Front graphic structure of solar cell, solar cell and photovoltaic module thereof

A technology of solar cells and graphic structures, applied in the fields of photovoltaic power generation, electrical components, circuits, etc., can solve the problems of reducing battery efficiency and increasing shading area, and achieve the effect of improving battery efficiency, reducing shading area and reducing consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

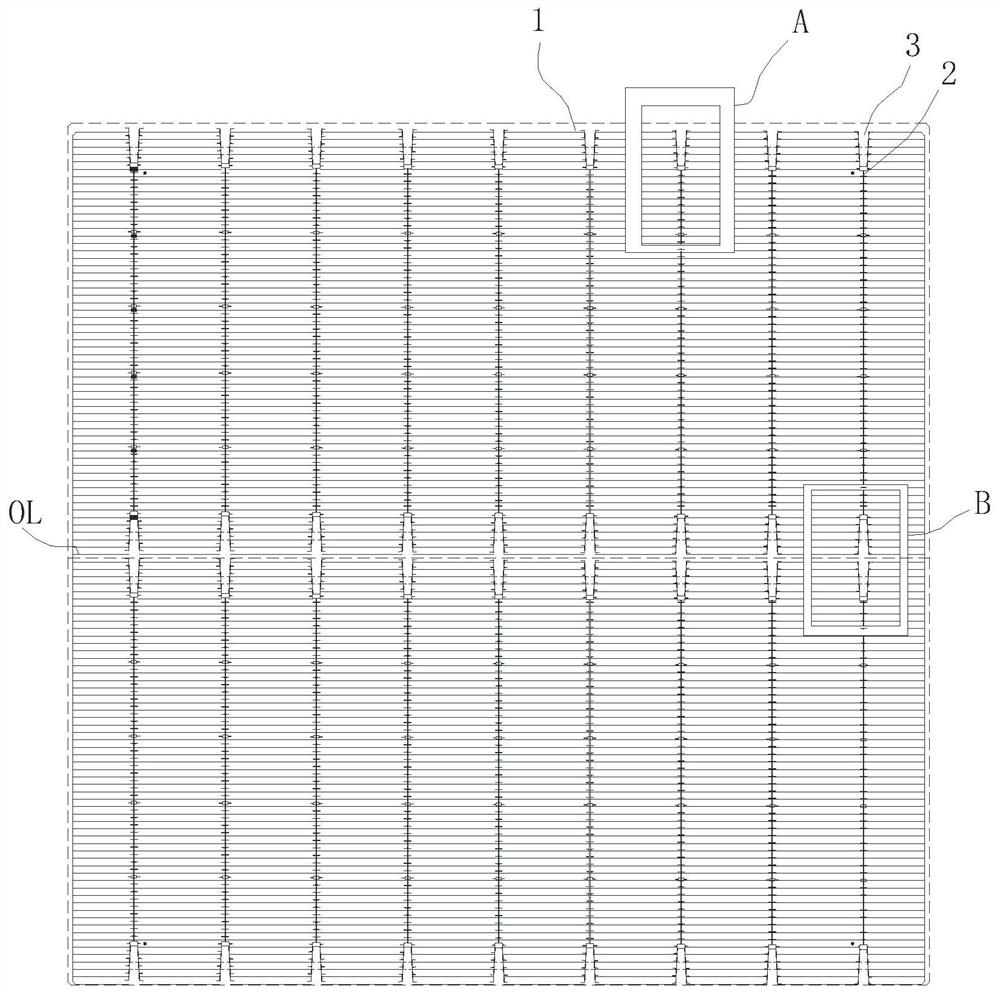

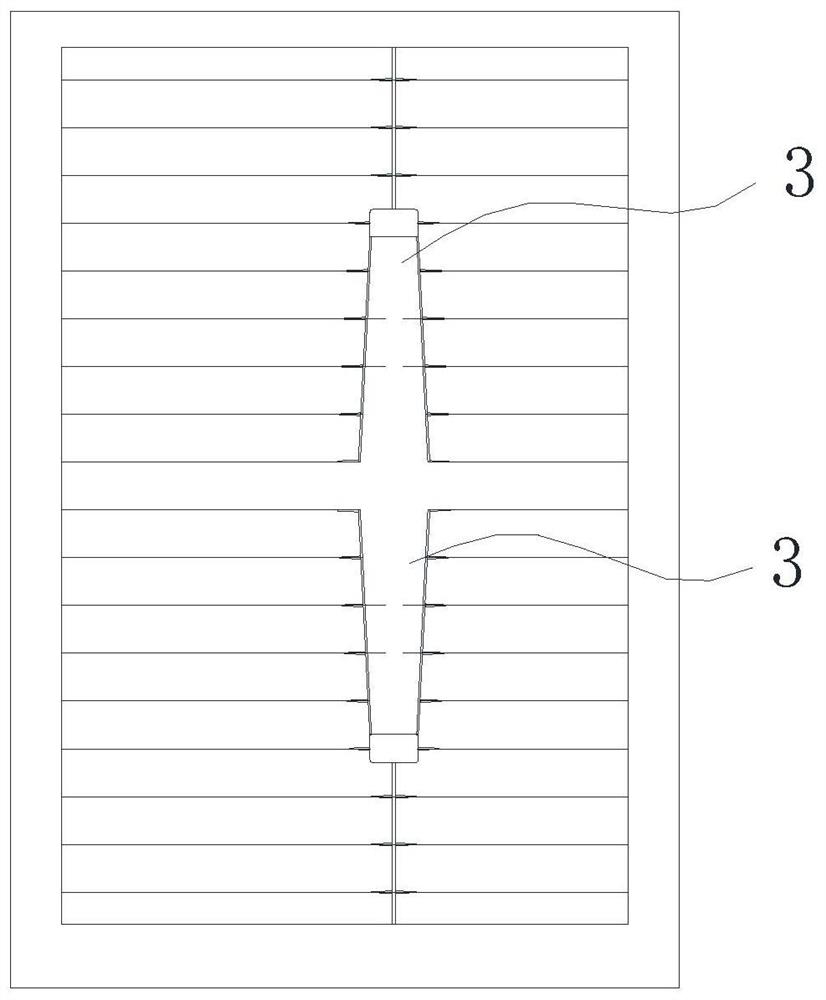

[0036] Such as Figure 1-3 As shown, the battery screen in the prior art is divided into several interconnected units 1, each of which is provided with a harpoon-type welding area 3 at both ends of the main grid line 2 on each unit 1, in addition, Near the cell cutting line OC, there are two mirror-symmetrical spear-shaped pads 3 , and when cutting in half, there is a spear-shaped pad 3 at both ends of the busbar 2 of each half.

[0037] The spear-type welding area 3 plays the role of collecting current and eliminating the difference of sight, but on the other hand, the spear-type welding area 3 also increases the shading area and reduces the battery efficiency.

[0038] The front graphic structure of the solar cell provided by this embodiment, such as Figure 4 As shown, the entire battery screen includes several units 1 isolated from each other by dividing lines OC, and several main grid lines 2 are arranged on the front of the unit 1, and the main grid lines on different u...

