Cooling and straightening device for metal thermal treatment

A metal heat treatment and straightening device technology, which is applied in heat treatment equipment, quenching devices, manufacturing tools, etc., can solve the problems of workpiece deformation and straightening difficulty, and achieve the effect of rapid cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

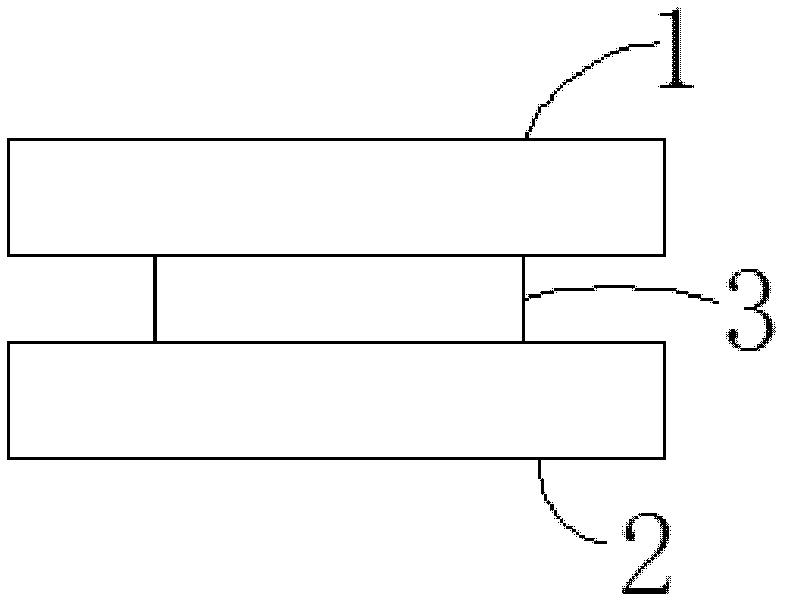

[0011] Embodiment: a cooling and straightening device for metal heat treatment, which is provided with several upper heat transfer blocks 1 and several lower heat transfer blocks 2, and the upper heat transfer blocks and the lower heat transfer blocks are all equipped with cooling liquid channels in a balanced manner. Coolant flows through the coolant channel, the upper heat transfer block is connected to a hydraulic press capable of pressing it down, the lower heat transfer block is positioned on the worktable, and the workpiece 3 can be placed on the lower heat transfer block.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com