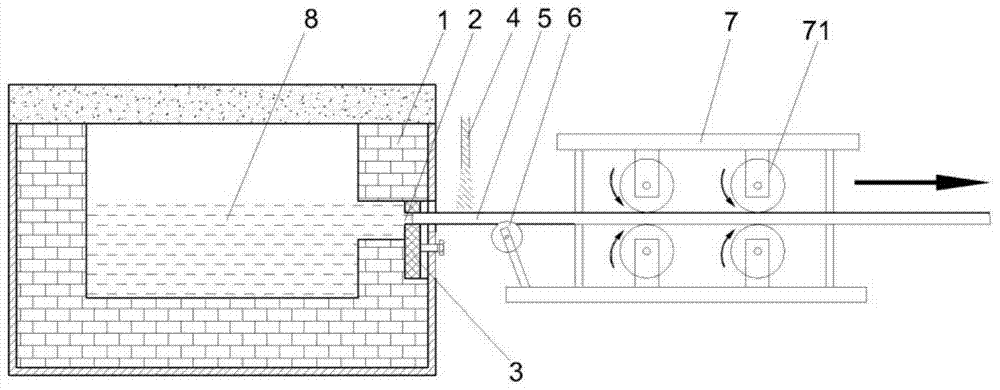

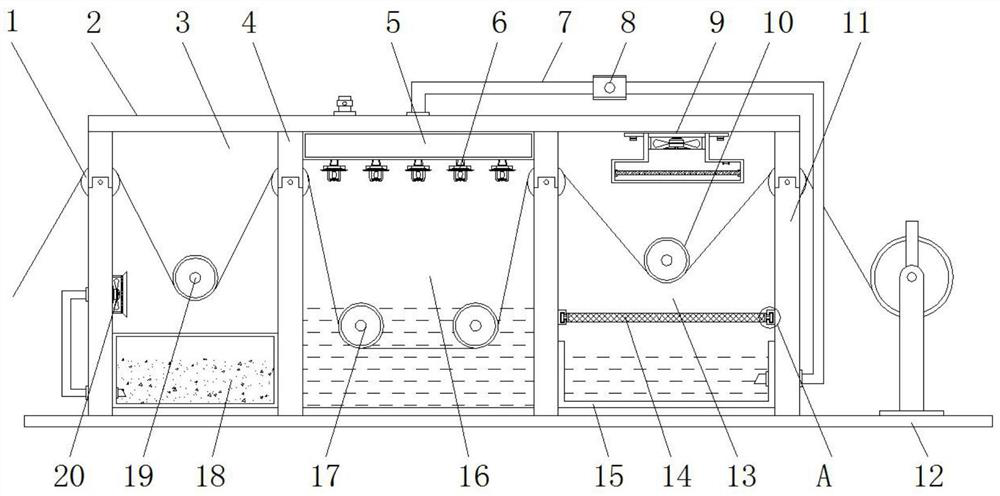

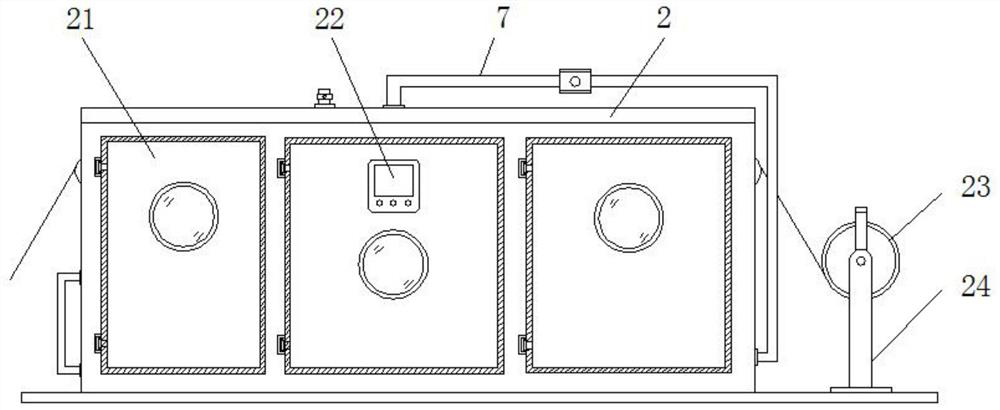

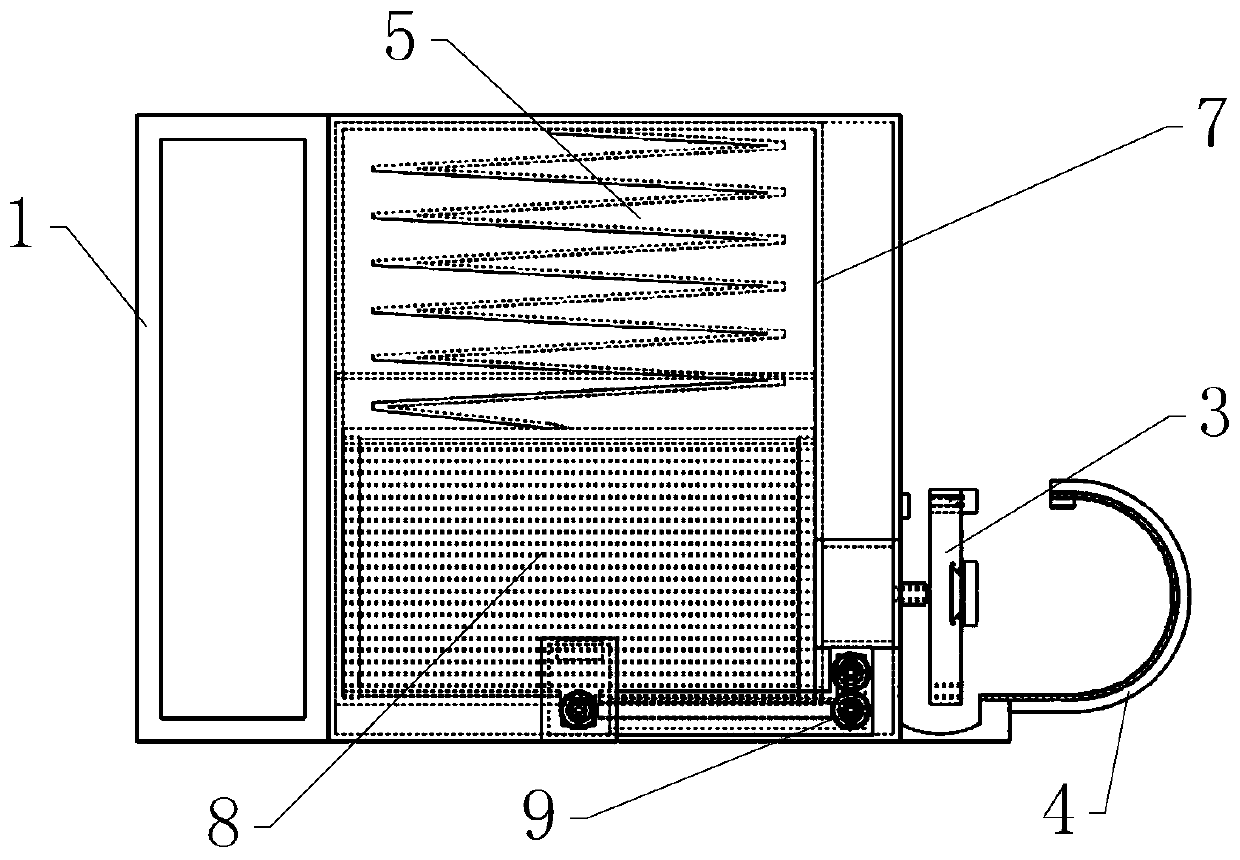

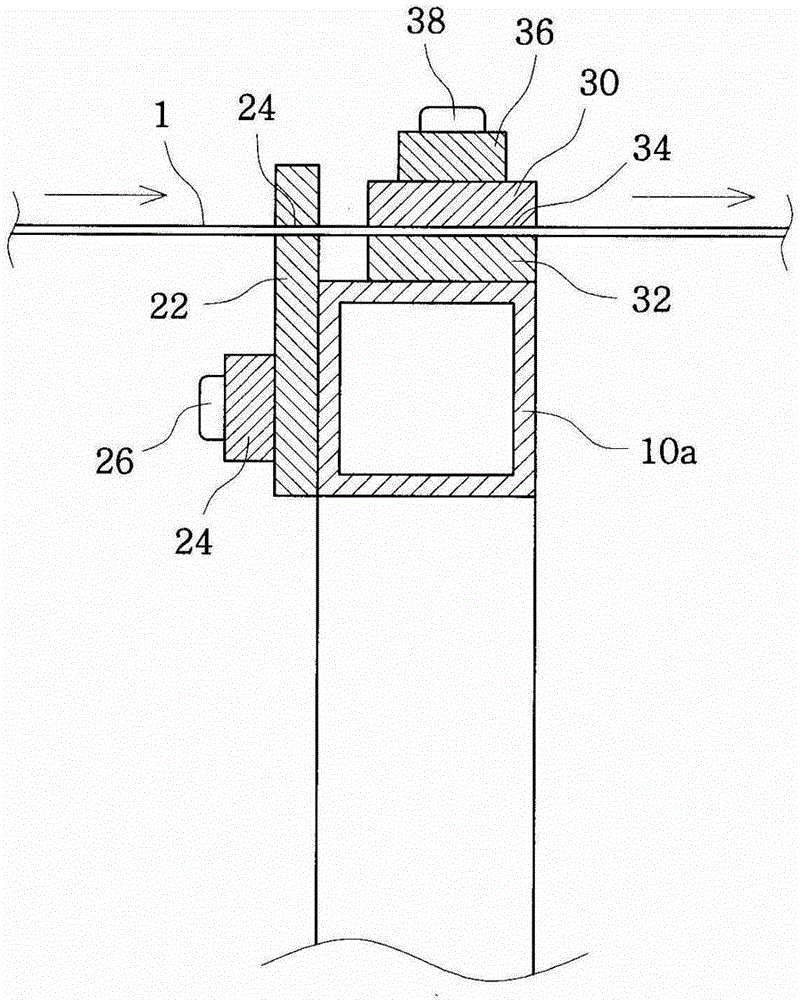

Aluminum wire straightening method of enamelling machine annealing furnace and mechanism of enamelling machine annealing furnace

InactiveCN104021884AGood collimationUniform annealingInsulating conductors/cablesMetallurgyCooling effect

The invention discloses an aluminum wire straightening method of an enamelling machine annealing furnace and a mechanism of the enamelling machine annealing furnace. The method comprises the following step of straightening an aluminum wire in an annealing furnace body by bypassing more than two straightening wheels sequentially, thereby improving the straightness of an enamelled wire after annealing. According to the invention, the straightness of the aluminum wire can be improved effectively; the problem of naked aluminum lead surface scratch caused by poor straightness is solved; the product performance is improved; additionally, the cooling effect in the annealing working procedure is ideal, and the quality problem of instability of paint membrane continuity, breakdown voltage and the like which are troubled for a long time in the aluminum enamelling wire manufacturing industry is solved. Meanwhile, the aluminum wire straightening method of the enamelling machine annealing furnace and the mechanism of of the enamelling machine annealing furnace are simple in structure, low in cost and suitable for industrialization.

Owner:张亚东

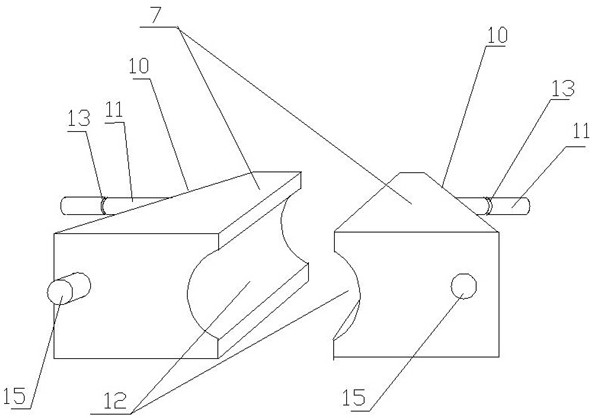

Novel female die structure for necking pipe fittings

InactiveCN102139330AImprove machining accuracyReduce frictional squeezeShaping toolsPipe fittingEngineering

The invention provides a novel female die structure for necking pipe fittings, which can prevent the bulging and wrinkling of the pipe fittings and the thinning of pipe walls due to extrusion in the necking process of the pipe fittings effectively, overcome the defect that the necked pipe fittings are bent due to the materials of welding lines of high-frequency welding pipes effectively when the pipe fittings are used as the high-frequency welding pipes, solve the problem that rear ends of the pipe fittings are bulged due to relatively long necking lengths of the pipe fittings and large friction extrusion force between necking sections and a female die cavity and ensure the necking accuracy of the welding pipe fittings. The female die structure comprises a necked female die body and is characterized in that: a hard alloy sleeve is inlaid at the inlet end of an inner hole of the necked female die body and comprises an inlet end pre-reducing section and a reducing section which are in arc transition connection with each other.

