Preparing method of whole back electrode P type crystalline silicon heterojunction solar battery

A technology of solar cells and full back electrodes, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increasing potential barriers and reducing open circuit voltage, achieving the effects of increasing light receiving area, increasing open circuit voltage, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

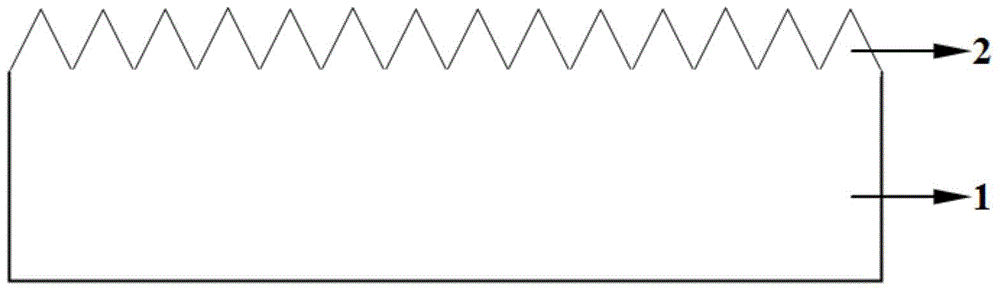

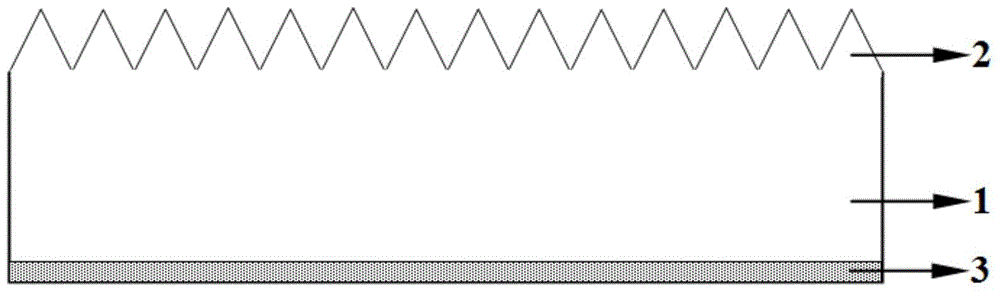

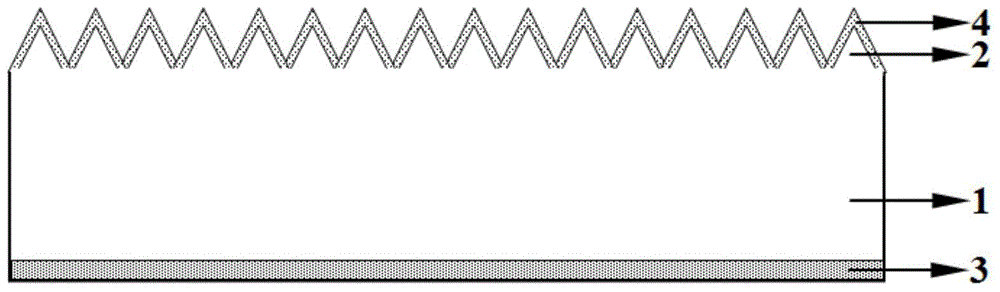

[0048] Example 1, as Figure 1-10 As shown, a preparation method of a full-back electrode P-type crystalline silicon heterojunction solar cell includes the following steps:

[0049] (1) Using the metal catalytic chemical etching method, a pyramid-like nano-suede surface is prepared on the front surface of the P-type silicon substrate, and the size of the nano-suede surface is 200 nm, and then the residual metal particles and other harmful substances are washed away by a cleaning process;

[0050] (2) Prepare p on the backside of p-type silicon substrate by high temperature diffusion of boron source ++ Type boron re-diffusion layer crystalline silicon layer, its thickness is 0.3μm, and the sheet resistance is 80ohm / Sq;

[0051] (3) Preparation of p on the backside of p-type silicon substrate by high-temperature shallow diffusion of boron source + Type boron shallow diffusion layer crystalline silicon layer, its thickness is 0.3μm, and the sheet resistance is 130ohm / Sq;

[00...

Embodiment 2

[0059] Example 2, as Figure 1-10 As shown, a preparation method of a full-back electrode P-type crystalline silicon heterojunction solar cell includes the following steps:

[0060] (1) Using the metal catalytic chemical etching method, a pyramid-like nano-suede surface is prepared on the front surface of the P-type silicon substrate, and the nano-suede size is 150 nm, and then the residual metal particles and other harmful substances are washed away by a cleaning process;

[0061] (2) By ion implantation, the p-type silicon substrate is prepared on the back side to obtain p ++ type boron re-diffusion layer crystalline silicon layer, its thickness is 0.2μm, and the sheet resistance is 70ohm / Sq;

[0062] (3) By ion implantation, the p-type silicon substrate is prepared on the back side to obtain p + Type boron shallow diffusion layer crystalline silicon layer, its thickness is 0.2μm, and the sheet resistance is 150ohm / Sq;

[0063] (4) By thermal oxidation method, SiOx film i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com