Patents

Literature

30results about How to "Improve coincidence accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

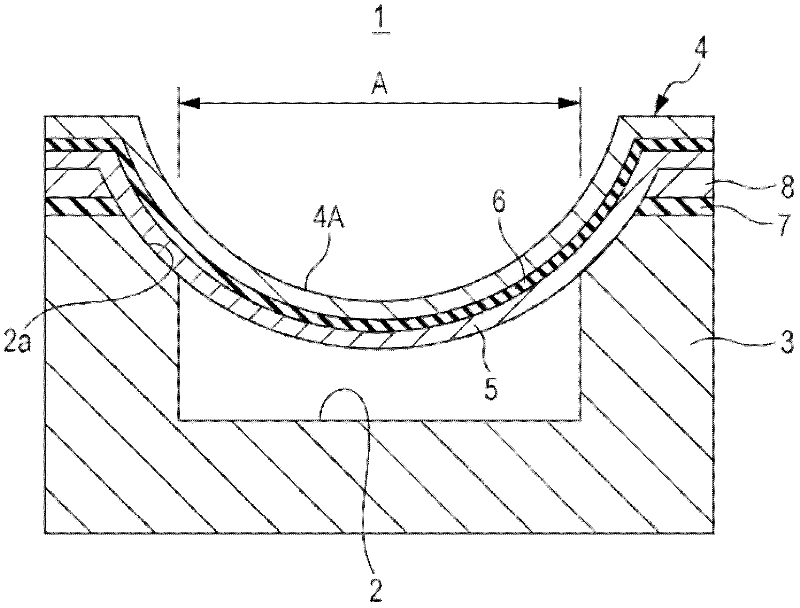

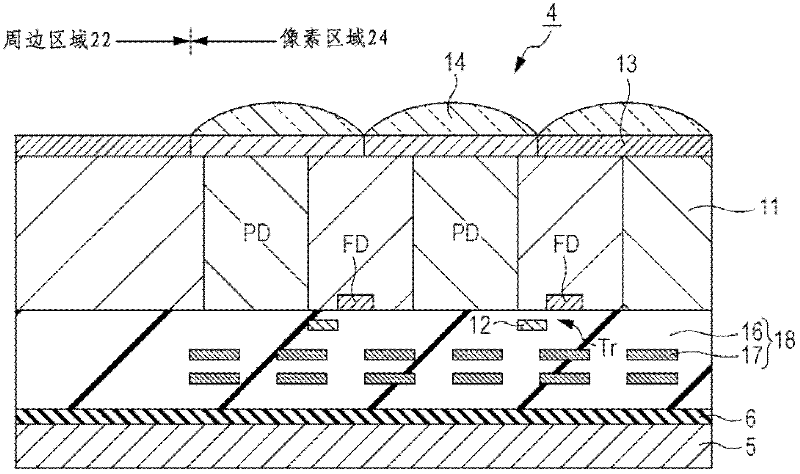

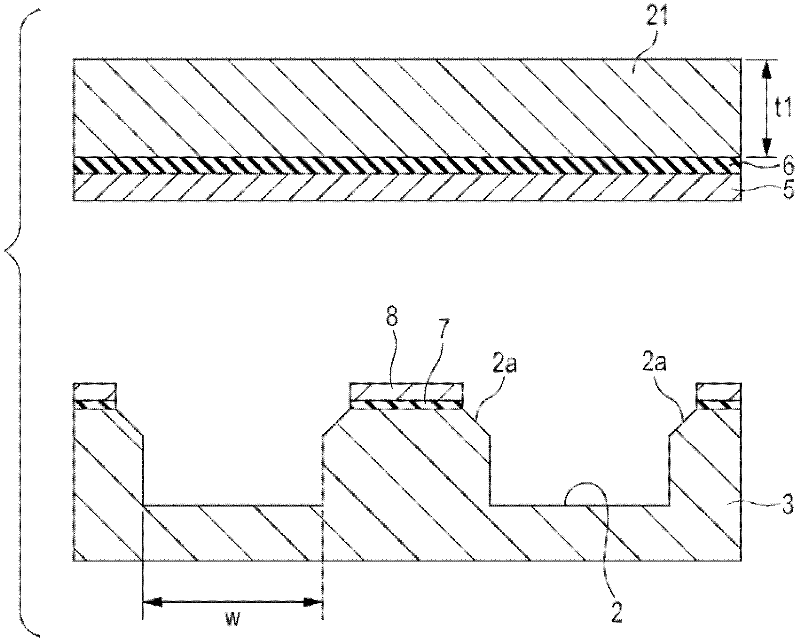

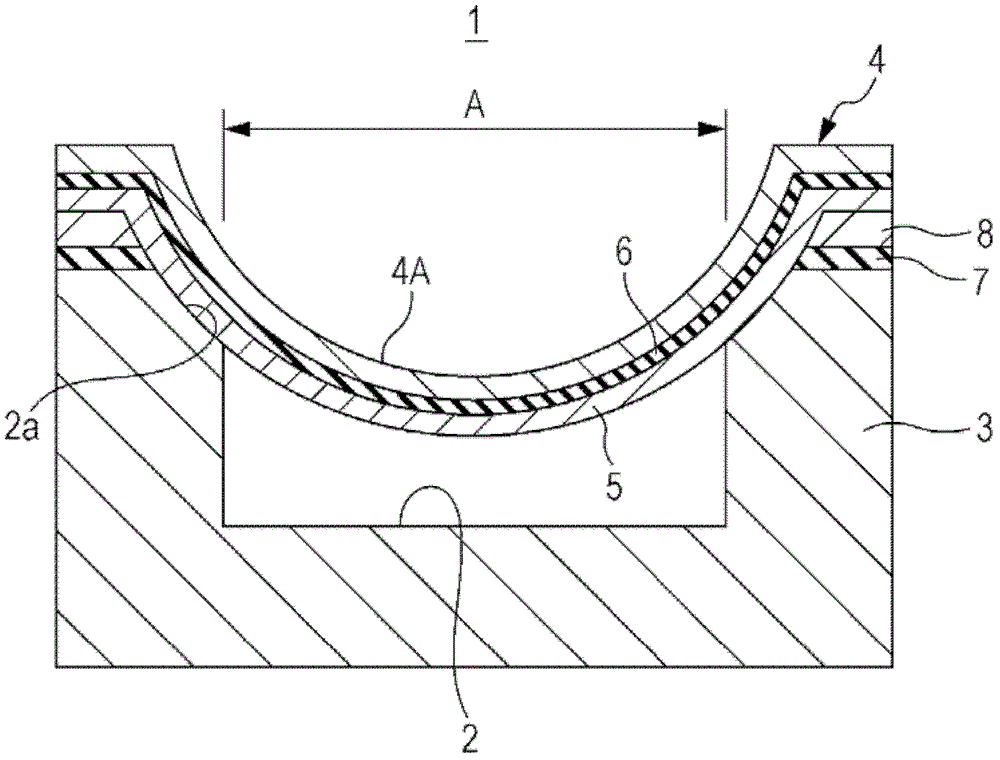

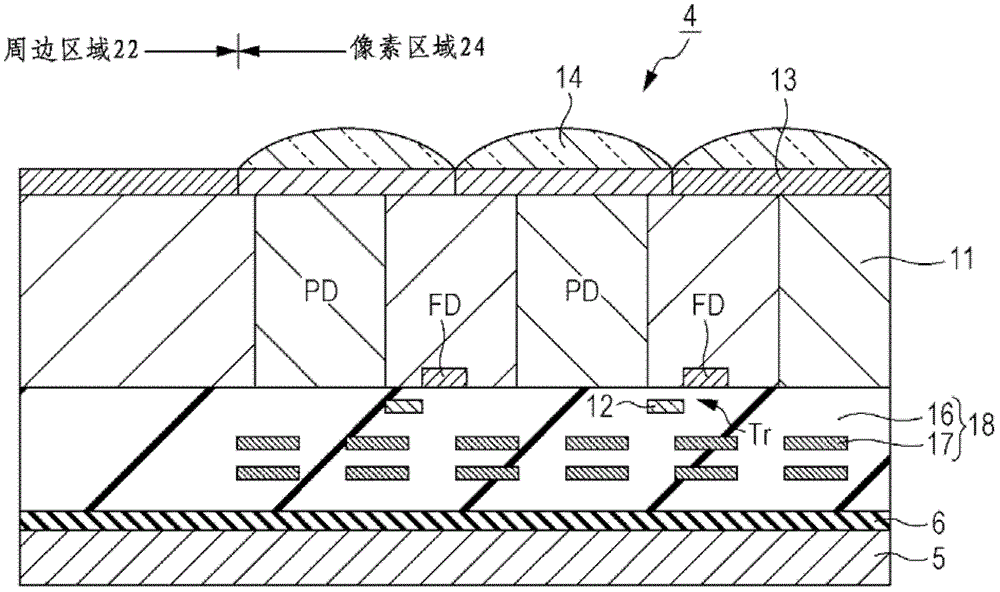

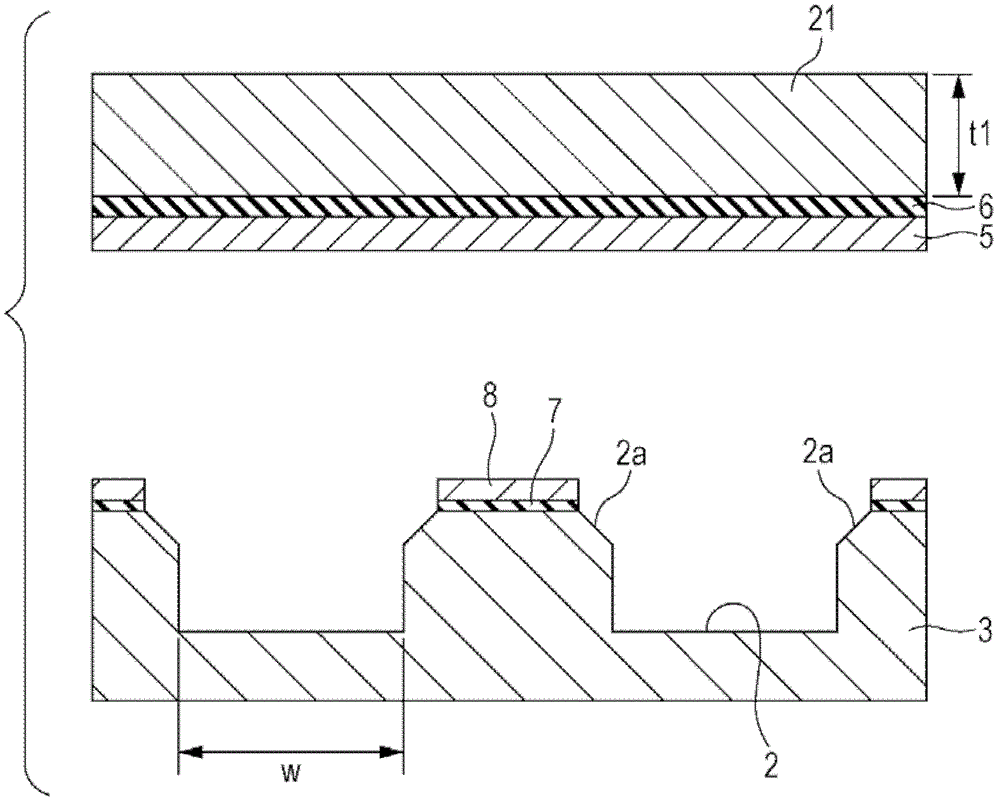

Solid-state imaging device and manufacturing method thereof, and electronic apparatus

InactiveCN102479794ALow number of lensesHigh precisionTelevision system detailsSemiconductor/solid-state device detailsEngineeringSolid-state

A solid-state imaging device (1) includes a supporting substrate (3) that includes a concave portion (2), a solid-state imaging chip (4) that is bonded on the supporting substrate (3) so as to seal the concave portion (2) in a view-angle region, a stress film (5) that is formed on the surface of the solid-state imaging chip (4), and an imaging surface curved toward the concave portion (2) at least in the view-angle region.