Owner:WUXI DAWN DIE & STAMPING

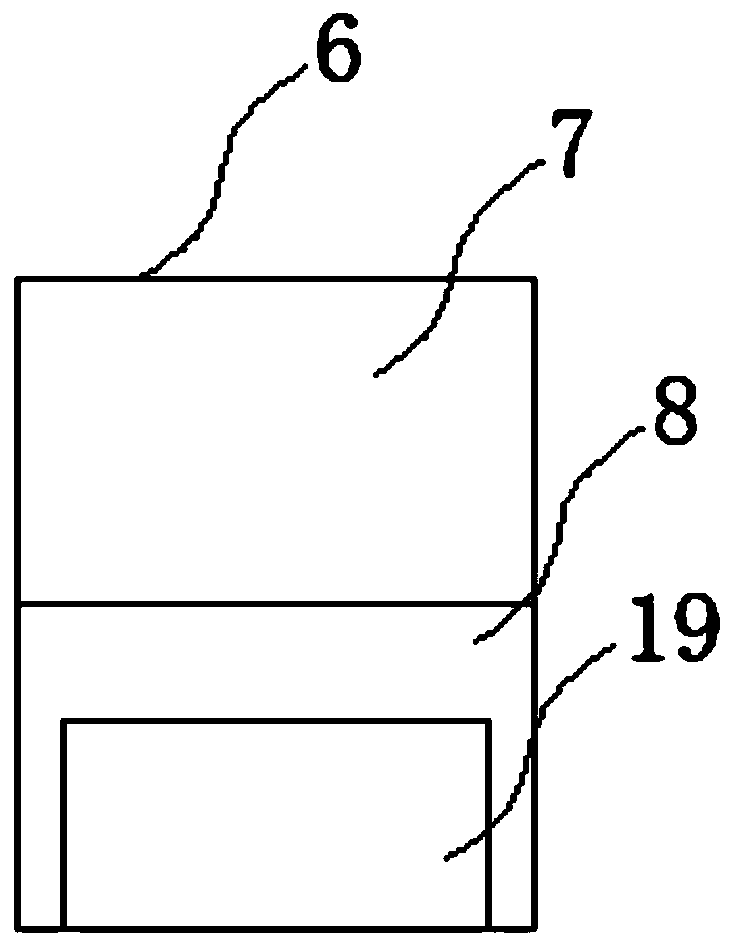

Cable storage drum for power transmission line

The invention discloses a cable storage drum for a power transmission line and relates to the technical field of cable storage. The cable storage drum for the power transmission line specifically comprises a device bottom plate, first supporting plates are fixedly connected to the two sides of the upper surface of the device bottom plate, a device plate is fixedly connected to one sides of the first supporting plates, cable sliding grooves are formed in the upper surface of the device plate, cable sliding sleeves are fixedly connected to the parts, located on the cable sliding grooves, of theupper surface of the device plate, an illumination device shell is fixedly connected to the part, below the device plate, on the upper surface of the device bottom plate, and an illumination lamp containing chamber and a storage battery containing chamber are arranged in the illumination device shell from top to bottom in sequence. According to the cable storage drum for the power transmission line, the effect of straightening a cable is achieved through the design of the cable sliding grooves and the cable sliding sleeves; and furthermore, the friction force with the cable is reduced throughrolling sliding balls in the cable sliding grooves and the cable sliding sleeves, and abrasion to the surface of the cable is relieved.

Owner:国网河南省电力公司宜阳县供电公司 +1

Pay-off rack for electric power communication construction

PendingCN113860083AImprove installation efficiencyAvoid wasting time and effortFilament handlingApparatus for laying cablesStructural engineeringControl theory

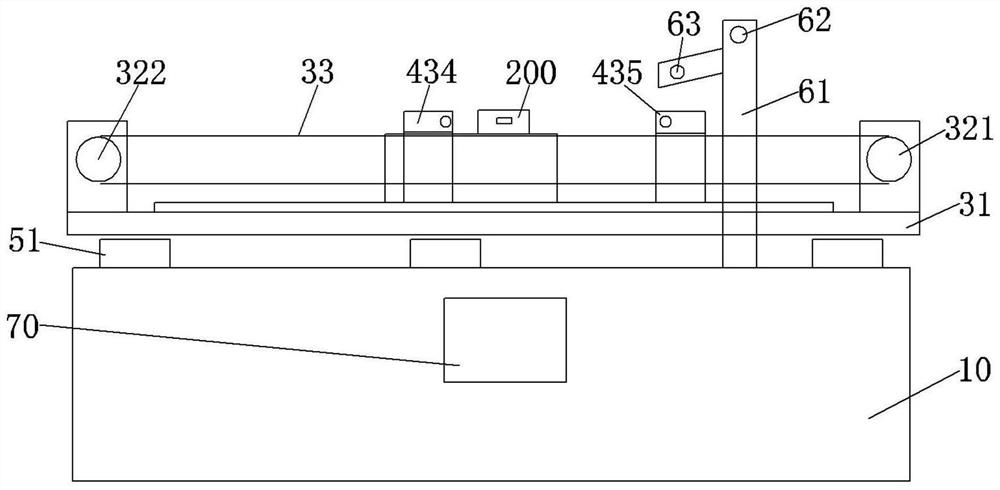

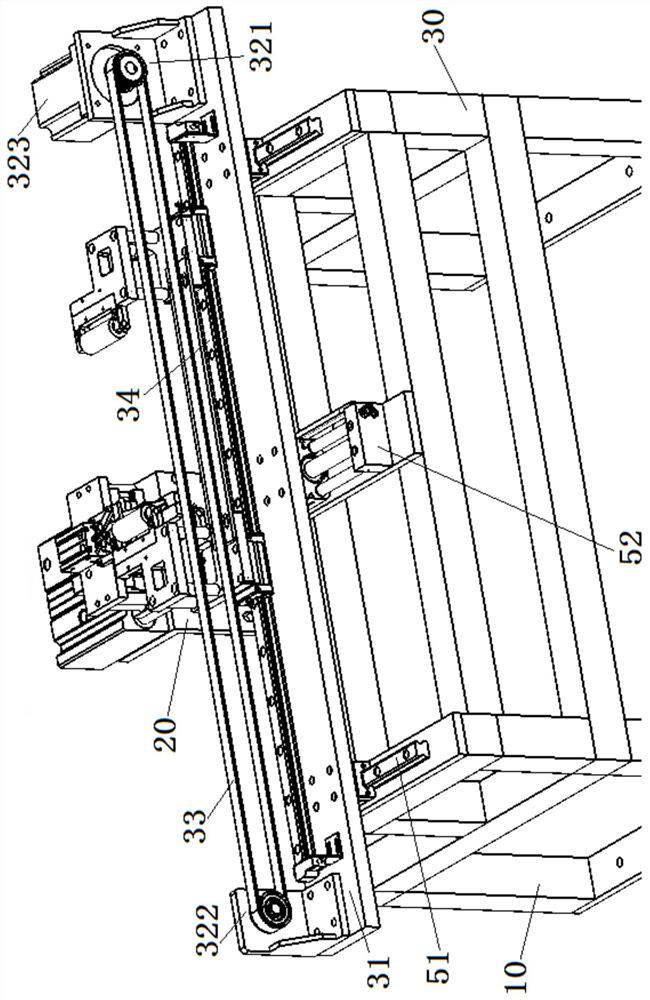

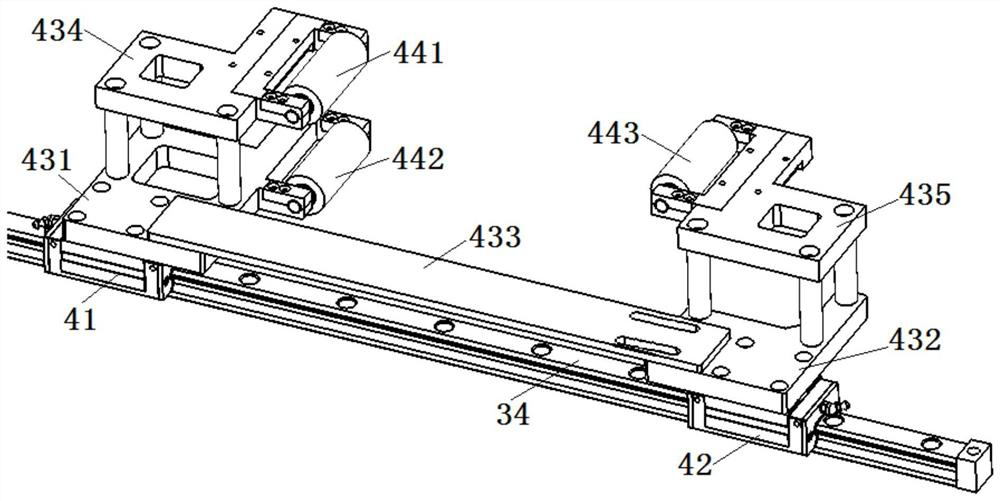

The invention discloses a pay-off rack for electric power communication construction. The pay-off rack comprises a vehicle body with the front side and the upper portion being opened, a belt conveyor capable of driving a cable roller to move front and back is arranged in the vehicle body, a carrying device is arranged on the front side of the vehicle body, a lifting device is arranged on the rear side of the vehicle body, and the cable roller is rotatably connected with the lifting device. A gravity sensor is arranged on the front side of the belt conveyor, the gravity sensor is in signal connection with the belt conveyor and the carrying device, the left side wall and the right side wall of the vehicle body are each provided with a first positioning sensor below the lifting device, and the first positioning sensors are in signal connection with the belt conveyor and the lifting device respectively. By arranging the belt conveyor, the carrying device, the lifting device, the gravity sensor and the first positioning sensors, the cable roller can be automatically mounted, the mounting efficiency is greatly improved, and the problems that a traditional pay-off rack cannot be operated by one person, and time and labor are wasted due to the fact that multiple persons need to cooperate for mounting are avoided.

Owner:JINAN LICHENG POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

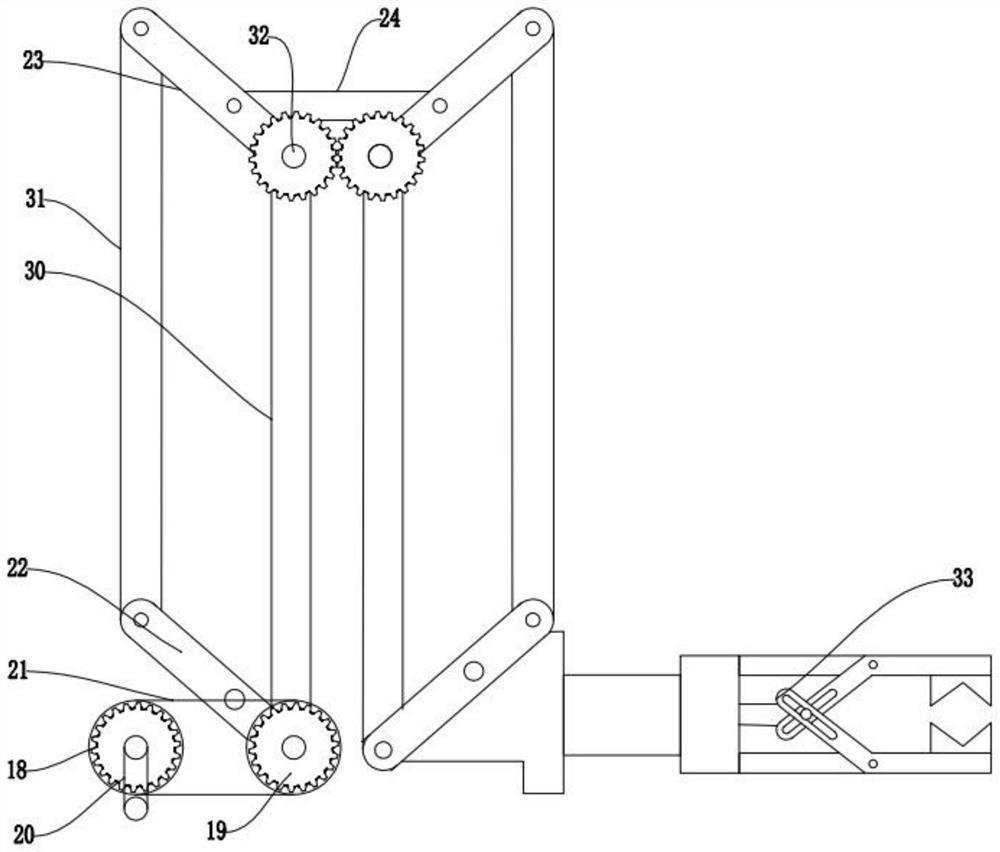

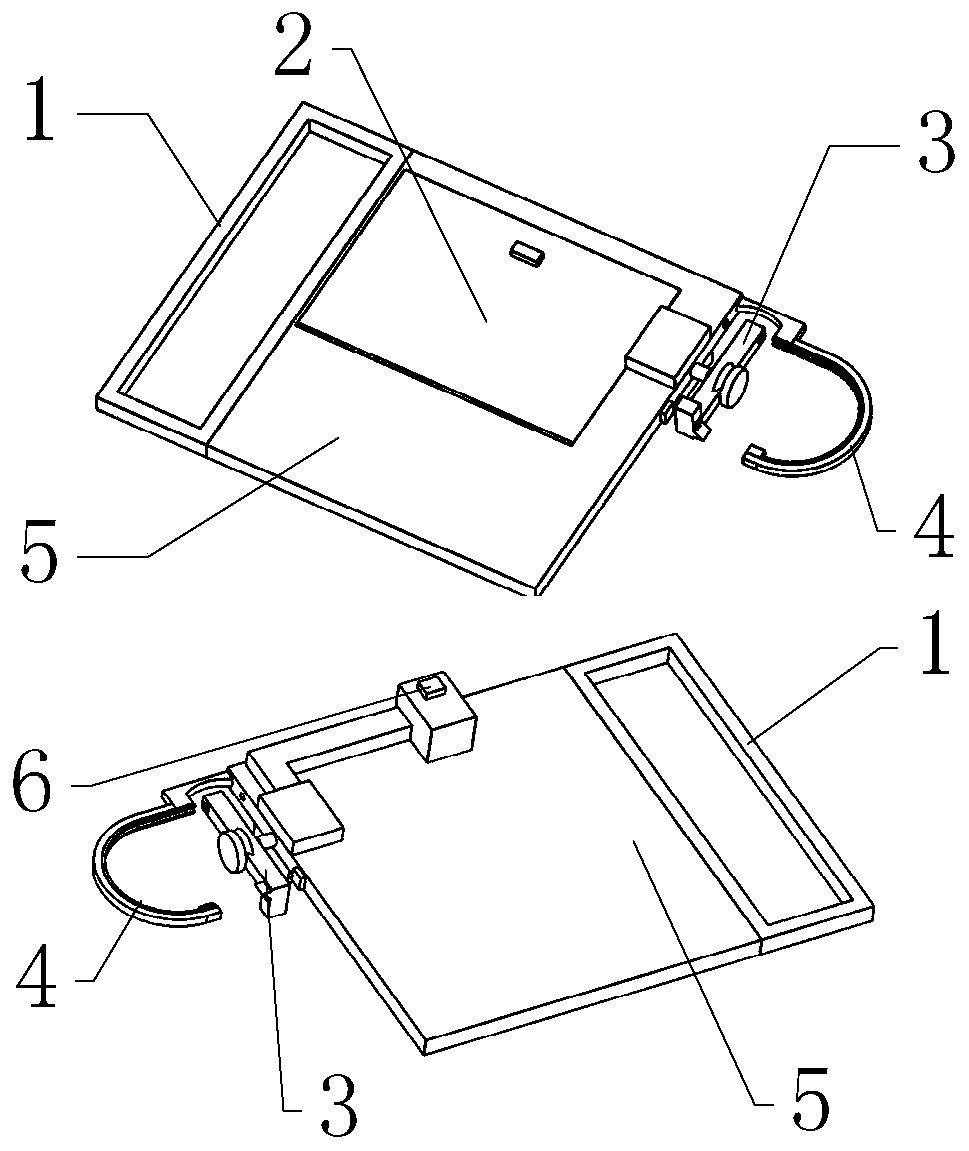

Novel pay-off non-return device

PendingCN114180412APrevent fallbackPlay a straightening roleApparatus for overhead lines/cablesStructural engineeringMechanical engineering

