Patents

Literature

70results about How to "Quick straightening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

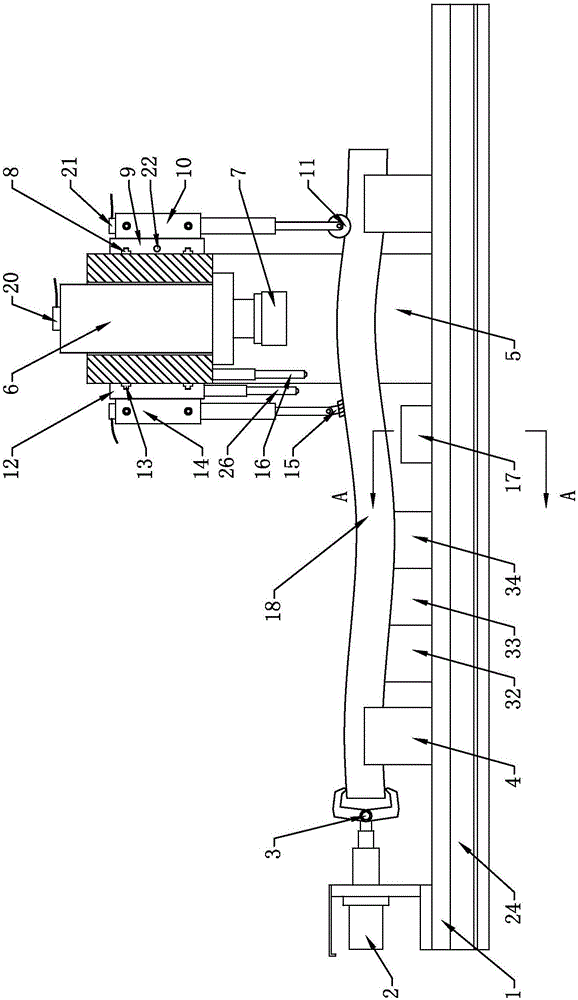

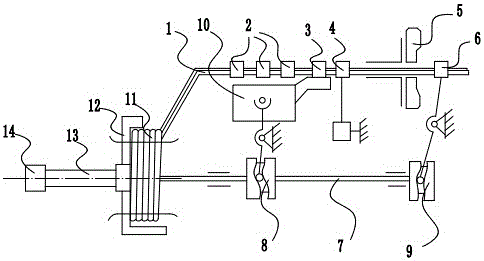

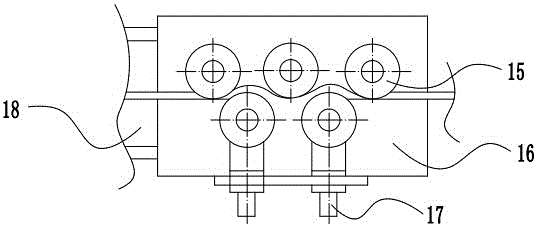

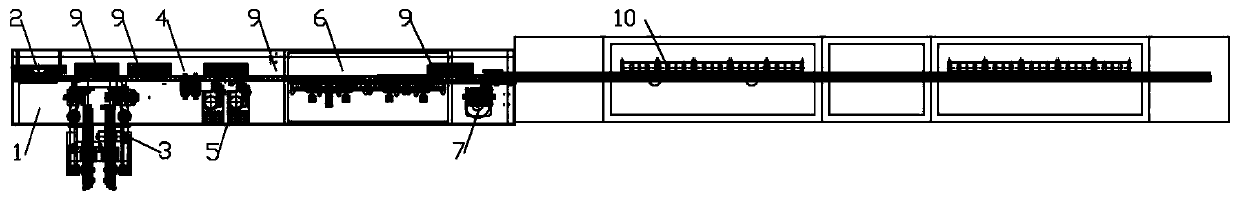

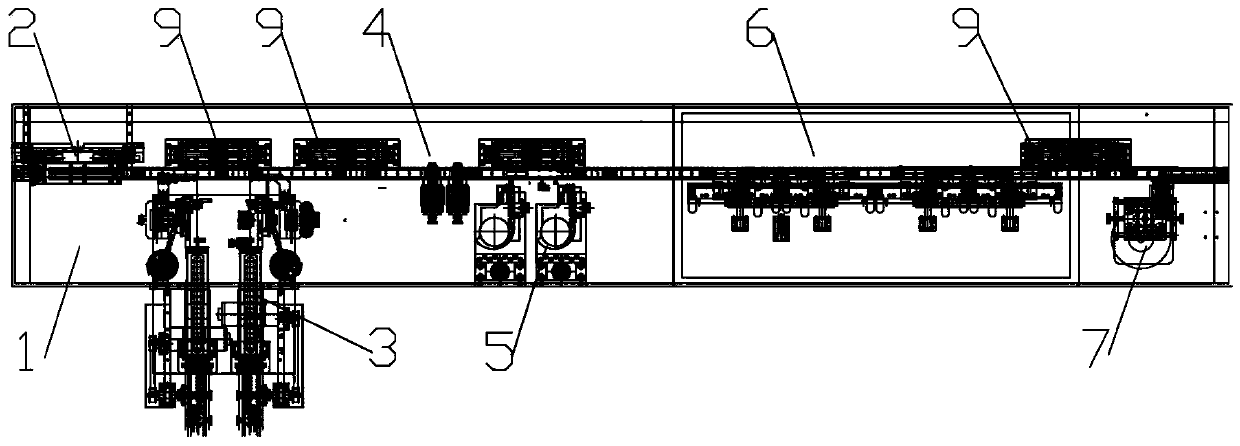

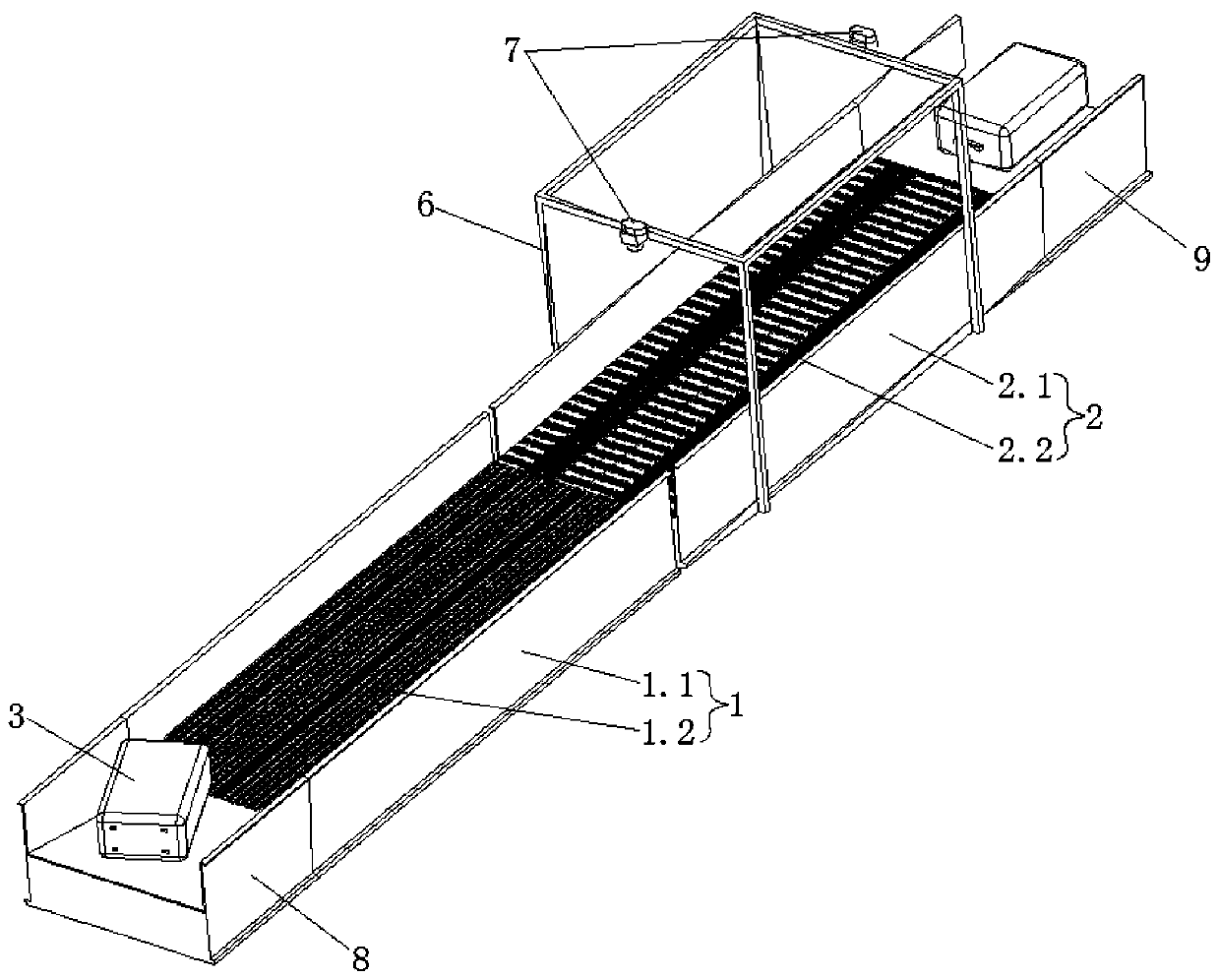

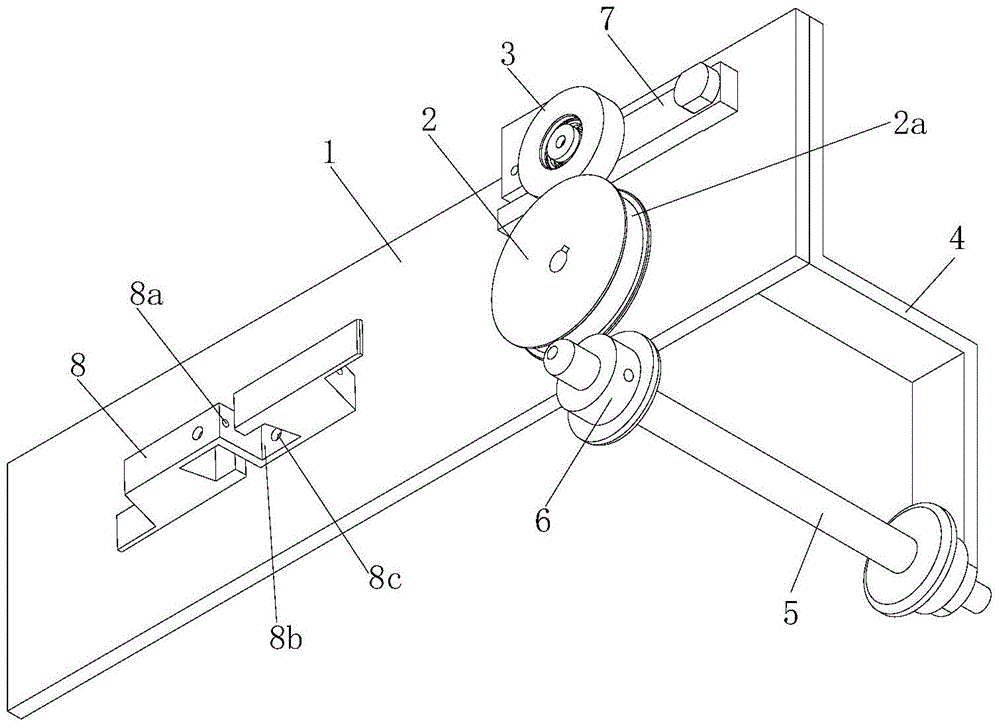

Multi-straightening head-based quick straightening device and method

InactiveCN101712053AQuick straighteningFast straightening of the straightening head Fast straighteningGear wheelLaser sensor