Owner:SONY SEMICON SOLUTIONS CORP

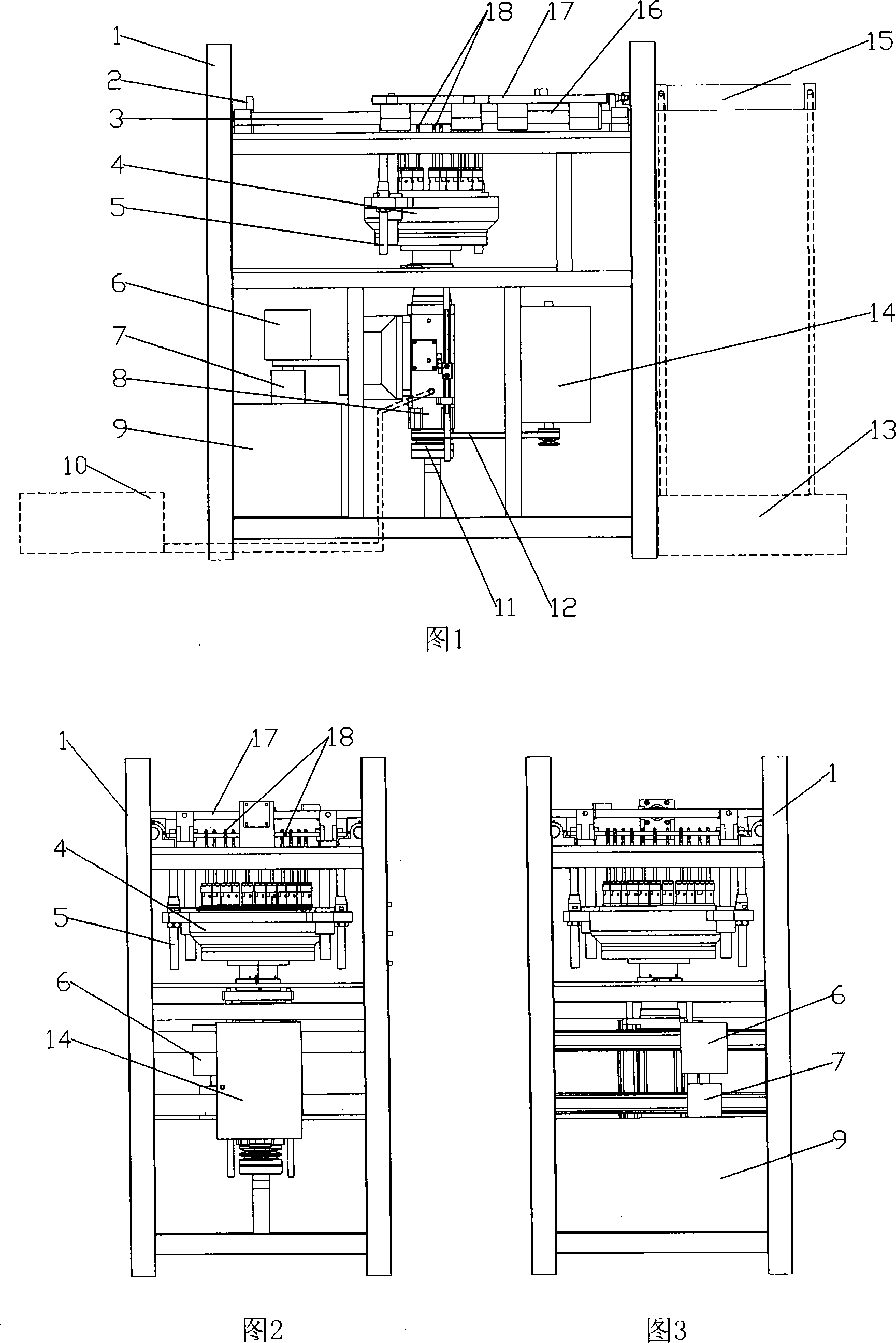

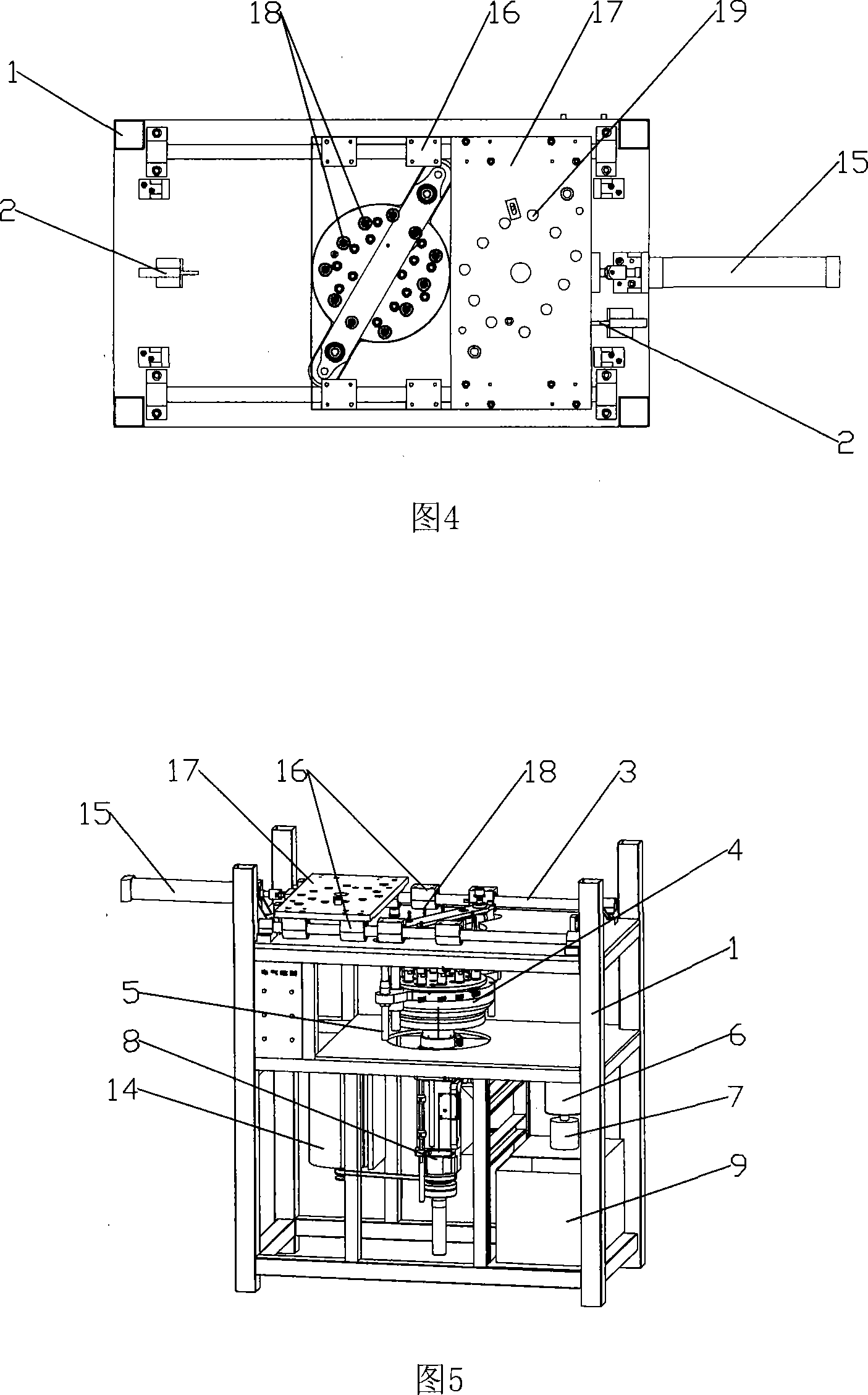

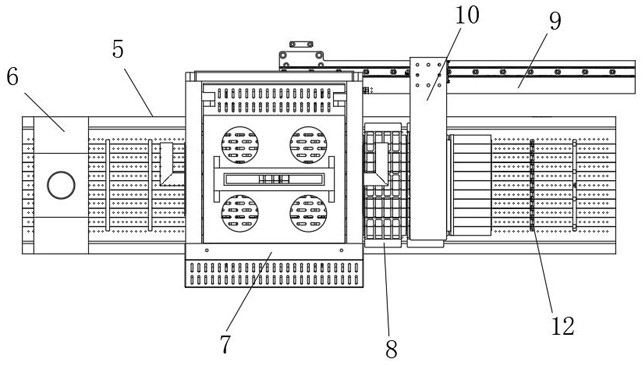

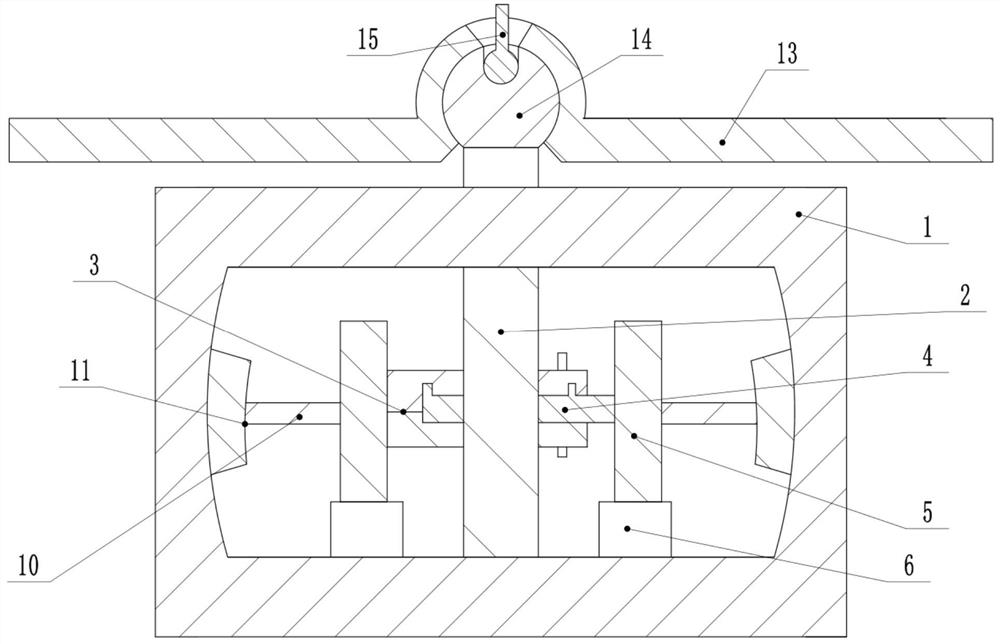

Inverted type machine tool

The invention discloses an inverted machine tool, comprising a power head and a cutter which are arranged on a frame, and a power device which drives the power head. The invention is characterized in that the power head is arranged on the frame in a way that the output terminal faces upwards; the cutter is arranged at the power output terminal of the power head forming a way that the cutter head faces upwards; the frame is provided with a frock clamp which is used for fixing a workpiece; the frock clamp is arranged above the cutter. The machine tool has the advantages of easy and exact clamping and low cost.

Owner:梁刚

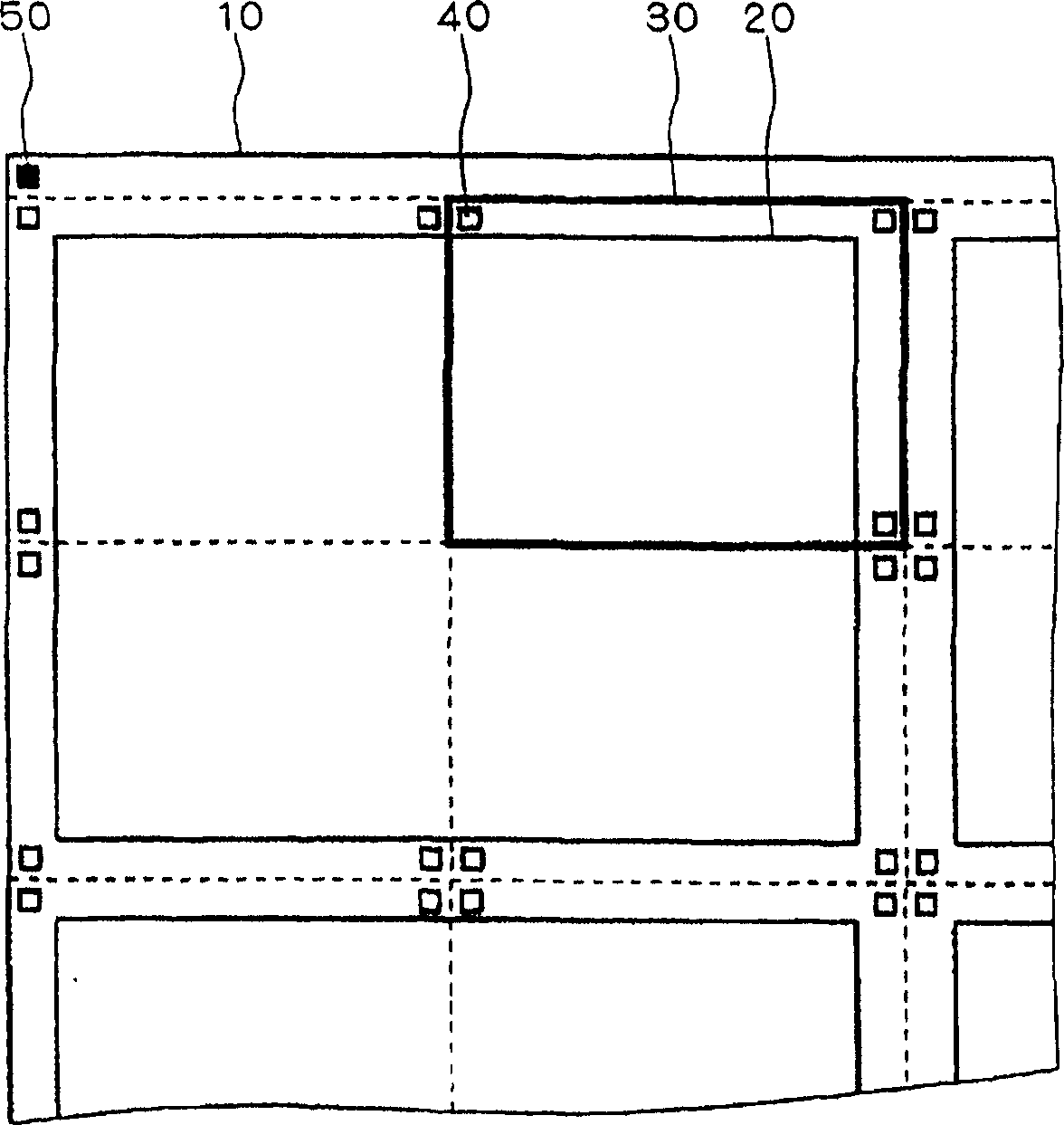

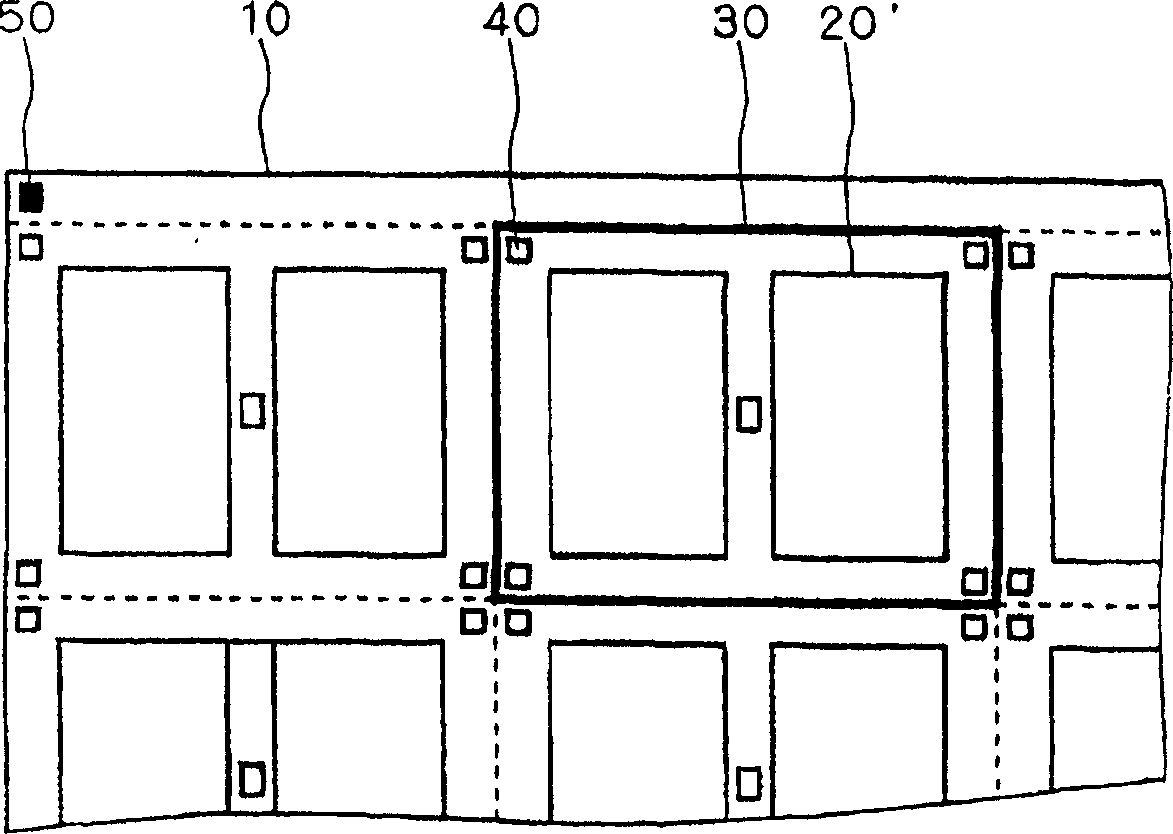

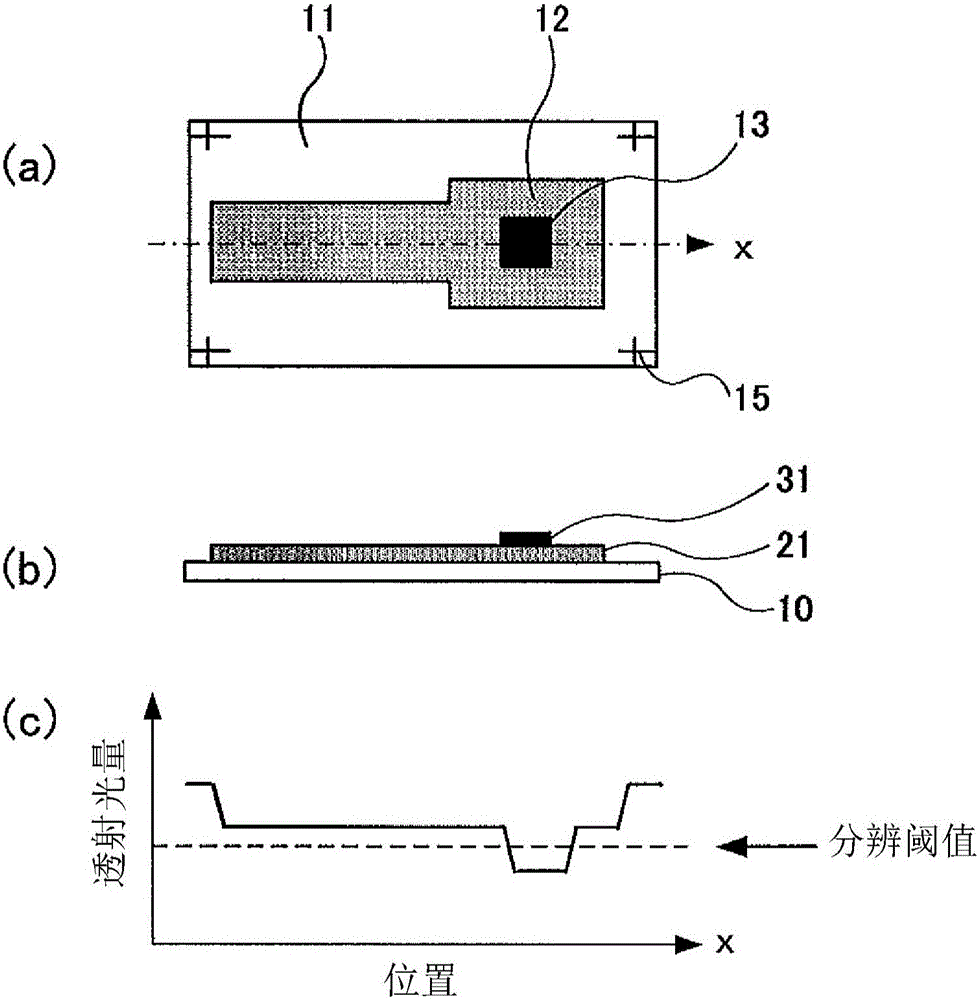

Method of manufacturing liquid crystal display device

InactiveCN1904686AImprove coincidence accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusLiquid-crystal displaySuperimposition

A plurality of display areas are formed on an array substrate by stepper exposure. The array substrate is divided into array shot areas serving as shot units at the time of divided exposure. One display area is divided into four array shot areas. One array shot area is provided with at least one alignment mark. The array substrate has a rectangular shape, and is provided with a superimposition mark at the corner thereof which is used as the reference for superimposing the array substrate and a CF substrate.