The invention discloses a novel pay-off non-return device which comprises a base, a first guide seat, a first non-return structure, a non-return trigger structure and a second guide seat are arranged in the base, guide rollers matched with the outer diameter of a cable are rotationally arranged in the first guide seat and the second guide seat, and the first non-return structure comprises a first non-return structure shell. A cable containing cavity is formed in the first non-return structure shell, the left side face and the right side face of the rear portion of the cable containing cavity shrink inwards to form inclined faces, cable clamping wedge blocks are arranged on the left side and the right side in the cable containing cavity in a sliding mode respectively, and cable clamping wedge block limiting structures are arranged on the outer sides of the cable clamping wedge blocks. A clamping roller rotating in one direction is arranged in the non-return triggering structure in an up-down rotating mode. The cable pay-off device can effectively prevent a cable from reversely slipping in the pay-off work, and potential safety hazards are completely eradicated.

Owner:国网河南省电力公司延津县供电公司 +4

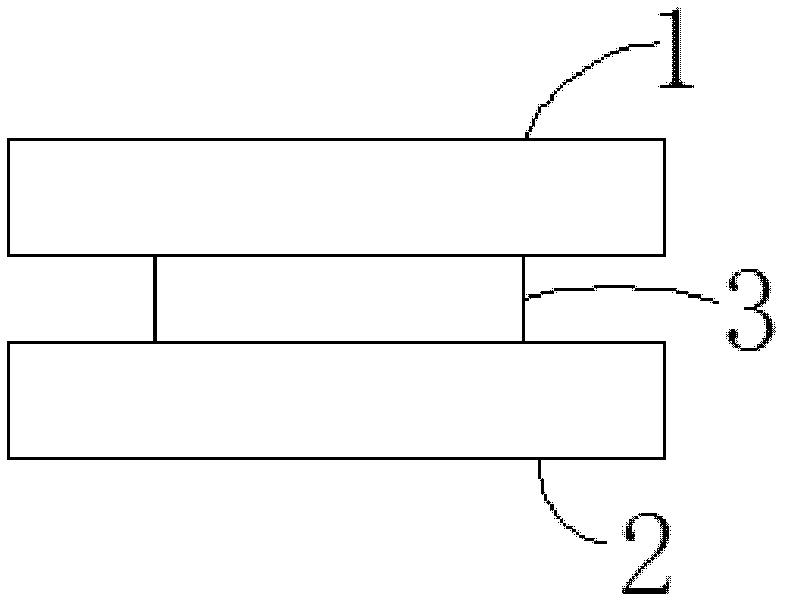

Cooling and straightening device for metal thermal treatment

The invention discloses a cooling and straightening device for metal thermal treatment. The cooling and straightening device mainly comprises an upper heat conduction hold-down block and a lower heat conduction block, wherein coolant channels are arranged on both the upper heat conduction hold-down block and the lower heat conduction block. After a workpiece is heated to a certain temperature through thermal treatment, the workpiece is put on the lower heat conduction block and pressed by the upper heat conduction hold-down block through a hydraulic machine, so that a straightening function is performed. Meanwhile, the workpiece is cooled by a coolant in the coolant channels in the upper heat conduction hold-down block and the lower heat conduction block. Therefore, the cooling and straightening device for metal thermal treatment not only can quickly cool the workpiece, but also can straighten the deformed workpiece while cooling the workpiece.

Owner:昆山鑫昌泰模具科技有限公司

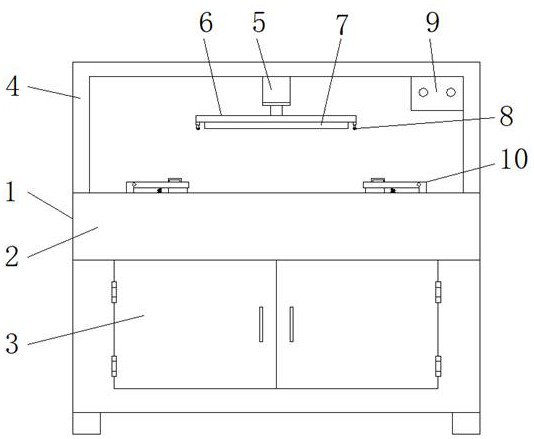

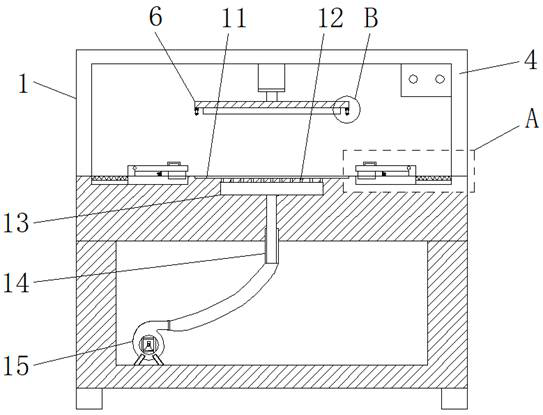

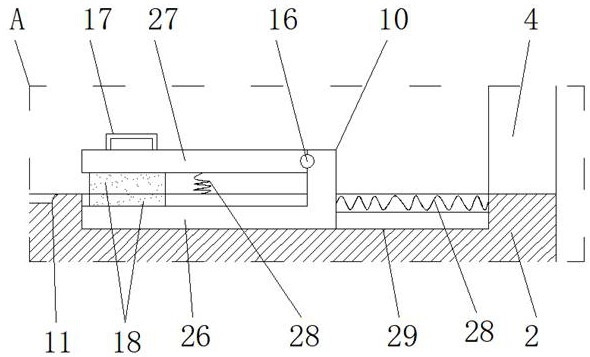

Stomatological ligature wire preparation device

InactiveCN108078639AImprove efficiencyQuality improvementOthrodonticsOrthodontic ligatureEngineering

the invention discloses a stomatological ligature wire preparation device. The preparation device structurally comprises a fixing base, a fixing table, a downward-pressing cutting mechanism, a fixingsupport, a ligature wire fixing frame, a ligature wire hanging rack and a straightening mechanism, wherein the fixing table and the fixing base are of an integrally-formed structure, the fixing tableis connected to the upper portion of the fixing base, the downward-pressing cutting mechanism is arranged on the fixing table, the fixing support is fixed to the surface of the side edge of the ligature wire hanging rack through a bolt, the ligature wire hanging rack is connected to the downward-pressing cutting mechanism through the fixing support, the bottom of the ligature wire hanging rack isvertically welded to the upper surface of the fixing base, and the bottom surface of the straightening mechanism is welded to the upper surface of the fixing base at a high temperature. According to the stomatological ligature wire preparation device, in the ligature wire preparing process, only manual pressing is needed, the preparation device can be more rapid and convenient to use, the operation efficiency and quality can be improved, in addition, the straightening mechanism is arranged so that the function of straightening ligature wires can be achieved, and convenience can be brought to the use by medical workers.