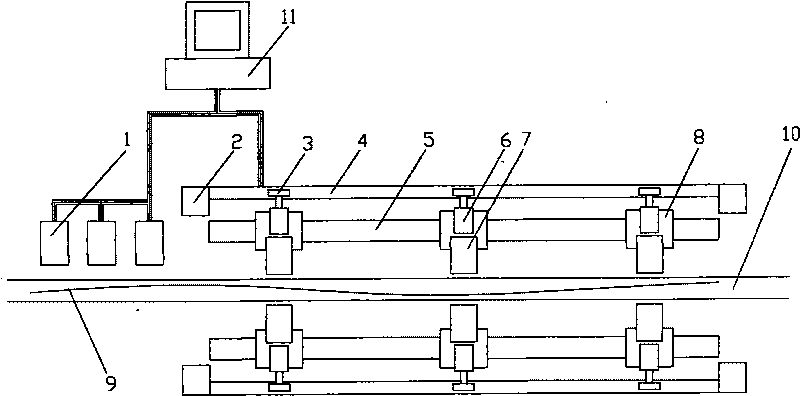

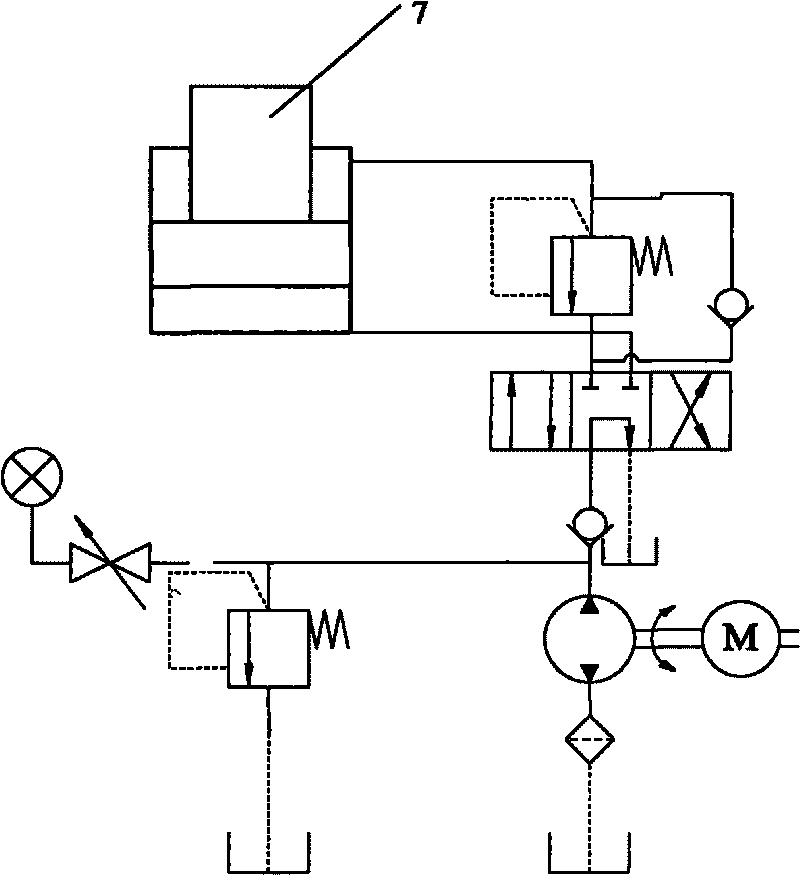

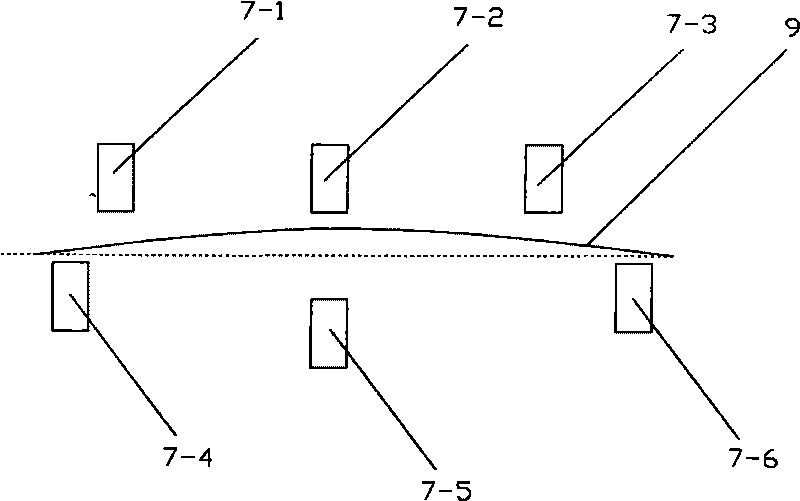

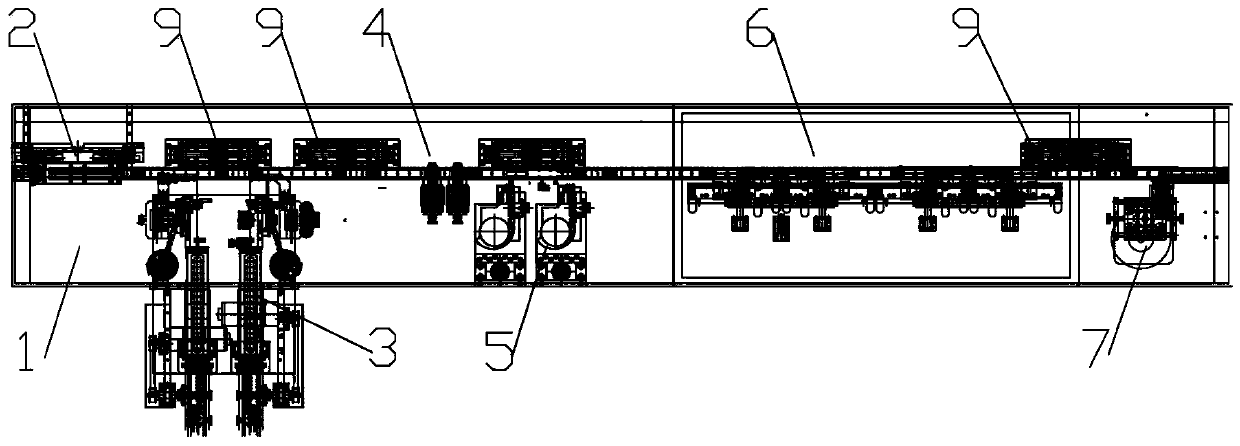

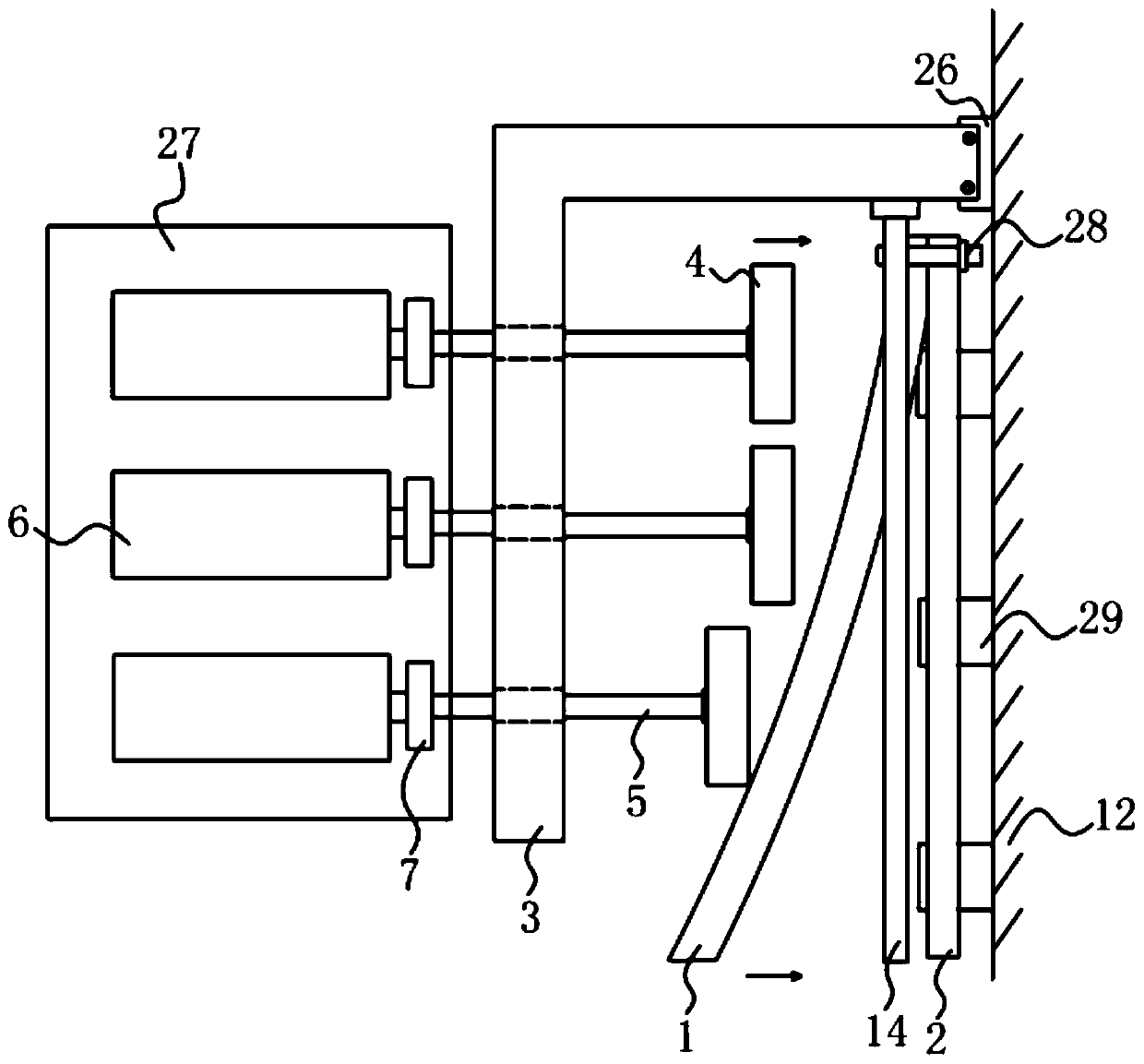

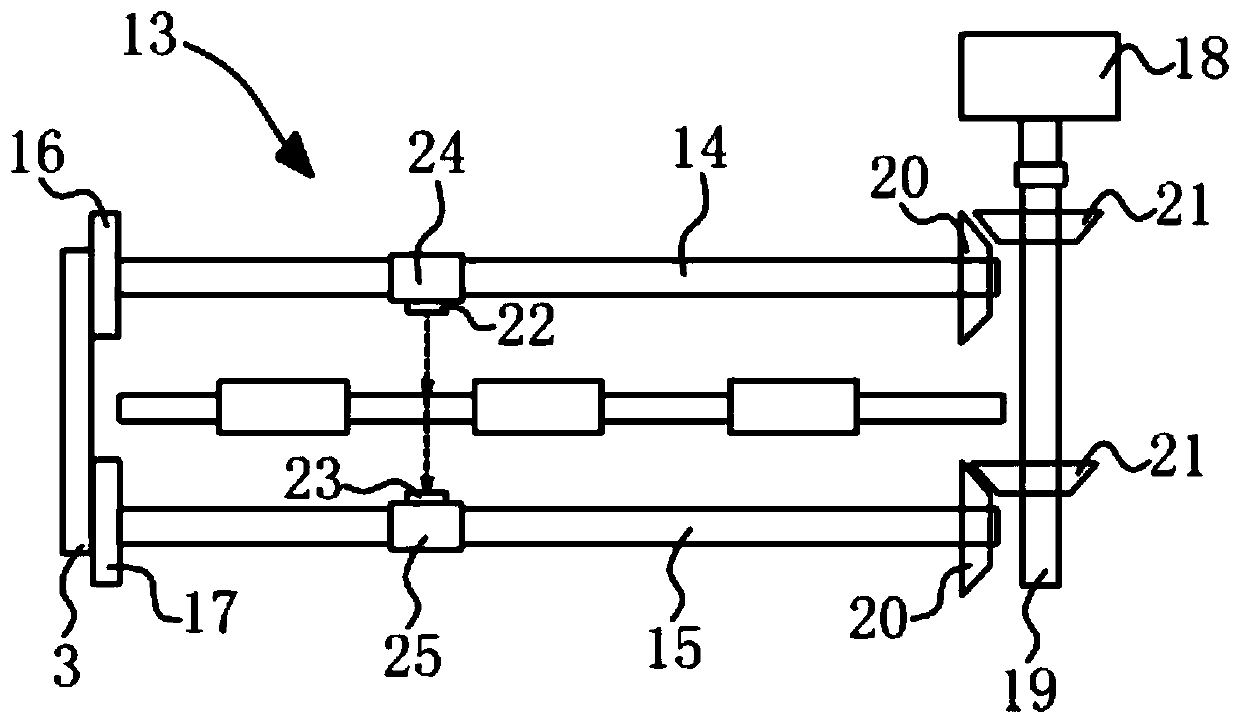

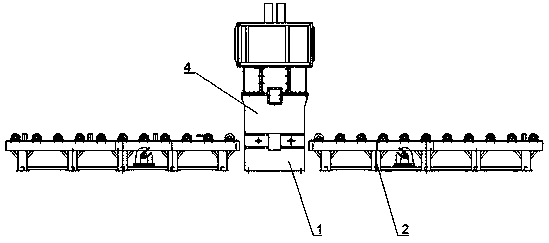

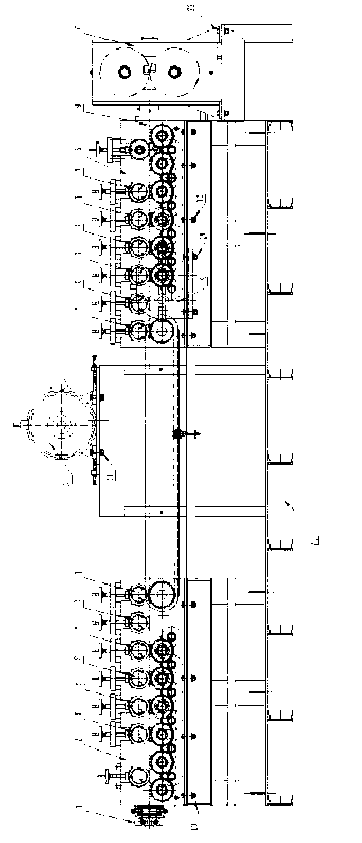

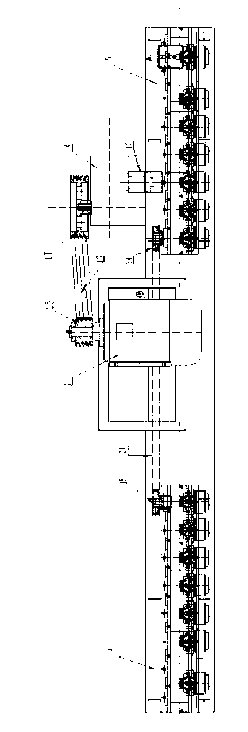

The invention discloses a multi-straightening head-based quick straightening device and a multi-straightening head-based quick straightening method. Two sides of a conveying roller table are respectively provided with a linear guide rails and a rack parallel to the conveying roller table in turn; two linear guide rails are respectively provided with three slide blocks; one end of each slide block is provided with a step motor which is meshed with the racks through a gear; the other end of each slide block is provided with a straightening head; two ends of the two racks are respectively provided with a limit block; one end of one of the linear guide rails and one side of a conveying channel are provided with three laser sensors which are in the same line at equal intervals and are parallel to the conveying channel; the three laser sensors and the step motors are connected with a computer; the computer determines the movement and feed of each straightening head by analyzing data acquired by the three laser sensors; and the computer makes the slide blocks drive the straightening heads to move in the direction of the linear guide rails by controlling the step motors. The device and the method can realize quick straightening of single-arc and S-shaped workpieces.