Owner:MITSUBISHI ELECTRIC CORP

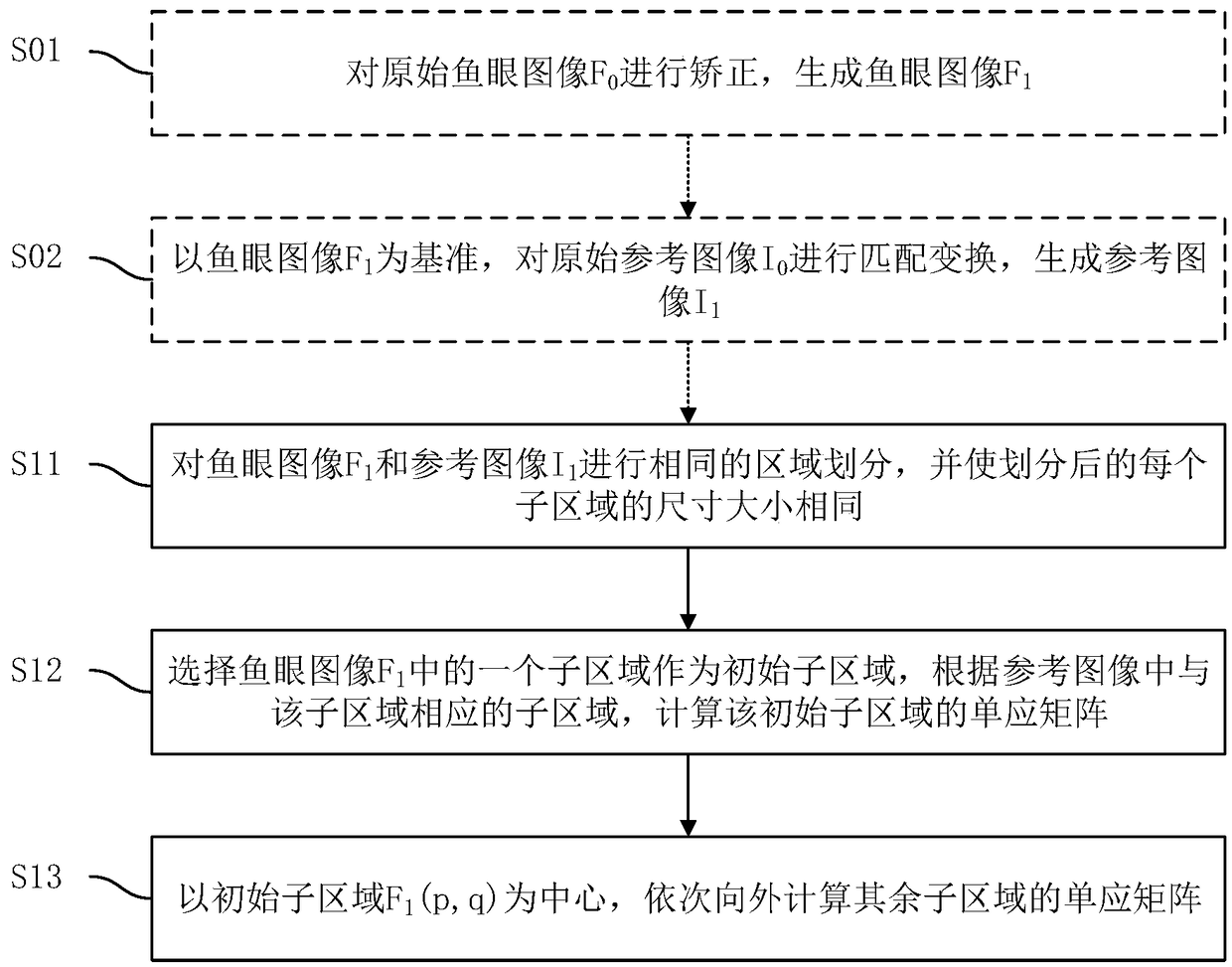

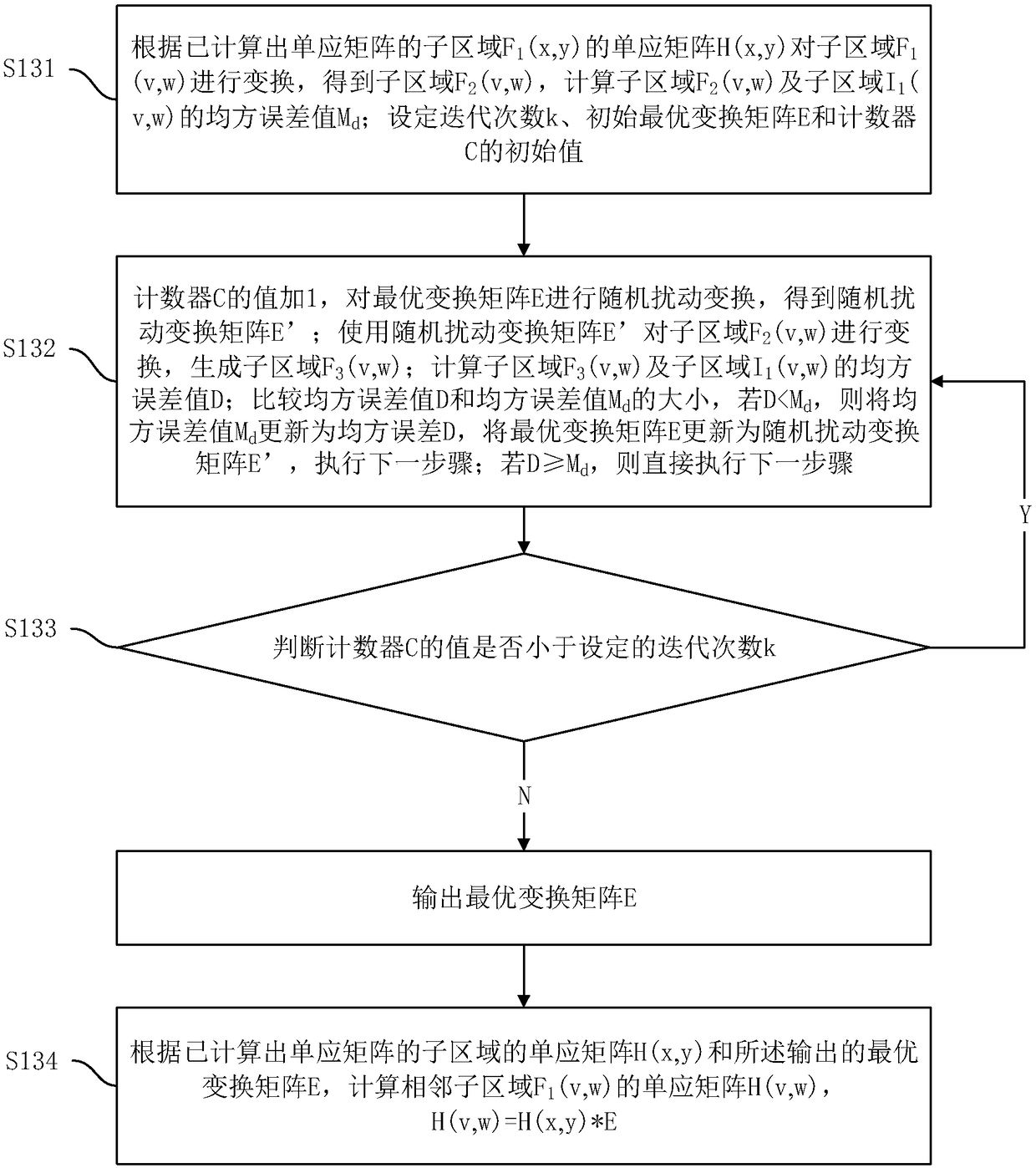

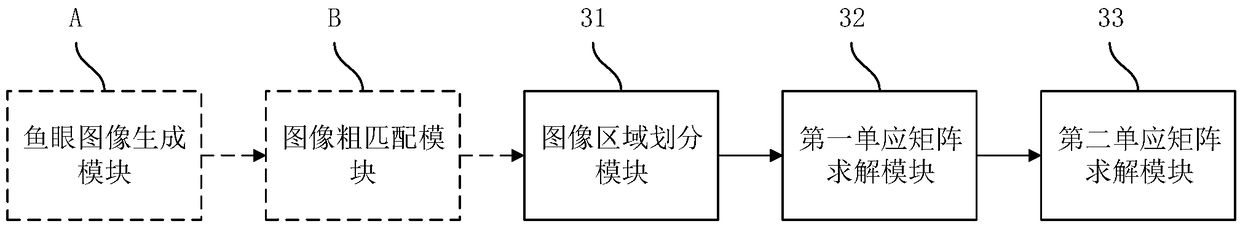

Method and system for determining homography matrix and image conversion method and system thereof

ActiveCN109064392AImprove coincidence accuracyAvoid the problem of low coincidence accuracyImage enhancementImage analysisPattern recognitionRadiology

The invention relates to a method and a system for determining a homography matrix and an image conversion method and a system thereof. The method for determining the homography matrix comprises the following steps: dividing the fisheye image and the reference image into the same regions, and making the size of the sub-regions in the divided fisheye image and the corresponding sub-regions in the reference image be the same, and the size of the fisheye image and the reference image be the same; Selecting a sub-region in the fisheye image as an initial sub-region, calculating a homography matrixof the initial sub-region according to the sub-region corresponding to the sub-region in the reference image; The homography matrices of the other subregions are calculated from the center of the initial subregion. The embodiment of the invention adopts the mode of dividing regions and each sub-region corresponds to a homography matrix respectively, which has high image coincidence accuracy, andavoids the problem that in the prior art, the whole fish-eye image adopts only one homography matrix, resulting in low image coincidence accuracy of the fish-eye camera.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

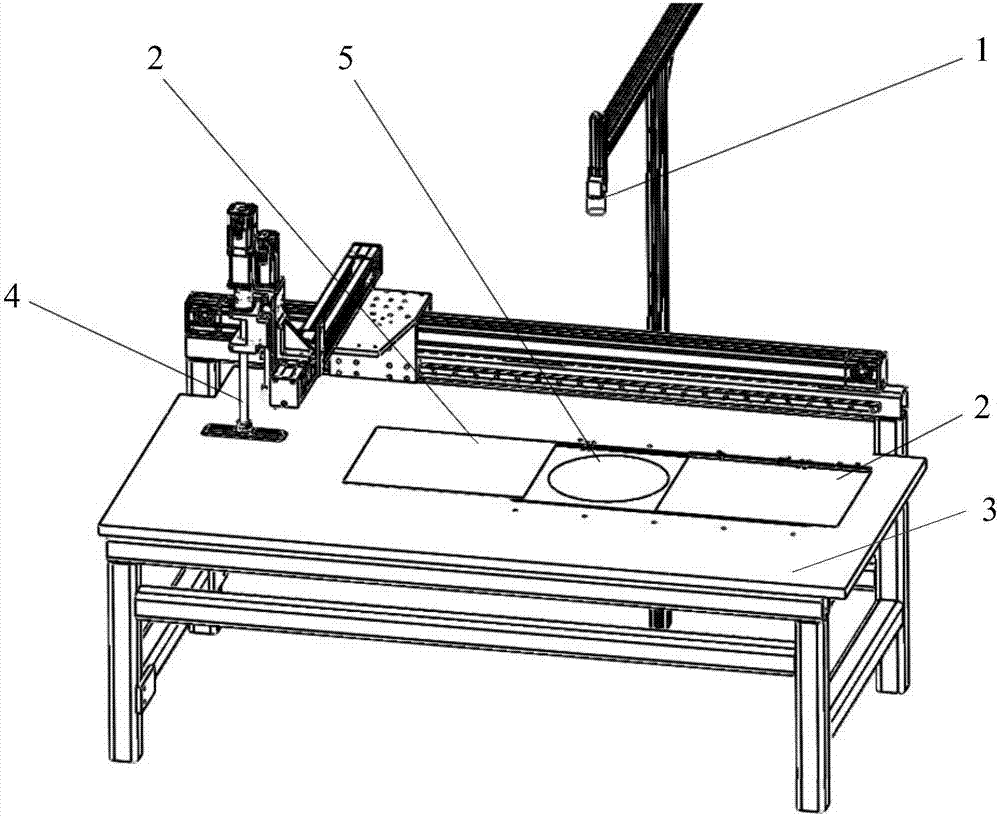

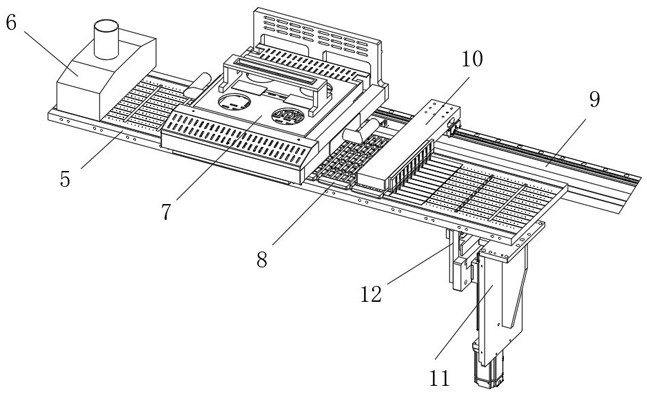

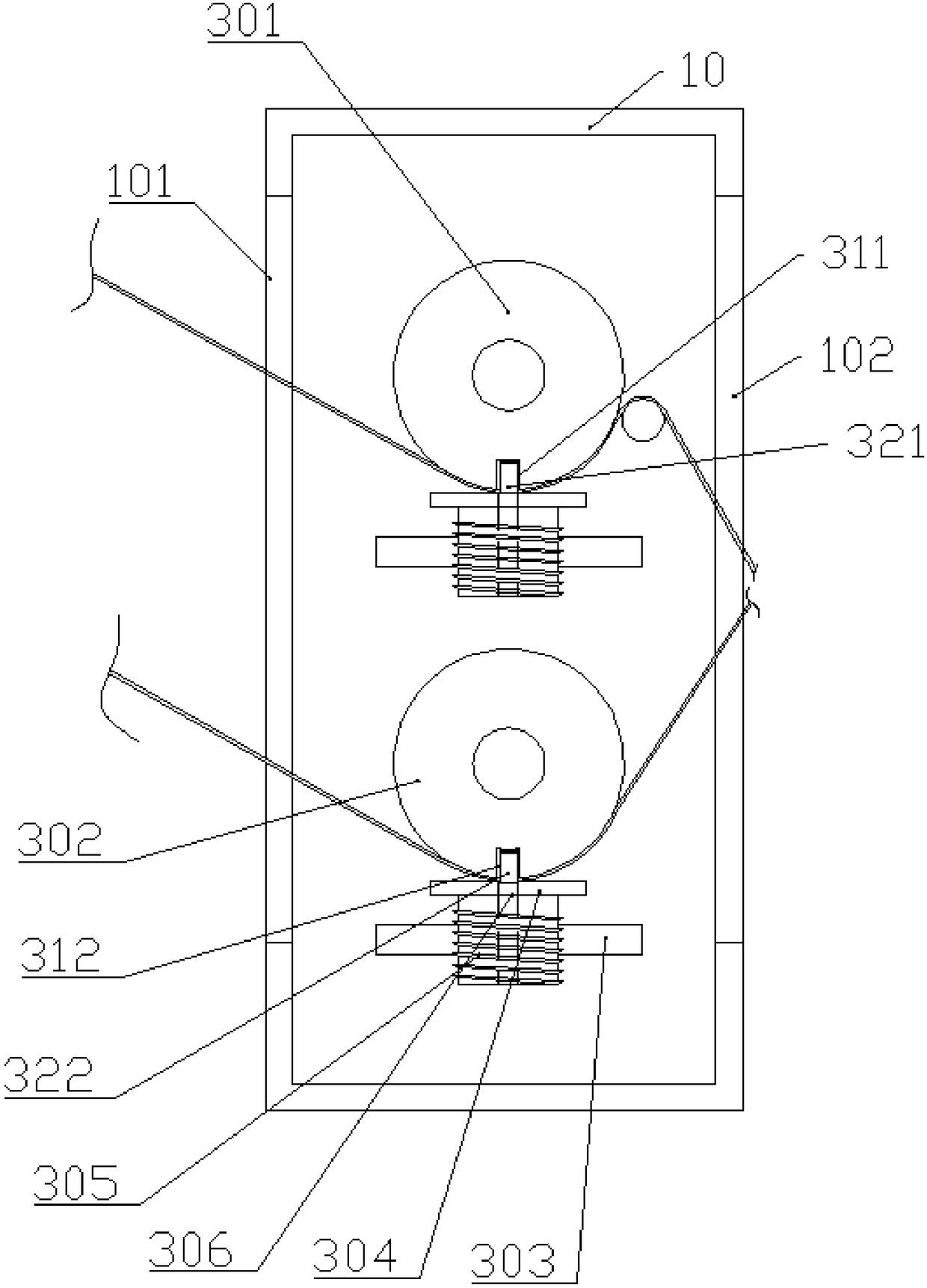

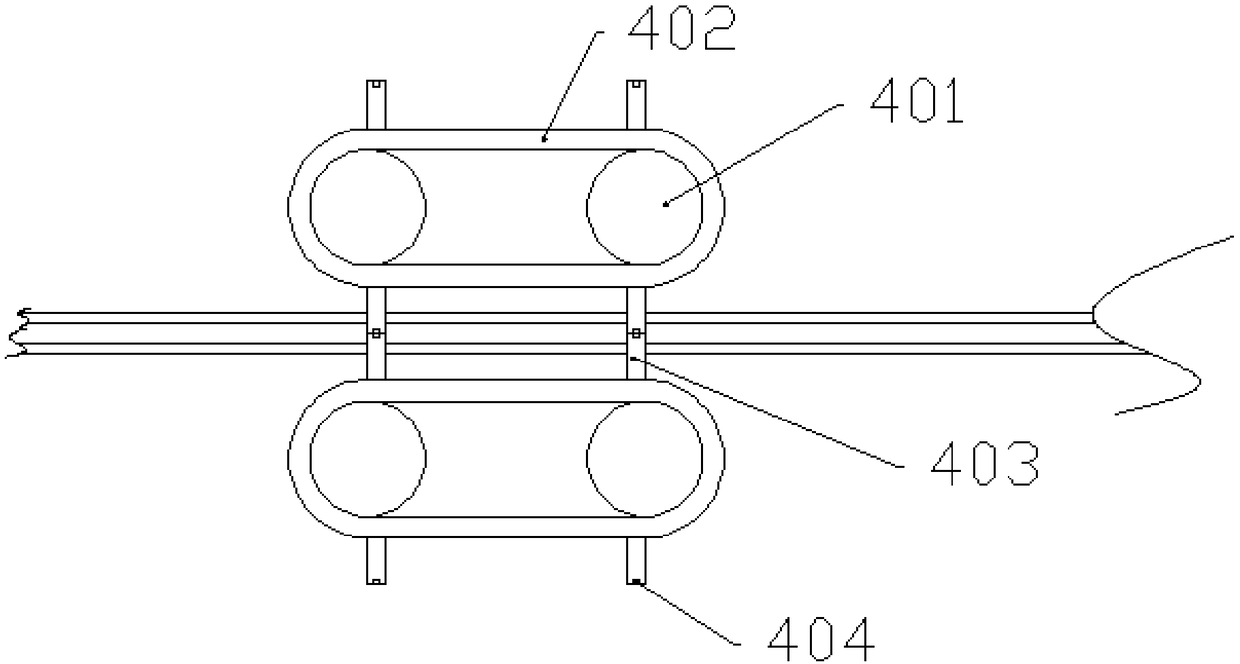

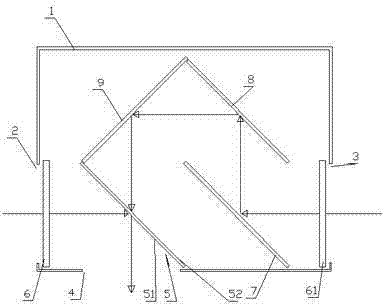

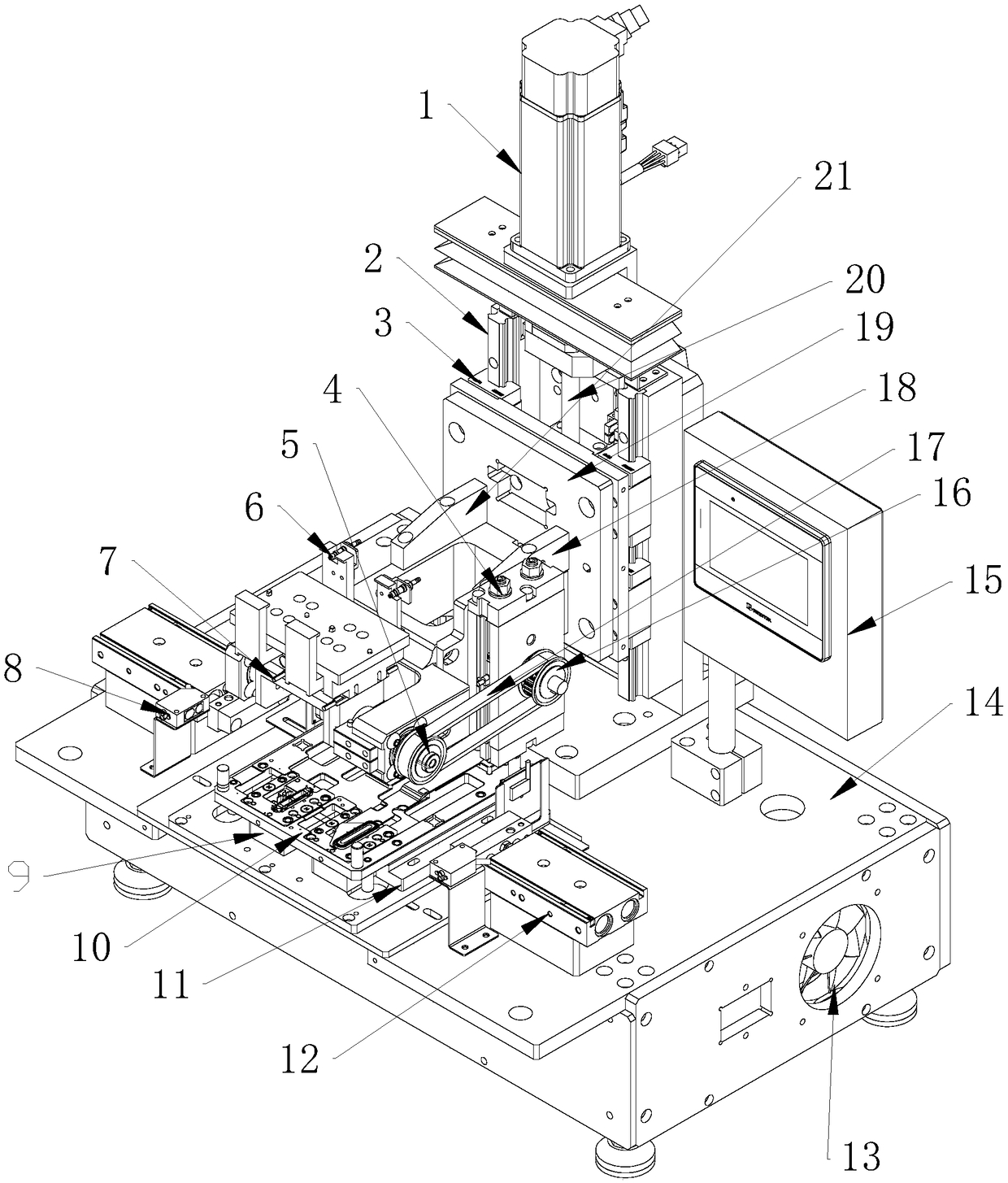

Overlapping sewing device

ActiveCN107419442ASimplify complexityImprove coincidence accuracyWork-feeding meansSewing-machine control devicesEngineeringManipulator

The invention discloses an overlapping sewing device which comprises a feeding plate, a storage plate, a driving device, a visual system, a rotating device and a manipulator. The feeding plate and the storage place are used for supporting cut parts, the driving device is used for driving the corresponding feeding plate to move to a position above or far away from the storage plate, the visual system is used for recognizing the positions of the cut parts placed on the feeding plate and recognizing the positions of the cut parts placed on the storage plate, the rotating device is used for controlling the storage plate to rotate according to recognition results of the visual system, so that the angle of one cut part on the storage place is adjusted to be as same as that of another cut part on an adjacent layer above the cut part, and the manipulator is used for moving one cut part on the feeding plate to be aligned to another cut part on an adjacent layer under the cut part according to the recognition results of the visual system and rotating results of the rotating device. The rotating device is matched with the manipulator to adjust relative positions of the cut parts, program setting complexity in the manipulator can be simplified, operation time is reduced, and overlapping accuracy of the cut parts is improved.