Owner:吕敏

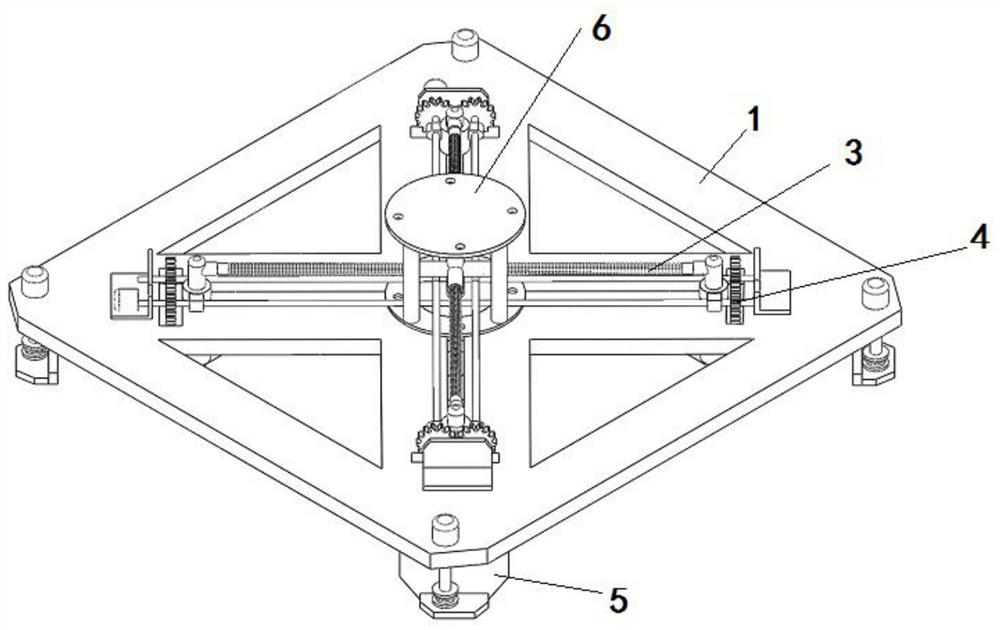

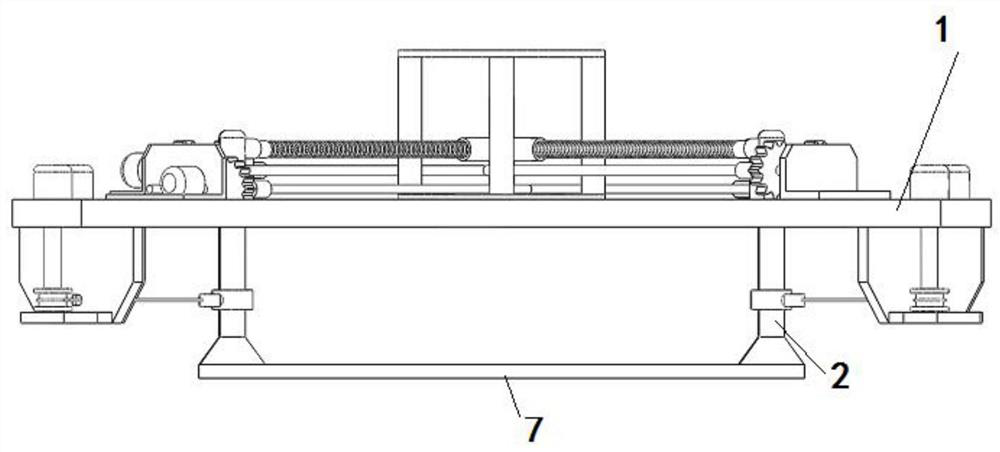

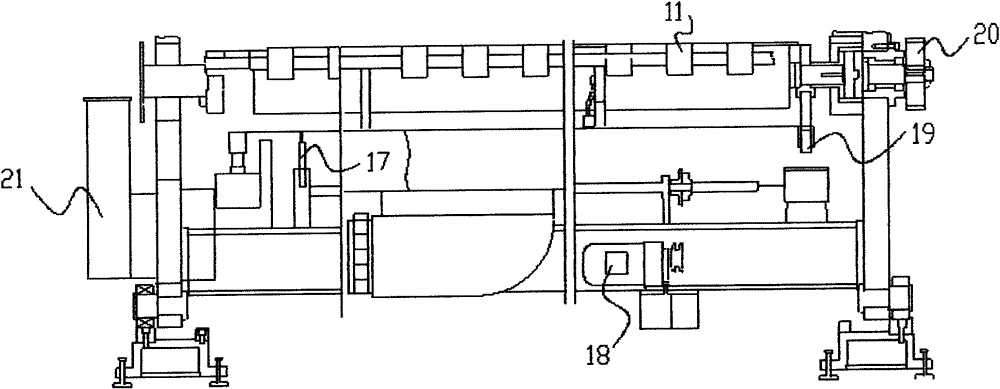

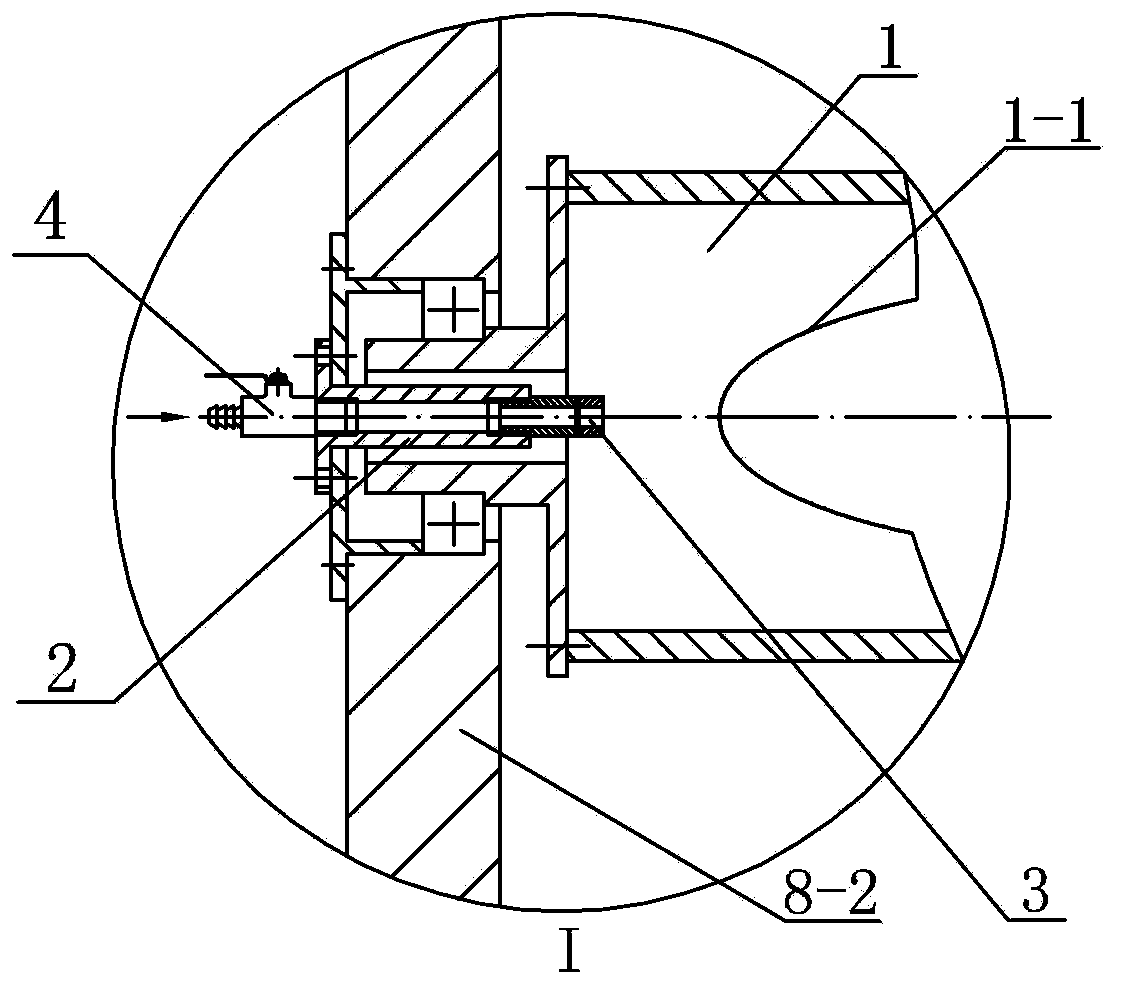

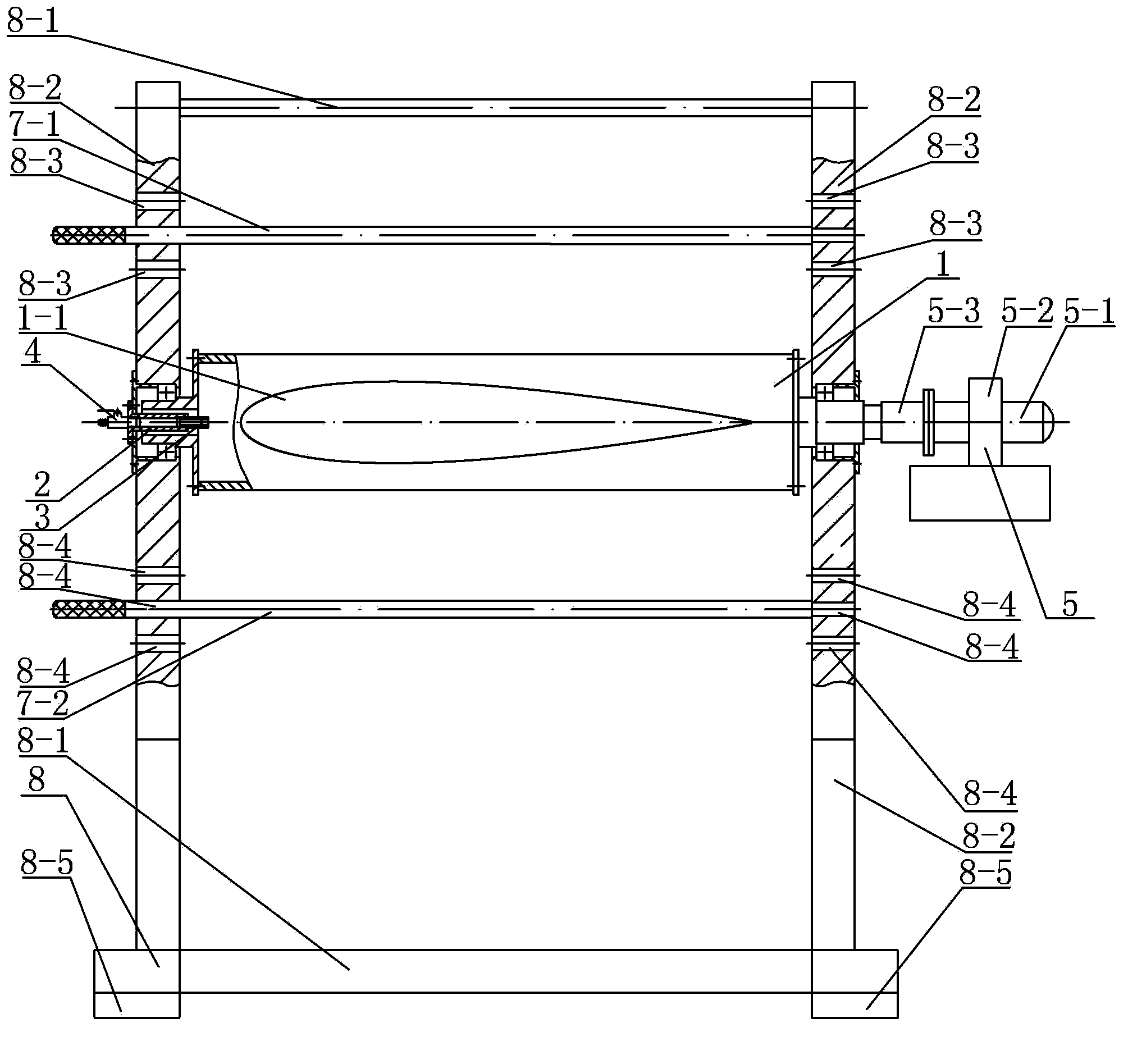

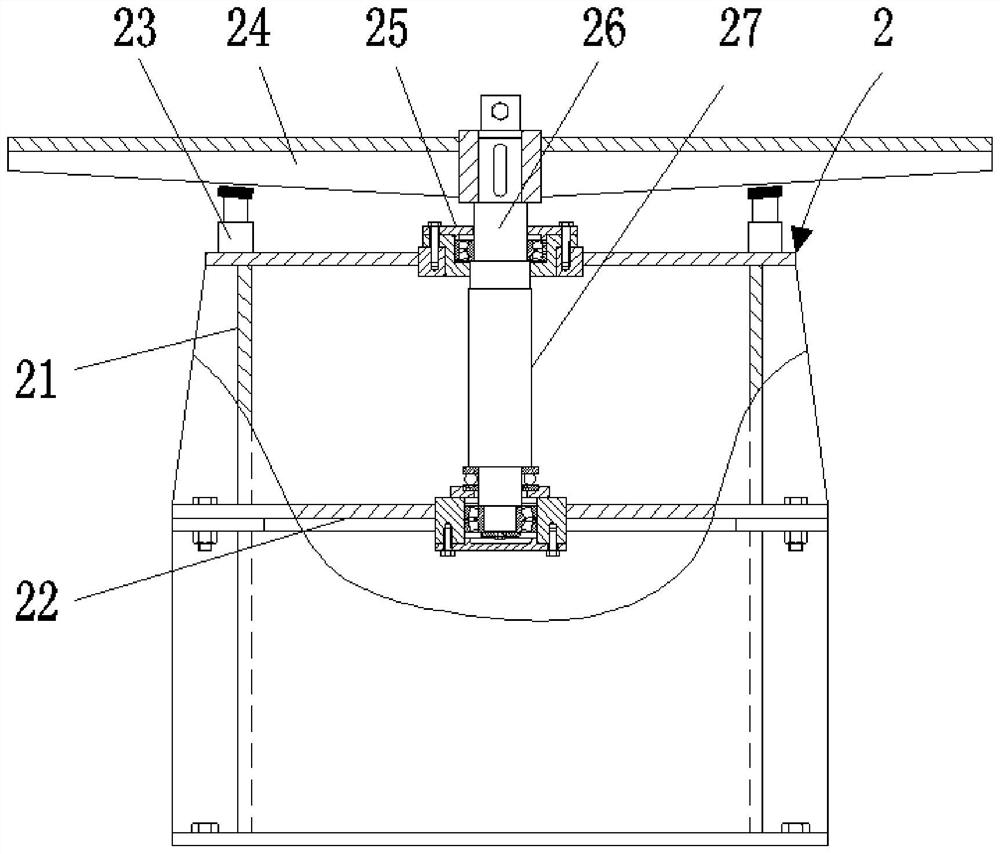

Inflation/deflation type air bag unfolding and coiling device

An inflation / deflation type air bag unfolding and coiling device relates to an unfolding and coiling device, and aims to solve the problem that in a conventional aviation spacecraft, the inflation structure is highly flexible, the folding and coiling are controlled difficultly, and the folding and unfolding process in the working state needs to be simulated and experimented on the ground, but no unfolding and coiling device capable of achieving the function of assisting the folding and the unfolding and unfolding controllability is available. The inflation / deflation type air bag unfolding and coiling device comprises a middle shaft, a driving and locking mechanism, a support saddle, an upper limiting stop lever, a lower limiting stop lever and a ventilation mechanism, wherein the ventilation mechanism comprises a ventilation connecting pipe, a rotary joint and an air valve; the support saddle comprises a base, two cross beams and two vertical beams; the middle shaft is arranged on the two vertical beams positioned between the two cross beams and can be rotated in the circumferential direction; the ventilation connecting pipe is connected to one vertical beam; the air valve is connected to the end part, opposite to the rotary joint, of the ventilation connecting pipe; and the other end of the middle shaft is connected with the driving and locking mechanism used for controlling the rotation and the stopping of the middle shaft. The device is used for inflatable structures of large-scale aviation spacecrafts.

Owner:HARBIN INST OF TECH

Continuous casting device

The invention provides a continuous casting device comprising a molten pool, a guide rod, a cooling device and a traction device. According to the continuous casting device, molten metal is solidified in a continuous casting through hole under the heat conduction effect of the guide rod or metal solidified previously, large cooling devices such as crystallizers do not need to be arranged, and therefore the space occupied by the whole continuous casting device can be reduced; and for the same reason that no large devices such as the crystallizers are used, multiple continuous casting blanks can be arranged side by side, the multiple continuous casting blanks are arranged as closely as possible, more continuous casting lines can be arranged within the same space, and the continuous casting efficiency is improved. In addition, as long as the cooling effects of the cooling devices are the same, the traction device can pull the guide rod and the casting blanks at a constant speed, and therefore the surfaces of the casting blanks can be smooth and clean, surface defects are greatly reduced, and pressure of subsequent surface processing steps is reduced.

