Glass package temperature sensor and manufacturing method thereof

A temperature sensor and glass packaging technology, applied in thermometers, thermometer applications, instruments, etc., can solve the problems of equipment not providing a foundation and a better solution, and achieving the effect of improving the utilization rate of silver paste and saving silver paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

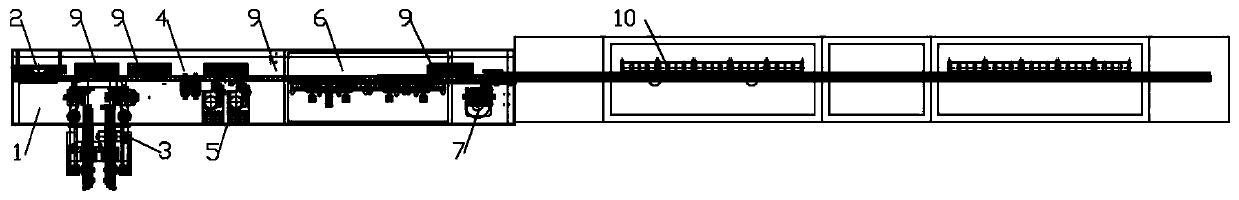

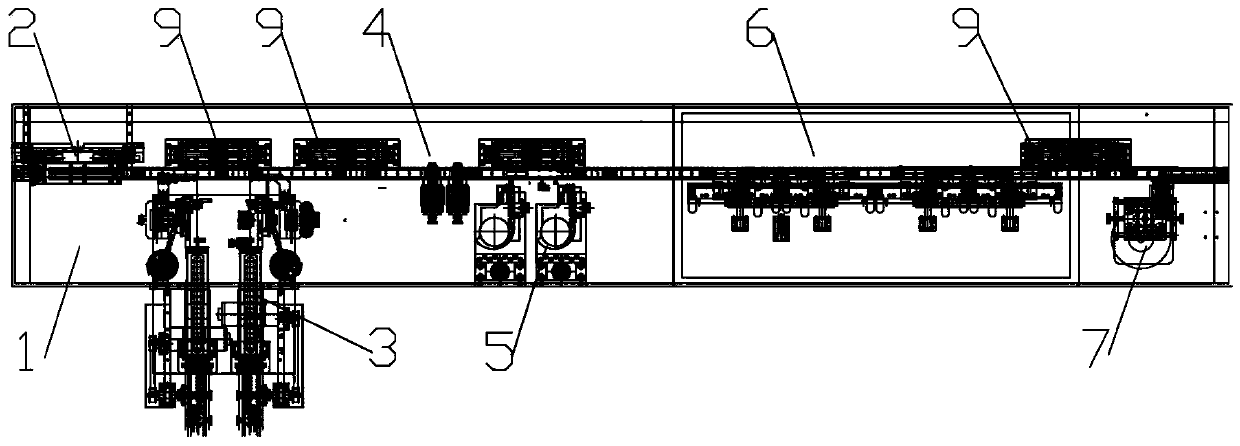

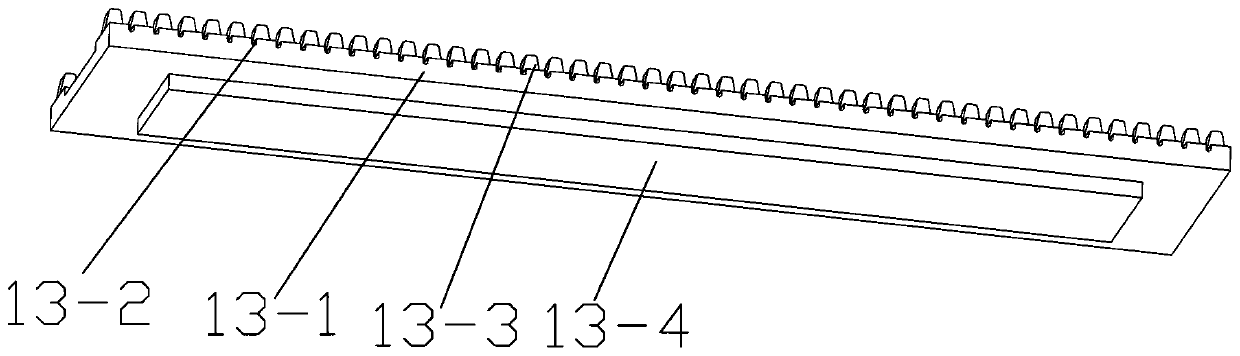

[0107] Such as Figure 1-4 As shown, a glass-encapsulated temperature sensor includes a chip 1, and a wire 2 is fixed on the left and right sides of the chip 1 by silver paste welding. The wire 2 is a dumet wire, and the diameter of the dumet wire is 0.3m / m. The ends of the chip 1 and the wire 2 are covered with a glass tube 3, and the glass tube 3 is integrated with the chip 1 and the wire 2 after heat melting.

[0108] A glass-encapsulated temperature sensor is processed and manufactured with special equipment. Specifically, the equipment includes a conveying platform 1, on which, from left to rear, there are successively a transfer fixture lowering mechanism 2, a straightening and shearing mechanism 3, a silver dipping mechanism 4, a chip welding mechanism 5, and a silver drying mechanism 6. , Insert glass bulb mechanism 7 and glass sealing forming mechanism 8. The above mechanisms respectively complete Dumet silk thread straightening --> Straightening --> Clamping wire -...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com