Owner:ZHEJIANG UNIV

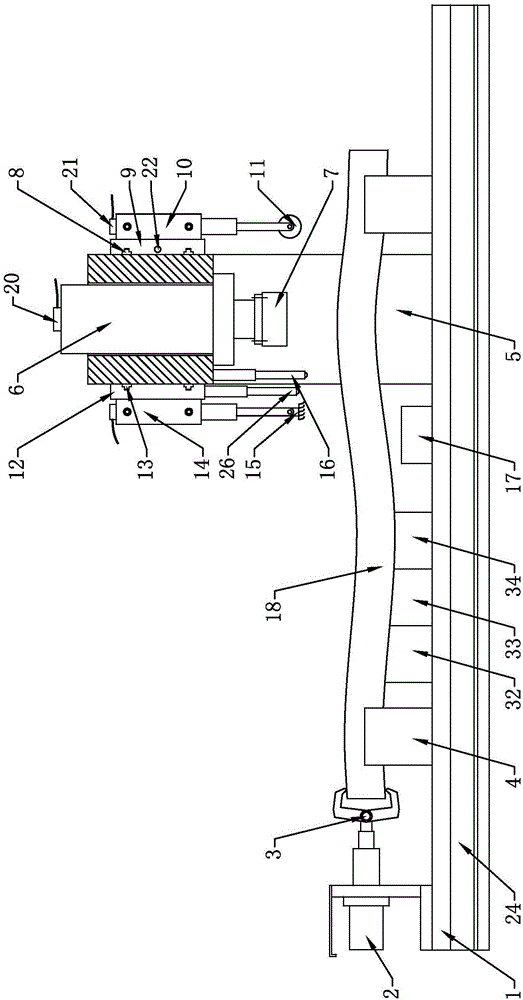

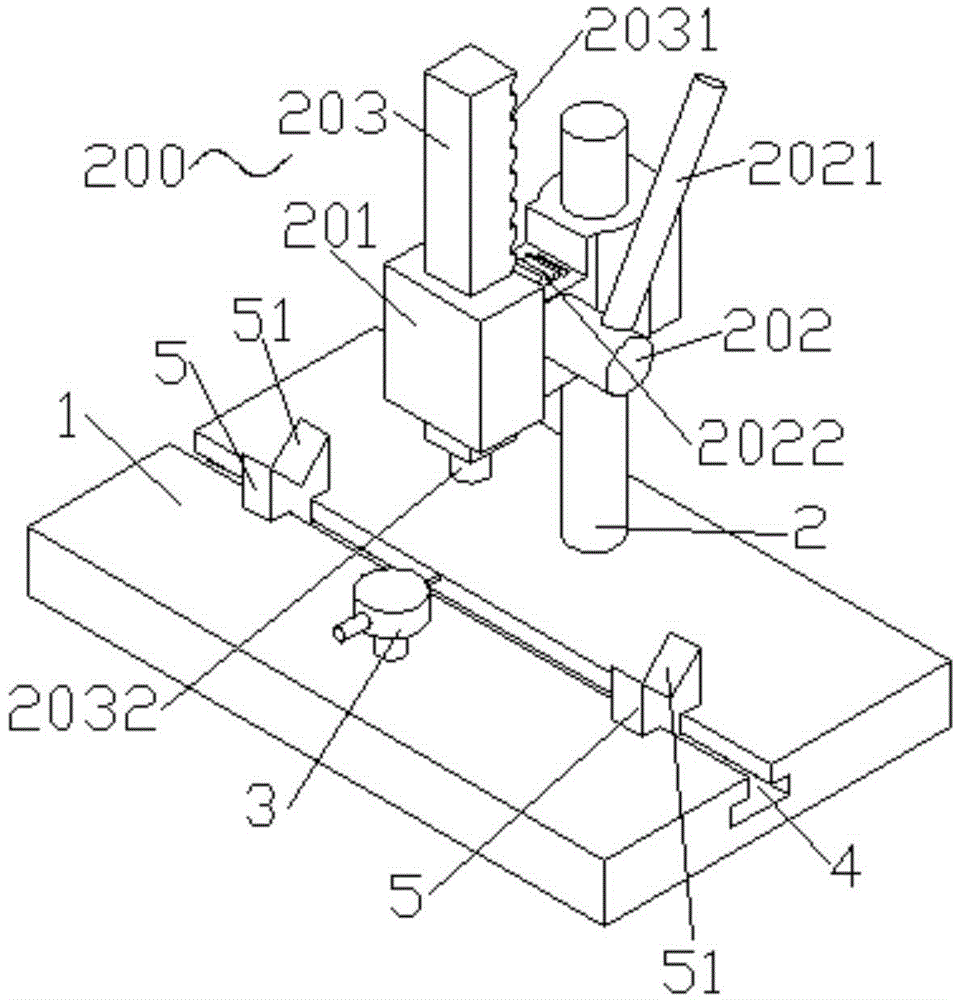

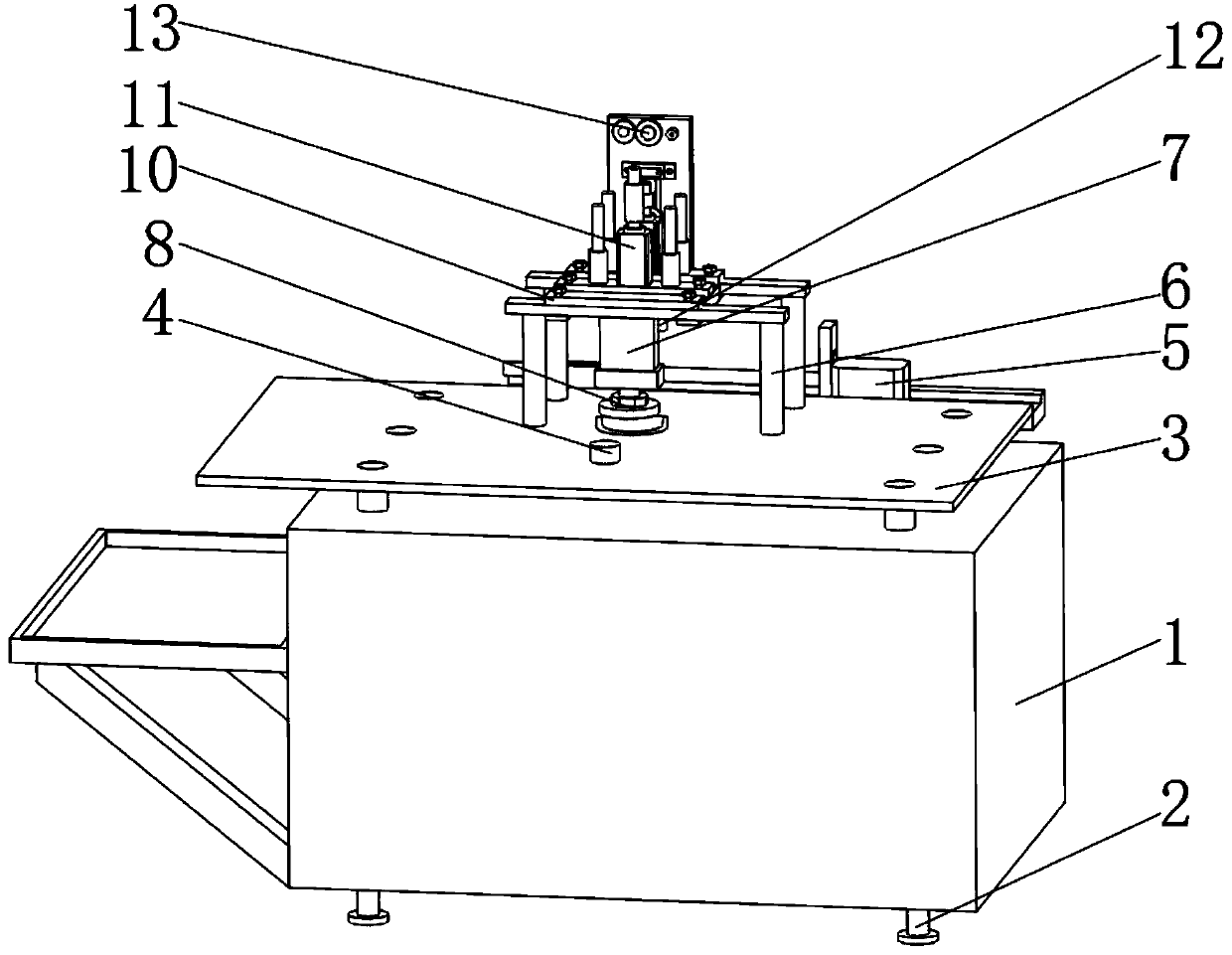

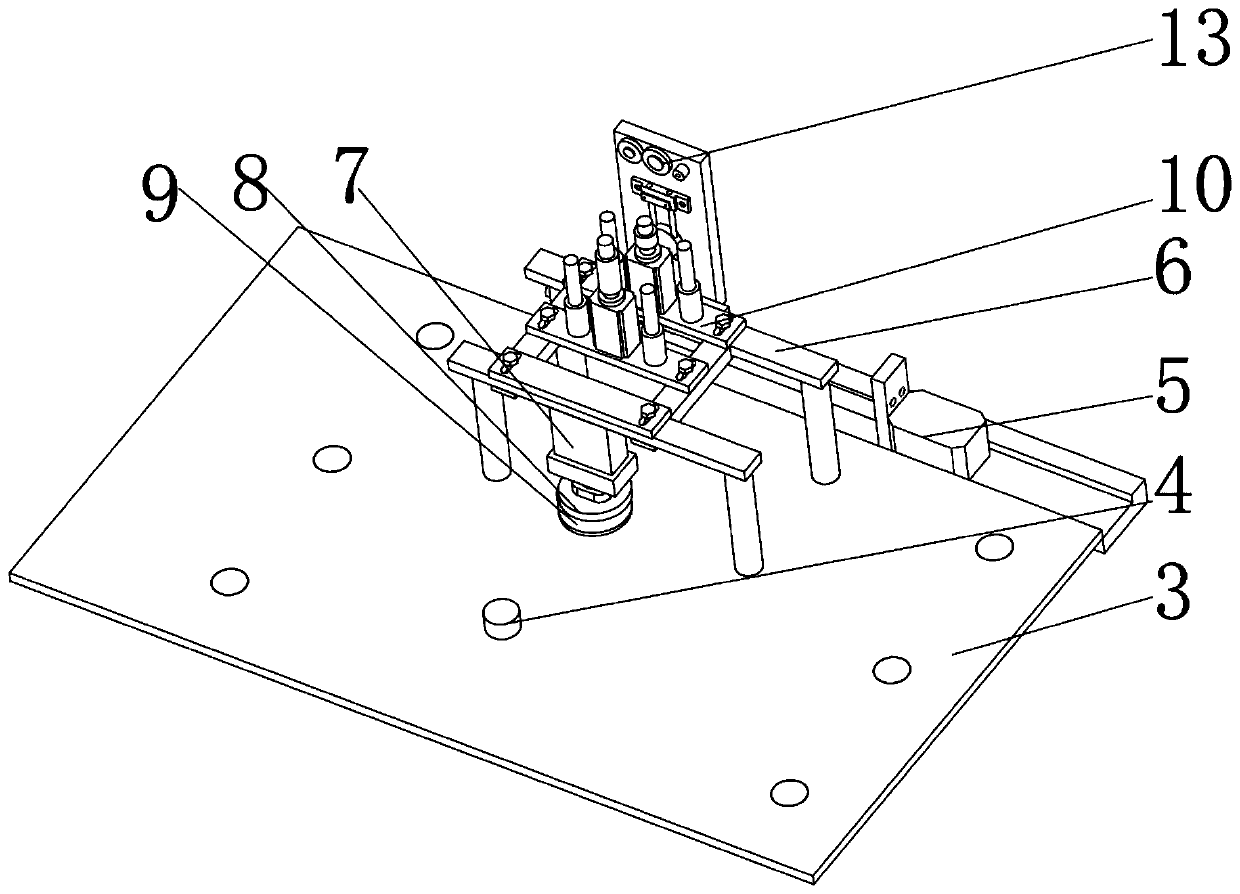

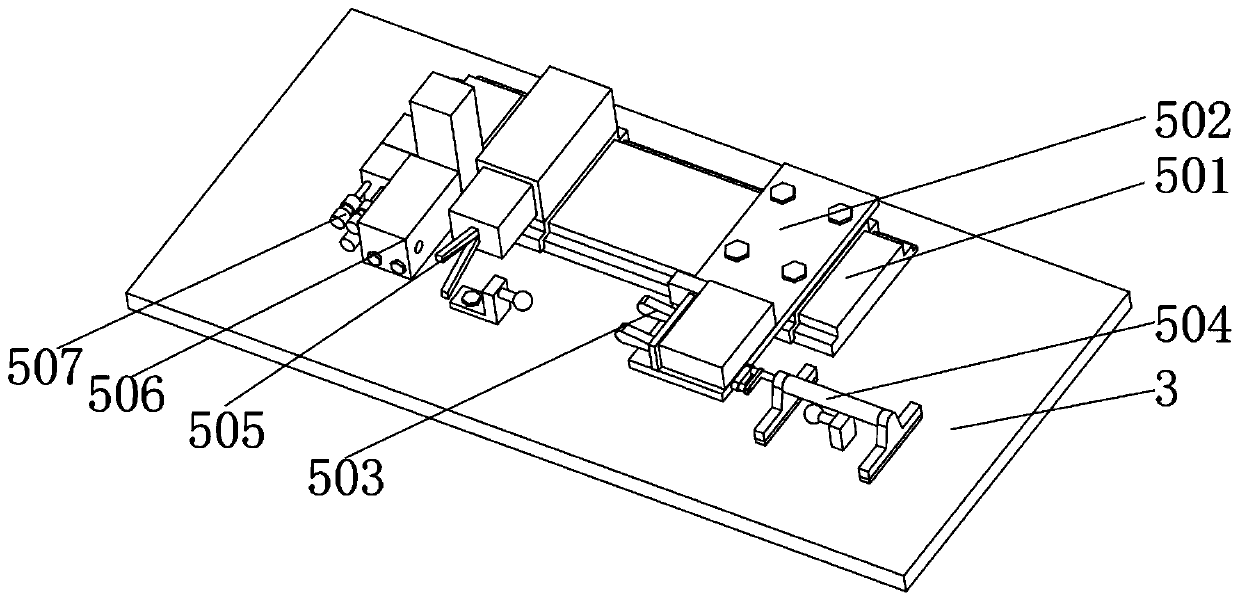

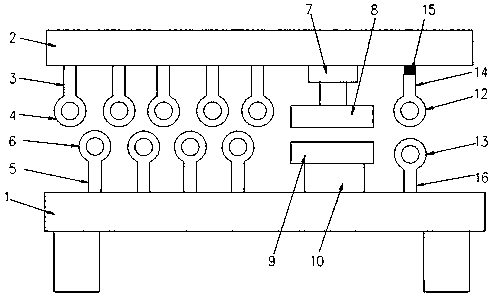

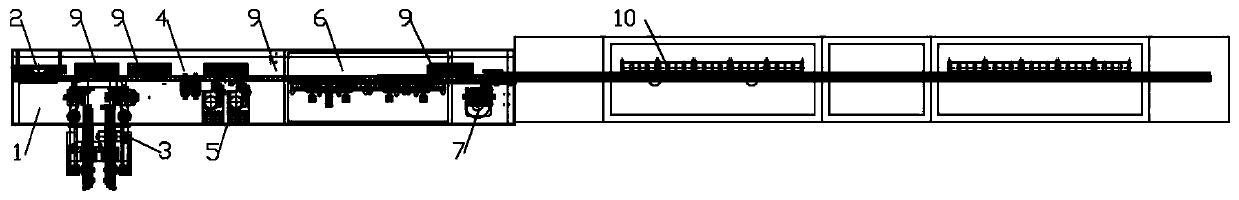

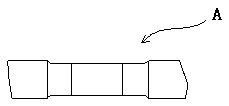

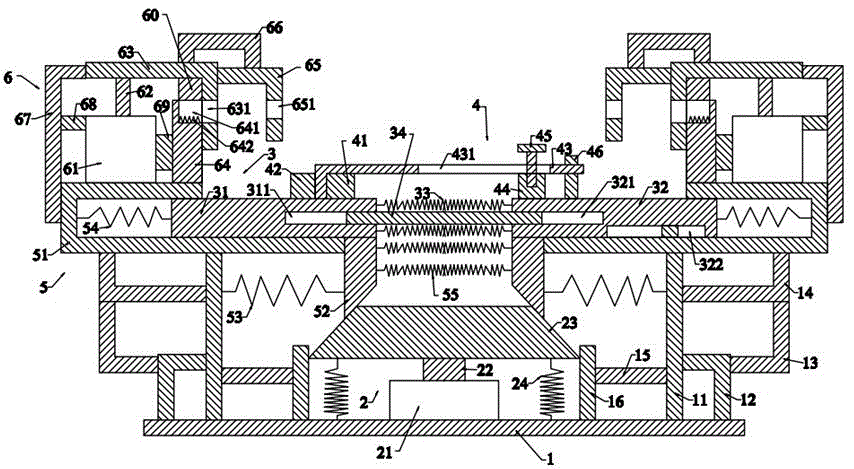

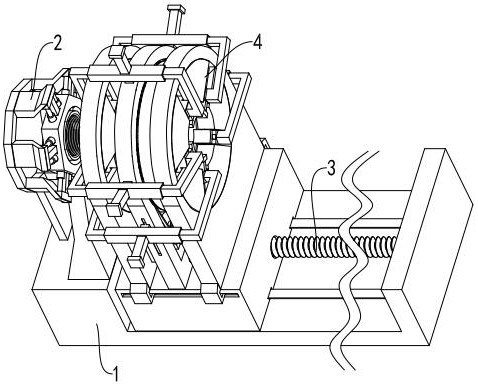

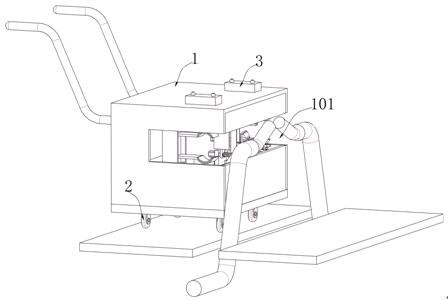

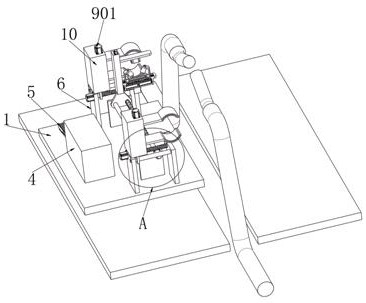

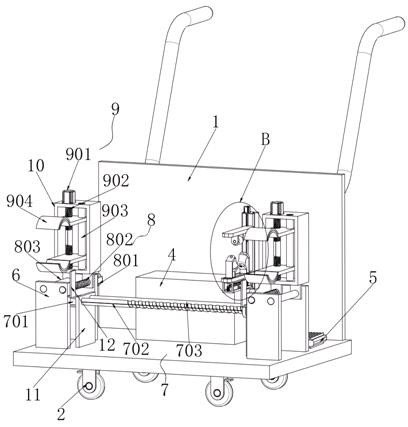

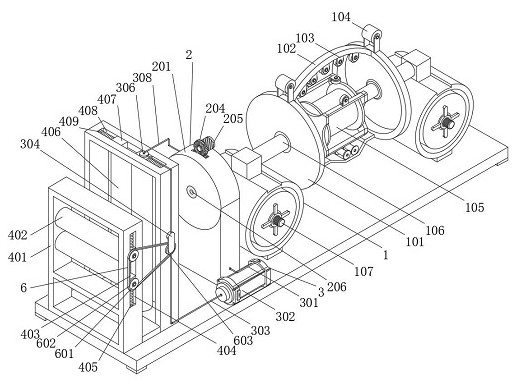

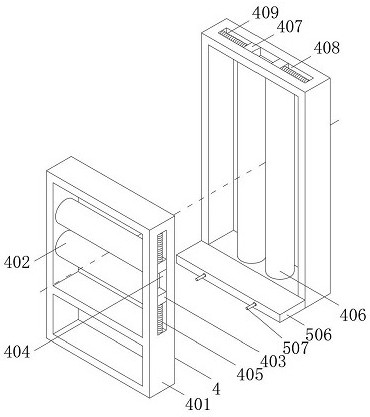

Detecting and straightening machine and method for shaft parts

ActiveCN106734386AReduce measurement errorPlace stableGrinding machinesMetal working apparatusEngineeringMechanical engineering

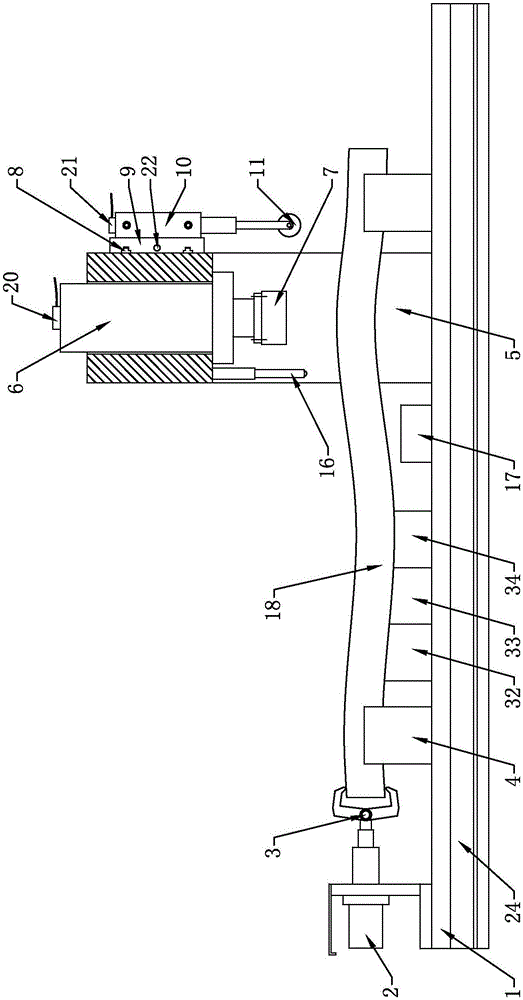

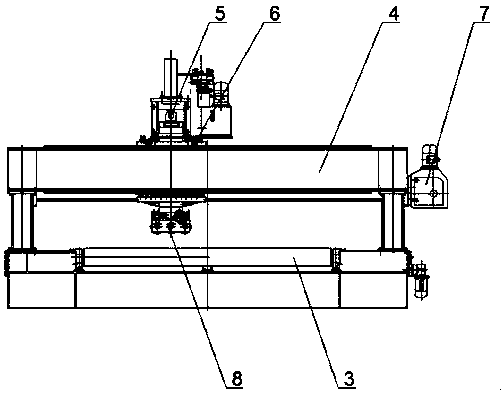

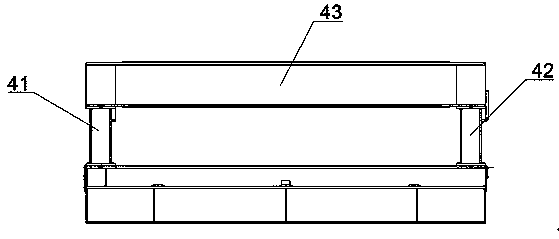

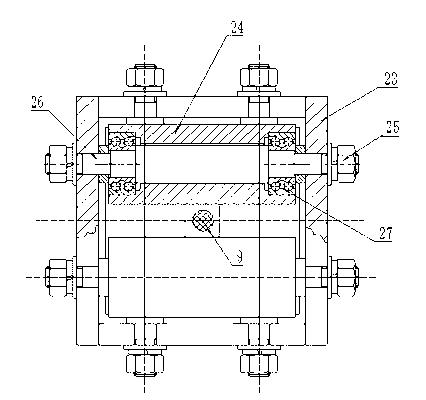

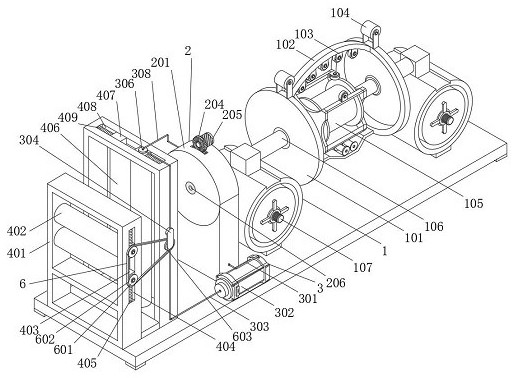

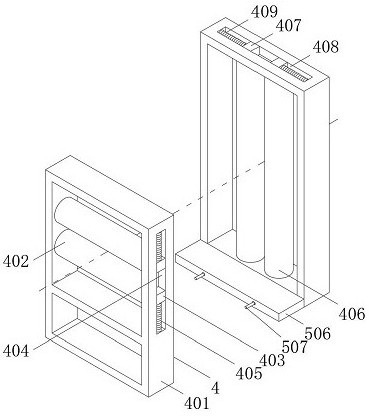

The invention discloses a detecting and straightening machine and method for shaft parts. The detecting and straightening machine comprises a console and a straightening machine body. The straightening machine body comprises a fixed work table and a movable main machine frame. The movable main machine frame can move on the fixed work table along the X axis and can feed data back to the console. A straightening hydraulic cylinder is arranged on the movable main machine frame and can straighten a workpiece. A rear bracket capable of moving along the Y axis is arranged on the rear side of the movable main machine frame. A measurement hydraulic cylinder is arranged on the rear bracket. A measurement rolling wheel is arranged below the measurement hydraulic cylinder. A displacement sensor for measuring the Y-axis movement amount and a displacement sensor for measuring the Z-axis movement amount are arranged on the movable main machine frame and the measurement hydraulic cylinder correspondingly. The displacement sensors can transmit information to the console. Detecting and straightening of the workpiece can be conducted on the same device and the same station through the same installation reference. When straightness detection is conducted on the workpiece, detection can be conducted on the workpiece on three-dimensional scale, and measurement errors are reduced.