Owner:JACK SEWING MASCH CO LTD

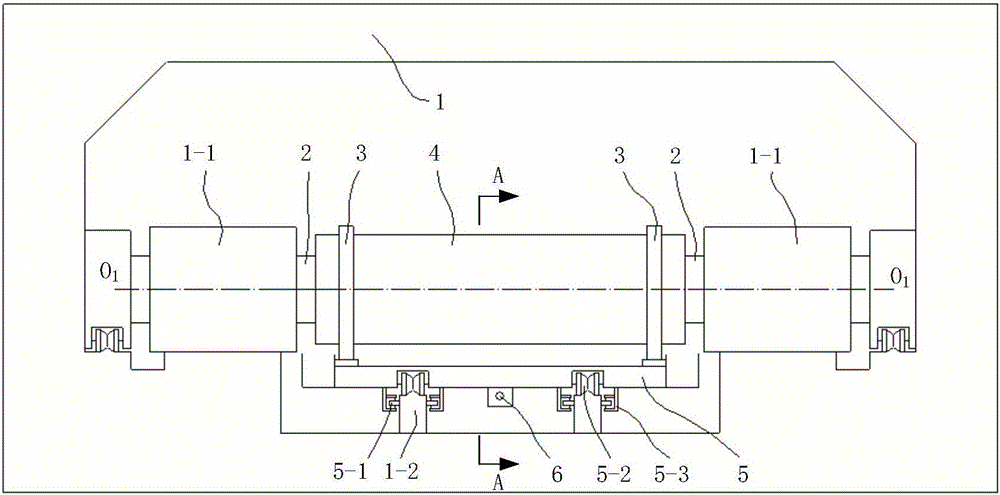

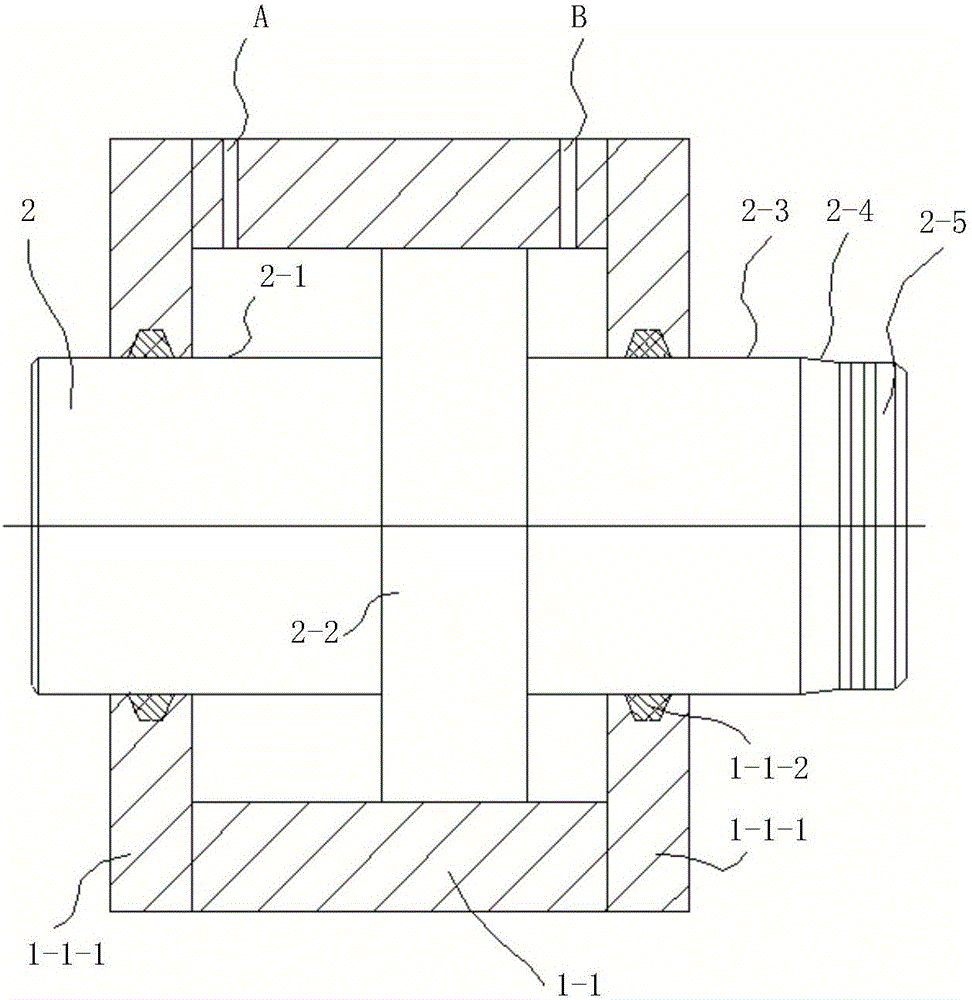

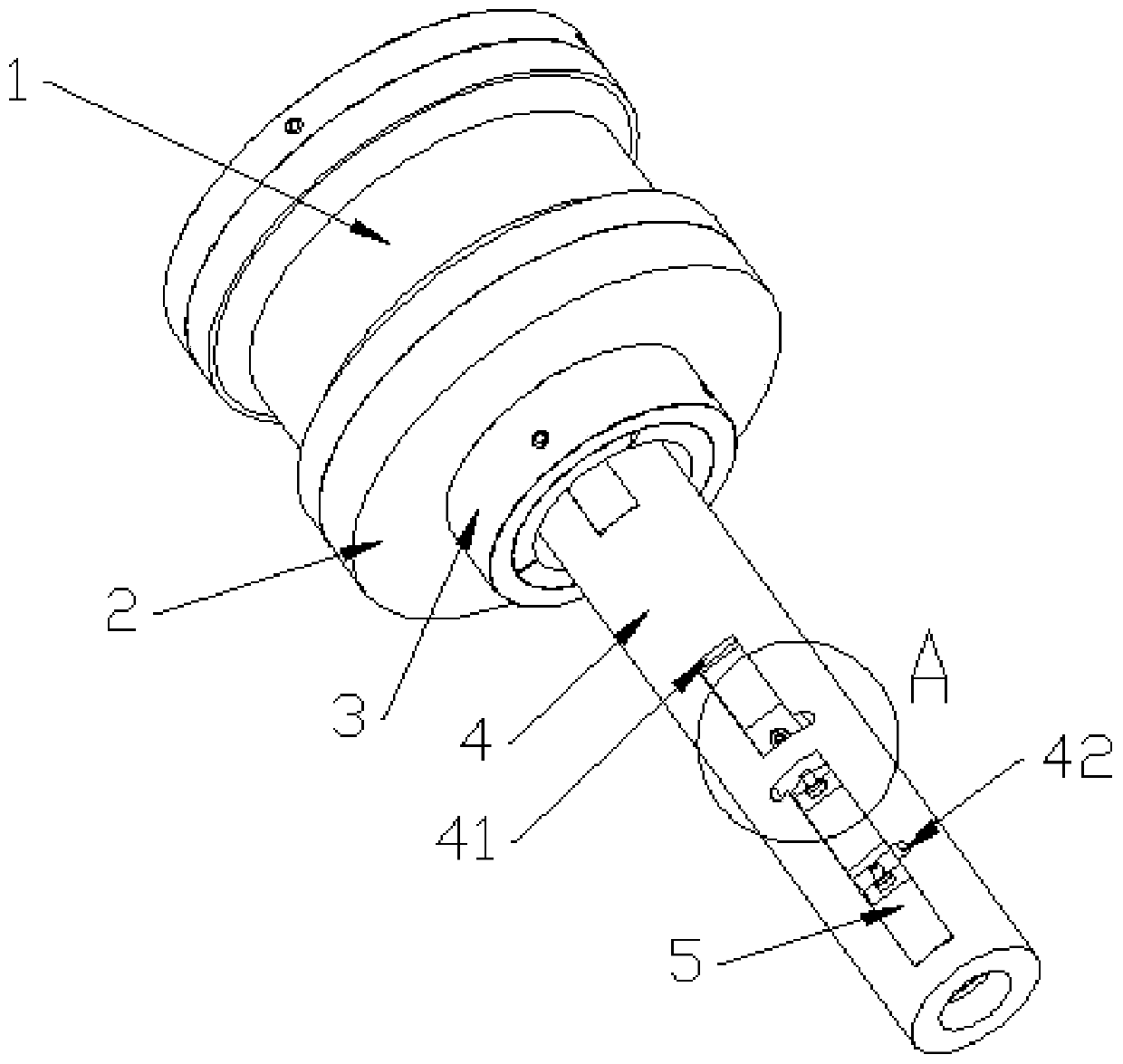

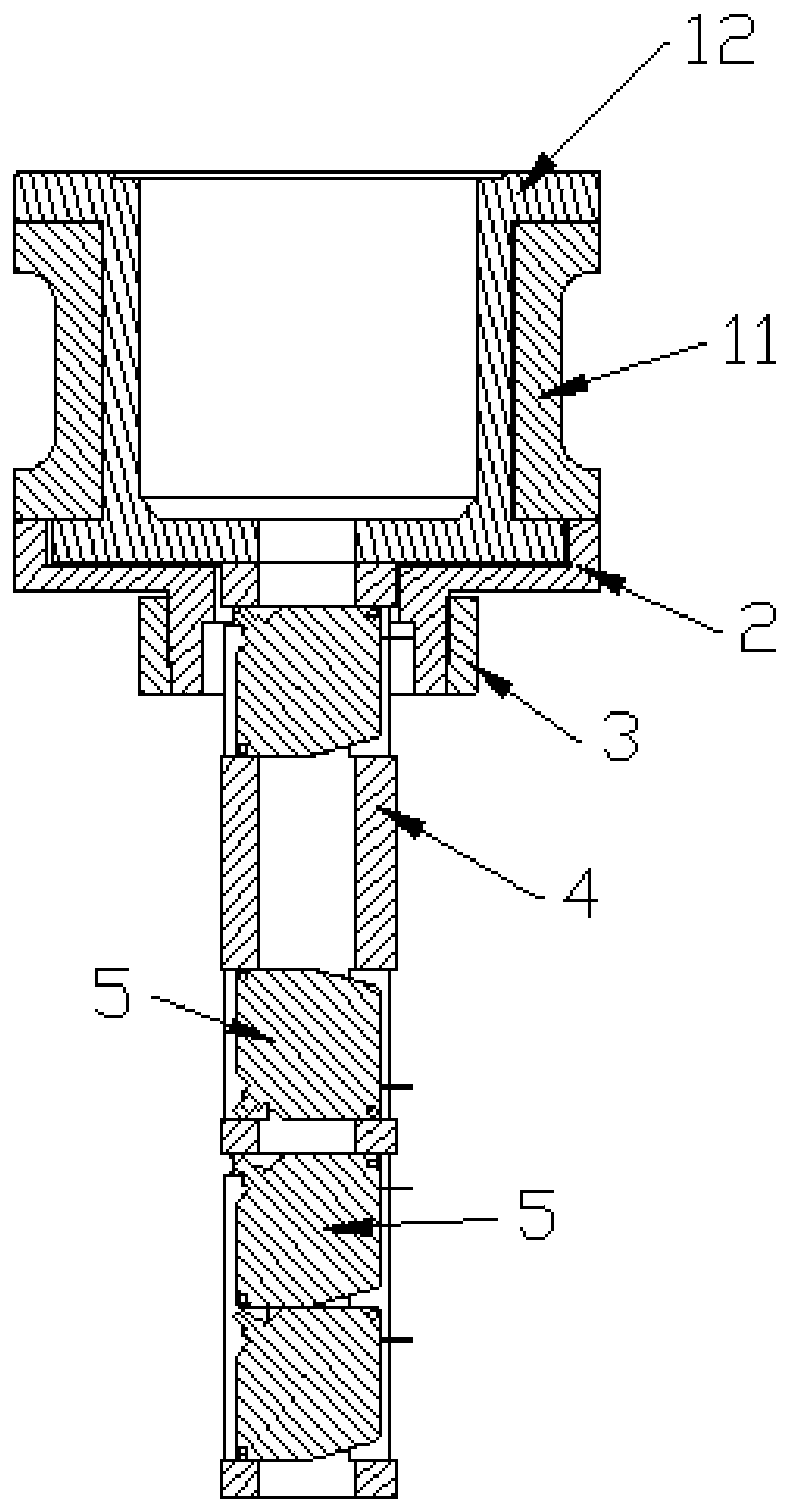

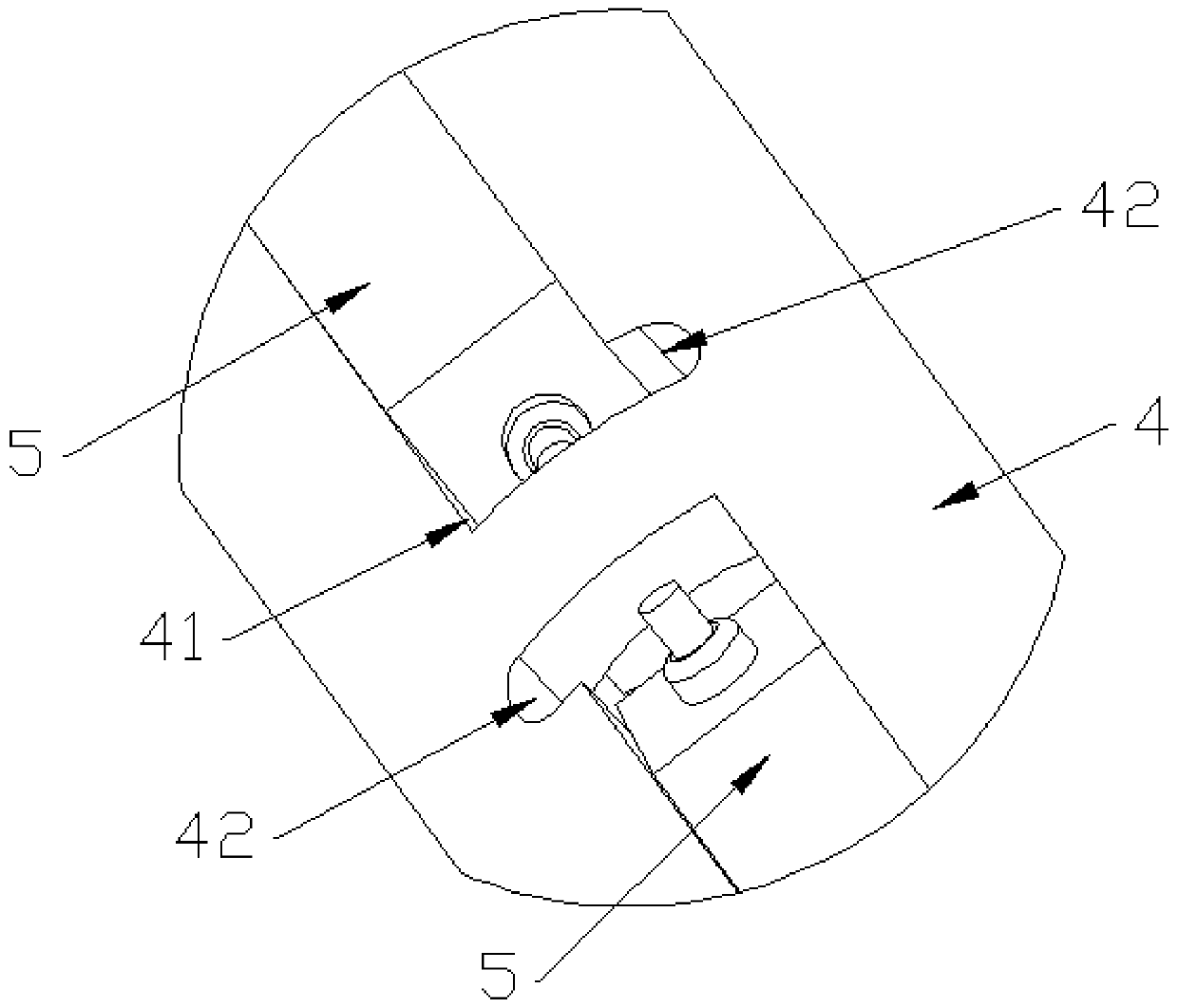

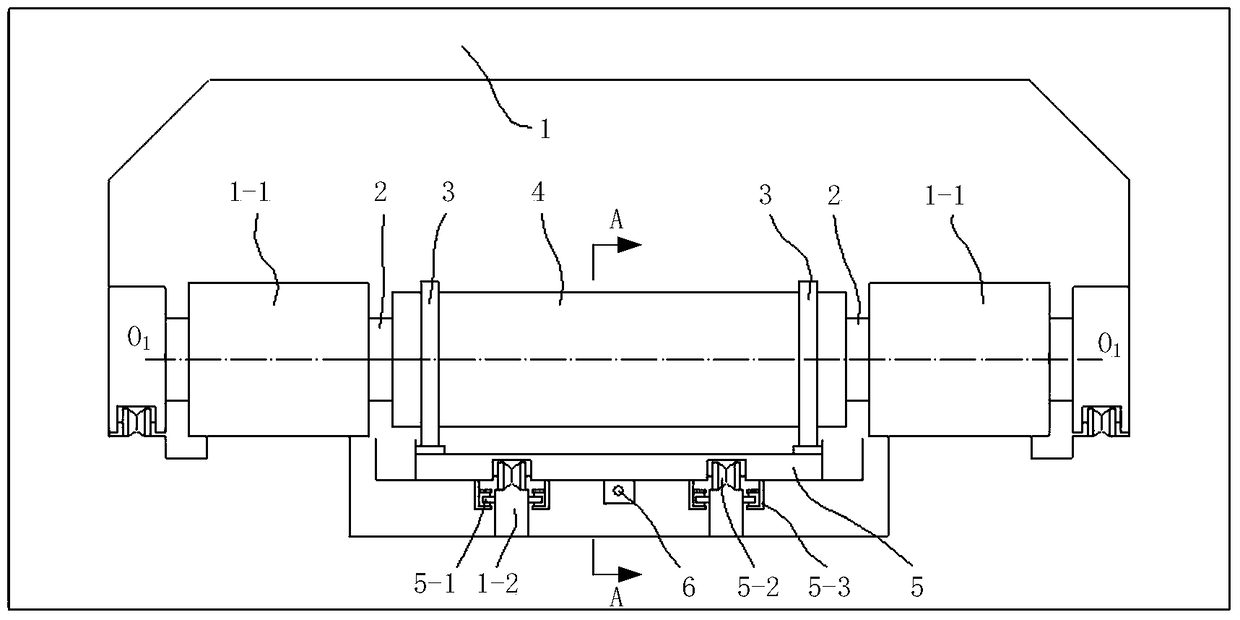

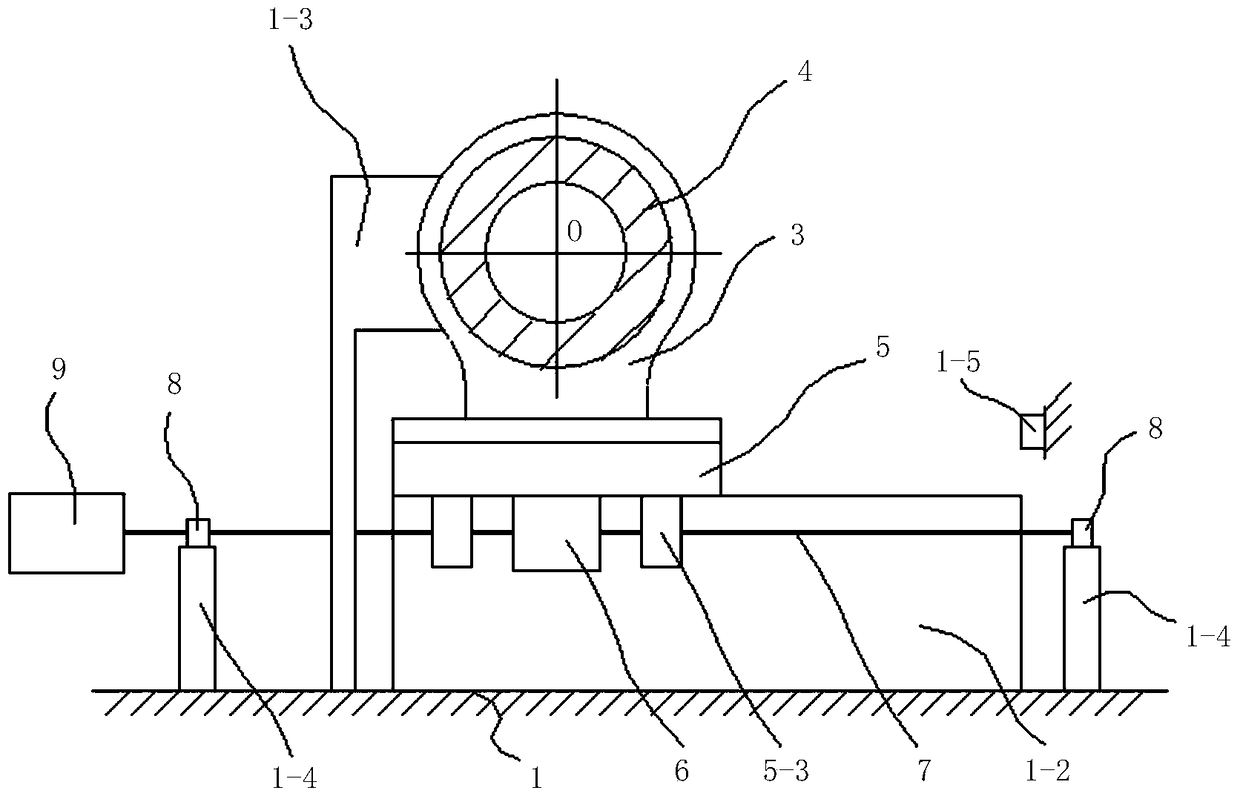

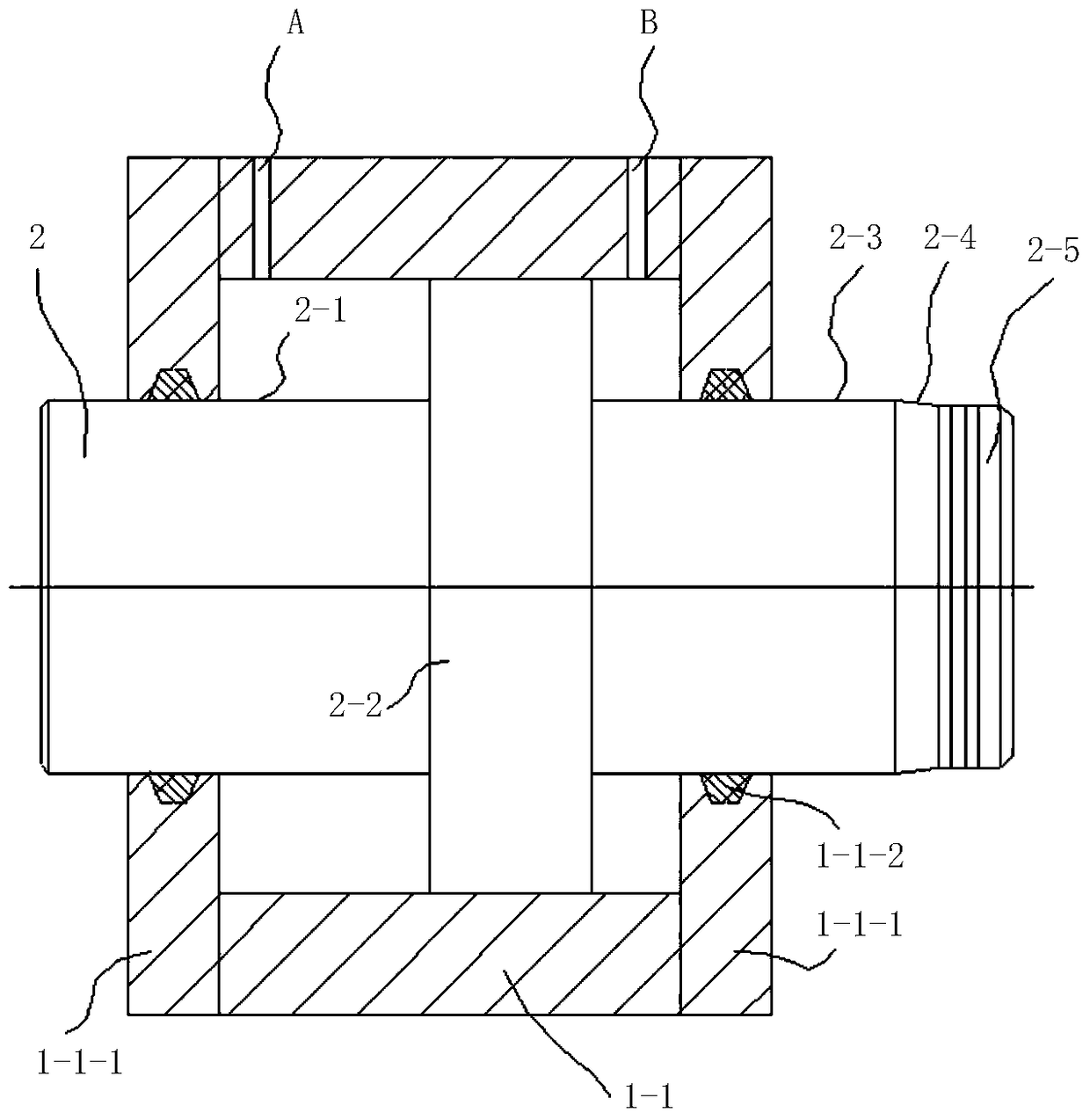

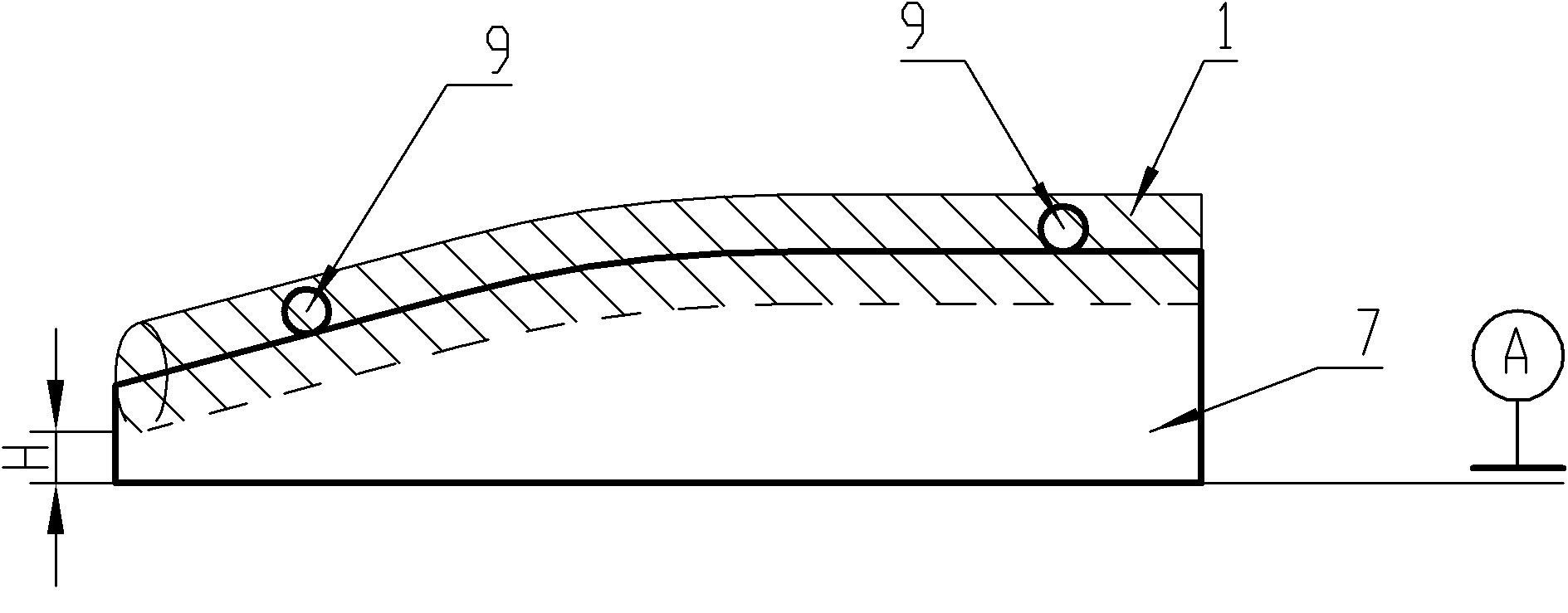

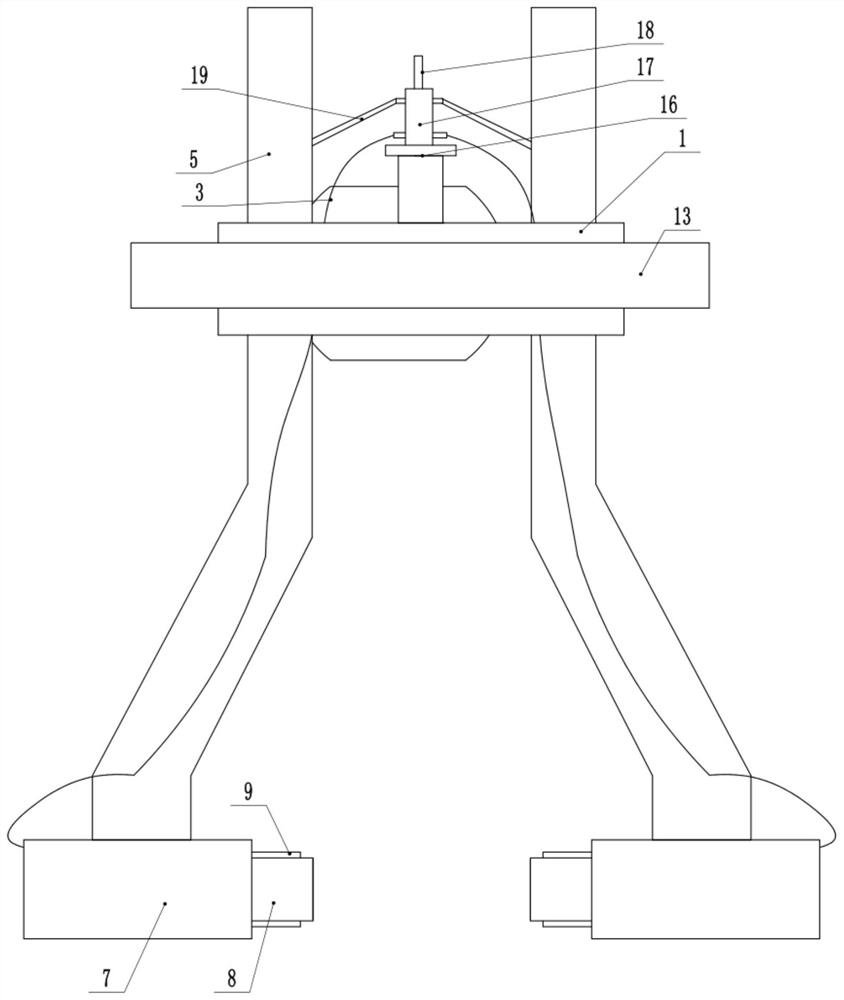

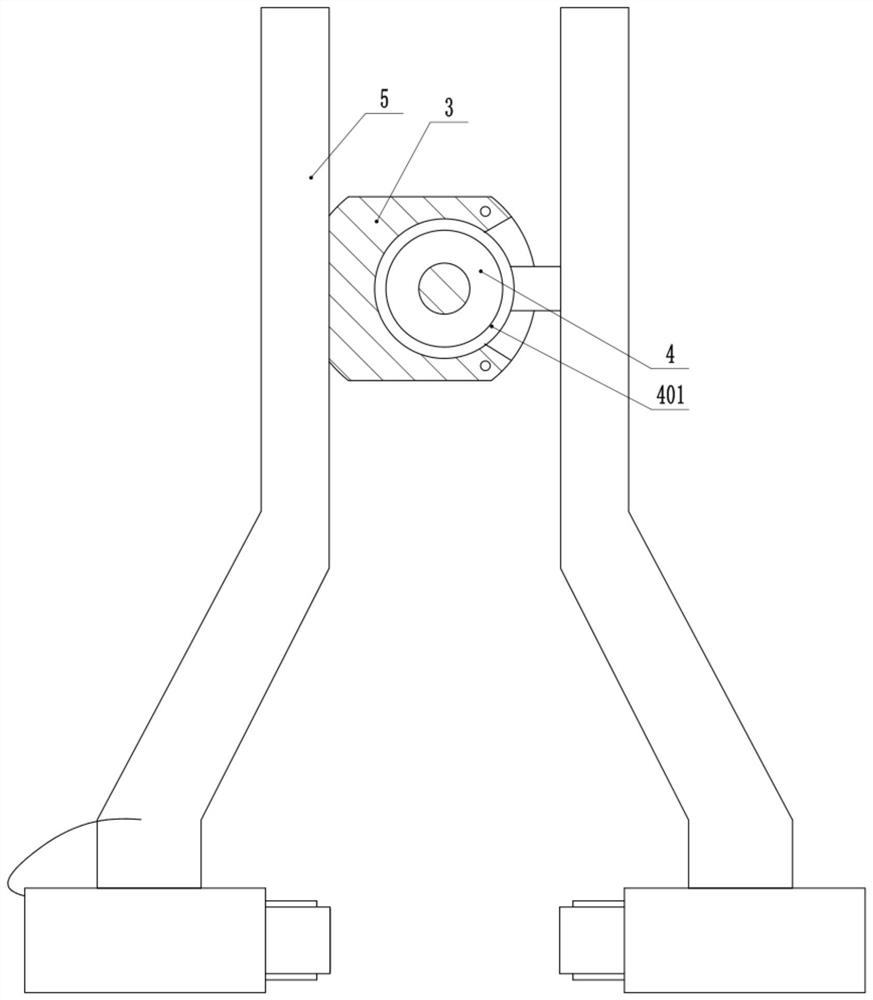

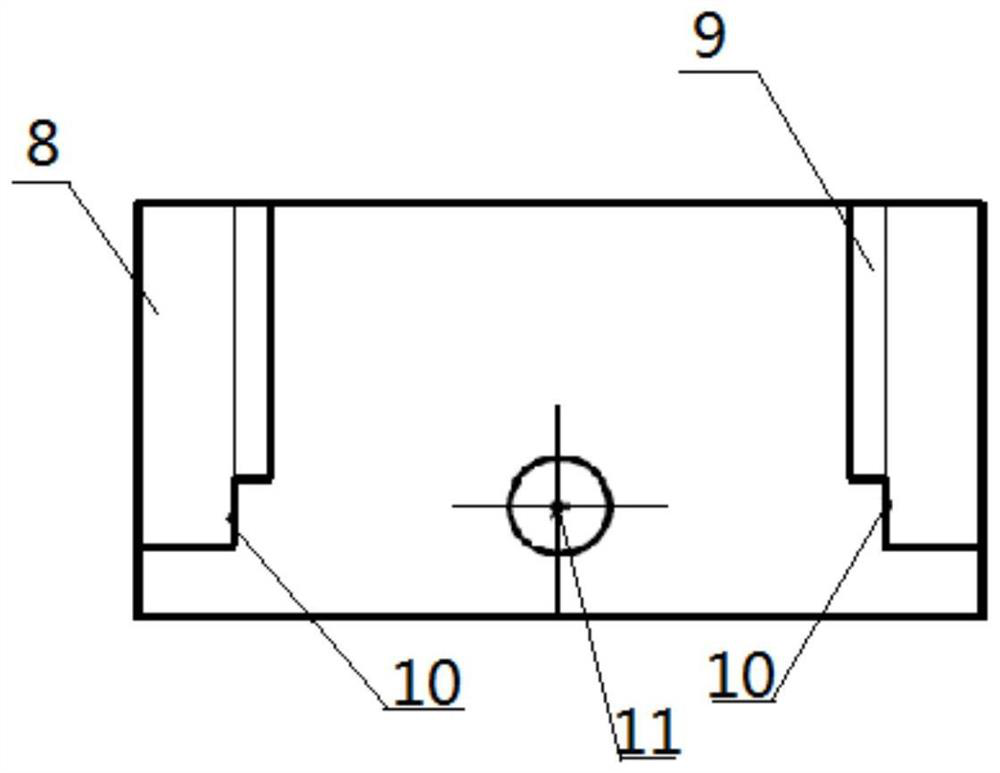

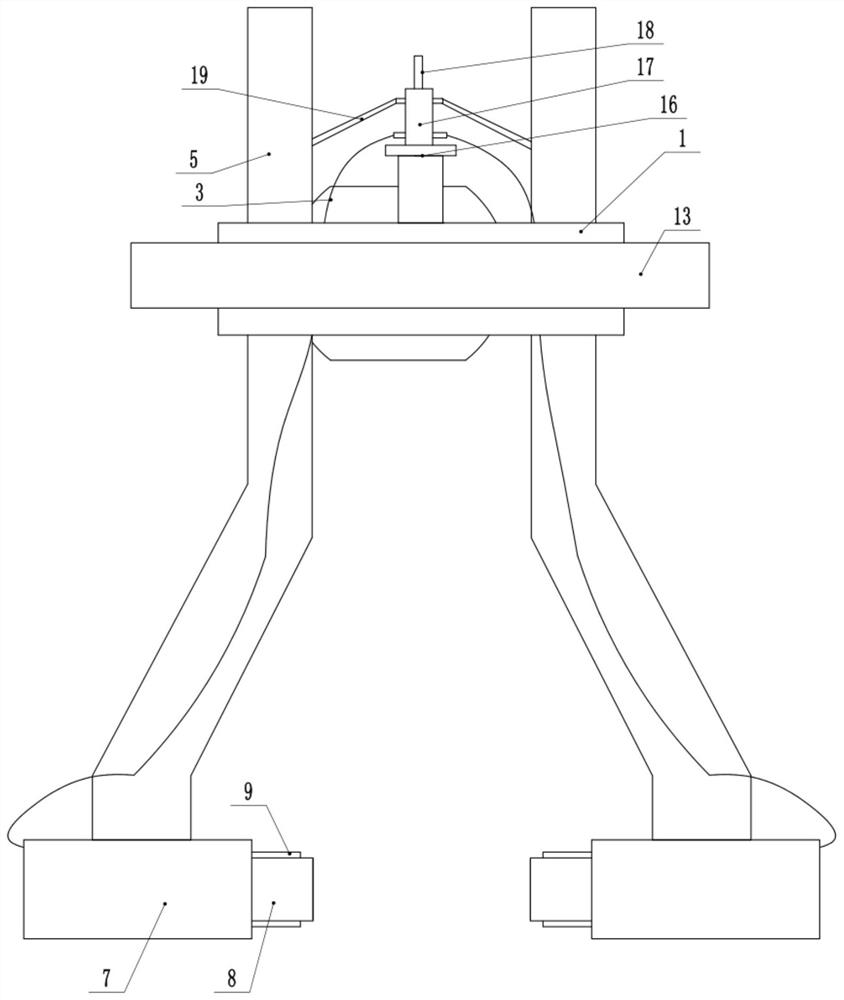

Horizontal-type ultra-high pressure sterilization equipment aligning mechanism

InactiveCN105077509AHigh Straight and Etc.Improve coincidence accuracyFood preservationUltra high pressureTurning frames

The invention provides a horizontal-type ultra-high pressure sterilization equipment aligning mechanism. According to the horizontal-type ultra-high pressure sterilization equipment aligning mechanism, cylinder bodies (1-1), trolley guide rail beams (1-2), aligning positioning blocks (1-3) and a frame (1) are connected into a whole, the axis of the left cylinder body (1-1) and the axis of the right cylinder body (1-1) are on the same straight line, and circle centers of concaved circular cambered surfaces of the left aligning positioning block (1-3) and the right aligning positioning block (1-3) and the axes of the left cylinder body (1-1) and the right cylinder body (1-1) are on the same straight line; the cylinder bodies (1-1) are matched with piston-type plugs (2) to form hydraulic oil cylinders, and the axes of the left piston-type plug (2) and the right piston-type plug (2) are on the same straight line; an ultra-high pressure barrel body (4) is fixed to a trolley frame (5) through barrel body fixing seats (3), the trolley frame (5) is pulled by a lead screw nut mechanism driven by a servo motor to move along guide rails on the trolley guide rail beams (1-2), positioning is achieved through contact between the barrel body fixing seats (3) and the aligning positioning blocks (1-3), and the situation that the axis of the ultra-high pressure barrel body (4) and the axes of the left piston-type plug (2) and the right piston-type plug (2) are on the same straight line is achieved.

