Bottom plate welding device and battery string production equipment

A technology for production equipment and base plates, applied in welding equipment, electric heating devices, auxiliary devices, etc., can solve problems such as busbar line deviation, poor welding, rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

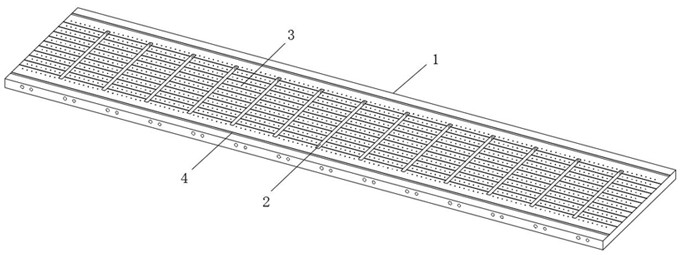

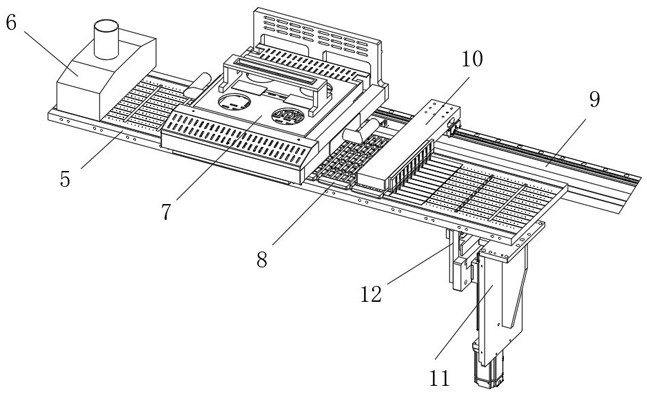

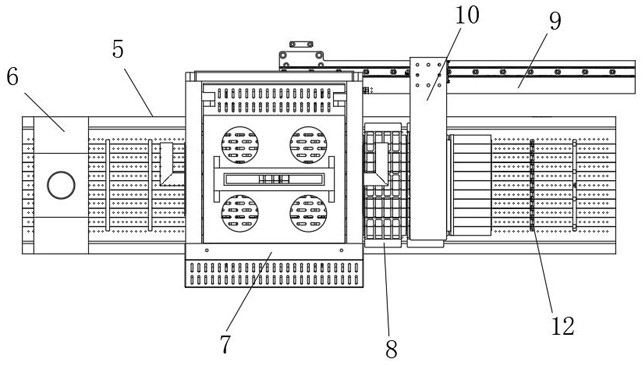

[0023] Such as Figure 1-3 As shown, the embodiment of the present invention provides a welding base plate device, including a welding base plate body 1, a plurality of parallel-arranged welding wire tail jaw avoidance grooves 2 are provided on the upper surface of the welding base plate body 1, and the surface of the welding base plate body 1 There are a number of cell negative pressure adsorption holes 3 arranged in a rectangular array, and the upper surface of the welding bottom plate body 1 and the two sides of the claw avoidance groove 2 at the tail of the welding wire are provided with high temperature resistant strong magnet pre-embedded grooves 4 .

[0024] The welding bottom plate body 1 is fixedly connected with a heat pipe and a thermocouple, the upper surface of the welding bottom plate body 1 is provided with a welding wire positioning groove, and the inside of the high temperature resistant strong magnet embedded groove 4 is provided with a high temperature resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com