Owner:JIANGXI KEMING COPPER IND CO LTD

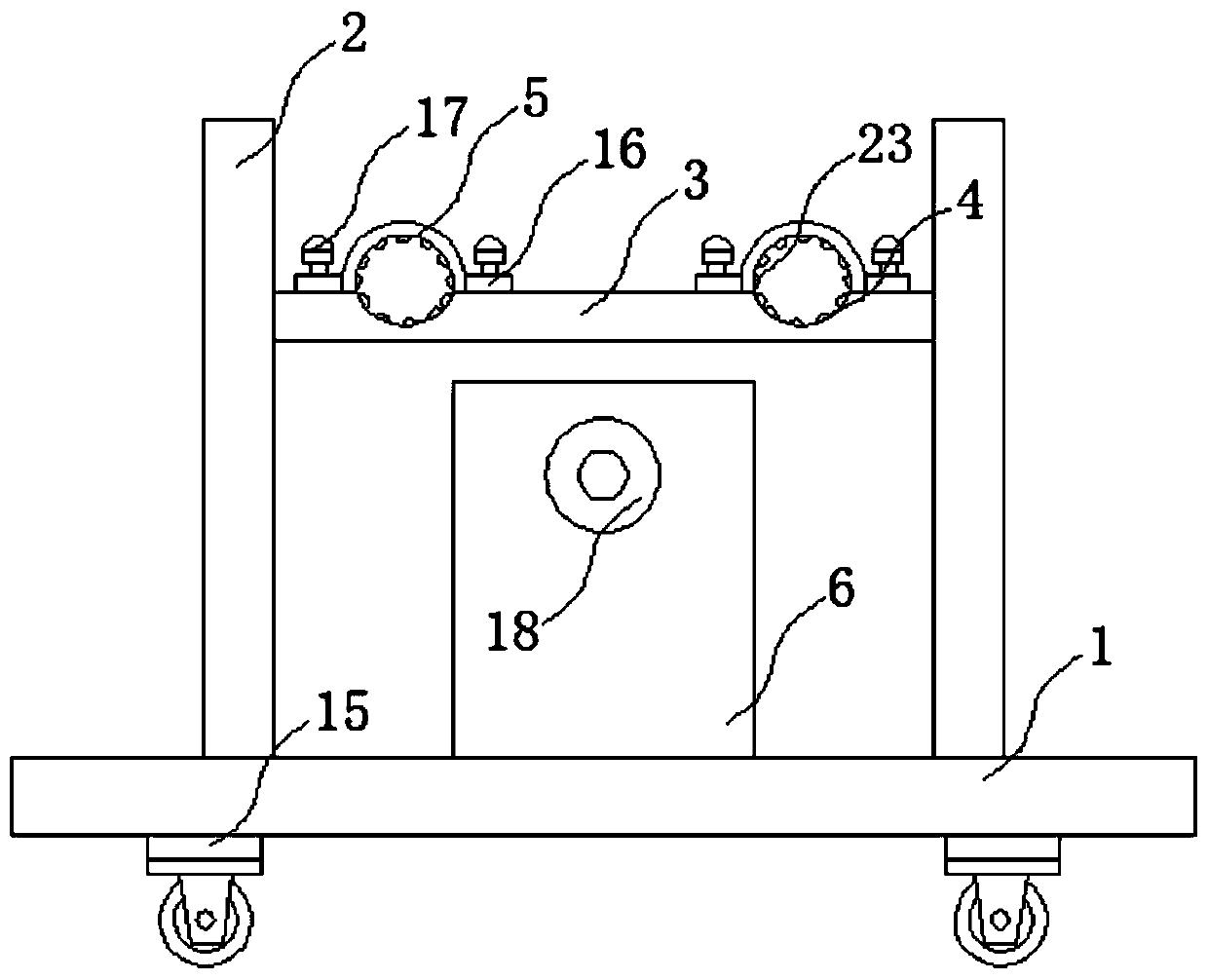

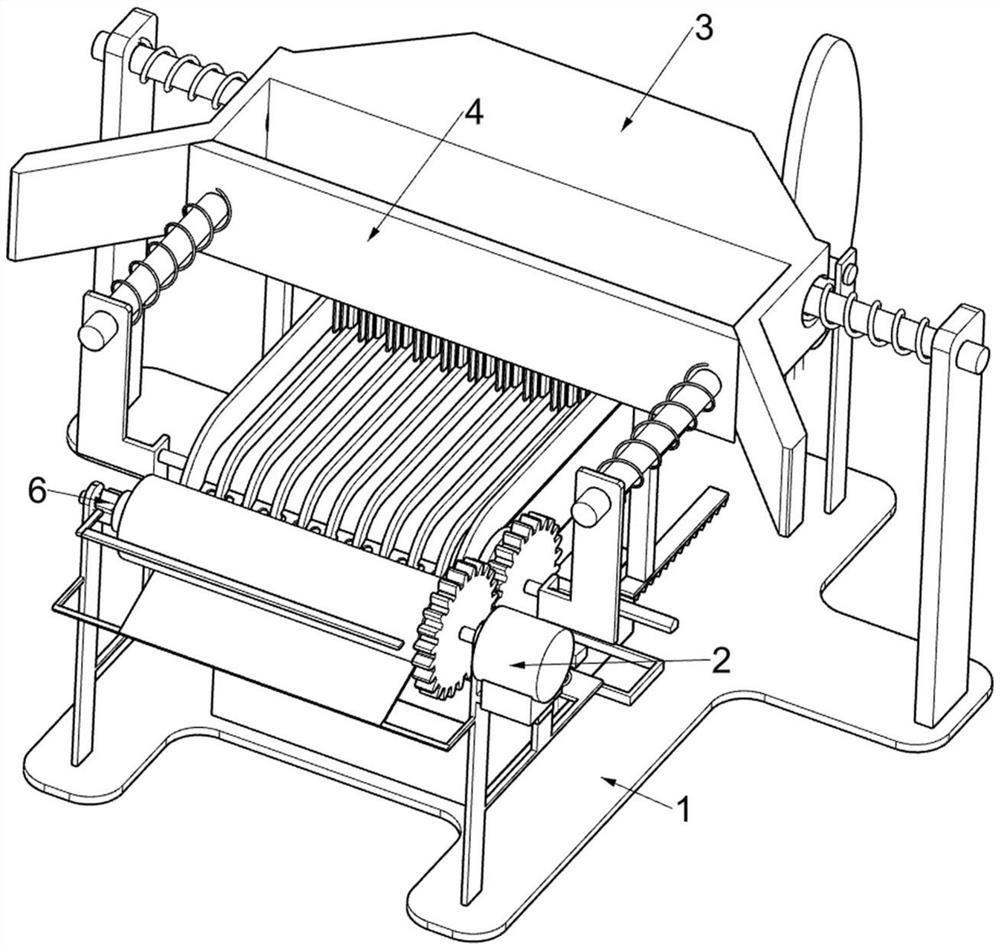

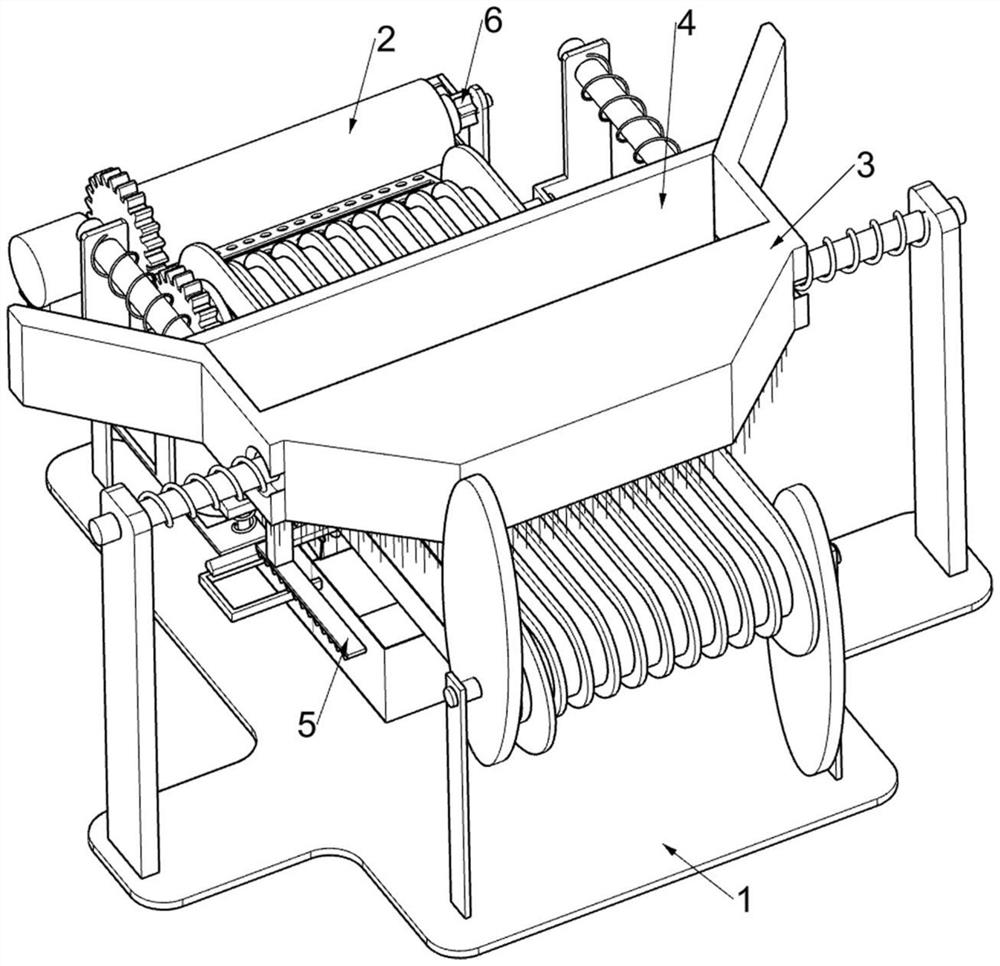

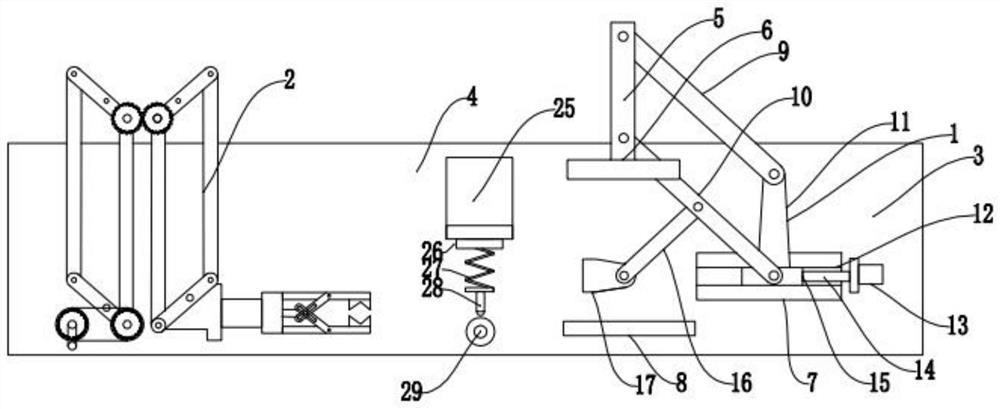

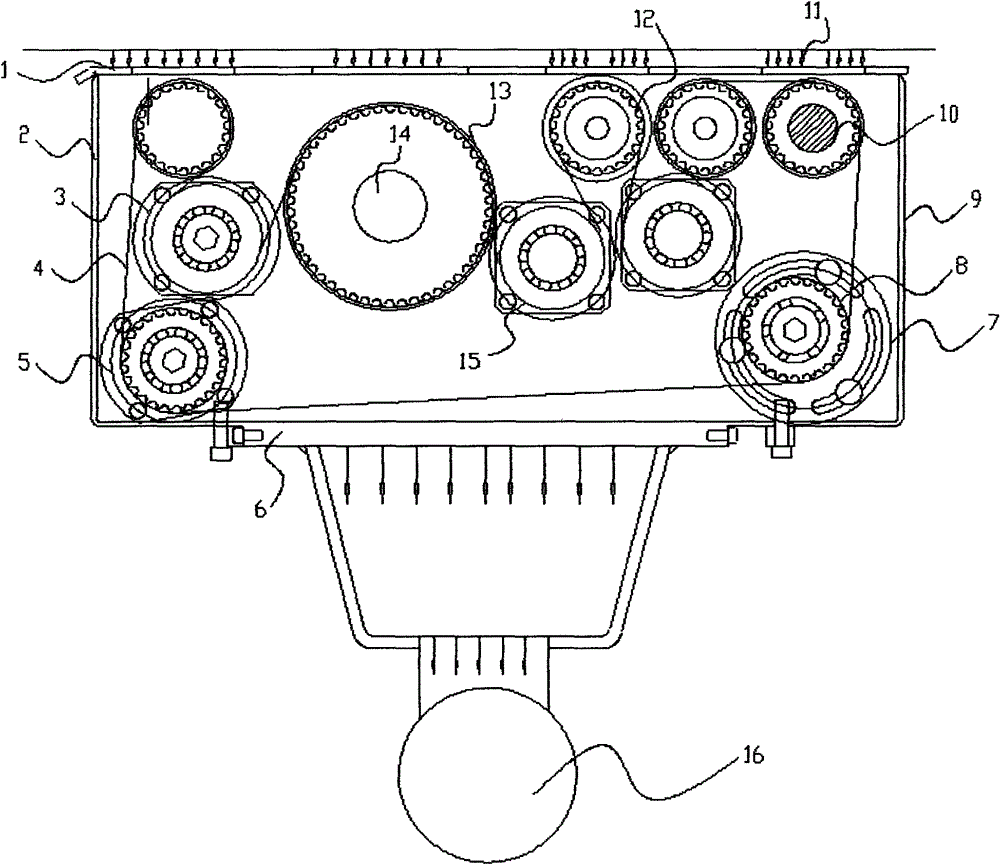

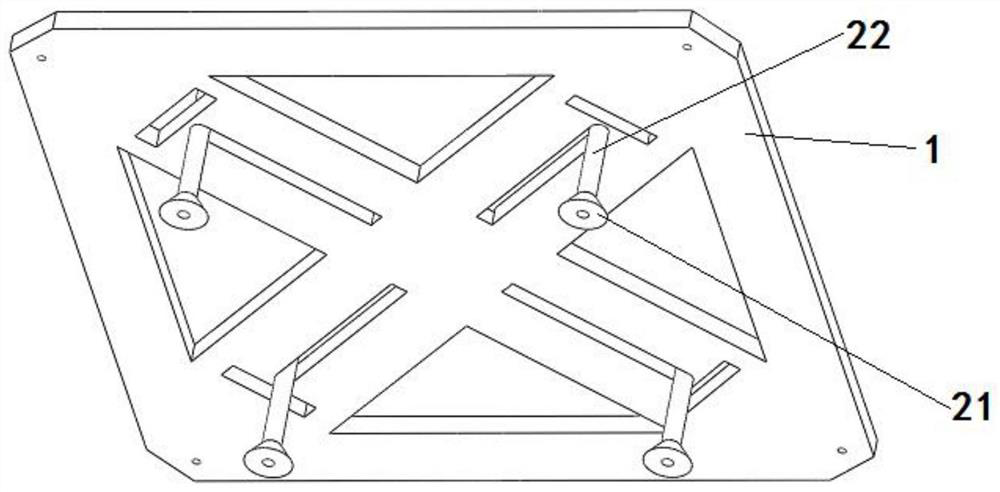

Bean-straightening-facilitated rotary-drum-cleanable green soybean extruder

ActiveCN112617248APlay a straightening roleAvoid interferenceSievingScreeningBiotechnologyEngineering

The invention relates to food processing equipment and more specifically relates to a bean-straightening-facilitated rotary-drum-cleanable green soybean extruder. The green soybean extruder comprises a bottom plate, a bean extruding mechanism, a spreading mechanism, a pushing and straightening mechanism and a dithering screening mechanism, wherein the bean extruding mechanism is fixedly arranged on the bottom plate, the spreading mechanism is arranged on the bottom plate and the bean extruding mechanism, the pushing and straightening mechanism is arranged on the bean extruding mechanism, and the dithering screening mechanism is arranged on the bottom plate and the bean extruding mechanism and is connected with the pushing and straightening mechanism. According to the green soybean extruder, green soybeans stacked together can be spread and can be straightened out prior to a shelling operation, thus, the improvement on efficiency and effect of shelling of the green soybeans is facilitated, and meanwhile, bean shells stuck to beans can be separated from the beans.