Owner:CHINA AGRI UNIV

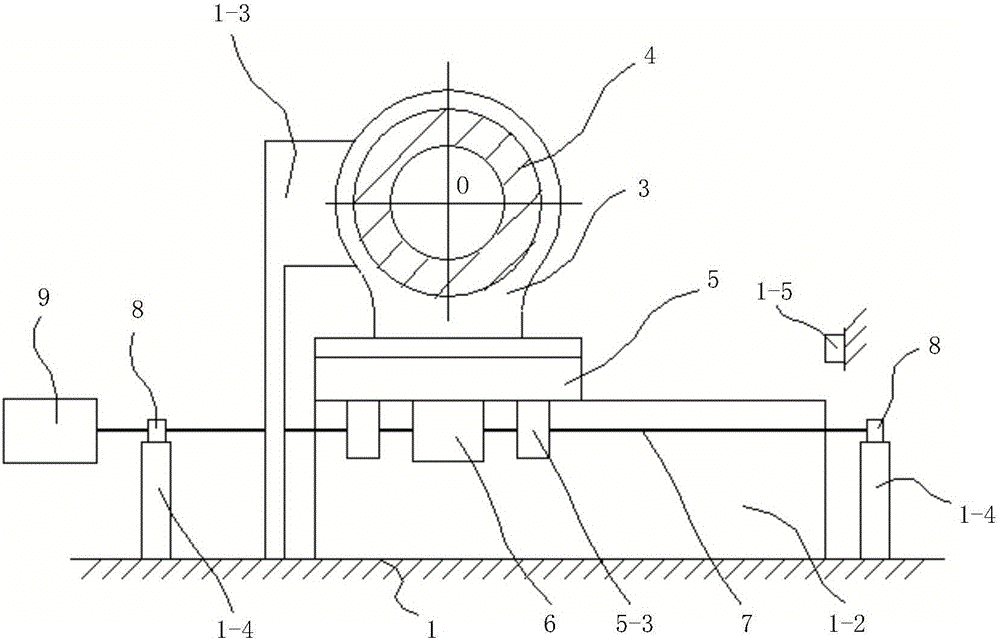

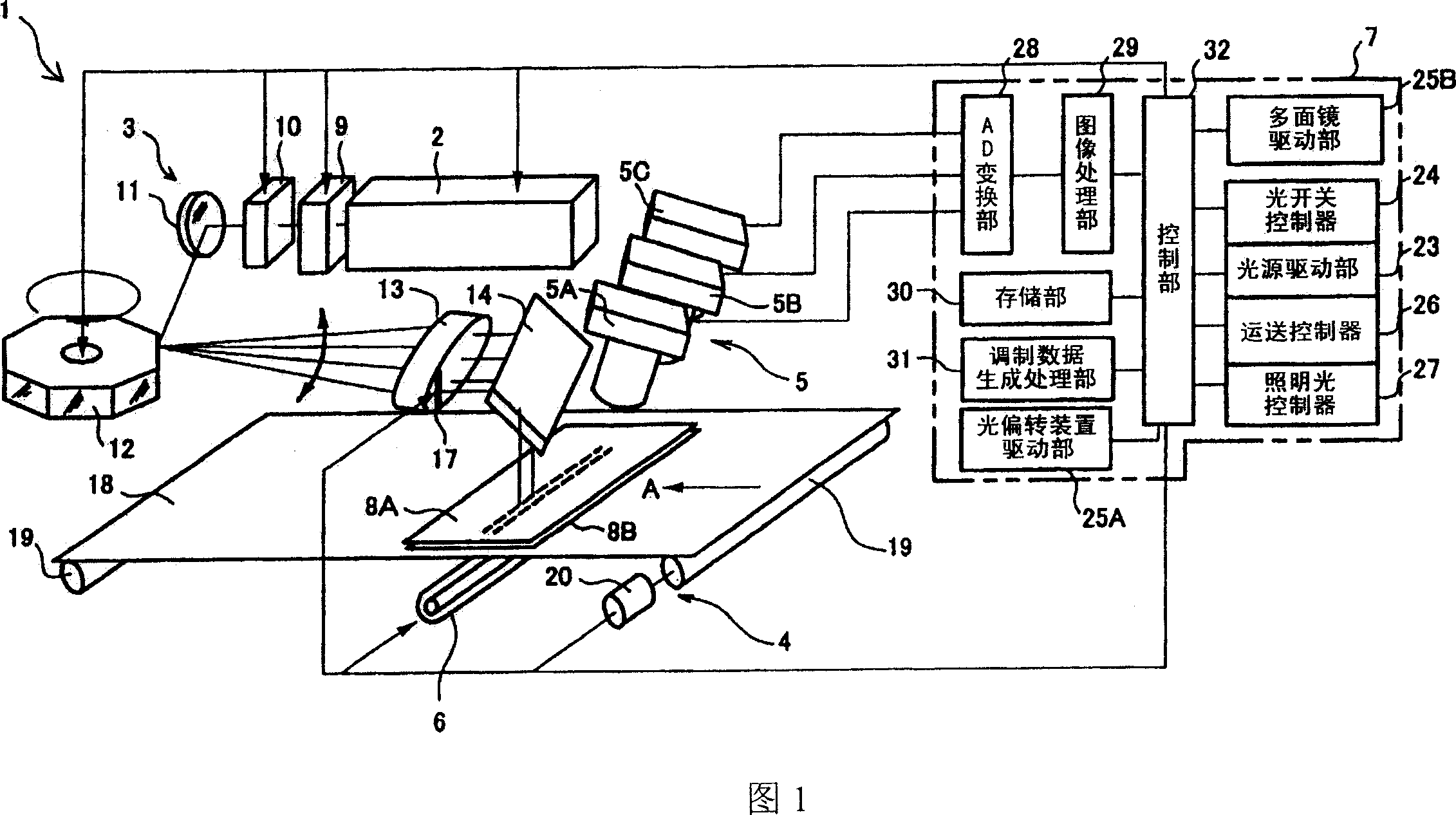

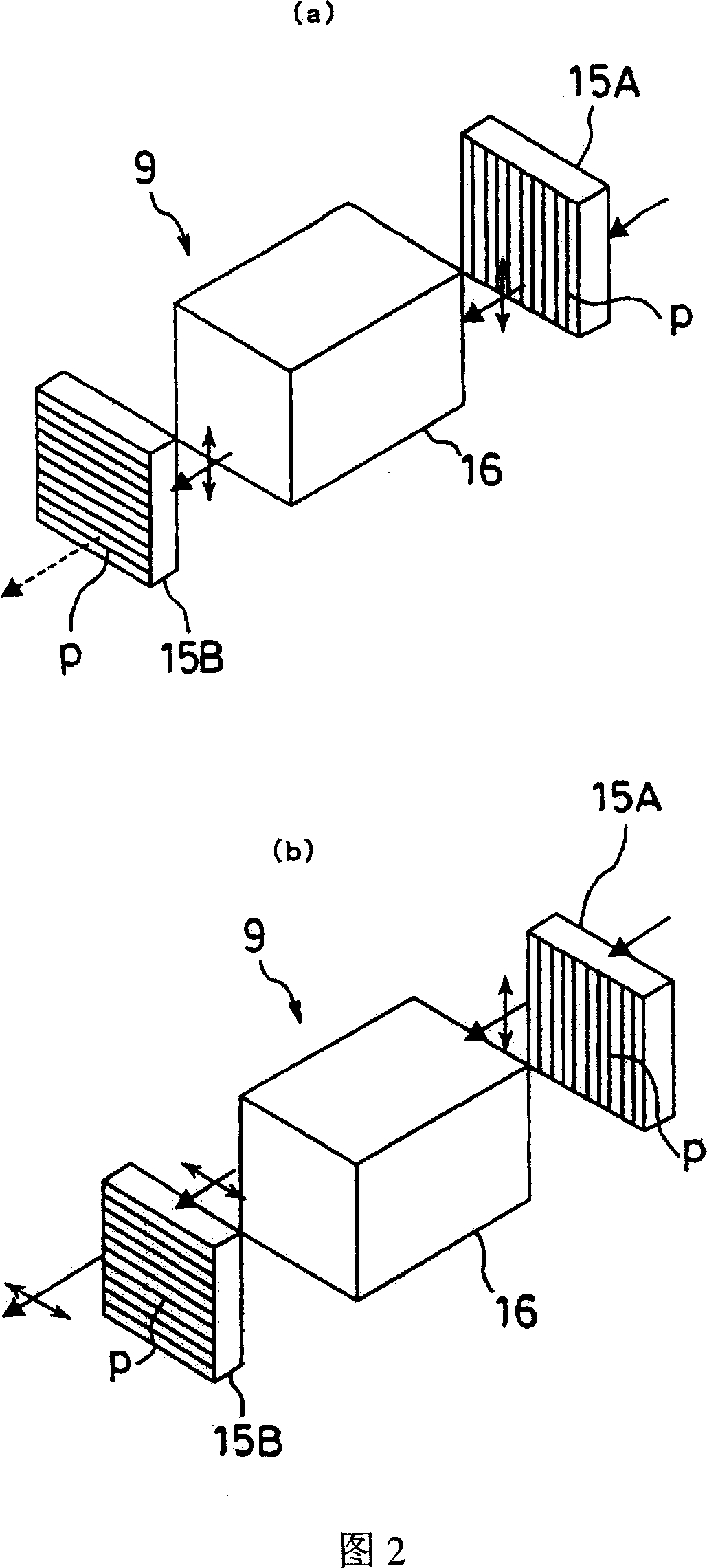

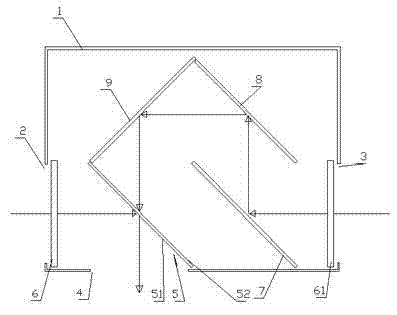

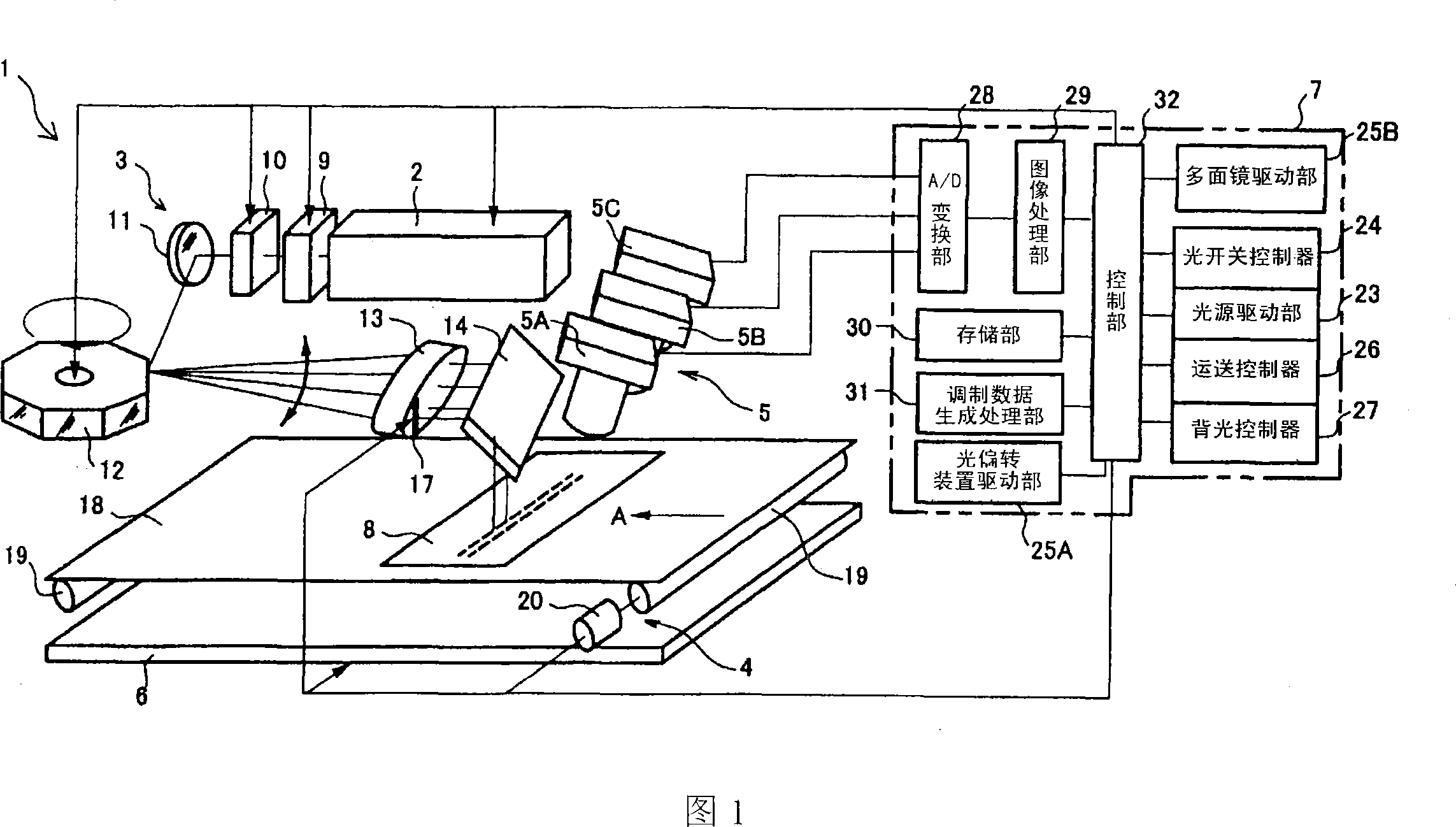

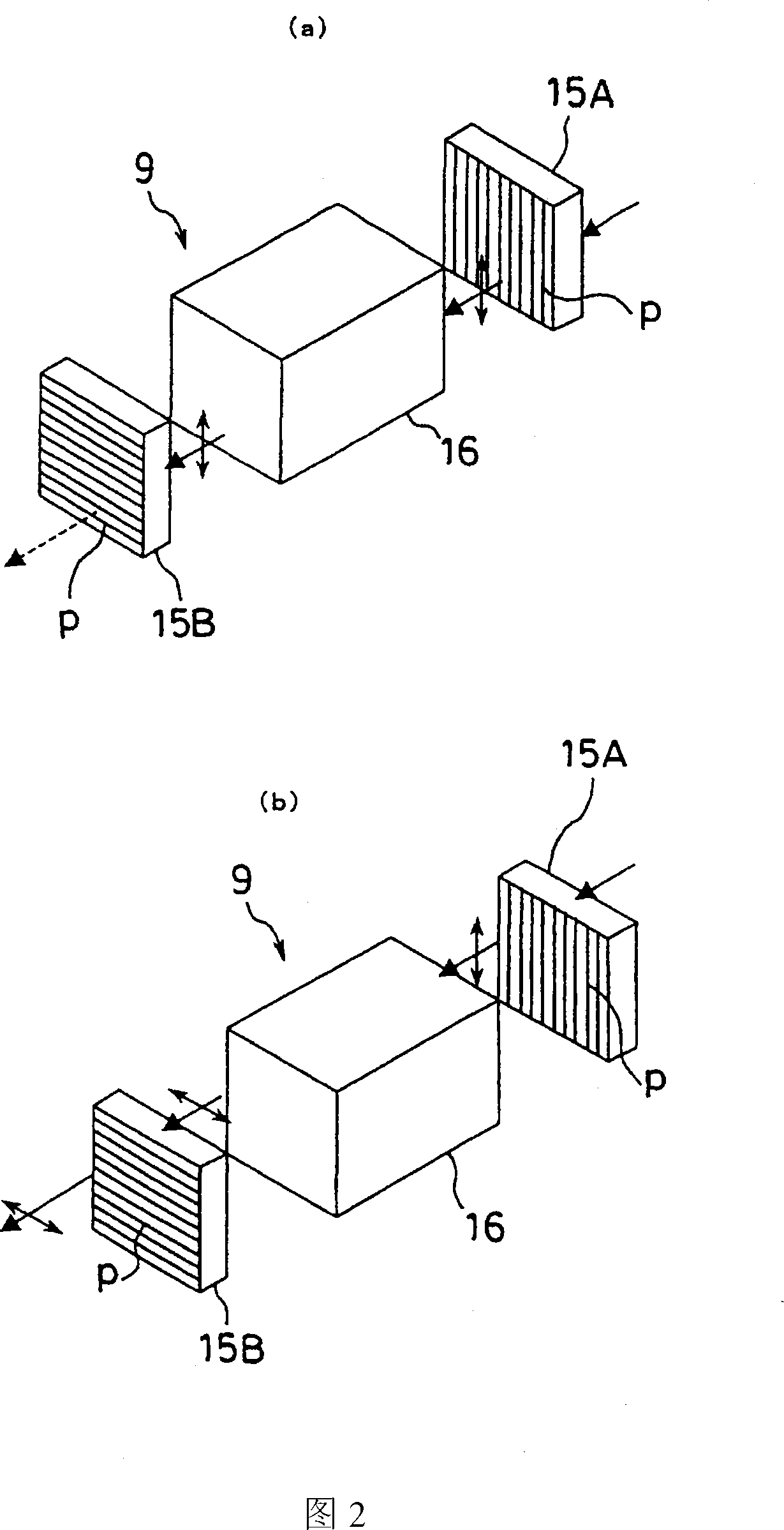

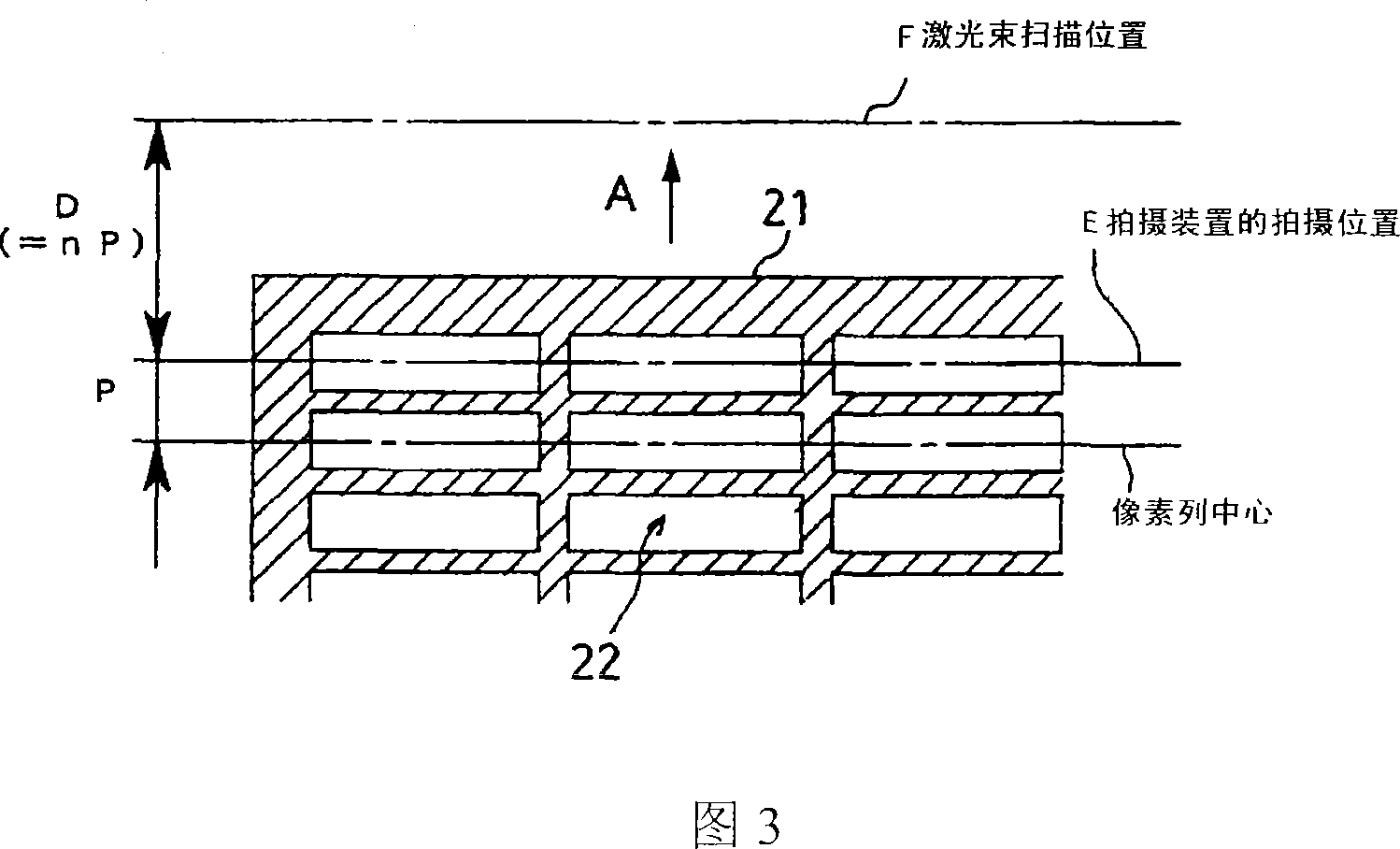

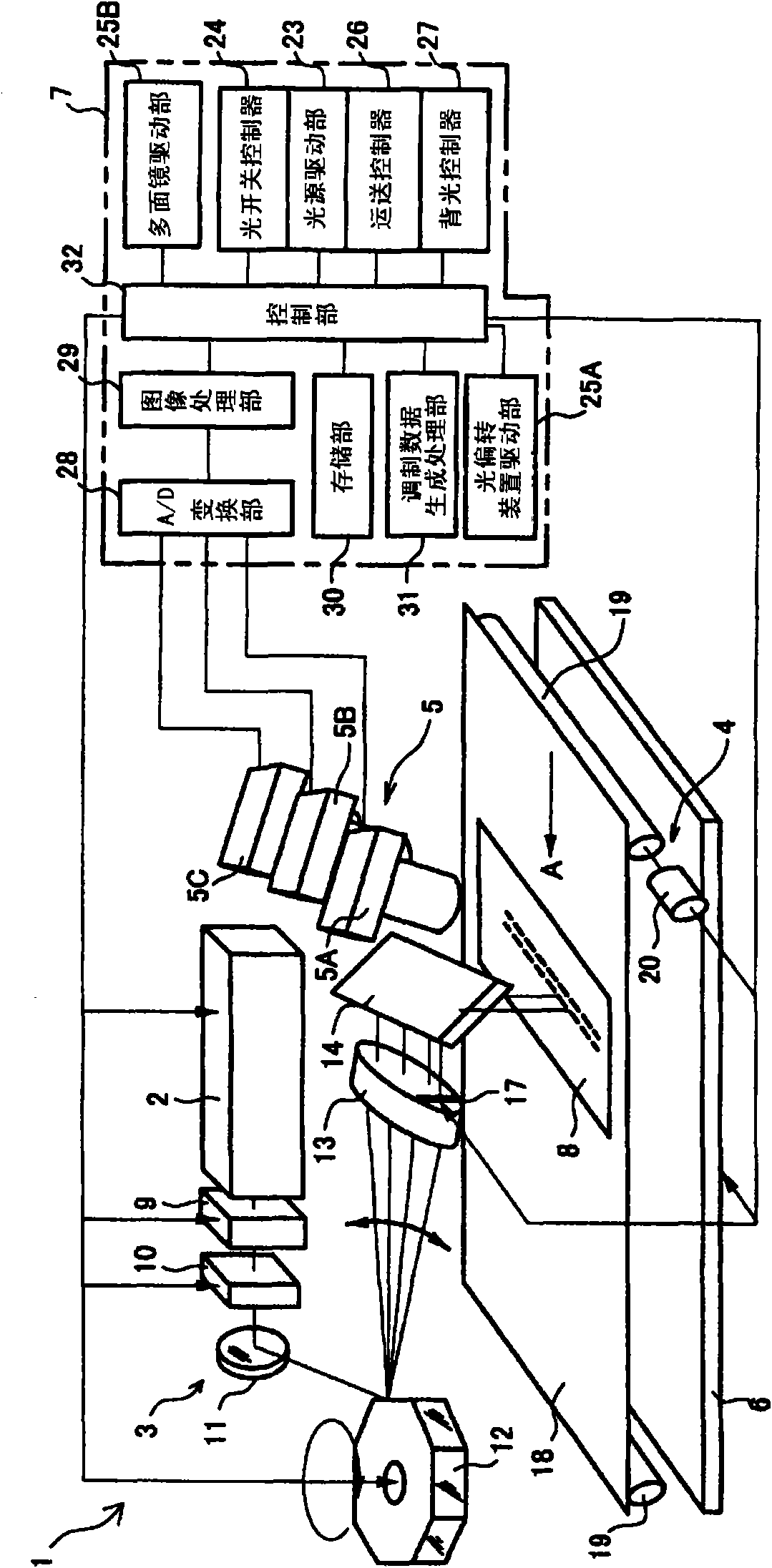

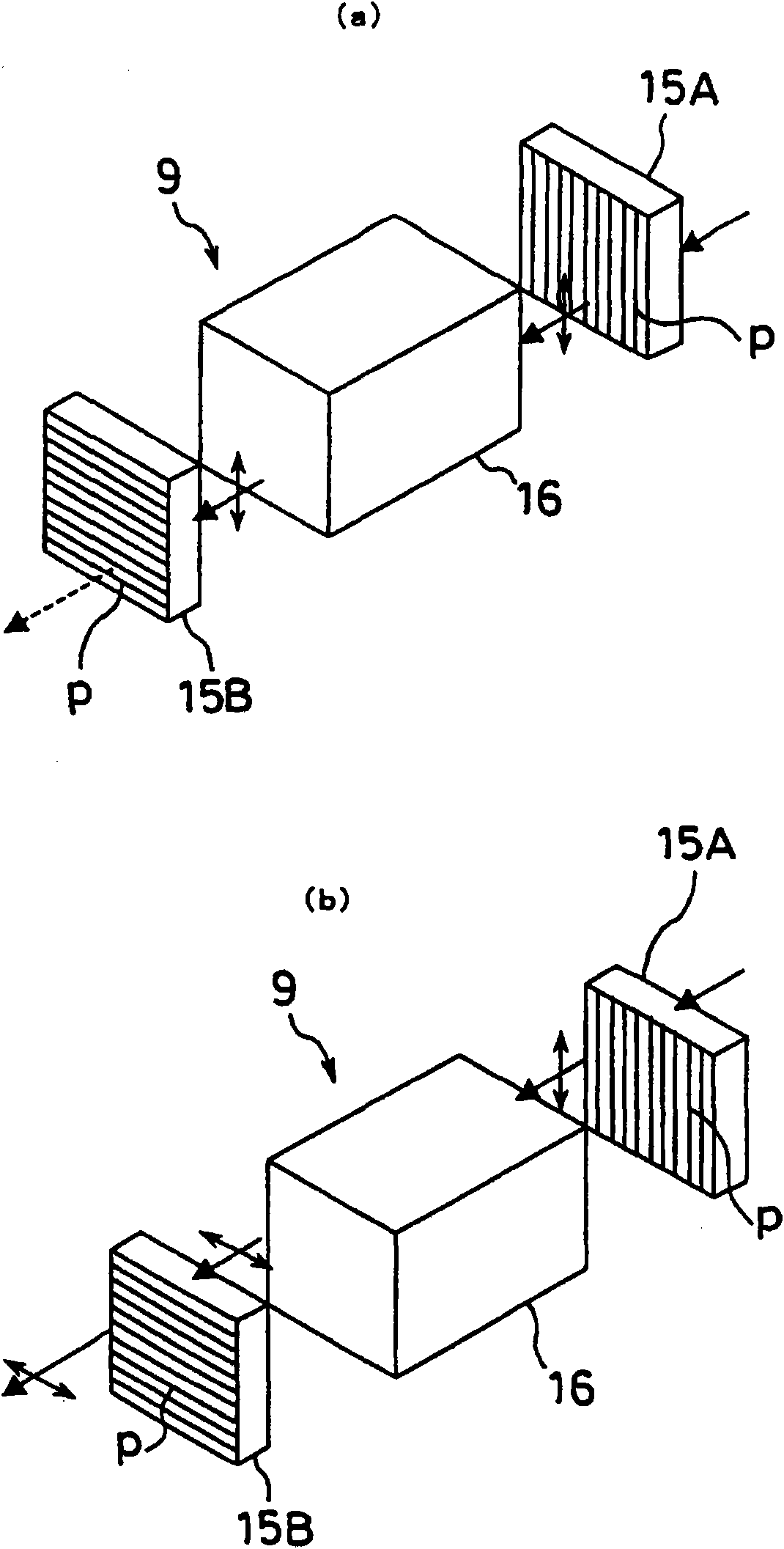

Exposure pattern forming method

ActiveCN1947064ALow costImprove coincidence accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringReference patterns

A reference glass board (8B) whereupon a reference pattern (P) to be an exposure position reference is previously formed is arranged on a lower side of a glass board (8A), and is transferred in an arrow A direction by a transfer means (4). The reference pattern (P) is illuminated from the lower part of the transfer means (4) by the illuminating means (6), and an image of the reference pattern (P) is picked up by an image pickup means (5) arranged on an upper part of the transfer means (4). An optical system control means (7) detects a reference position previously set to the reference pattern (P) of which the image is picked up by the image pickup means (5), and controls irradiation start or irradiation stop of laser beams, having the reference position as a reference. Then, a pixel of a black matrix to be a reference of a functional pattern formed by being laminated on the glass board (8A) is exposed at a prescribed position on the glass board (8A). Thus, alignment accuracy of the functional pattern is improved and cost increase of an exposure apparatus is suppressed.