Owner:SHANDONG UNIV

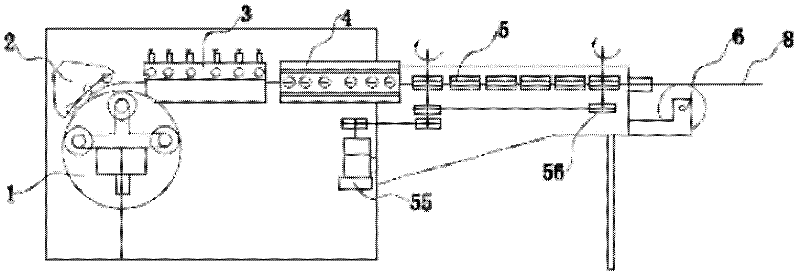

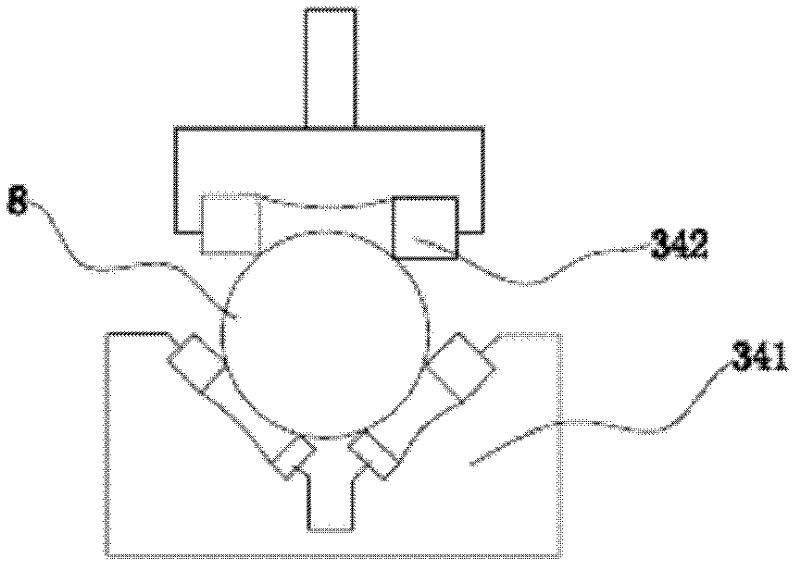

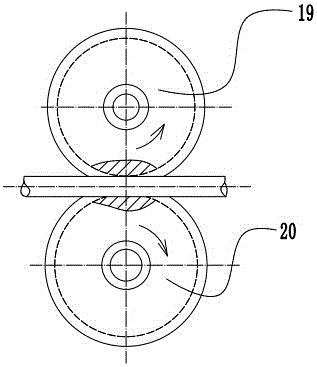

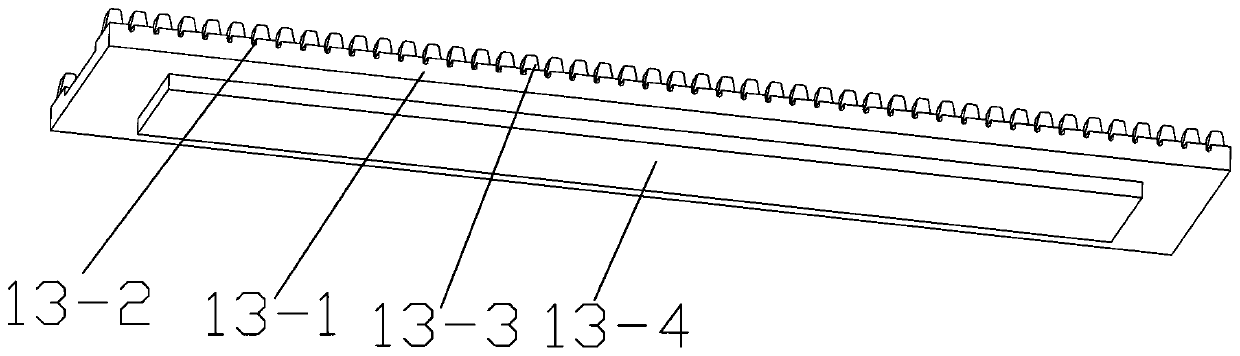

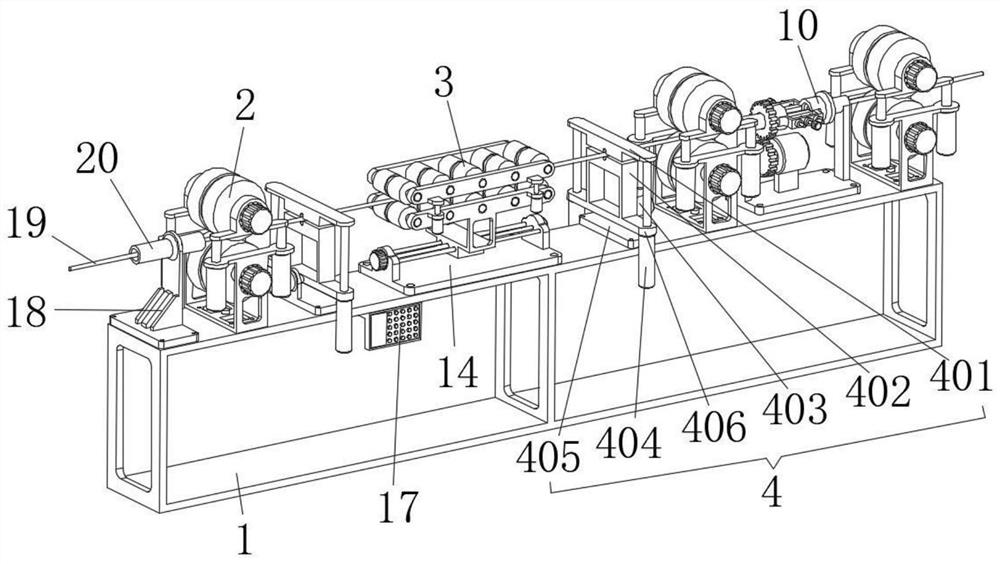

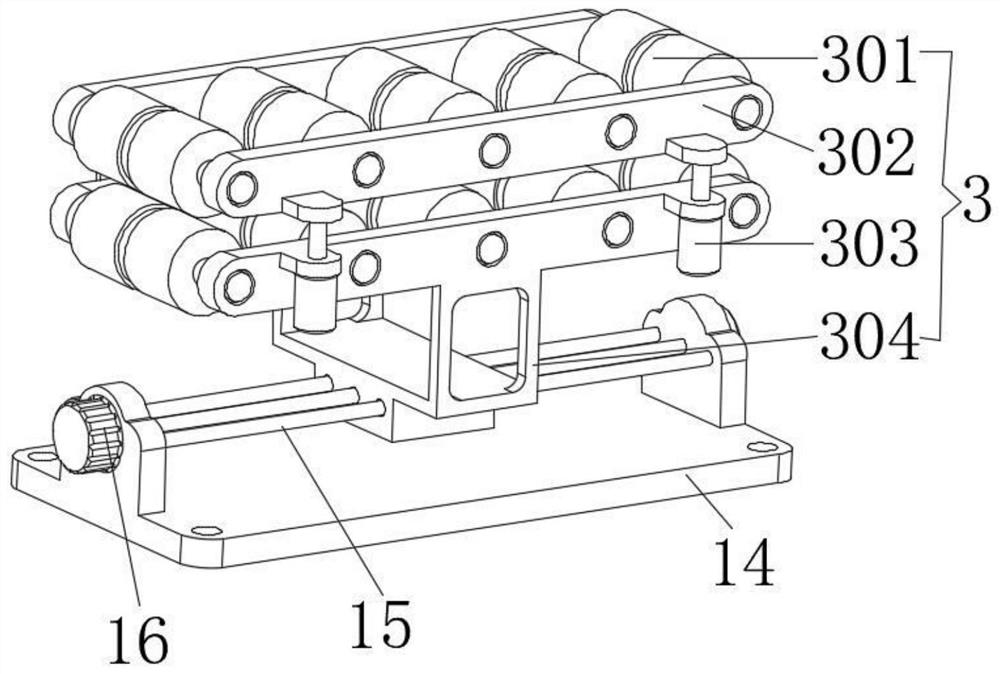

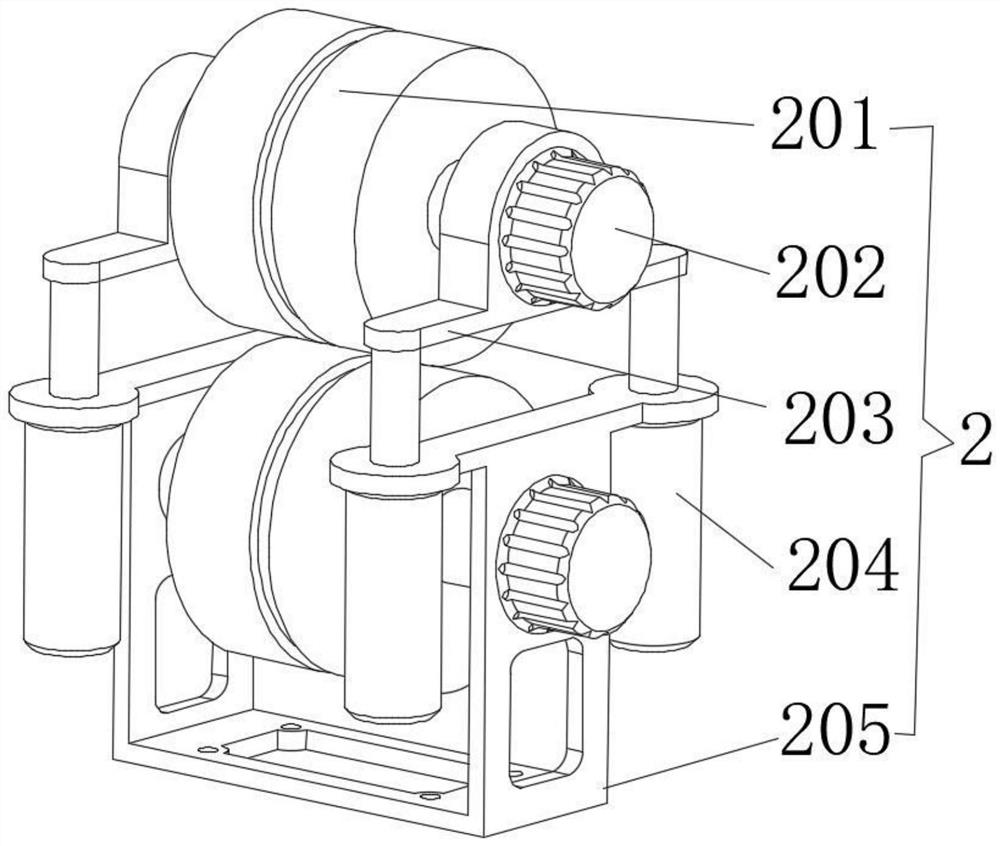

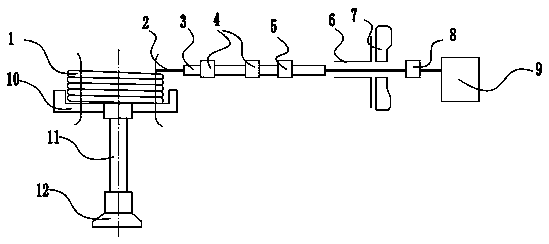

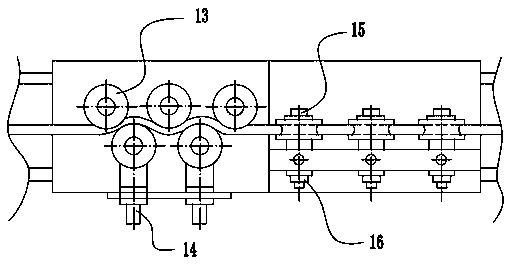

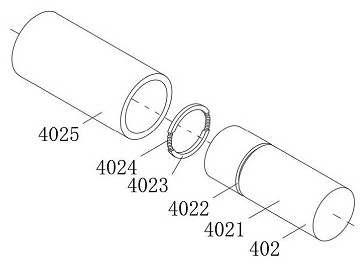

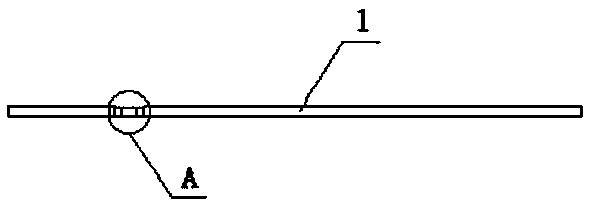

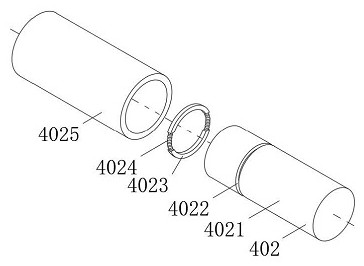

Straightening device for large-diameter material of cold header and straightening method

The invention discloses a straightening device for the large-diameter material of a cold header and a straightening method. The straightening device comprises a wire rod component, a pressing frame and a support wheel, wherein the wire rod component is matched with the pressing frame; a rolling shaft straightening frame A, a rolling shaft straightening frame B and a roller straightening frame are sequentially arranged between the wire rod component and the support wheel; and the rolling shaft straightening frame A, the rolling shaft straightening frame B, the roller straightening frame and the support wheel are in a coaxial structure. In the invention, an optimal combination method of rolling shaft straightening and roller straightening is adopted to achieve the aim of straightening the multi-directional multi-radian curved form of the material before cold heading, thus, the large-diameter material can be quickly straightened in a short path and the elastic rebound of the heading product can be effectively reduced, and the yield or the yield of secondary processing is improved; in the straightening method, the headed material is placed on the wire rod component in a wire rod form and then pulled to sequentially enter the multi-dimensional rolling shaft straightening frame A and rolling shaft straightening frame B and the roller straightening frame under the restriction and guidance of the pressing frame so as to finish the material straightening; and finally, the material enters the body of the cold header.

Owner:SIJIN INTELLIGENT FORMING EQUIP CO LTD

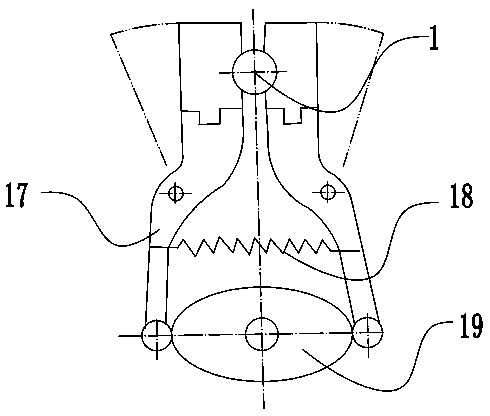

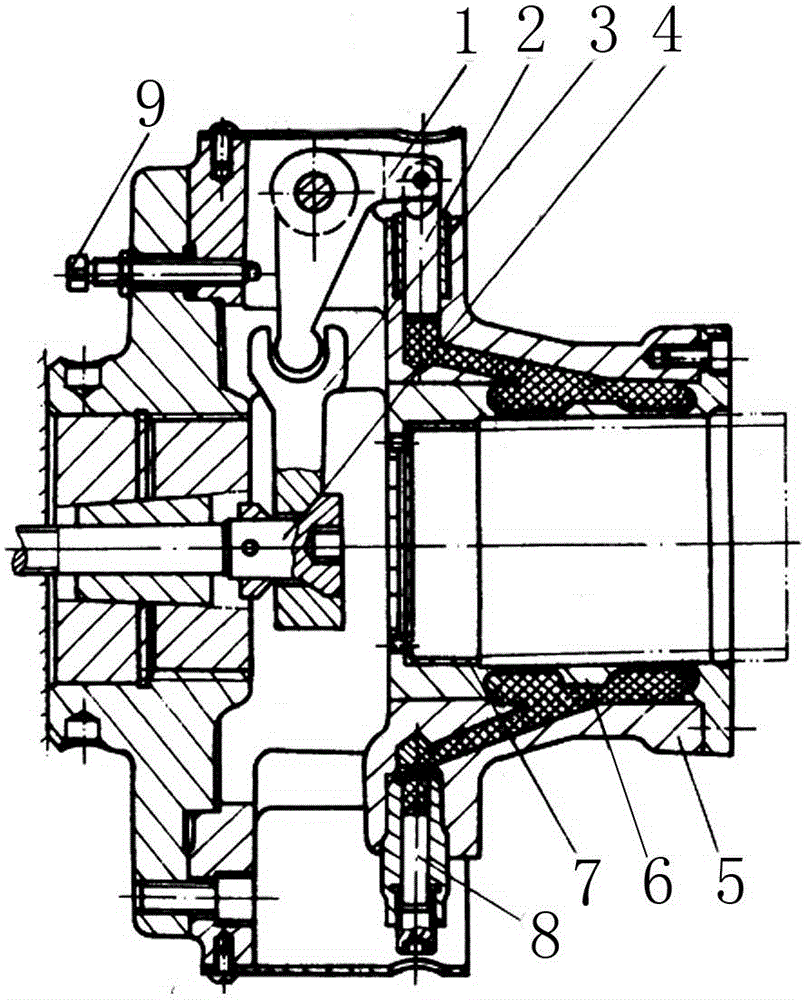

Shaft straightening device

InactiveCN103949505AQuick straighteningReduce turning timeMetal working apparatusBiochemical engineeringMachining time

The invention discloses a shaft straightening device, and relates to the field of fitness equipment production and processing. The shaft straightening device comprises a bottom plate; a stand column is arranged on the bottom plate; a stamping unit is arranged above the stand column; a dial indicator is arranged on the bottom plate in front of the stand column; a T-shaped groove is formed between the dial indicator and the stand column; two cushion blocks which have the same shape are arranged in the T-shaped groove; a V-shaped groove is formed above each cushion block; the two cushion blocks are connected with the T-shaped groove in a sliding way. The stamping unit and the dial indicator are arranged in the shaft straightening device, so that a shaft with a bended diameter can be rapidly straightened, and the turning processing time of the shaft on a lathe can be effectively shortened.

Owner:SUZHOU XINRONG FITNESS EQUIP

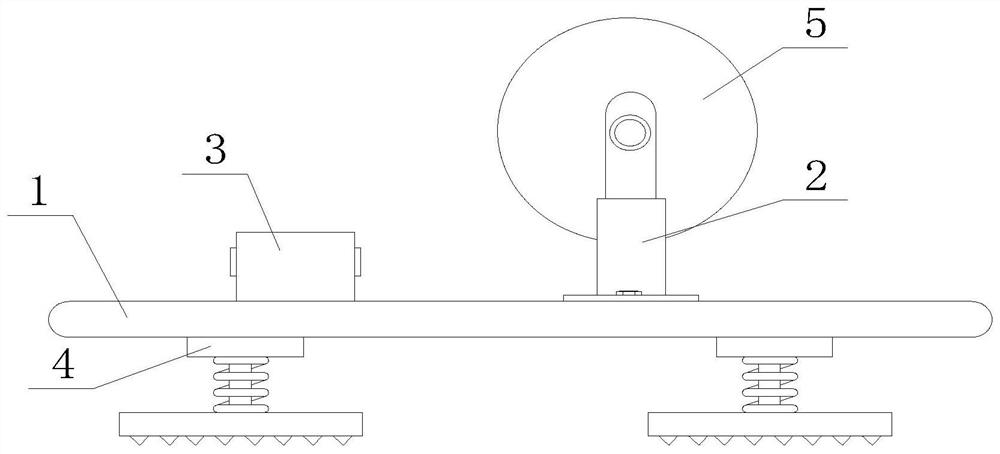

Feeding device

The invention discloses a feeding device, and relates to the field of auxiliary machining. The feeding device comprises a workbench, a motor, a rotating shaft connected with the motor, and a supporting disc connected with the rotating shaft and used for a coil stock to be placed. The end, close to the coil stock, of the workbench is an inclined face, and the end, far away from the coil stock, of the workbench is horizontally arranged. A straightening mechanism, a conveying mechanism, a front clamping head, a rotation cutter and a rear clamping head are sequentially arranged at the horizontal position of the workbench. The supporting disc is of a cylindrical structure with the axis being horizontal. The circle center of the supporting disc is detachably connected with a cam shaft. The cam shaft is sequentially provided with a first cam and a second cam which are provided with a first lever and a second lever respectively. A forklift body is arranged between the first lever and the conveying mechanism and can shift the conveying mechanism to move left and right according to the movement of the first lever. The second lever is connected with the rear clamping head. The feeding device is simple in structure and convenient to operate.