Owner:漳州新永创食品机械有限公司

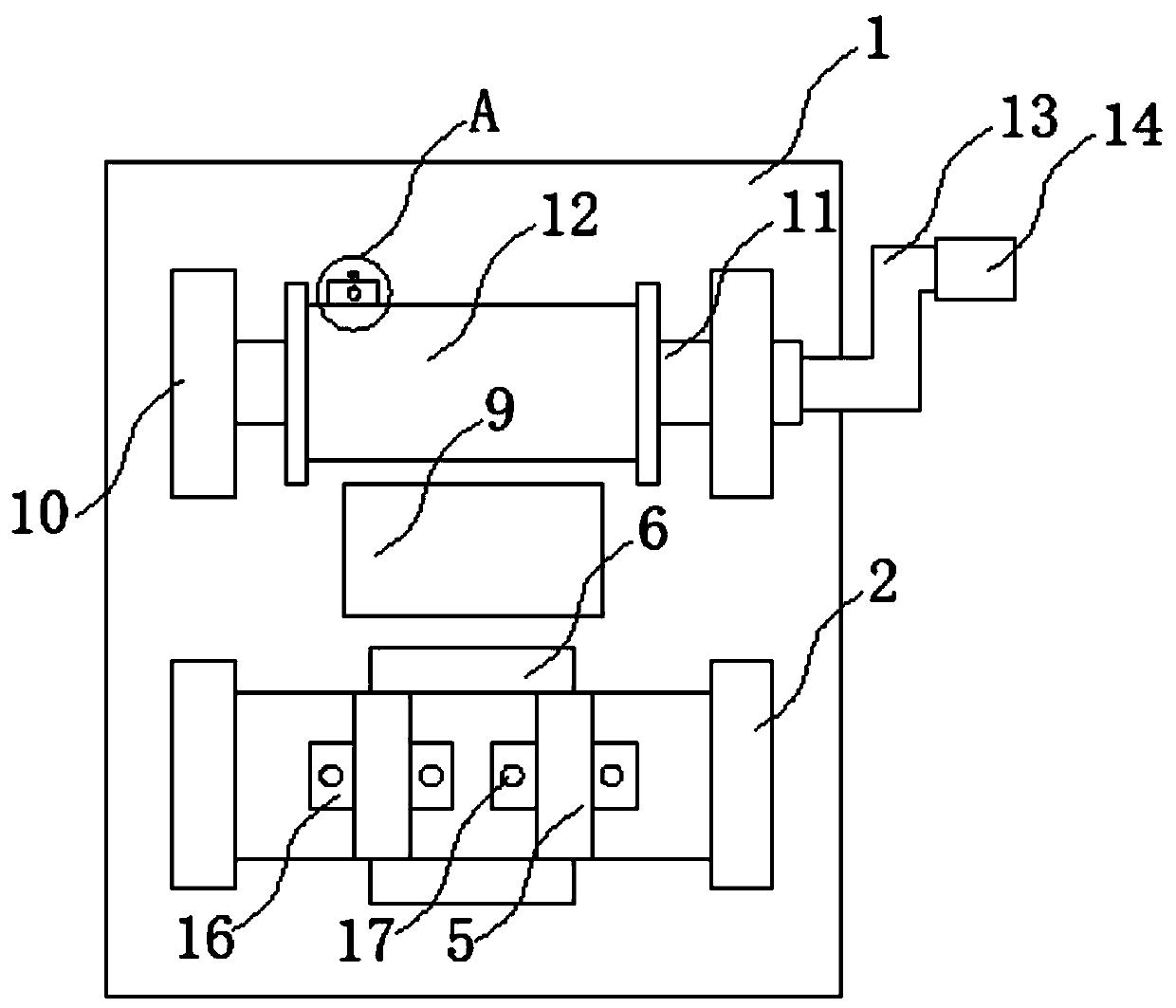

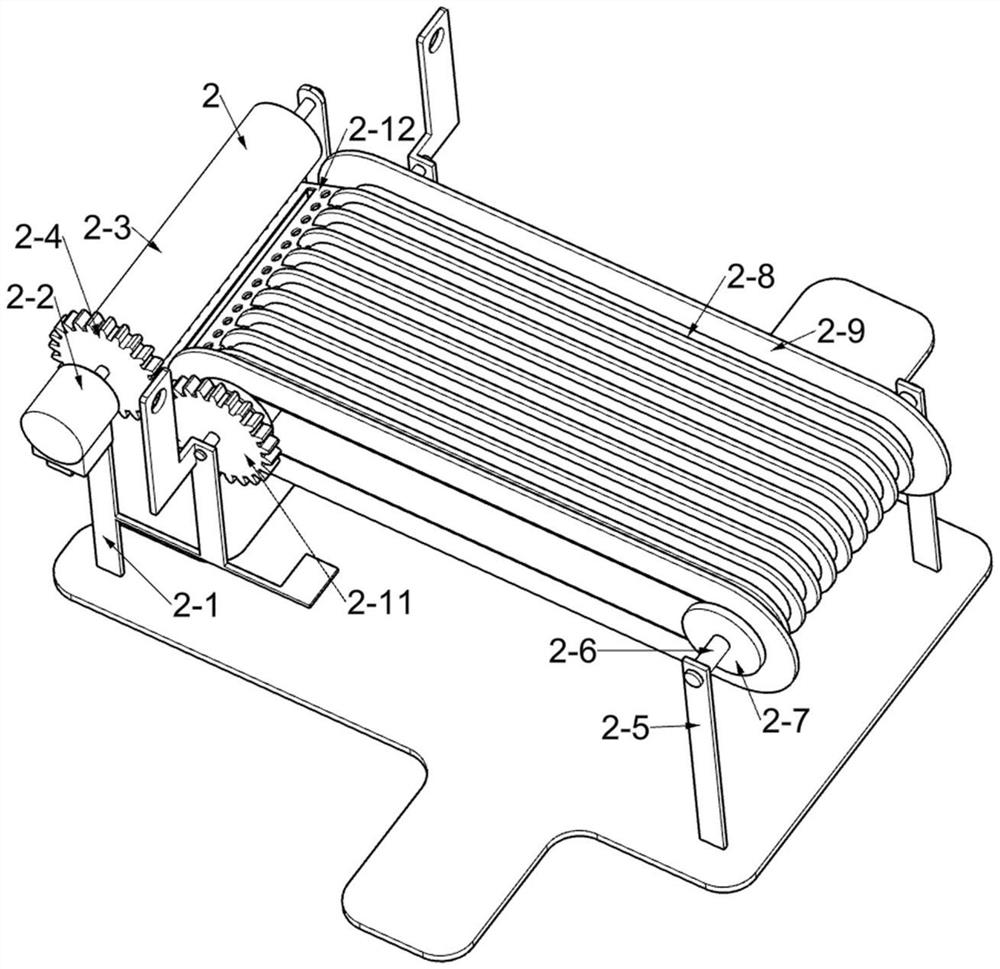

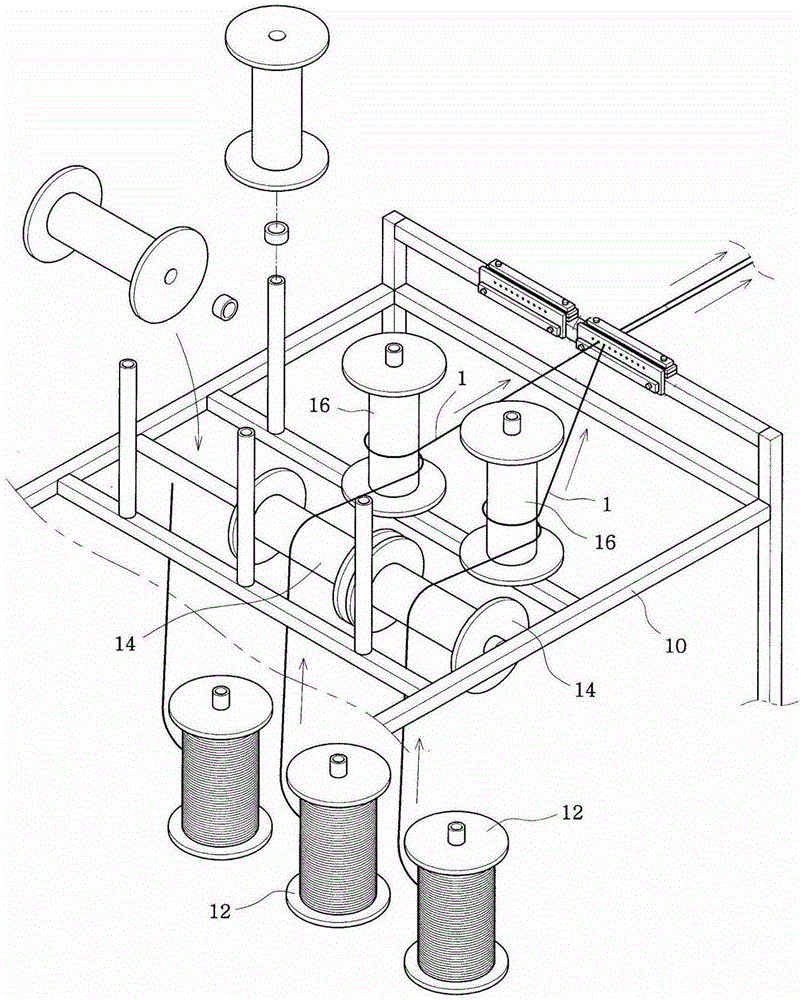

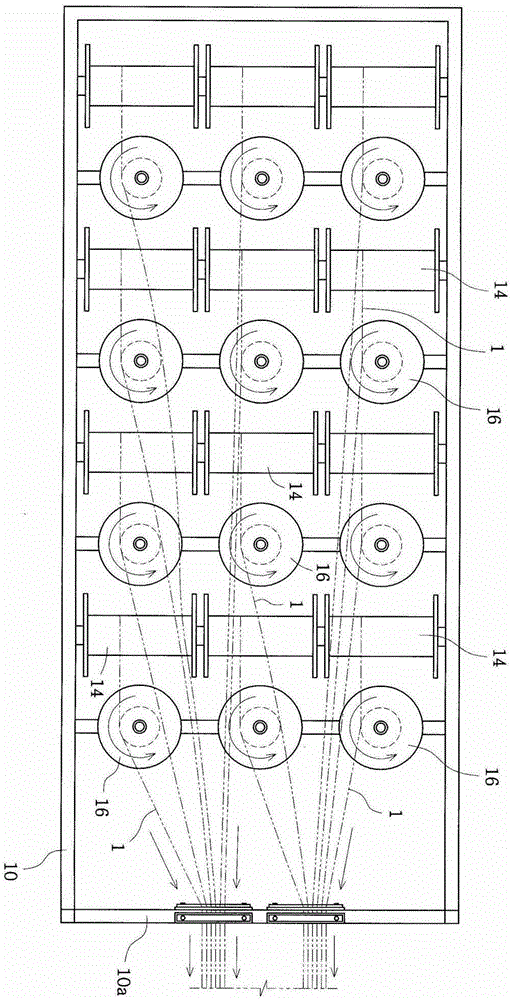

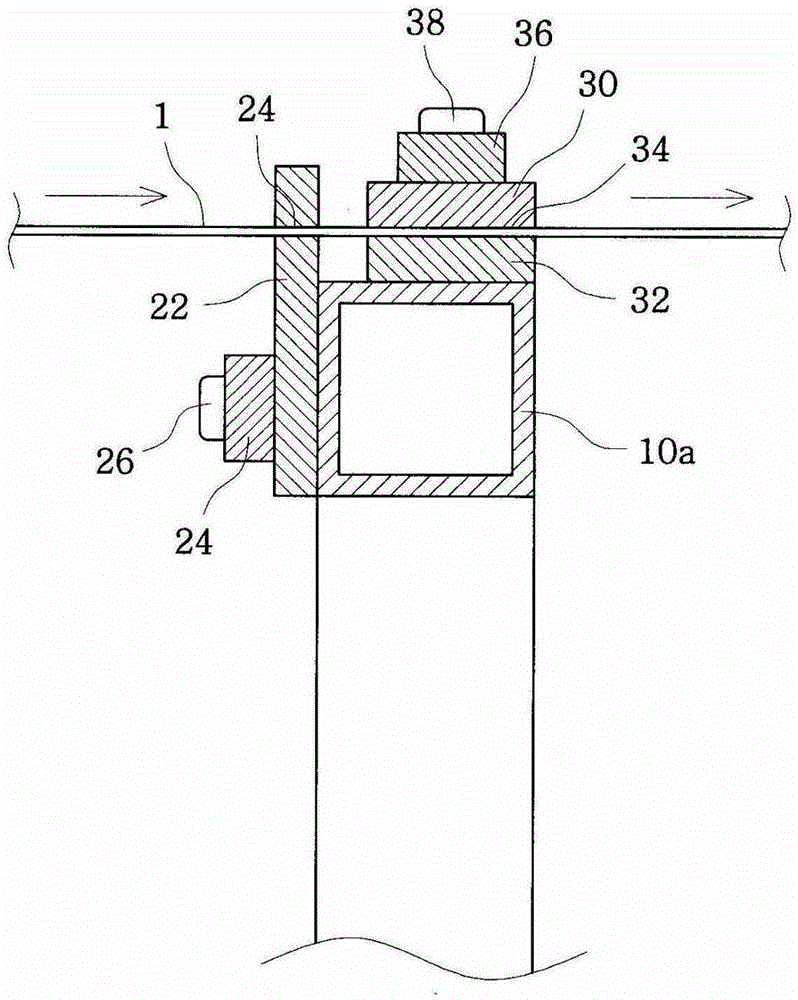

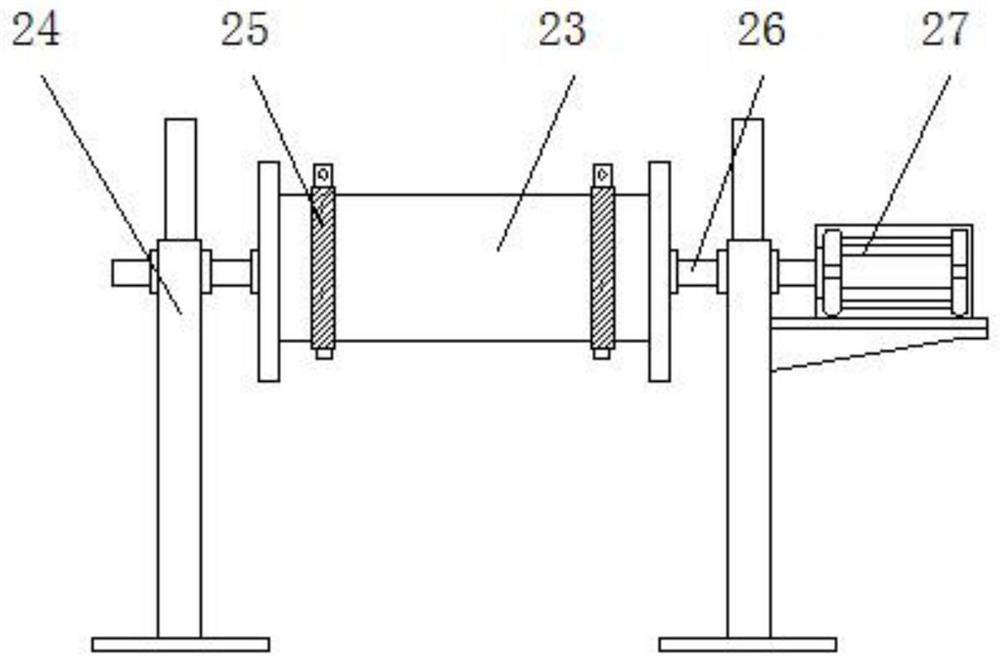

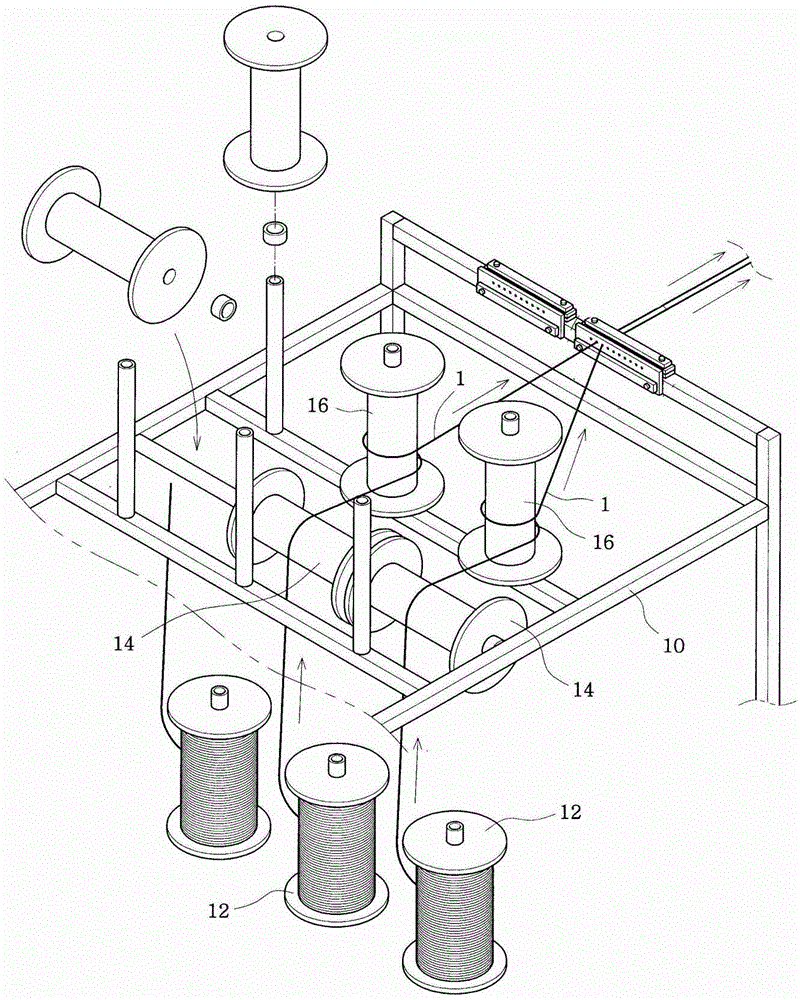

Full-automatic stepless speed regulation self-adaption winding device

InactiveCN105206419AControl tensionPlay a straightening roleCoils manufactureTransformerSelf adaptive

The invention discloses a full-automatic stepless speed regulation self-adaption winding device for power transformer coils used in the transformer manufacturing industry. The full-automatic stepless speed regulation self-adaption winding device comprises a take-up mechanism and a pay-off mechanism for winding and unwinding lines. A winding displacement mechanism is arranged between the take-up mechanism and the pay-off mechanism and comprises a machine frame, and line guide blocks connected to the machine frame in a sliding mode. A set of line holes are formed in each line guide block. Lines can penetrate through the line holes. The aperture of the line holes is consistent with the outer diameter of the lines. The winding displacement mechanism comprises a set of guide wheels arranged between the pay-off mechanism and the line guide blocks. The guide wheels are connected to the machine frame in a rotating mode. The lines are wound around the guide wheels and are wound around the single guide wheels by two circles at most. The technical defect that in the prior art, the line flatness can not be controlled is overcome, and the full-automatic stepless speed regulation self-adaption winding device which can automatically regulate the line flatness is provided.

Owner:CHONGQING WANGBIAN ELECTRIC GRP CORP

Negative pressure type embossing device capable of rapidly unfolding clothes

InactiveCN112680920AAvoid wrinklesGood for normal embossing operationsPattern makingEngineeringPleat

The invention discloses a negative pressure type embossing device capable of rapidly unfolding clothes. The embossing device comprises an embossing device body, an operation table, a protective door, a support frame, a telescopic mechanism, a support plate, an embossing plate, a control box, a connecting pipe, an exhaust fan, a reset rotating shaft and a fixing screw, wherein the operation table is arranged on the embossing device body; the protective door is arranged on the front side of the operation table; a sliding part is arranged at the lower end of a tensioning structure; the sliding part is connected with a sliding groove in the upper end face of the operation table; meanwhile, a pulling frame is welded to the upper end of a pressing part; and pressing blocks are glued to the inner sides of the front ends of the sliding part and the pressing part. According to the negative pressure type embossing device capable of rapidly unfolding the clothes, by improving an operation table and an embossing plate mounting structure of an existing embossing device, when the clothes are embossed, the area, needing to be embossed, of the clothes can be spread flatly, so that wrinkles of the clothes are avoided, normal embossing operation of the clothes is facilitated, and the embossing quality of the clothes is improved.

Owner:马鞍山鸿儒工业设计有限公司

Steel straightening device and using method thereof

PendingCN112742905APlay a straightening roleReduce frictionMetal working apparatusLever pressingStructural engineering

Owner:江苏润居建设科技发展有限公司

A wire stripping machine for cables

ActiveCN113783142BEasy to peelAvoid Situations That Affect PeelingApparatus for cutting/splicing cablesApparatus for removing/armouring cablesEngineeringControl theory

The invention relates to the technical field of cables, in particular to a wire stripping machine for cables, comprising: a waste box, the waste box is located below the output end of the conveying mechanism; a slitting mechanism, the slitting mechanism is installed at the output end of the conveying mechanism, and The cutting mechanism is used to cut the cable; the stripping mechanism is used to cut off the insulation layer of the cut cable end and separate it from the cable; the driving mechanism is used to drive the slitting mechanism and the stripping mechanism to work simultaneously; the cross-cutting mechanism , the cross-cutting mechanism is in an inverted "U" shape, and the two ends of the cross-cutting mechanism pass through the two side walls of the cutting position of the stripping mechanism, and the heights of the two ends of the cross-cutting mechanism are different; the cross-cutting mechanism follows the stripping mechanism to cut off the cable end When removing the insulation layer of the head, one end of the cross-cutting mechanism retracts to the inside of the stripping mechanism, and the other end of the cross-cutting mechanism is inserted into the insulation layer of the cable; when the stripping mechanism is separated from the cable, the retracted end of the cross-cutting mechanism rebounds to push Drop and insert the insulation at the other end of the crosscutting mechanism.

Owner:常州市生生线缆有限公司