Owner:V TECH CO LTD

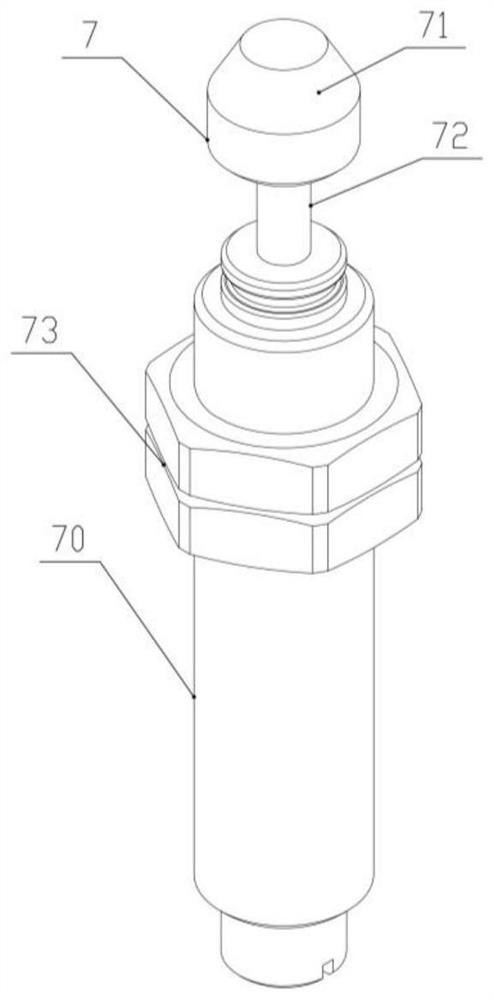

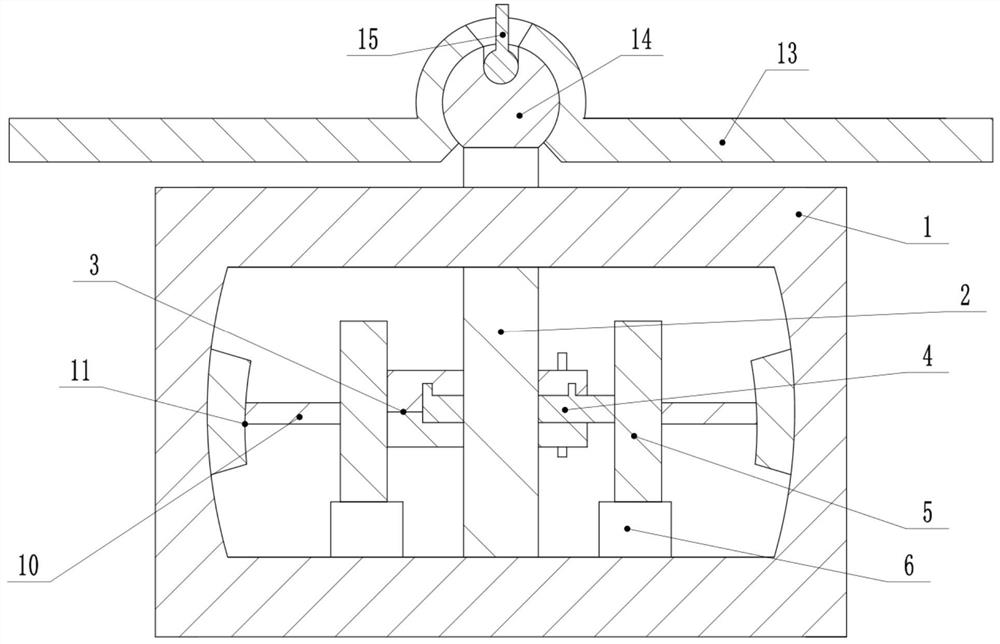

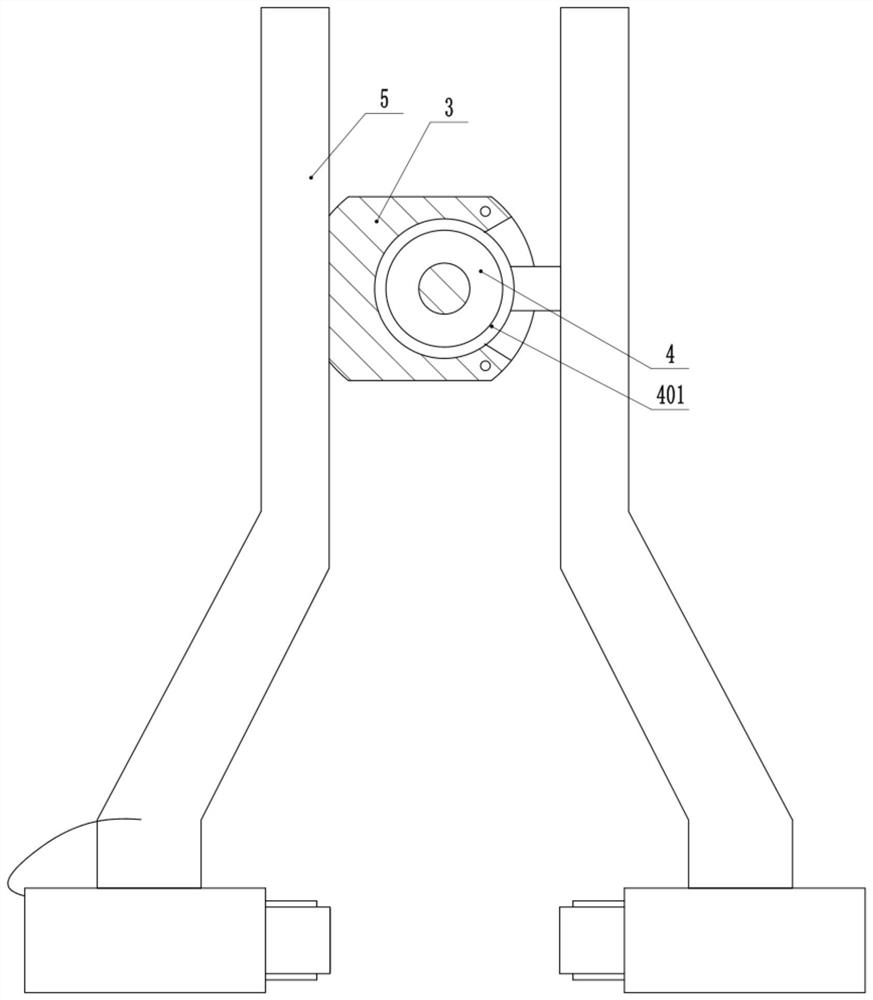

High-pressure rotor inner hole concentricity measuring instrument

PendingCN109916276ARealize clamping positioningGuaranteed accuracyMechanical measuring arrangementsMeasuring instrumentEngineering

The invention provides a high-pressure rotor inner hole concentricity measuring instrument and belongs to the field of detecting equipment. The instrument comprises an air floating turntable, a connecting sleeve, a measuring rod and a sensor; the air floating turntable comprises a rotating body and a fixing shaft sleeve; the measuring rod is detachably and vertically fixed at the lower end of therotating body; the sensor is embedded in the measuring rod and is corresponding to the inner cross section of a high-pressure rotor; a connecting sleeve is fixedly connected with the lower end of thefixing shaft sleeve; and the connecting sleeve is arranged at the outer periphery of the rotating body and fix the upper end of the high-pressure rotor. With the high-pressure rotor inner hole concentricity measuring instrument of the invention adopted, the concentricity of the high-pressure rotor can be quickly and accurately measured, and operation is convenient and quick.