Owner:CHONGQING YUKUNLONG METALLURGICAL MATERIAL CO LTD

Full-automatic rotating plate type ear wire electric welding machine for mask production

InactiveCN111497266ARealize no movementHigh degree of automationDomestic articlesEngineeringSpot welding

The invention relates to the technical field of mask production, and discloses a full-automatic rotating plate type ear wire electric welding machine for mask production. The full-automatic rotating plate type ear wire electric welding machine comprises an mask machine main body, fixed supports are fixedly installed at four corners of the bottom of the mask machine main body, a platform plate is fixedly installed at the top of the mask machine main body, a button induction switch is fixedly installed on the front face of the top of the platform plate, an ear strap straightening and length fixing device is fixedly installed on the back face of the platform plate, a supporting frame is fixedly installed on the back face of the top of the platform plate, three crosspieces are fixedly installed on the top of the supporting frame, and a tabletting air cylinder is fixedly installed at the bottoms of the crosspieces at the front end. According to the full-automatic rotating plate type ear wire electric welding machine for the mask production, the purpose of high ear wire electric welding automation degree is achieved by arranging two rotating air cylinders, the tabletting air cylinder, the crosspieces and the like, a mask sheet does not deviate in the rotating process through a first rotating air cylinder and a rotating plastic pressing plate on the upper part, and it is guaranteed that second-time spot welding succeeds.

Owner:俞建峰

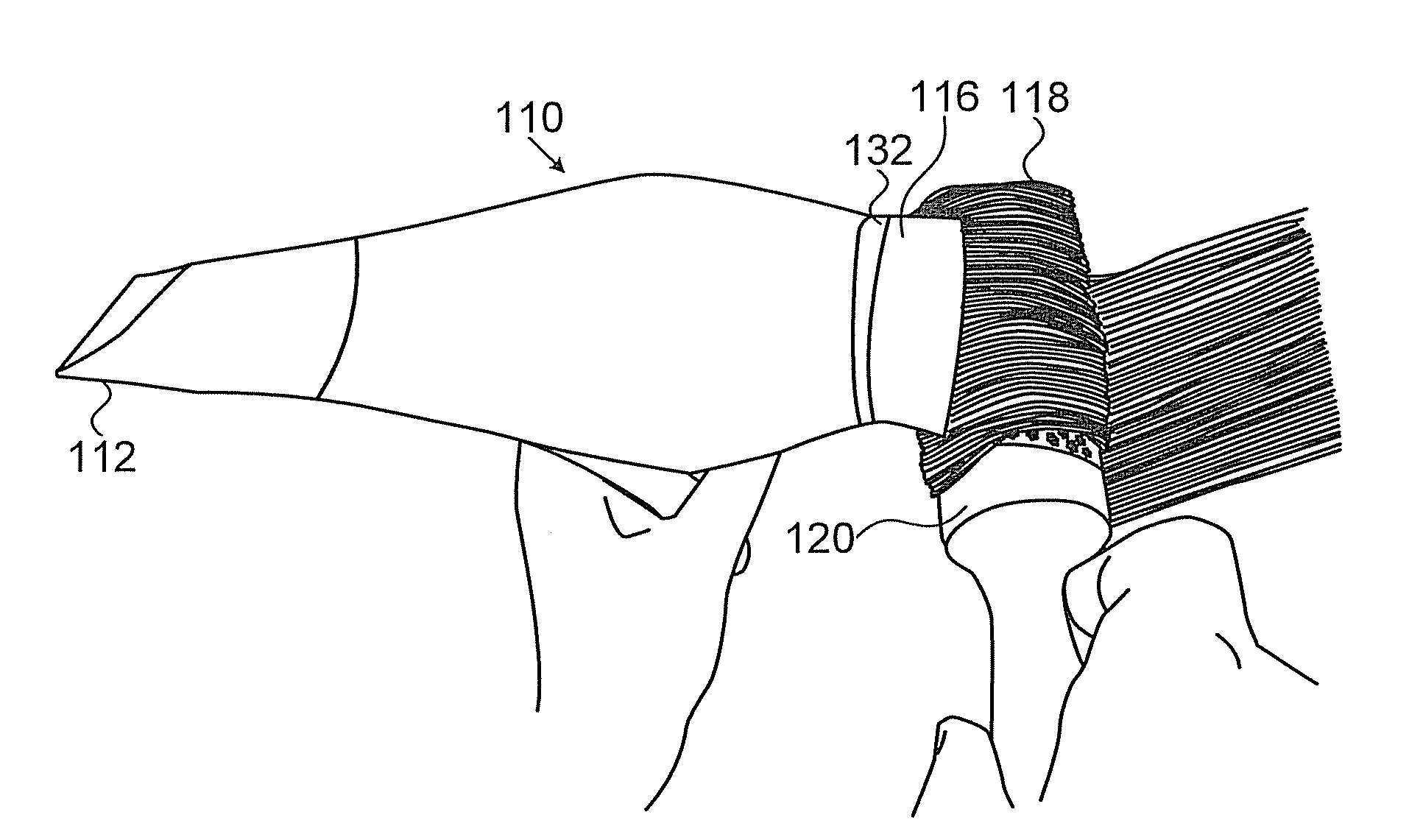

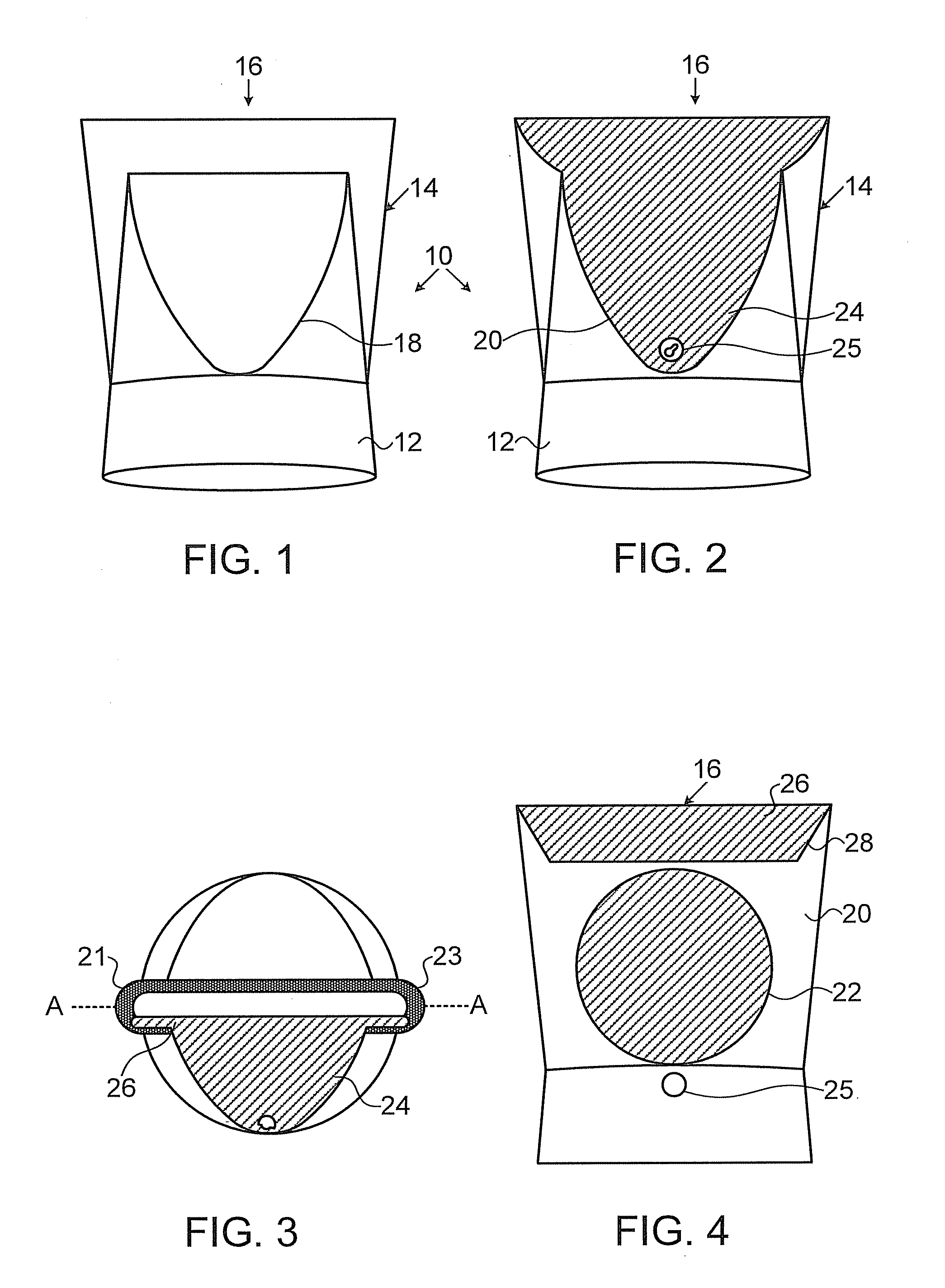

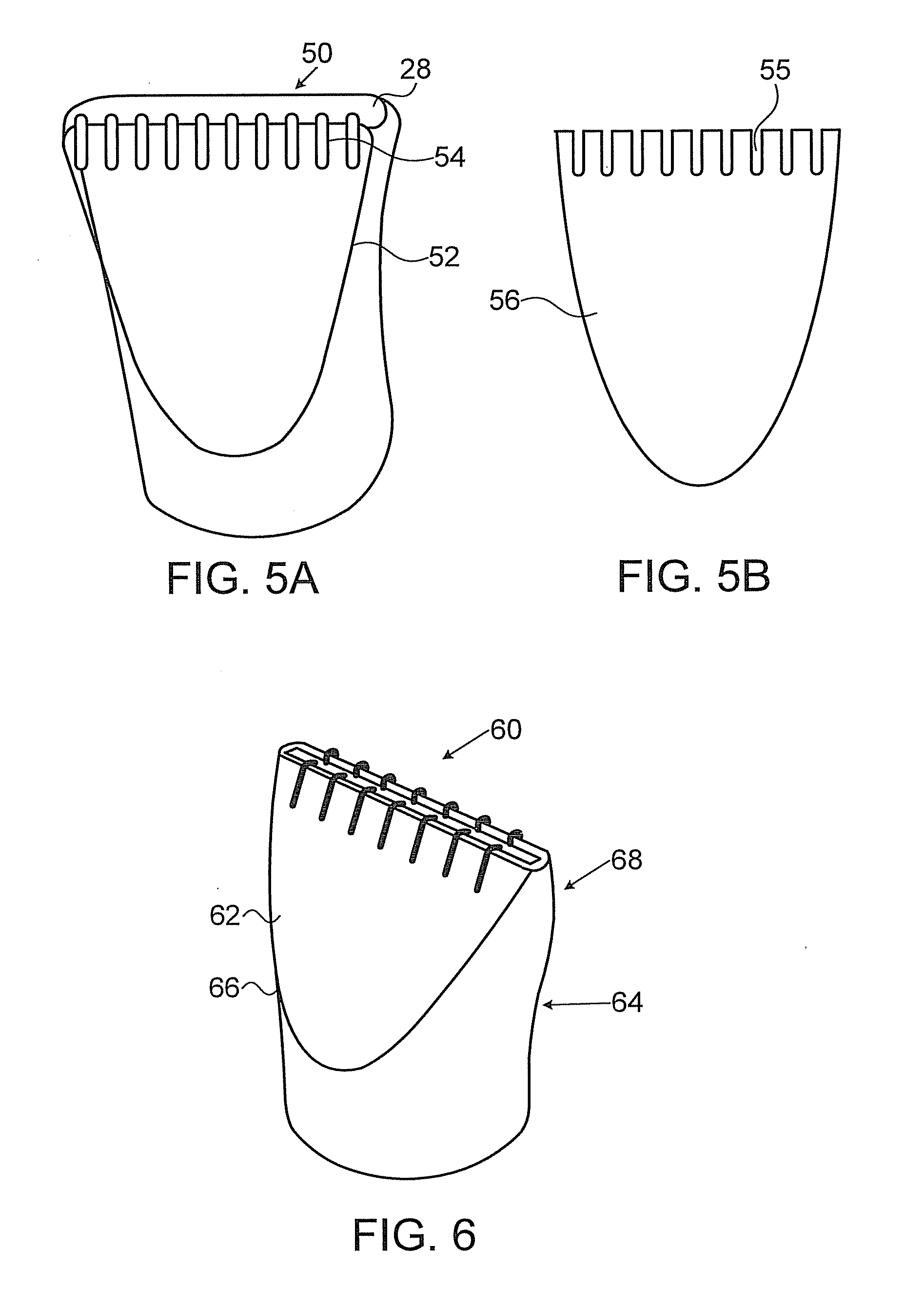

Hair styling attachment

InactiveUS20120234343A1Quick straighteningImprove cooling effectHair dryingHeat conductingSpray nozzle

A hair dryer / blower for use in straightening or styling hair with a round hair brush, comprising a hot air outlet, an attachment to the hot air outlet comprising a heat conducting device terminating in a flat elongated nozzle, an air inlet, and an attachment to the air inlet having a terminal shape conforming to the curvature of a round hair brush used in shaping the hair.

Owner:GIDON COSMETICS

Automatic welding packaging equipment of glass package temperature sensor

ActiveCN110631728ADestructive implementationIncrease surface tensionThermometer detailsConveyor partsMachiningElectrical and Electronics engineering

The invention discloses automatic welding packaging equipment of a glass package temperature sensor. The equipment includes a conveying platform. A load transfer jig lowering mechanism, a straightening shearing mechanism, a silver dipping mechanism, chip welding mechanisms, a silver baking mechanism, a glass shell insertion mechanism and a glass sealing forming mechanism are arranged in turn froma left to a back on the conveying platform. First load transfer jig conveying mechanisms are arranged in an intersected manner among the straightening shearing mechanism, the silver dipping mechanism,the chip welding mechanisms and the glass shell insertion mechanism. Second load transfer jig conveying mechanisms are arranged at the silver baking mechanism and the glass sealing forming mechanism.The automatic welding packaging equipment of the glass package temperature sensor provided by the invention can realize automatic machining of the glass package temperature sensor.

Owner:XINGQIN YICHANG ELECTRONICS

Intelligent rebar straightening device for building construction

PendingCN110280692AAchieve protectionExtended service lifeMetal working apparatusControl systemEngineering

The invention relates to the technical field of building construction, in particular to an intelligent rebar straightening device for building construction. The intelligent rebar straightening device comprises a straightening rod, a rebar straightening mechanism and a guide rod, wherein the rebar straightening mechanism comprises a plurality of groups of straightening device bodies and further comprises a control system; the control system controls the working states of the straightening device bodies according to the rebar bending position and comprises a controller, a detecting element and a mobile device; after detecting a rebar bending part, the detecting element sends a detecting signal to the controller; after receiving the detecting signal, the controller sends a signal for controlling the operating states of the straightening device bodies to the straightening device bodies and also sends a signal for controlling the operating state of the mobile device; and after straightening, the controller sends the signal for controlling the operating state of the mobile device to the mobile device. The intelligent rebar straightening device is simple in structure and convenient to use, adopts part of driving devices for driving according to the rebar bending part, is low in energy consumption, can automatically and rapidly straighten the rebar on a construction site, and is high in straightening precision and construction efficiency.

Owner:QINGDAO NO 1 CONSTR GRP

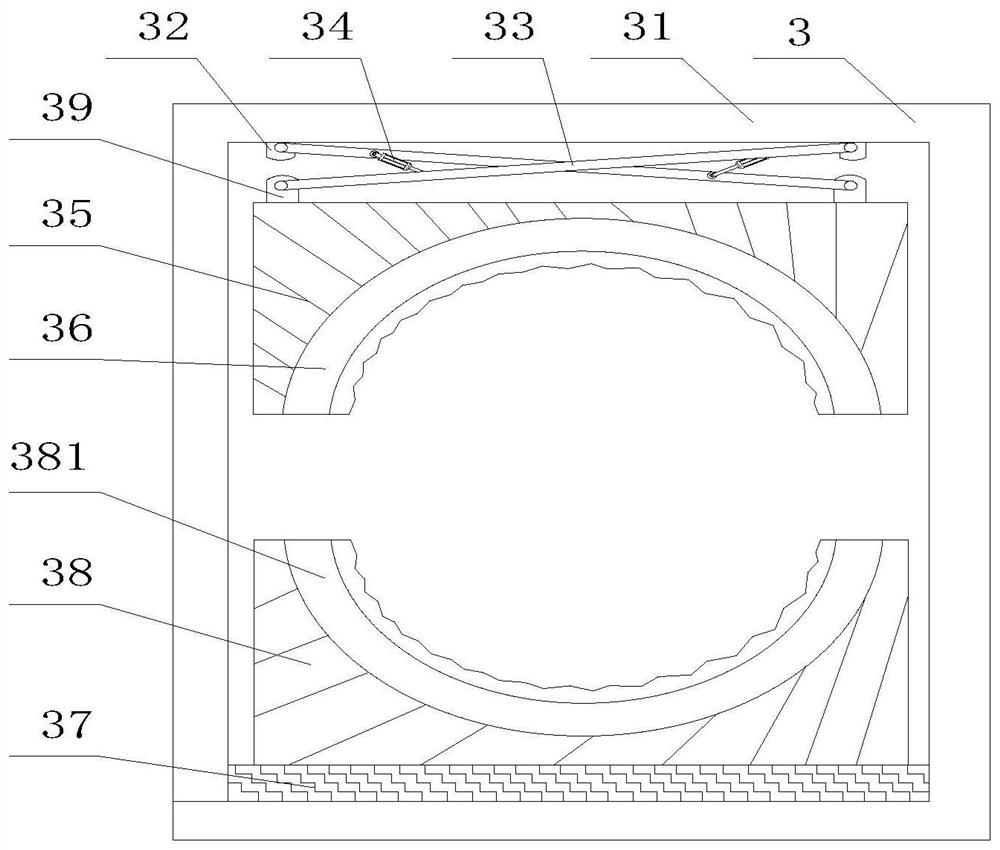

Straightening device for processing steel wire rope

InactiveCN110950173AQuick straighteningImprove processing efficiencyEdge grinding machinesGrinding machine componentsWire ropeManufacturing engineering

The invention discloses a straightening device for processing a steel wire rope. The straightening device comprises a bottom bracket, an upper beam and a straightening mechanism. The upper beam is installed directly above the bottom bracket, the straightening mechanism comprises an upper straightening wheel mounting frame, upper straightening wheels, a lower straightening wheel mounting frame andlower straightening wheels, the upper straightening wheel mounting frame is fixed on the lower end surface of the upper beam, the upper straightening wheels are mounted on the upper straightening wheel mounting frame, the lower straightening wheel mounting frame is mounted on the bottom bracket, the lower straightening wheels are installed on the lower straightening wheel mounting frame, and the upper straightening wheels and the lower straightening wheels are arranged up and down in a staggered manner; and the straightening device also includes a grinding component and a conveying component,the grinding component is arranged on the rear side of the straightening mechanism, and the conveying component is arranged on the rear side of the grinding component. The straightening device is novel in structural design, can realize rapid straightening of the steel wire rope, can perform grinding processing on the straightened steel wire rope, can also perform guided transporting on the groundsteel wire rope and improves the processing efficiency of the steel wire rope.