A high-efficiency special spinning solution impregnation equipment for electrospinning nanofibers

ActiveCN110607622BAffect the subsequent infiltration effectConducive to follow-up centralized cleaningFibre cleaning/openingTextile treatment machine arrangementsSpinningNanofiber

Owner:ZHONG HONG NANO FIBER TECH DANYANG

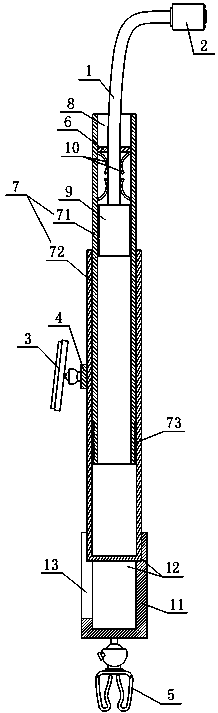

multifunctional test rod

ActiveCN107202911BConvenient wiring operationDoes not take up external spaceClosed circuit television systemsMeasurement instrument housingPower flowEngineering

The invention relates to a multifunctional test bar. The multifunctional test bar comprises a hollow length adjustable bar body, a universal locating flexible tube is connected to the top end of the bar body and is installed in an inner cavity in the top part of the bar body in a sliding manner, a flexible tube clamping and locating mechanism is arranged in the inner cavity in the top end part of the bar body, a camera box is installed at the outer extending end of the universal locating flexible tube, a camera is installed on the camera box, the test bar further comprises display screen equipment in wireless communication connection with the camera, the display screen equipment is handheld or is detachably clamped on the bar body through a clamping seat, a spring cable clamp is installed at the bottom end of the bar body, and a current detection wire and a voltage detection wire are led out from the spring cable clamp. The multifunctional test bar helps to read a name plate rapidly, assists in wiring, is simple in structure, is flexible to operate, and is quite convenient to carry and use.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY WEIFANG POWER SUPPLY +1

Steel wire knotting device for building construction and steel wire knotting method for construction

InactiveCN110656781APlay a straightening roleReduce labor intensityBuilding material handlingArchitectural engineeringElectric machinery

The invention belongs to the technical field of steel wire knotting and especially relates to a steel wire knotting device for building construction. The device comprises a binding driving bar, a conveying guiderail, a shell and a steel wire conveying mechanism. During binding of reinforcing steel bars, the conveying guiderail is at first hooked between the two reinforcing steel bars to be bound,so a turntable installed on the binding driving bar can be pressed on the two reinforcing steel bars; then, a binding mechanism is moved upwards for a short distance, a driving motor is switched on bya switch button and starts work, a steel wire clamped in advance inside the shell is conveyed out by the steel wire conveying mechanism, and a speed reduction stepping motor starts work when a secondsteel wire thickening end on the steel wire gets contact with a sensor on the shell; and the binding driving bar is driven by the speed reduction stepping motor to rotate and wind the steel wire. Incomparison with traditional manual binding, the device disclosed by the invention has the beneficial effects that binding efficiency is high and workers' labor strength is low; and in comparison withexisting binding machines of reinforcing steel bars, the device can be operated conveniently and can be operated with one hand.

Owner:马桂花

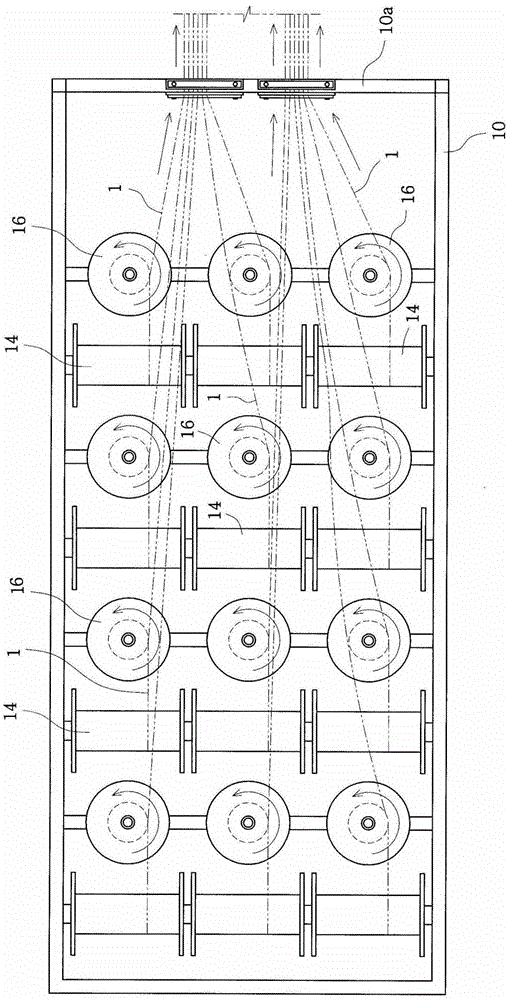

A vacuum adsorption conveying device in a water-based printing machine

ActiveCN102267283BImprove color registration accuracyCompressive strength does not decreasePrinting press partsCardboardScreen printing

Owner:BENGBU AOTE CARTON MACHINERY

Inflation/deflation type air bag unfolding and coiling device

An inflation / deflation type air bag unfolding and coiling device relates to an unfolding and coiling device, and aims to solve the problem that in a conventional aviation spacecraft, the inflation structure is highly flexible, the folding and coiling are controlled difficultly, and the folding and unfolding process in the working state needs to be simulated and experimented on the ground, but no unfolding and coiling device capable of achieving the function of assisting the folding and the unfolding and unfolding controllability is available. The inflation / deflation type air bag unfolding and coiling device comprises a middle shaft, a driving and locking mechanism, a support saddle, an upper limiting stop lever, a lower limiting stop lever and a ventilation mechanism, wherein the ventilation mechanism comprises a ventilation connecting pipe, a rotary joint and an air valve; the support saddle comprises a base, two cross beams and two vertical beams; the middle shaft is arranged on the two vertical beams positioned between the two cross beams and can be rotated in the circumferential direction; the ventilation connecting pipe is connected to one vertical beam; the air valve is connected to the end part, opposite to the rotary joint, of the ventilation connecting pipe; and the other end of the middle shaft is connected with the driving and locking mechanism used for controlling the rotation and the stopping of the middle shaft. The device is used for inflatable structures of large-scale aviation spacecrafts.