Embodiment 2

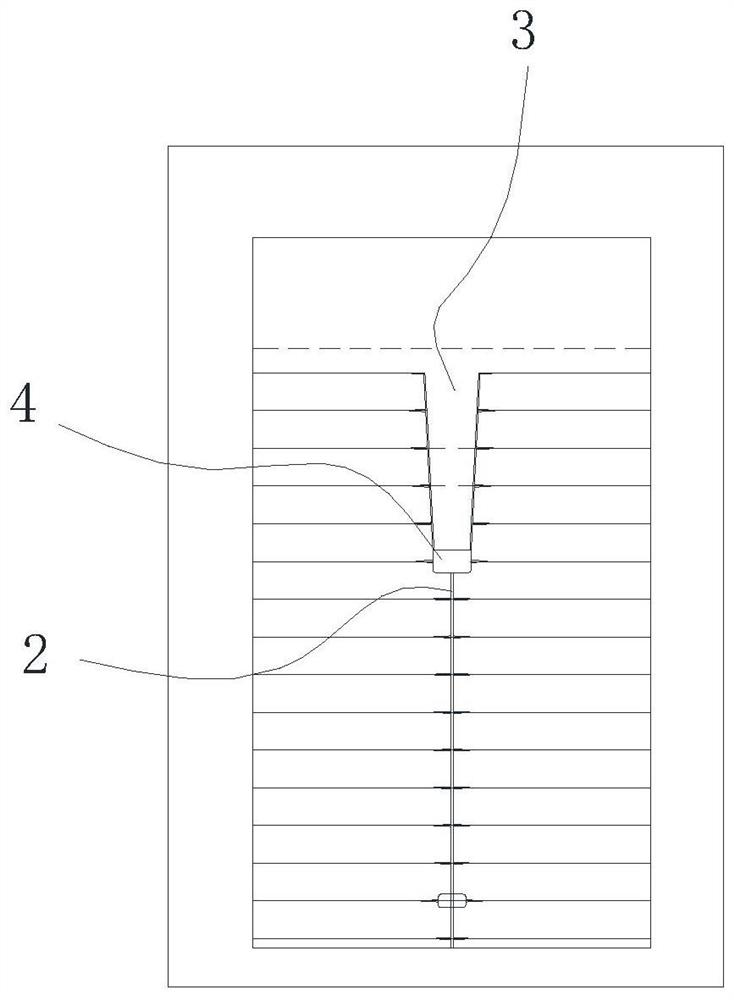

[0043] This embodiment provides a solar cell adopting the above-mentioned front pattern structure. Several busbars 2 are provided on the front of the unit 1 , each busbar 2 on each unit 1 is provided with a harpoon pad 3 at only one end, and the harpoon pad 3 is located on the front of the unit 1 .

[0044] Such as figure 2 As shown, the size of the pad 4 of a solar cell will be different, and the size of the connecting harpoon pad 3 is relatively large. The increase of the pad will lead to an increase in the amount of silver paste, an increase in cost, and an increase in the volume of the cell. , the shading area increases, reducing battery efficiency.

[0045] In this embodiment, the ends of the busbars are connected to the spear-shaped pads 3 through pads 4 , and the pads 4 are in the shape of a cross. Several pads 4 are evenly spaced on the busbar 2 and between the two pads 4 connected to the spear-shaped pads 3 .

[0046]The existing pad body is rectangular, and after...

Embodiment 3

[0059] This embodiment provides a photovoltaic module formed by adopting the above-mentioned solar cells, which are connected in series and / or in parallel, and subjected to processes such as encapsulation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com