Owner:马鞍山贝特福科技有限公司

Device for removing oxide layer on metal wire surface

ActiveCN111761487AQuick straighteningReduce occupancyRevolution surface grinding machinesGrinding drivesSurface oxidationEngineering

The invention relates to the technical field of metal wire processing, in particular to a metal wire surface oxide layer removal device. The device comprises a base. A fourth fixing seat is fixedly arranged on a controller by bolts. A guide rod is fixedly arranged on the fourth fixing seat by bolts. The guide rod is provided with a straightening device, and the straightening device comprises a moving seat which is slidably arranged on the guide rod. The invention has the beneficial effects that the metal wire surface oxide layer removal device can quickly straighten various metal wires which have been used and have oxide layers on the surfaces through a clamping device and the straightening device. Through the matching between a grinding plate and a matching pipe, the grinding process canbe carried out quickly. The device can effectively replace the traditional manual hand-held sandpaper to polish the metal wires. The device effectively improves the production efficiency and processing accuracy, and effectively reduces the occupation of labor.

Owner:CHANGLE LITIAN KNITTING TEXTILE CO LTD

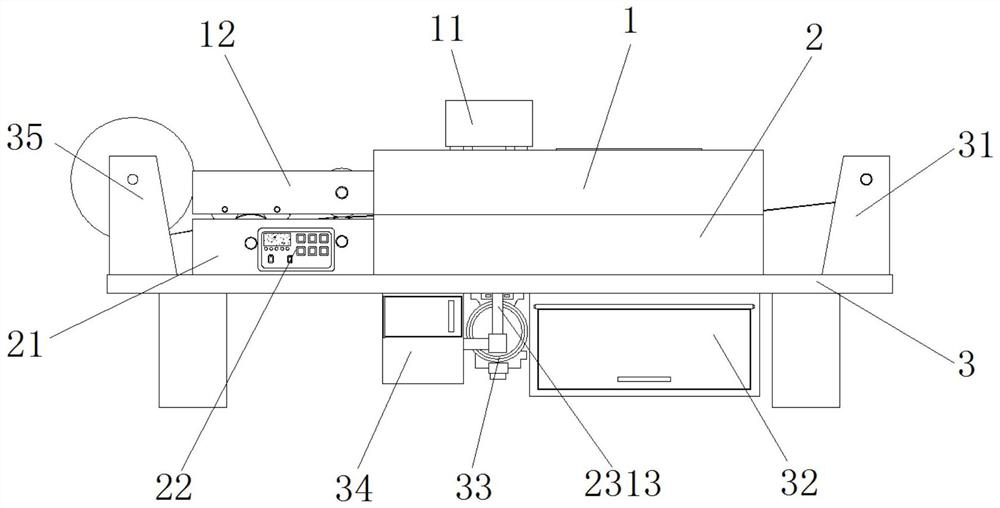

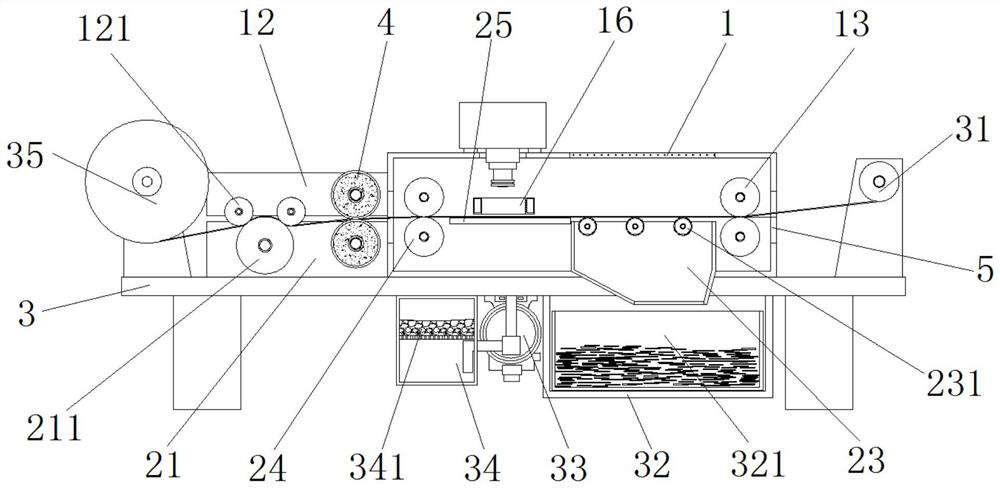

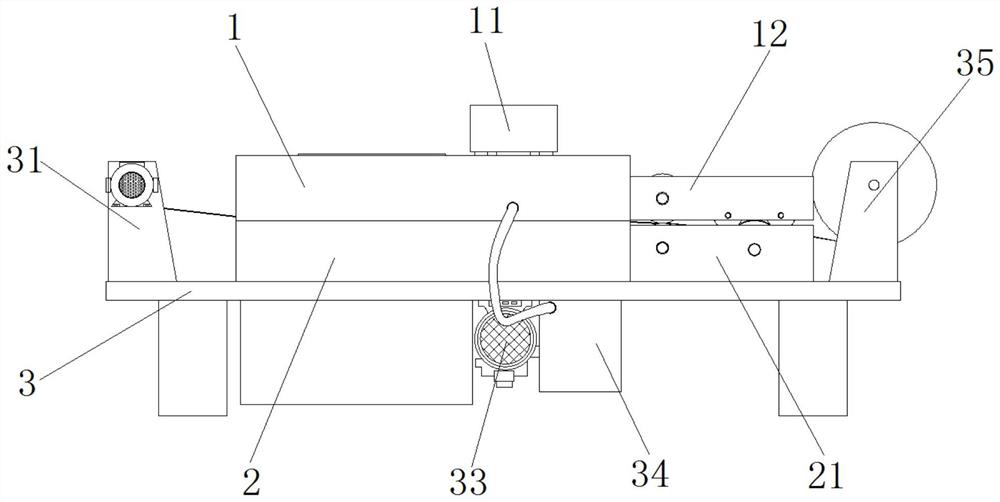

Feeding mechanism

PendingCN105500003AReduce resistanceSimple and efficient operationFeeding apparatusOther manufacturing equipments/toolsEngineeringSlide plate

The invention discloses a feeding mechanism and relates to the field of auxiliary machining. The feeding mechanism comprises a supporting frame and further comprises a motor and a feeding screw connected with the motor. A straightening mechanism, a front chuck, a rotary knife and a rear chuck are sequentially arranged on the feeding screw. A sliding plate is arranged on the feeding screw and slidably connected to the feeding screw. The straightening mechanism and the front chuck are fixedly connected to the sliding plate. The supporting frame comprises a supporting tray, a telescopic supporting rod and a supporting base, wherein the supporting tray is used for containing roll materials, the telescopic supporting rod is connected with the supporting tray, and the supporting base is connected with the supporting rod. By the adoption of the feeding mechanism, the labor intensity of carrying the roll materials during feeding can be relieved.

Owner:CHONGQING YUKUNLONG METALLURGICAL MATERIAL CO LTD

Glass package temperature sensor and manufacturing method thereof

ActiveCN110220616ASave silver pasteImprove the utilization rate of silver pasteThermometer applicationsEngineeringGlass tube

The invention discloses a glass package temperature sensor and a manufacturing method thereof. The glass package temperature sensor which is formed by wrapping and fusing glass bulb is made through the steps of wire straightening, straightening, clamping pulling line, cutting, jig transfer, trimming, silver staining, bonding sheet, preheating, silver baking, inserting and sleeving glass tube, pre-heating, high temperature molding, overturning, preheating, high temperature molding and material receiving. According to theglass package temperature sensor and the manufacturing method thereof, theworking efficiencycan be improvedwhen processing is carried out in a reasonable manner.

Owner:XINGQIN YICHANG ELECTRONICS

Straightening machine for butt weld of steel plate

PendingCN109226346AQuick straighteningImprove reliabilityMetal-working feeding devicesPositioning devicesSheet steelSteel plates

The invention discloses a straightening machine for a butt weld of a steel plate. The machine includes a roller device, a reciprocating driving device, a reciprocating guiding device, a press roll device, a press roll supporting device, a bottom plate adjusting device, feeding devices and a chassis. The bottom plate adjusting device is installed on a chassis, and the press roll supporting device is erected on the two sides of the chassis, the press roll is connected with the press roll supporting device through the reciprocating driving device, the lower portion of the press roll device is provided with a roller device, the roller device is located right above the bottom plate adjusting device, the press roll device is connected with the press roll supporting device through the reciprocating guiding device, a steel plate straightening channel is formed between the bottom plate adjusting device and the press roller device, the two ends of the chassis are provided with the feeding devices, and the feeding devices adapt to the position of the steel plate straightening channel. According to the machine, mechanized steel plate rolling is adopted, therefore, the straightening speed is high, the technical requirements for workers are low, the process is simple, the labor intensity of workers is low, errors are small, the reliability is high, and the precision of finished products is high.

Owner:TAIAN HUALU METALFORMING MACHINE TOOL

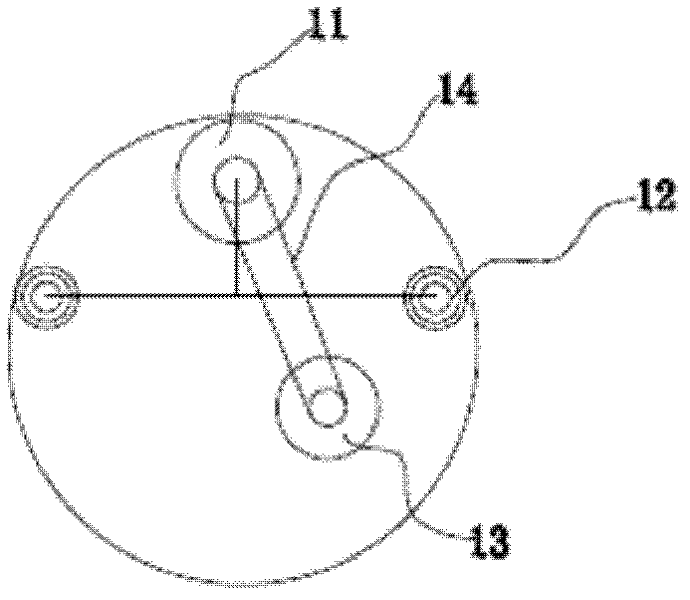

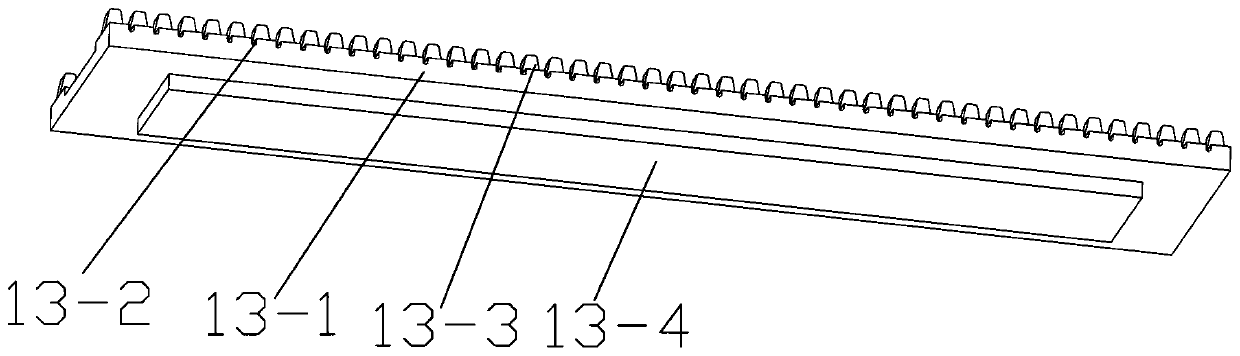

Reinforcement steel bar no-twist straightening shearing machine

A reinforcement steel bar no-twist straightening shearing machine comprises a straightening assembly, a dragging assembly, a shearing assembly and a dynamic assembly. The straightening assembly is arranged before the dragging assembly, the shearing assembly is arranged after the dragging assembly, and the dynamic assembly is arranged between the straightening assembly and the dragging assembly. The dragging assembly is provided with a dragging wheel set and an acceleration chain wheel, wherein the dragging wheel set is connected with the output end of the dynamic assembly, and the acceleration chain wheel is driven by the dragging wheel set. The straightening assembly is provided with a deceleration chain wheel and an aligning wheel set, wherein the deceleration wheel is connected with the acceleration chain wheel of the dragging assembly, the straightening assembly is driven by the deceleration chain wheel, and the number of teeth of the deceleration chain wheel is larger than that of the acceleration chain wheel. The dragging wheel set and the straightening wheel set both are provided with a plurality of pairs of plane anti-twist wheels and groove location wheels, wherein the plurality of pairs of plane anti-twist wheels and groove location wheels are arranged at intervals, an outer circle of each plane anti-twist wheel is a smooth cylindrical surface, a rectangular narrow slit used for passage of a reinforcement steel bar is formed between each pair of plane anti-twist wheels and prevents the reinforcement steel bar from twisting. An outer circle of each groove location wheel is a cylindrical surface with an annular groove, and a circular channel is formed between each pair of groove location wheels and used for passage of the reinforcement steel bar and locating the reinforcement steel bar. The reinforcement steel bar no-twist straightening shearing machine utilizes the speed difference between the straightening assembly and the dragging assembly to enable the reinforcement steel bar to generate plastic deformation, and therefore the purpose of straightening the reinforcement steel bar is achieved.

Owner:广西国盾人防工程有限公司

Cable pair twister with multi-direction cable production technology

ActiveCN113643860AQuick straighteningGuaranteed straightening accuracyCable/conductor manufactureStructural engineeringElectric cables

The invention discloses a cable pair twister with a multi-direction cable production technology, belonging to the technical field of cable production equipment. The cable pair twister comprises a pair twisting mechanism, wherein a burr cleaning mechanism is arranged on one side, corresponding to a cable core conveying direction, of the pair twisting mechanism. Through mutual cooperation of a designed straightening assembly, a self-debugging assembly, a linkage assembly, a drainage assembly, the burr cleaning mechanism and other structures, a quick torsion-free straightening function of a reel cable core is achieved; particularly, a disc-shaped copper-aluminum cable core can be effectively and quickly straightened, and on the basis of ensuring high efficiency, the straightening precision of a first straightening roll and a second straightening roll on a cable inner core can be guaranteed, flexible strain capacity is high, and straightening work can be conducted on cable inner cores of different models; and acting force acting on the cable inner core can be automatically kept along with the abrasion degree of the surfaces of the first straightening roll and the second straightening roll, and the quality of a processed cable is prevented from being influenced by too large pressure or too small action.

Owner:江苏昕讯光电科技有限公司

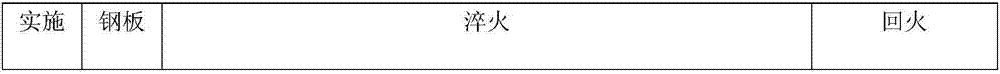

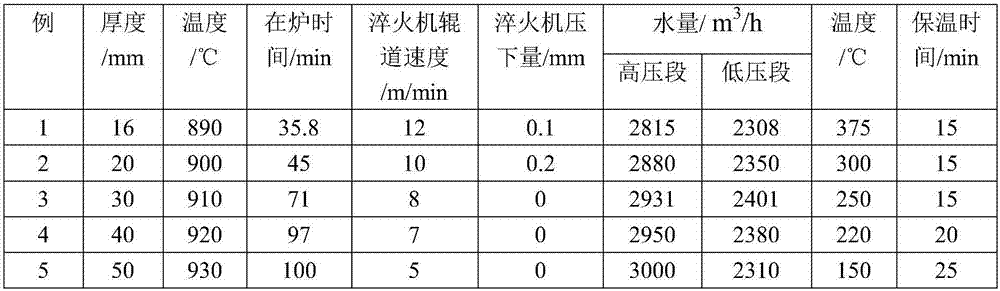

Heat treatment method for improving hardness uniformity of wear-resistant steel surface

InactiveCN107164612ASmall amount of depressionReduce roller speedFurnace typesHeat treatment furnacesQuenchingSteel plates

The invention relates to the technical field of wear-resistant steel, in particular to a heat treatment method for improving the uniformity of surface hardness of wear-resistant steel. The heat treatment method for improving the uniformity of surface hardness of wear-resistant steel of the present invention comprises the following steps: 1) carrying out shot blasting treatment on the wear-resistant steel plate in a hot-rolled state; 2) entering the steel plate after shot blasting treatment into a roller hearth type continuous heat treatment furnace Heating; 3) using high-pressure water in the spiral roller gap type pressure quenching machine to perform quenching treatment; wherein, the water volume of the high-pressure section of the quenching machine is 2800~3000m3 / h, and the water volume of the low-pressure section of the quenching machine is 2300~2500m3 / h; 4 ) Tempering the quenched steel plate. The wear-resistant steel plate produced by the production method of the invention has good hardness uniformity, excellent plate shape and good surface quality, the unevenness of the steel plate reaches 0-3 mm / m, and a tempered martensite structure is obtained. The preparation method is simple and practical.