Owner:HARBIN INST OF TECH

Wire rod flat steel putting device

The invention discloses a wire rod flat steel putting device which comprises a base and forming groove wheels. A rotating device comprises second supports, a connecting plate, electric telescopic rods, a second supporting plate, a bearing seat, a rotating shaft and a motor is arranged at the left end of the top of the base, and a supporting sliding block comprising a third supporting plate, ejecting plates, a shaft sleeve, adjusting screws, second threaded plates and first threaded plates is arranged on the top of the rotating device. A stop wheel is fixedly connected to the right end of the top of the base through a third support. By means of the wire rod flat steel putting device, the base, the rotating device, the supporting sliding block, the stop wheel, carrier rollers, guide wheels and the forming groove wheels are arranged, a put wire rod flat steel body can be directly formed, no intermediate link exists, in addition, after one wire rod flat steel body is formed, only the wirerod flat steel body needs to be cut off, then forming of the next wire rod flat steel body can be conducted, continuous work can be achieved, and the production efficiency is improved; and meanwhile the wire rod flat steel putting device is simple in structure, convenient to operate and capable of facilitating application and popularization.

Owner:XINXING ENERGY EQUIP

A plate taking mechanism for preventing deformation of glass substrate

ActiveCN112193832BPlay a straightening roleAvoid warpingCharge manipulationConveyor partsStructural engineeringMechanical engineering

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

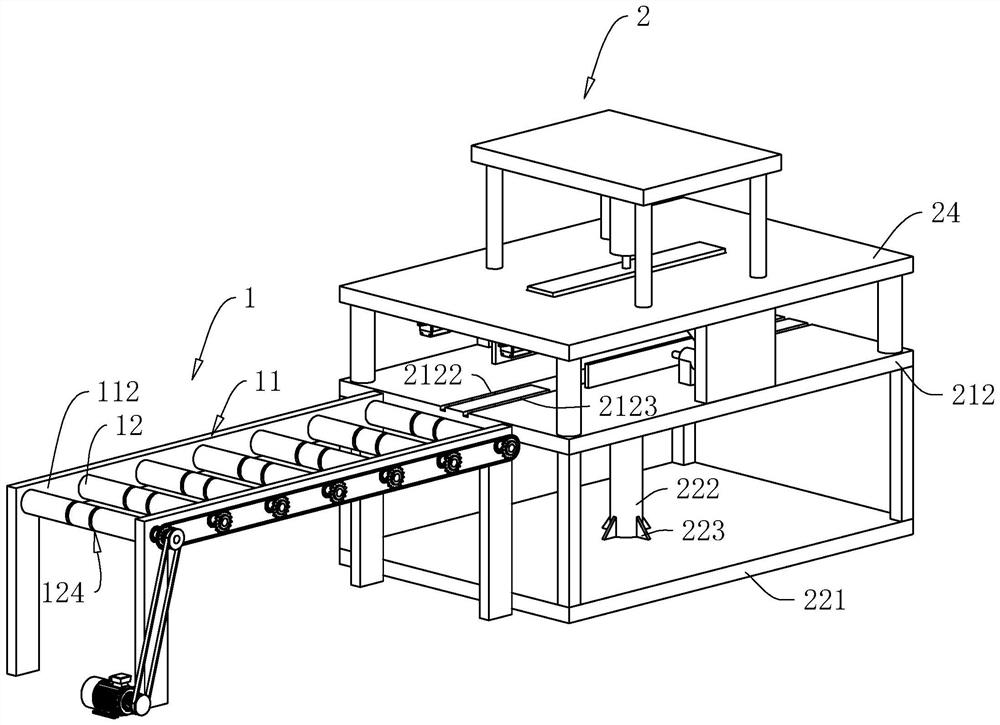

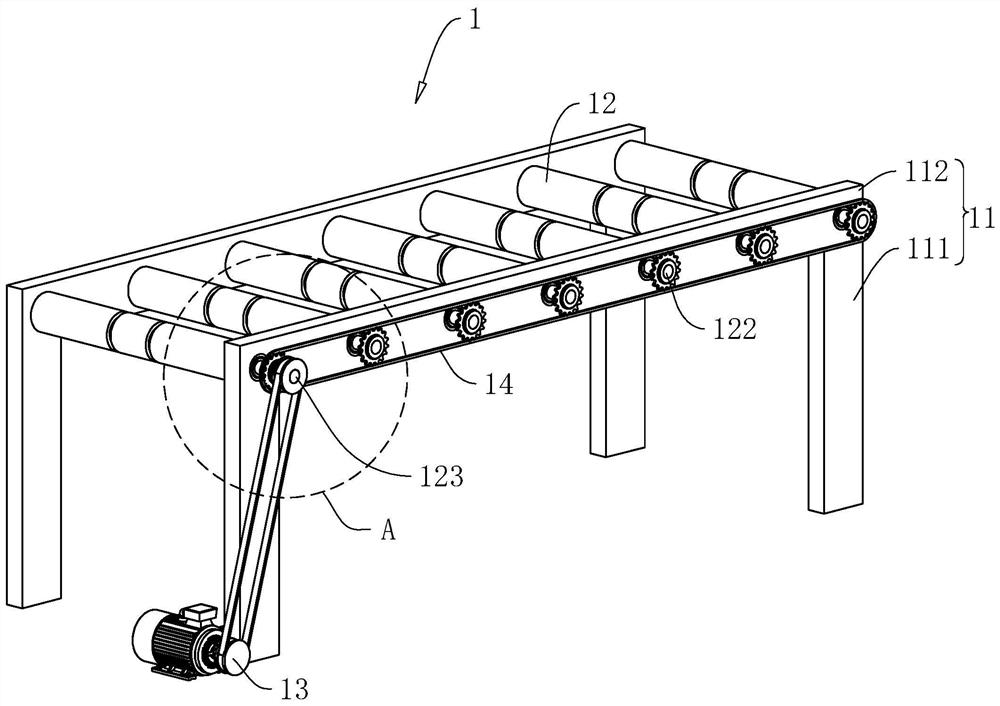

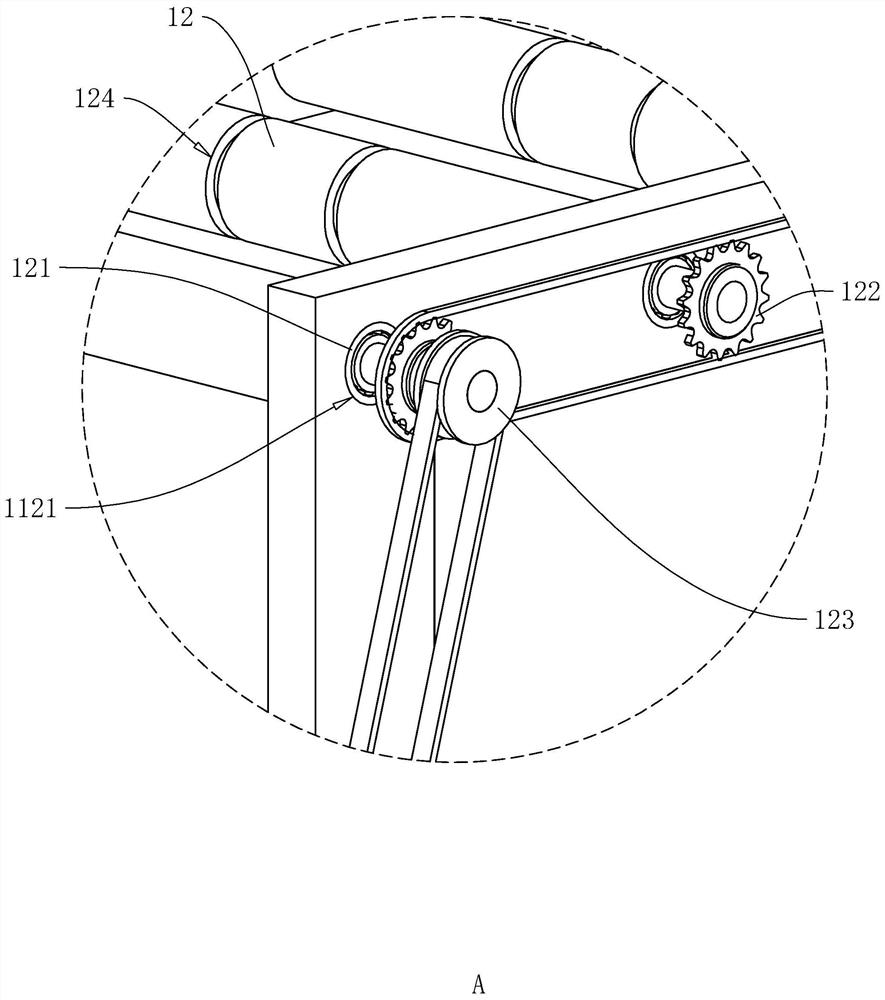

Straightening machine for manufacturing air-tight door

PendingCN113828658APlay a straightening roleReduce frictionMetal-working feeding devicesPositioning devicesStructural engineeringWorkbench

The invention relates to the field of workpiece straightening, in particular to a straightening machine for manufacturing an air-tight door, the straightening machine comprises a conveying mechanism and a workbench which are arranged in sequence, wherein a jacking plate hole is formed in the workbench, and the conveying mechanism is used for conveying I-shaped steel machined by the straightening machine to the position above the jacking plate hole in the workbench; a jacking assembly capable of penetrating through the jacking plate hole to jack up the I-shaped steel is arranged below the jacking plate hole, and extrusion assemblies used for applying extrusion force to the I-shaped steel jacked up by the jacking assembly are arranged on the two sides of the upper portion of the jacking plate hole; a pressure drop assembly is arranged above the jacking plate hole and used for applying downward extrusion force to the I-shaped steel jacked up by the jacking assembly. The simple tractable vehicle axle lifting device has the effect of conveniently improving the straightening efficiency of the I-shaped steel on an air-tight door.

Owner:深圳市岭南人防防护设备有限公司

Full-automatic stepless speed self-adapting winding technology

ActiveCN105161286AControl tensionPlay a straightening roleCoils manufactureSelf adaptiveDeflection angle

The invention discloses a full-automatic stepless speed self-adapting winding technology for a power transformer coil used in a transformer manufacturing industry. The full-automatic stepless speed self-adapting winding technology comprises the following steps: (a) line adjustment, enabling a line to sequentially pass through a guide wheel and a guide block, and connecting the line to a take-up reel; (b) line checking, starting a motor on a take-up mechanism, pulling the line on a pay-off mechanism gradually, enabling the line to pass through the guide block and to wind the take-up reel through guide of the guide wheel, and sliding the guide block to a proper position on a rack or adjusting a line hole into which the line penetrates until the deflection angle of the line from the guide block is less than 30 degrees; and (c) line winding, after checking the line, locking the guide block on a determined position through a lock mechanism, and restarting the motor. According to the full-automatic stepless speed self-adapting winding technology, the technical defect that the line flatness cannot be controlled in the prior art is overcome; and the full-automatic stepless speed self-adapting winding technology capable of automatically adjusting the line flatness is provided.

Owner:CHONGQING WANGBIAN ELECTRIC GRP CORP

A beam-column energy-dissipating connector based on a U-shaped plate and its construction method

ActiveCN113529946BImprove seismic performanceExtended service lifeProtective buildings/sheltersPhotovoltaic energy generationEarthquake resistanceClassical mechanics

Owner:陕西勤创矩阵建筑科技有限公司

Hinge type expansion joint

PendingCN111503404AEliminate deformationEliminate destructionPipeline expansion-compensationNatural stateEngineering

The invention relates to a hinge type expansion joint. The two ends of an intermediate pipe are provided with a corrugated pipe and an end pipe respectively, and the left side and the right side of the expansion joint are provided with first hinge frames respectively. The front side and the rear side of the expansion joint are provided with second hinge frames respectively. Upper hinge shafts andlower hinge shafts of the second hinge frames are provided with flat opening torsion springs respectively, and the second hinge frames keep upright in the natural state of the flat opening torsion springs. When the expansion joint has angular deformation, the first hinge frames and the second hinge frames rotate to eliminate angular stress, and after the angular deformation is eliminated, the first hinge frames and the second hinge frames are reset under the straightening effect of the second hinge frames under the support of the flat opening torsion springs, so that the expansion joint is reset.

Owner:营口庆营石化设备有限公司

An automatic shearing device for steel plates

ActiveCN107671345BAdjustable clamping degreePlay a straightening roleMetal-working feeding devicesShearing machinesClassical mechanicsStructural engineering

The invention discloses an automatic shearing device for a steel plate. The automatic shearing device comprises a workbench, a frame block and a stand. The stand is provided with a clamping mechanism.The clamping mechanism comprises a transverse plate, a driving belt, an X-axis sliding rail and a sliding mechanism. The sliding mechanism comprises two sliding sleeves capable of sliding oppositely.The two sliding sleeves are provided with a first roller shaft, a second roller shaft and a third roller shaft. The frame block is provided with a first air cylinder with the movable end being provided with an L-shaped mounting plate. A clamping cylinder and a vertical plate with a horizontal sliding groove are fixed to the top face of the L-shaped mounting plate. A fixing block and a sliding block are arranged in the horizontal sliding groove. The front end of the fixing block and the front end of the sliding block are connected with an L-shaped first clamping plate and an L-shaped second clamping plate correspondingly. A shearing cylinder used for driving a shear body to operate is arranged above the clamping cylinder. The automatic shearing device for the steel plate is compact in structure and convenient to use, the steel plate can be cut automatically and the labor intensity of workers is greatly relieved.

Owner:嘉善优耐特滑动轴承厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com