Owner:SHANDONG IRON & STEEL CO LTD

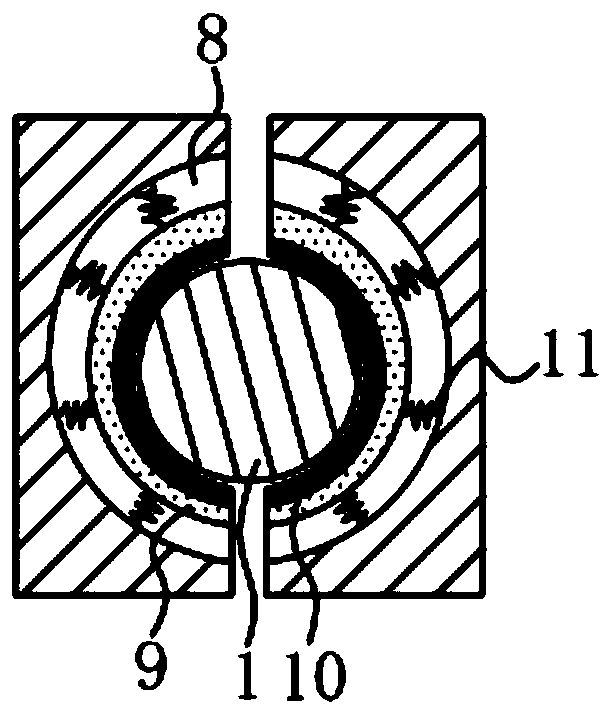

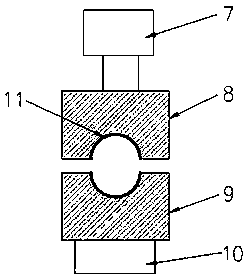

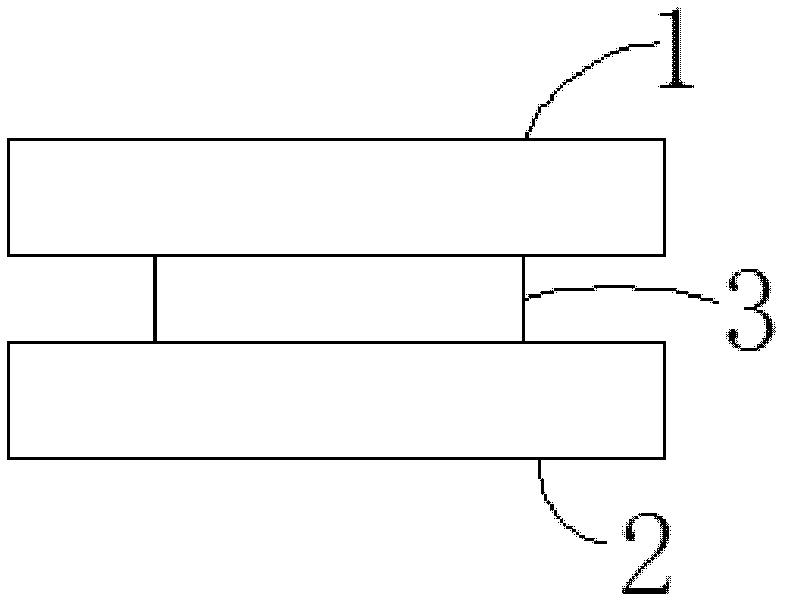

Cooling and straightening device for metal thermal treatment

The invention discloses a cooling and straightening device for metal thermal treatment. The cooling and straightening device mainly comprises an upper heat conduction hold-down block and a lower heat conduction block, wherein coolant channels are arranged on both the upper heat conduction hold-down block and the lower heat conduction block. After a workpiece is heated to a certain temperature through thermal treatment, the workpiece is put on the lower heat conduction block and pressed by the upper heat conduction hold-down block through a hydraulic machine, so that a straightening function is performed. Meanwhile, the workpiece is cooled by a coolant in the coolant channels in the upper heat conduction hold-down block and the lower heat conduction block. Therefore, the cooling and straightening device for metal thermal treatment not only can quickly cool the workpiece, but also can straighten the deformed workpiece while cooling the workpiece.

Owner:昆山鑫昌泰模具科技有限公司

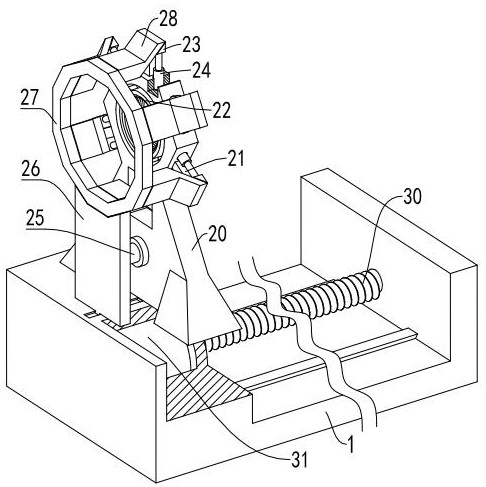

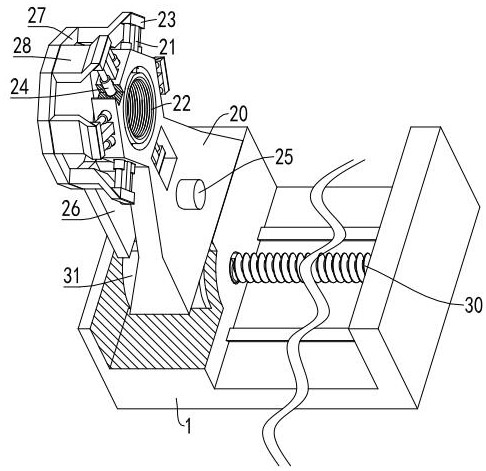

Precision slender shaft processing straightening fixture and precision slender shaft processing method

ActiveCN103978070BSolve the correction problem of ultra-small rangeReduce defective rateRevolution surface grinding machinesMetal working apparatusEngineeringMachining

The invention discloses a straightening jig for machining for precise slender shafts. The straightening jig for machining for the precise slender shafts comprises a base, a slender shaft fixation device, a correction device and a detection device, wherein the slender shaft fixation device, the correction device and the detection device are installed above the base, and the slender shaft fixation device and the correction device are opposite. The straightening jig for machining for the precise slender shafts disclosed by the invention is capable of realizing straightening the accuracy to be less than 0.005mm, thus effectively solving the problem of ultra-small-range correction for the precise slender shaft, capable of realizing rapid straightening for the precise slender shafts with a jitter amplitude of greater than 0.005mm, thus reducing the defective percentage of the precise slender shafts, simple and fast to straighten, thus increasing production efficiency. The invention further discloses a method for machining precise slender shafts, thus mechanized production is realized for the precise slender shaft, and the defective percentage is low.

Owner:TAICANG DELTA PRECISION TOOLS

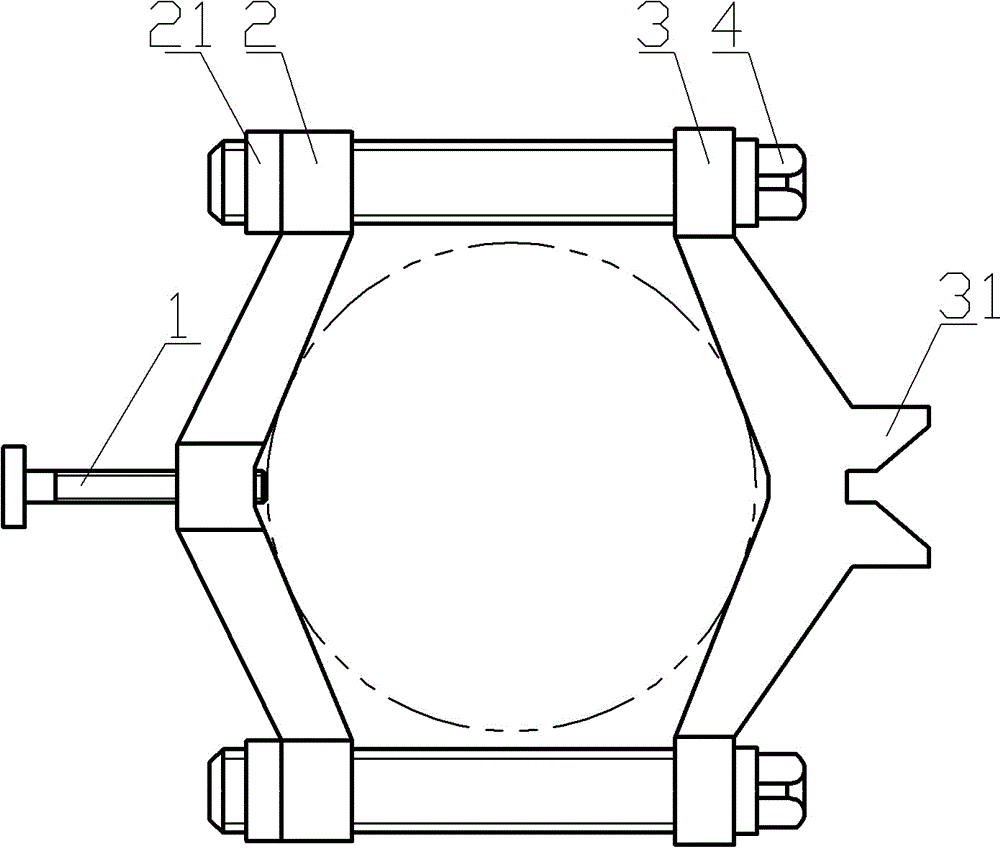

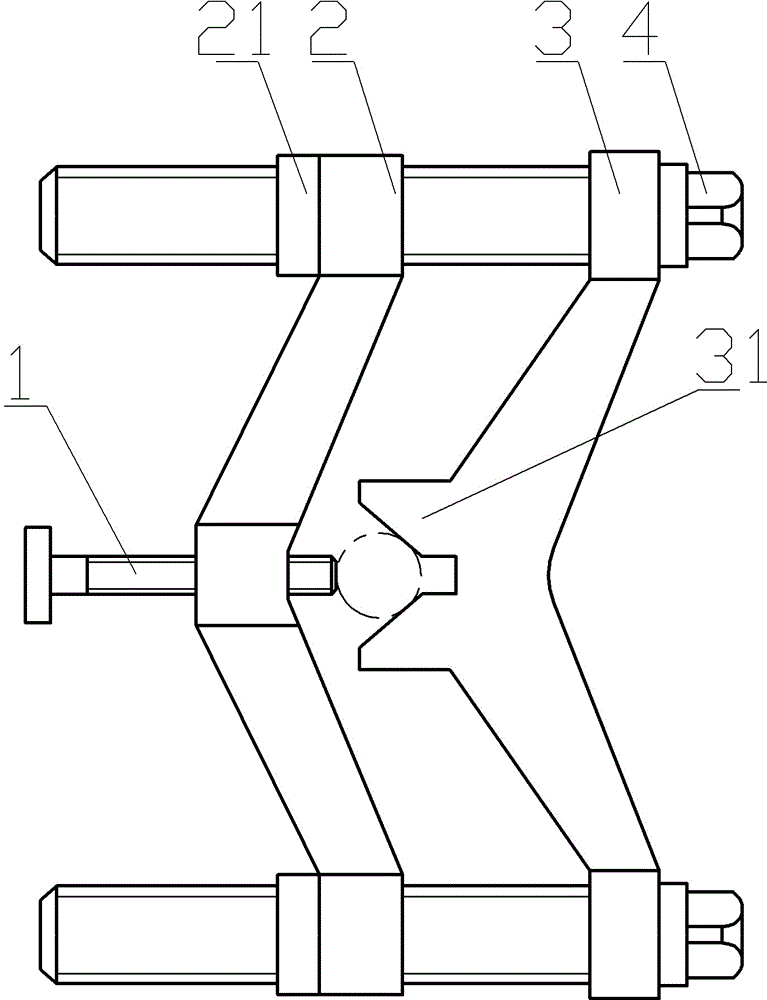

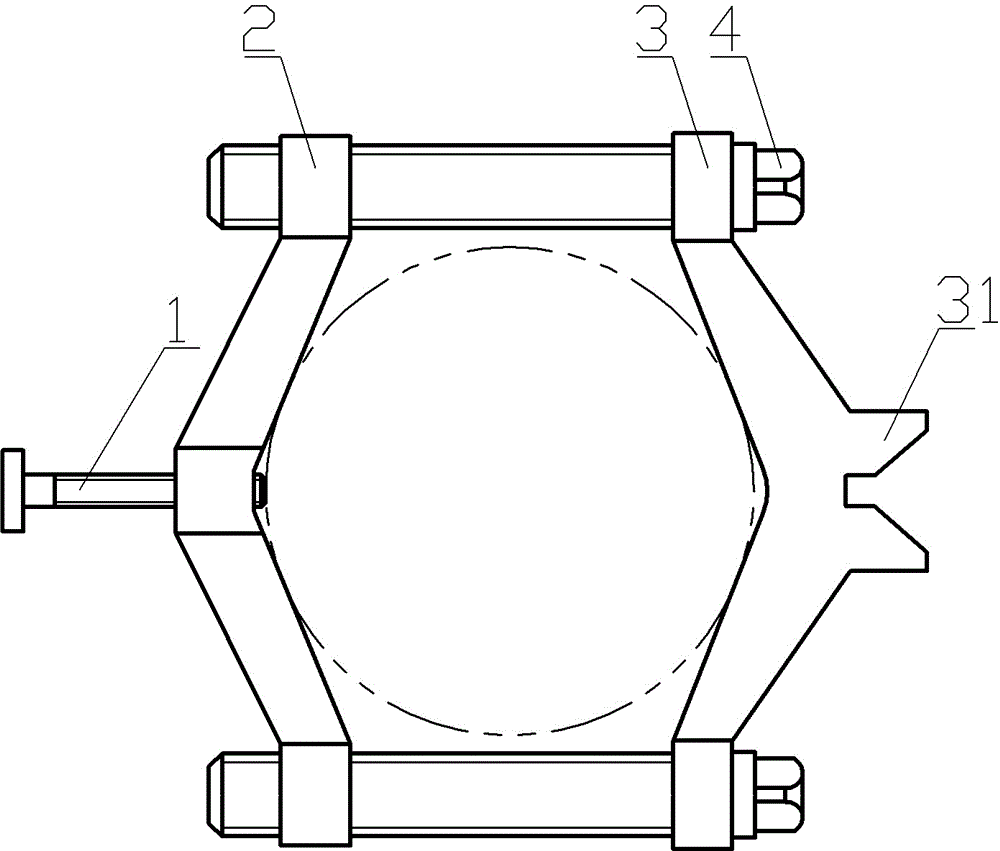

Manual self-centering clamp plate

InactiveCN104475602AQuick clampingSimple structureMetal-working feeding devicesPositioning devicesSet screwEngineering

The invention discloses a manual self-centering clamp plate which comprises an upper bolt, a lower bolt, a left clamp plate, a right clamp plate and a set screw. The upper bolt and the lower bolt are distributed side by side, the upper end of the right clamp plate sleeves the upper bolt, the lower end of the right clamp plate sleeves the lower bolt, a V-shaped positioning surface is arranged on one side of the right clamp plate, a small V-shaped block is arranged on the other side of the right clamp plate, the left clamp plate is V-shaped, the upper end of the left clamp plate can be locked with the upper bolt, the lower end of the left clamp plate can be locked with the lower bolt, and the middle of the left clamp plate is connected with the set screw in a threaded manner. The manual self-centering clamp plate is simple in structure, easy to operate and conveniently and rapidly straightened, automobile steering yoke rods can be rapidly clamped, and cost is reduced.

Owner:CHONGQING ZETIAN AUTO PARTS

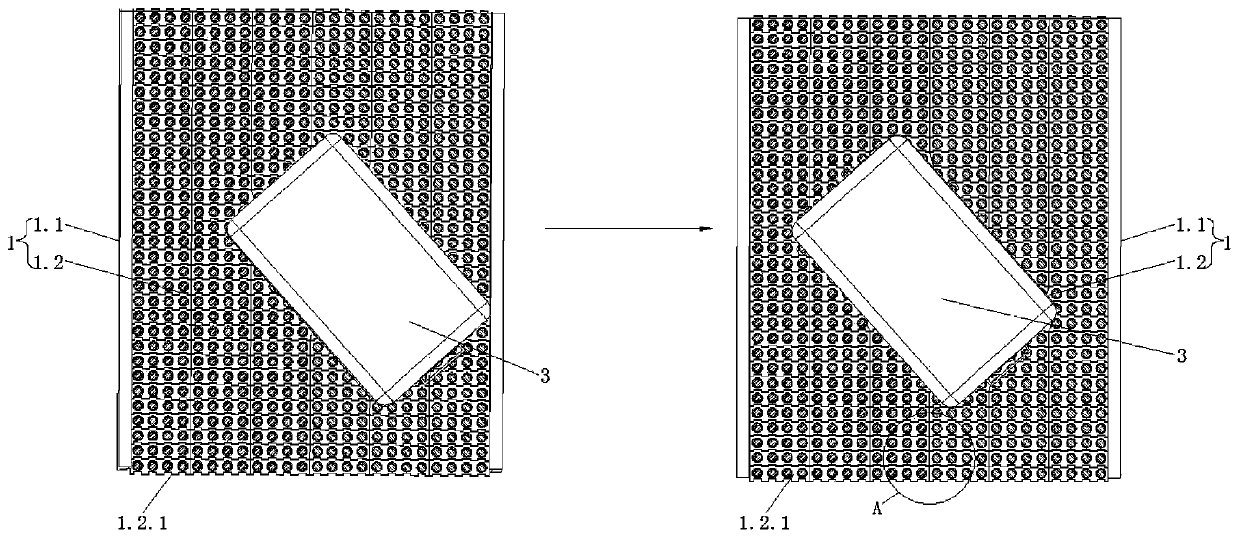

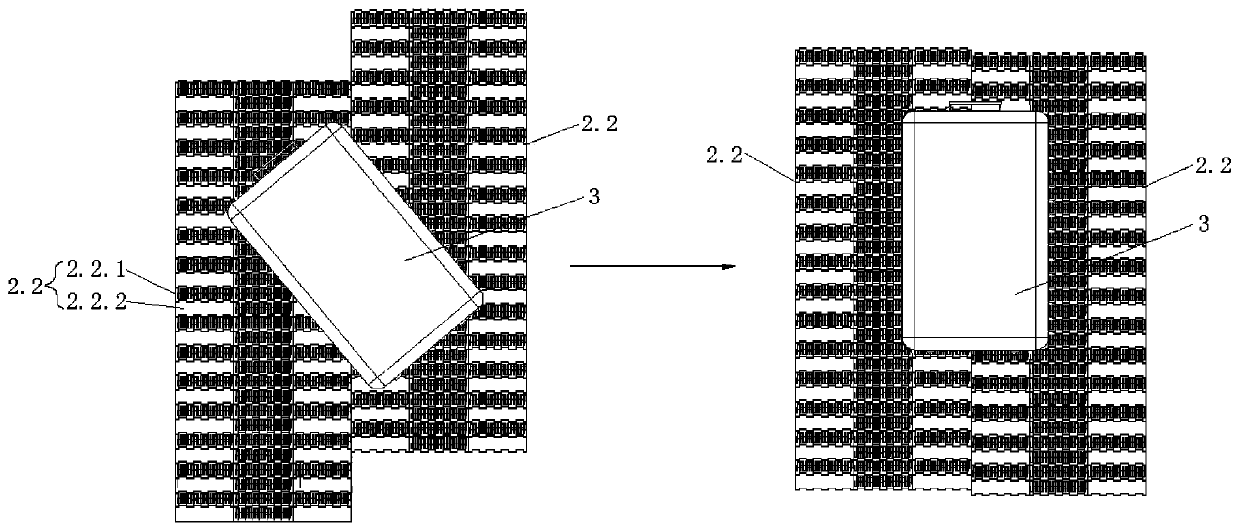

Luggage high-speed automatic packing device

InactiveCN110759067AImprove efficiencyMeet the needs of useConveyorsControl devices for conveyorsManufacturing engineeringLogistics management

The invention discloses a luggage high-speed automatic packing device, and relates to the technical field of logistics conveying devices. The device comprises a first adjusting conveyor and a second adjusting conveyor assembled together; the first adjusting conveyor comprises a first main machine; a roller conveying track is arranged on the first main machine, and is used for adjusting luggage tothe middle position of a conveying line; the second adjusting conveyor comprises a second main machine; the second main machine is provided with two differential conveying tracks assembled parallel tothe direction of the conveying line; and the differential conveying tracks are used for centering the luggage. In the first step, the luggage is firstly adjusted to the center position of the conveying line; and in the second step, the luggage is centered to finish the luggage packing without influencing the conveying efficiency.

Owner:CIVIL AVIATION LOGISTICS TECH

Steel rib straightening machine for construction

A steel rib straightening machine for construction comprises a bottom plate, a cylinder device, a supporting plate device, a positioning device, a moving device and a fixed device. A first supporting rod, a first support, a second support, a third support, a first transverse rod and a second supporting rod are arranged on the bottom plate. The cylinder device comprises a first cylinder, a push rod, a push block and a first spring. The supporting plate device comprises a first supporting plate, a second supporting plate, a second spring and a first positioning rod. The positioning device comprises a first fixing block, a second fixing block, a positioning frame, a third fixing block, a screw and a fourth fixing block. The moving device comprises a moving frame, a moving block, a third spring, a fourth spring and a fifth spring. The fixed device comprises a second cylinder, a first vertical rod, a first fixed frame, a supporting block, a second fixed frame, a third fixed frame, a fourth fixed frame, a second transverse rod, a third transverse rod and an ejecting block. The steel rib straightening machine can be used for quickly straightening steel ribs, and straightening is convenient and stable.

Owner:广州联勤建筑安装工程有限公司

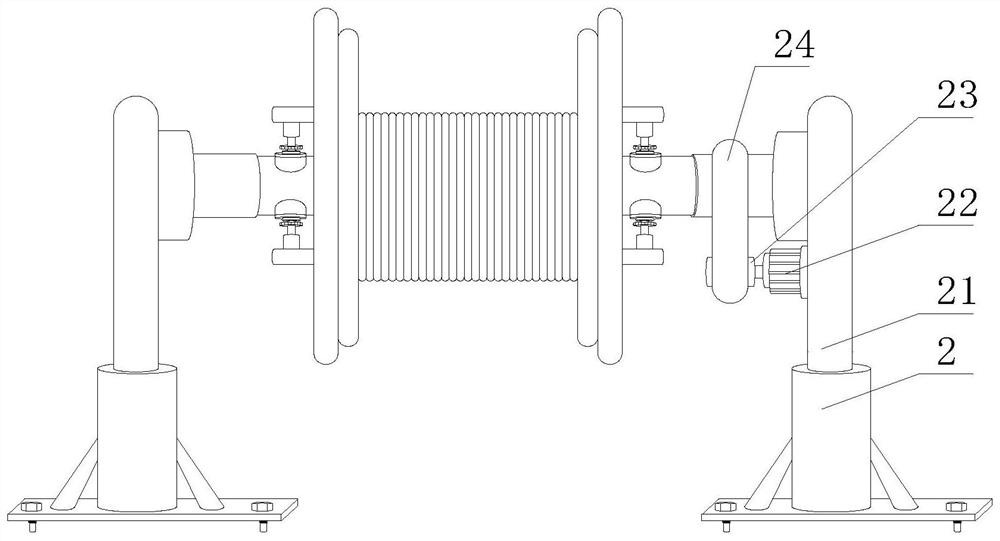

Cable take-up and pay-off device

ActiveCN112864950AImprove work efficiencyShorten the timeArrangements using take-up reel/drumElectronic waste recyclingElectric machineryControl theory

The invention discloses a cable take-up and pay-off device, and relates to the technical field of cables, the cable take-up and pay-off device comprises a cable workbench, the top of the cable workbench is fixedly connected with two supporting devices, the two supporting devices are symmetrically arranged at the top of the cable workbench, and the two supporting devices comprise supporting plates. By adopting the combined arrangement of the direct-current driving motor, the rotating shaft, the crawler belt, the first turntable, the electric telescopic rod, the fixed block and the cable rack, the direct-current driving motor is started and drives the rotating shaft, the crawler belt, the first turntable, the electric telescopic rod, the fixed block and the cable rack to rotate, so that a cable is quickly separated from the cable rack, the problem that when a cable is laid, a worker usually pulls the cable manually, due to the fact that the weight of the cable is high, great difficulty is brought to manual laying, and the cable laying efficiency is low is avoided, the work time of the worker is shortened, and the cable winding and unwinding work efficiency is improved.

Owner:沂蒙电缆有限公司

Metal bar material straightening machine

ActiveCN113649436AQuick straighteningImprove straightening efficiencyMetal-working feeding devicesPositioning devicesNumerical controlThin metal

The invention relates to the field of metal material machining, in particular to a metal bar material straightening machine which comprises a base, a clamping mechanism, a displacement mechanism and a straightening mechanism. The clamping mechanism is arranged at the left side of the upper end of the base, a mounting groove is formed in the right side of the upper end of the base, and the displacement mechanism is arranged in the mounting groove; and the straightening mechanism is mounted at the upper end of the displacement mechanism. The metal bar material straightening machine can solve the following problems in the prior art that in the process that a bar straightening machine is adopted to straighten a metal bar in a pressing manner, the efficiency of straightening the metal bar in a single-point step-by-step pressing manner of the existing bar straightening machine is low and the straightening effect is poor when the thin metal bar is straightened; and an existing large numerical control bar straightening machine is complex in structure, high in manufacturing cost and high in daily use and maintenance cost.

Owner:徐州卓越精密科技有限公司

FPC cover film laser automatic cutting equipment

ActiveCN114083149AQuick straighteningGuaranteed cutting accuracyLaser beam welding apparatusWebs handlingEngineeringLaser cutting

The invention discloses FPC cover film laser automatic cutting equipment which comprises a mounting table, wherein a collecting bin is mounted on one side of the bottom part of the mounting table, a drawer bin is arranged in the collecting bin, an air extracting pump is mounted in the middle of the bottom part of the mounting table, a purifying bin is mounted on the side, away from the collecting bin, of the bottom part of the mounting table, and an activated carbon bag is arranged at the middle position in the purifying bin. According to the FPC cover film laser automatic cutting equipment, an electromagnetic heating roller is firstly controlled to be heated to a preset temperature, a FPC cover film can be temporarily heated to become soft and plastic, then the FPC cover film passes through the space between the two sets of cooling guide rollers containing cooling liquid to be cooled, the FPC cover film can be automatically and rapidly straightened in cooperation with an upper guide roller and a lower guide roller, thus the FPC cover film can be quickly straightened, the FPC cover film can be in a straight and non-bent state under the condition that the FPC cover film is not stressed, and then when the FPC cover film passes through the lower portion of the laser cutting device, the cutting precision of the laser cutting device on the FPC cover film can be fully guaranteed.

Owner:SHENZHEN BEYOND LASER TECH CO LTD

Joint connection auxiliary equipment for low-voltage cable

ActiveCN112310900AFast clamping and fixingQuick straighteningConnection formation by deformationApparatus for joining/termination cablesLow voltageStructural engineering

The invention discloses joint connection auxiliary equipment for a low-voltage cable, which comprises a box body. A U-shaped opening is formed in the side wall of the box body, and a first driving mechanism, a second driving mechanism, a clamping mechanism, a straightening mechanism, a first mounting shell, a second mounting shell, two pressing type switches, a power source and a controller are arranged in the box body; two parallel first rack plates are symmetrically welded to the side wall of the bottom of the box body, a first driving mechanism used for driving the straightening mechanism to move is arranged on the first rack plates, and the straightening mechanism is arranged on the second mounting shell and used for straightening the cable inner core. Four second rack plates are welded to the side wall of the bottom in the box body, and every two of the four second rack plates are symmetrical and located on the two sides of the two first rack plates. The invention relates to the technical field of cable connection auxiliary equipment, and straightening operation can be conducted on two low-voltage cable ends before wiring, so that the labor intensity is greatly reduced, and the wiring efficiency is improved.

Owner:山东诺环建工有限公司

Wire straightening device

InactiveCN104690190AQuick straighteningStraightening and saving effortEngineeringMechanical engineering

Owner:REROS CHANGZHOU ELECTRONICS

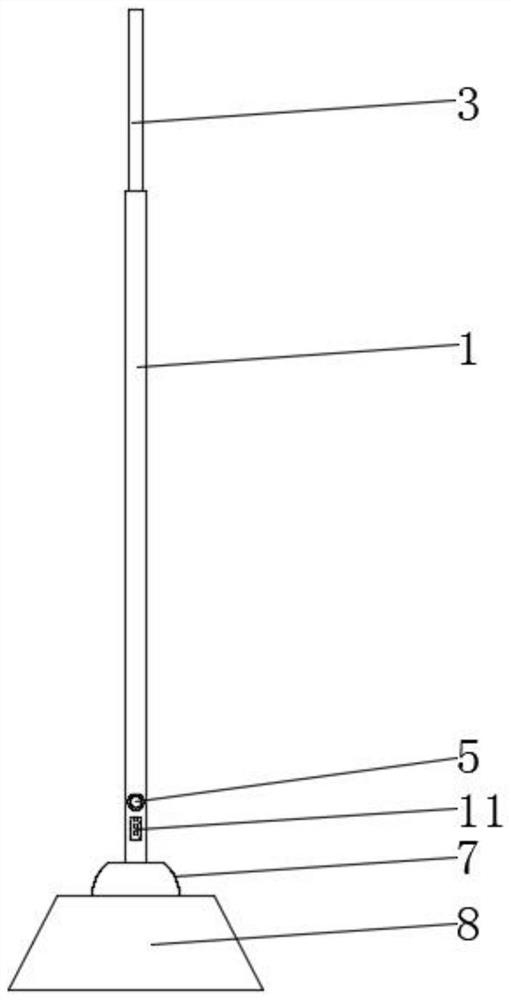

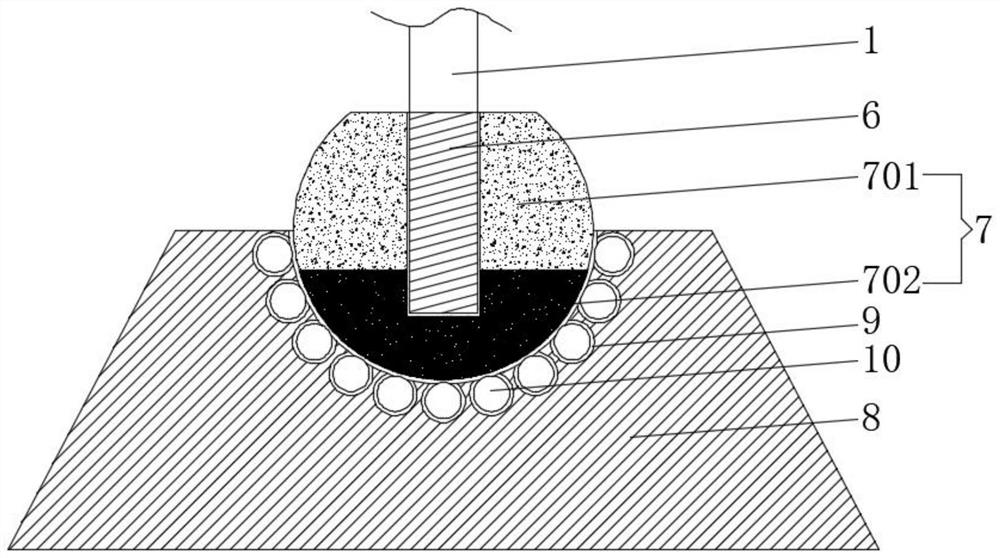

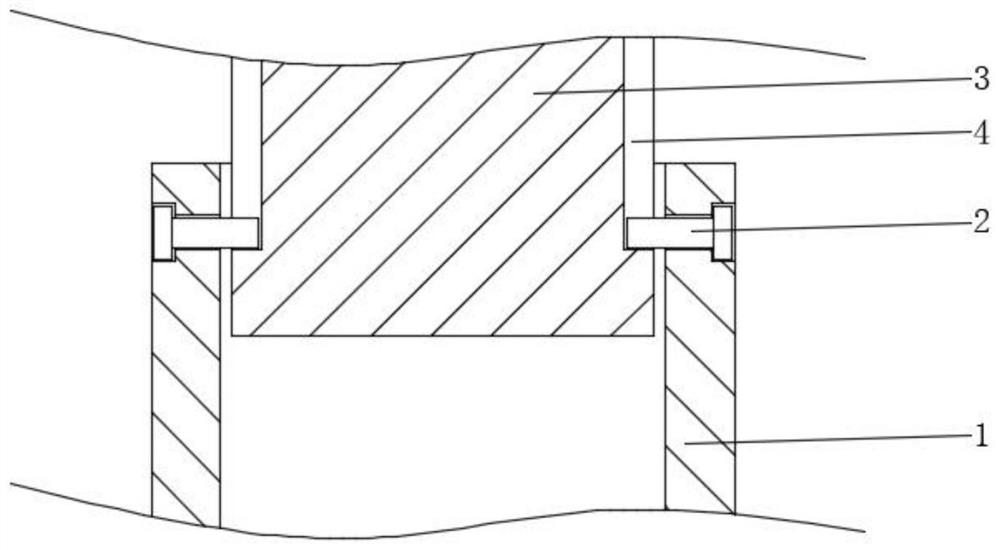

Box staff capable of being straightened quickly and accurately

PendingCN112683230AStraighten quicklyFast and accurate straighteningSurveying instrumentsHeight/levelling measurementGas bubbleSteel ball

The invention discloses a box staff capable of being straightened quickly and accurately, threaded holes are formed in the two sides of the top of a box staff body, limiting screws are in threaded connection with the interiors of the threaded holes, an extension ruler is arranged in the box staff body in a sleeved mode, limiting grooves are formed in the two sides of the extension ruler, and the limiting grooves and the limiting screws are used in cooperation. An electronic horizontal bubble instrument is arranged on the lower portion of the box staff body, a threaded portion is in threaded connection with a balance weight ball, and a base is arranged on the lower side of the balance weight ball. The base is placed on the ground of a to-be-detected place, the balance weight ball is placed in a spherical groove of the base, the balance weight ball can enable the box staff body to be in a vertical state through the tumbler principle, the balance weight ball can roll and reset in the spherical groove conveniently through steel balls in the ball grooves, and meanwhile checking and correcting are conducted through an electronic level bubble instrument. And the purpose of quickly straightening the box staff body is achieved.

Owner:ZHONG HANG TIAN CONSTR ENG COMPANY

A cable twisting machine with multi-directional cable production technology

ActiveCN113643860BQuick straighteningGuaranteed straightening accuracyCable/conductor manufactureStructural engineeringElectric cables

The invention discloses a cable twisting machine with multi-directional cable production technology, which belongs to the technical field of cable production equipment, and includes a twisting mechanism. The side of the twisting mechanism corresponding to the conveying direction of the cable core is provided with a burr cleaning mechanism. In the present invention, through the mutual cooperation of the designed straightening component, self-adjusting component, linkage component, drainage component and burr cleaning mechanism, etc., the rapid and non-torsion straightening function of the reel cable core is realized, especially for disc-shaped The copper-aluminum cable core can be straightened effectively and quickly, and on the basis of ensuring high efficiency, it can also ensure the straightening accuracy of the first straightening roller and the second straightening roller to the inner core of the cable. It has strong flexibility and adaptability, and can be used in different models The straightening work of the inner core of the cable can be accompanied by the degree of wear on the surface of the first straightening roller and the second straightening roller. The quality of the processed cable.

Owner:江苏昕讯光电科技有限公司

Die guide column straightening machine

InactiveCN104438472AQuick clampingQuick straighteningShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

The invention discloses a die guide column straightening machine. The die guide column straightening machine comprises a frame, a pressure head fixed on the frame, and a clamping part perpendicular to the pressure head, wherein the clamping part comprises a seat body and a fixed block detachably connected with the seat body, and further comprises liquid plastic, a sliding column, a thin-wall expanding sleeve, an expanding sleeve body sleeving the fixed block, a pull rod glidingly connected with the seat body, a connecting plate connected and fixed with the pull rod, and a rocker hinged with the connecting plate; a channel for containing the liquid plastic is formed in the expanding sleeve body; the thin-wall expanding sleeve is fixed in an expanding sleeve body inner hole and covers an opening in the inner wall of the channel; the sliding column is glidingly connected with the expanding sleeve body; the inner end of the sliding column covers an opening in the outer end of the channel; the outer end of the sliding column is hinged with one end of the rocker, which is far from the connecting plate; a cavity for the connecting plate, the pull rod and the rocker to move is arranged in the fixed block; the middle of the rocker is pivoted in the cavity. The scheme has a simple structure, is convenient to operate, can rapidly clamp die guide columns, is convenient for rapidly straightening, and reduces the cost.

Owner:CHONGQING TIANYE MOLD PUNCHING MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com