Owner:天津中精微仪器设备有限公司

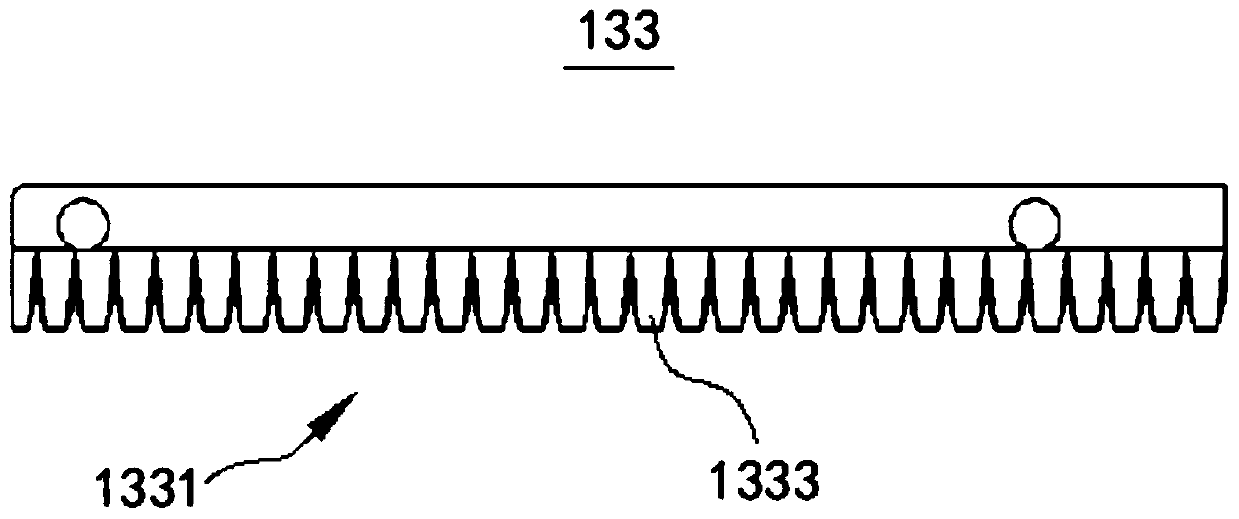

Pole piece cutter mechanism and battery cell production device

PendingCN111215905AReduce powder shedding rateQuality improvementElectrode manufacturing processesOther manufacturing equipments/toolsEngineeringPole piece

The invention discloses a pole piece cutter mechanism and a battery cell production device, and relates to the technical field of battery cell production. The pole piece cutter mechanism comprises a rack, a creasing assembly and a cutting assembly, the creasing assembly and the cutting assembly are arranged on the rack, and the rack is used for bearing a pole piece; the creasing assembly is used for creasing the pole piece once every time the pole piece moves by a preset piece width relative to the rack; and the cutting assembly is used for cutting off the pole piece when the pole piece movesby a preset number of preset piece widths relative to the rack. According to the pole piece cutter mechanism, the pole piece can be creased, so that the powder falling rate of the pole piece is reduced to a great extent, the lamination overlapping precision can be improved, and the quality of the battery cell is further improved.

Owner:GEESUN AUTOMATION TECH

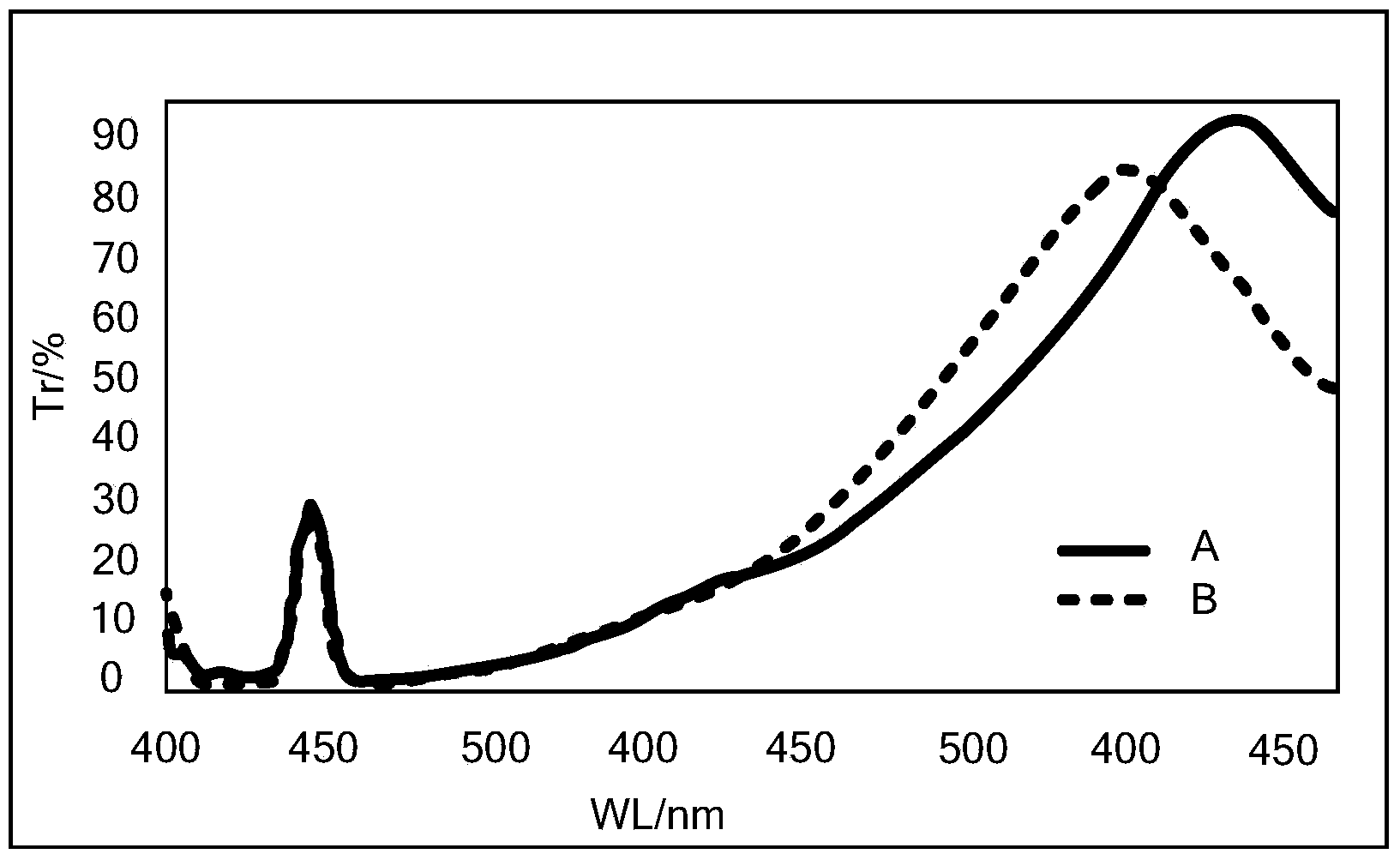

Grid line printing method of solar cell

InactiveCN106891629AImprove coincidence accuracyImprove printing qualityOther printing apparatusGraphicsSolar cell

The invention discloses a grid line printing method of a solar cell. Through changing a second-time printed graph, equipment prints a bottom-layer graph and a second-layer graph through regular calibration, and displacement of a rear piece is compensated through the line width difference and offset of grid lines in the printed graphs to increase the overlap ratio of the grid lines, so that the printing quality and efficiency are improved.

Owner:SUZHOU RUNYANG PHOTOVOLTAIC TECH

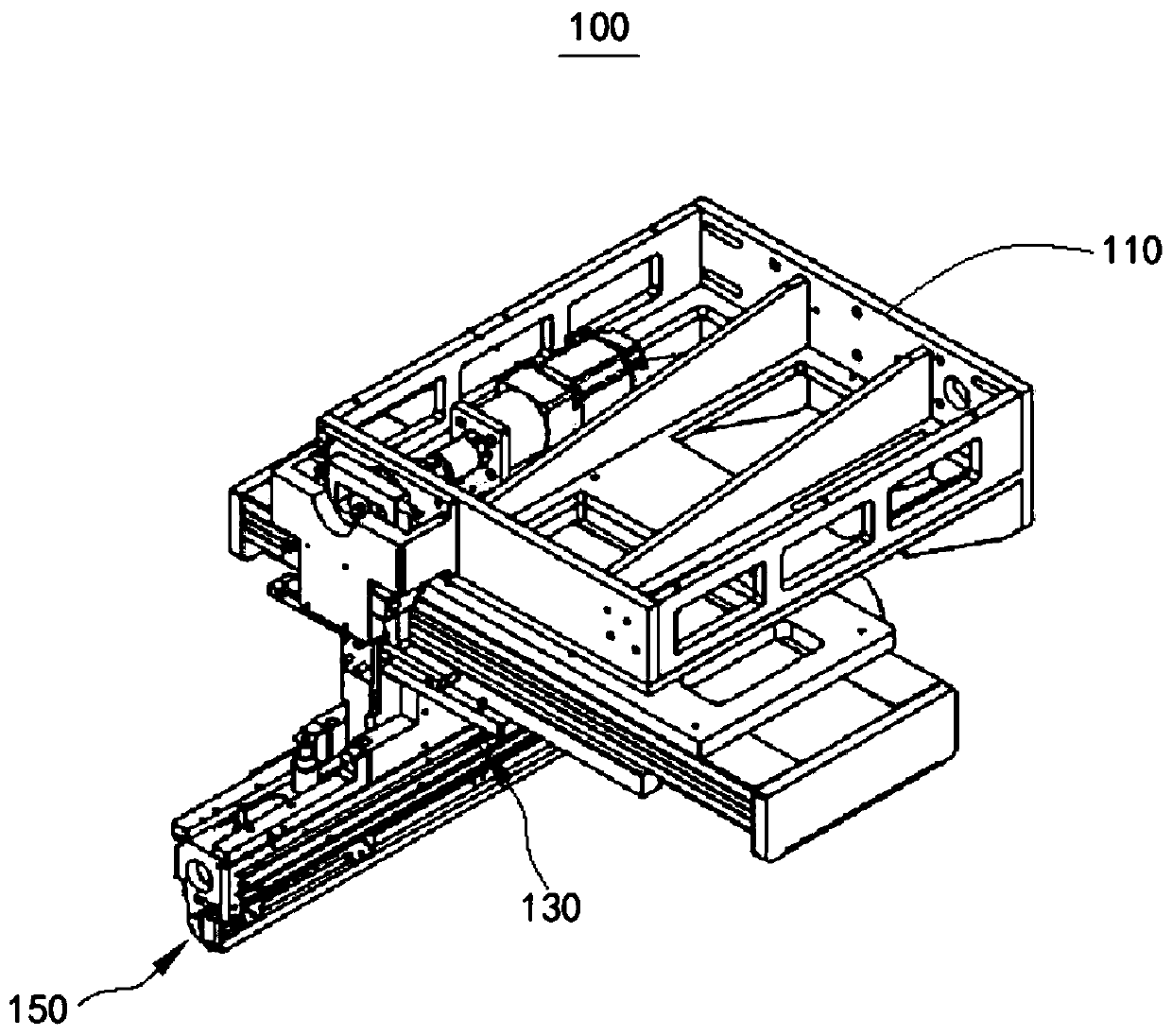

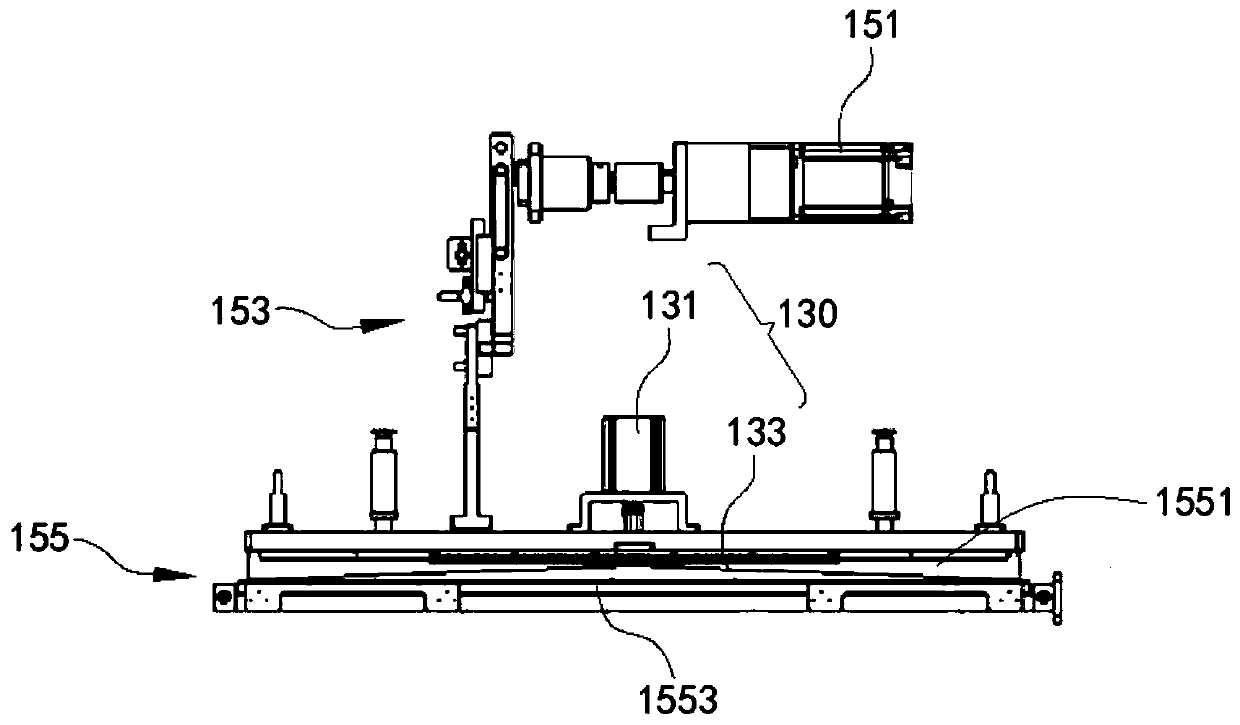

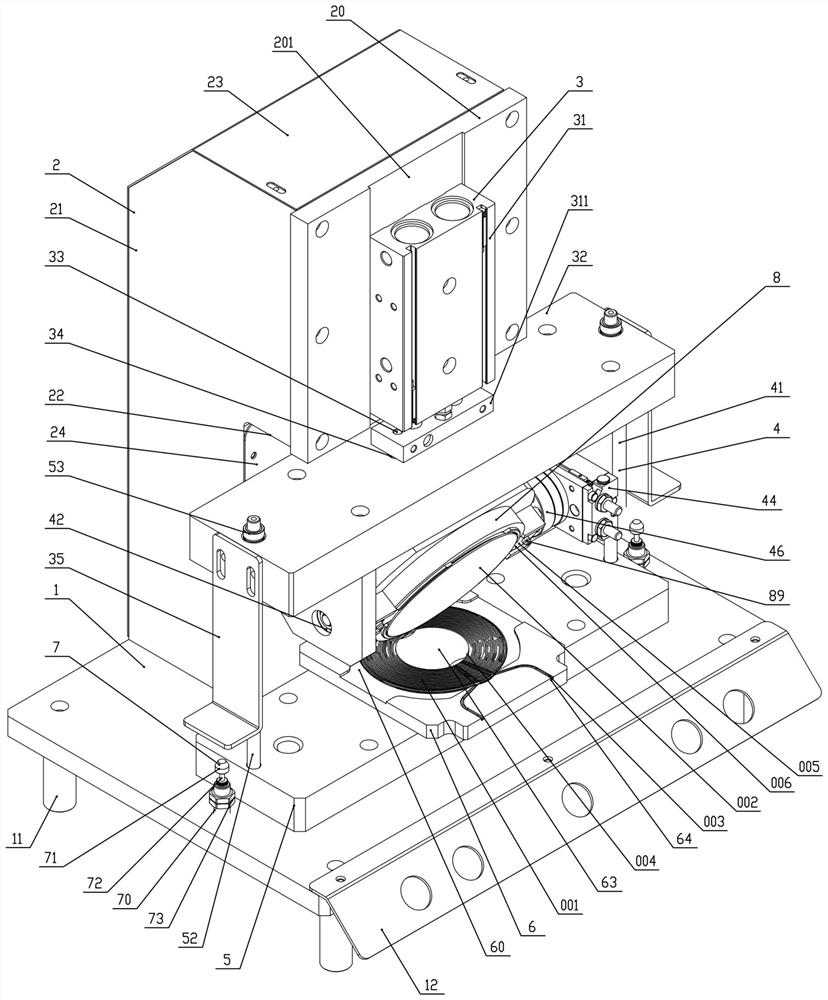

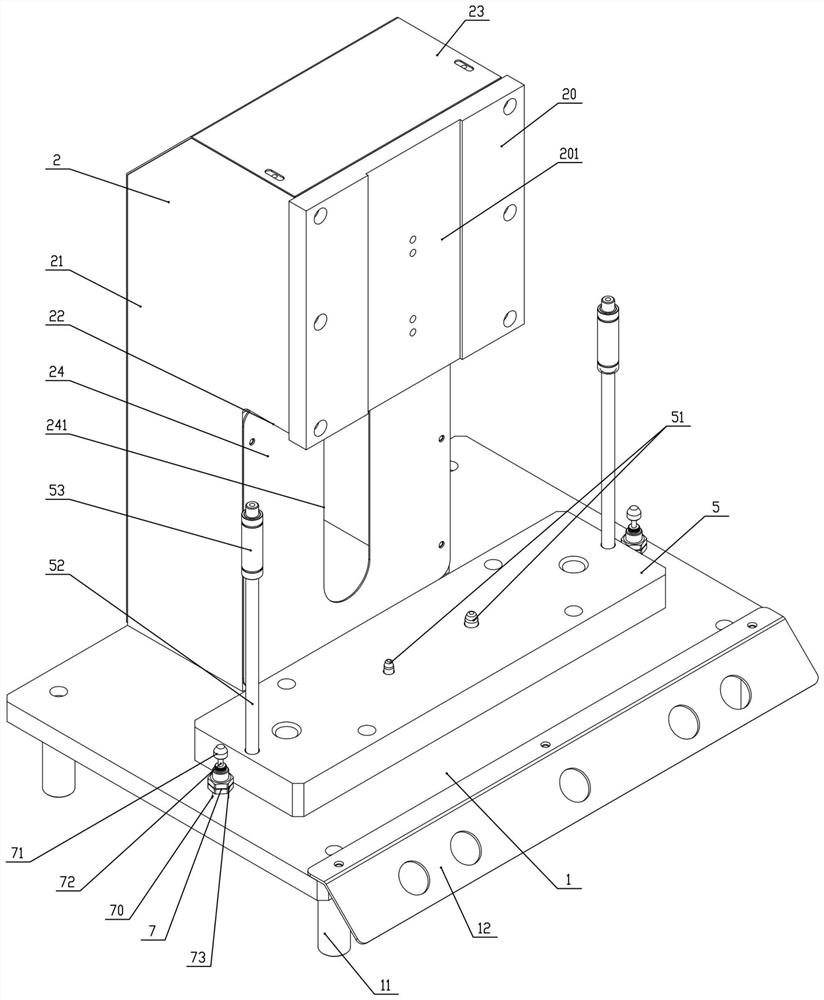

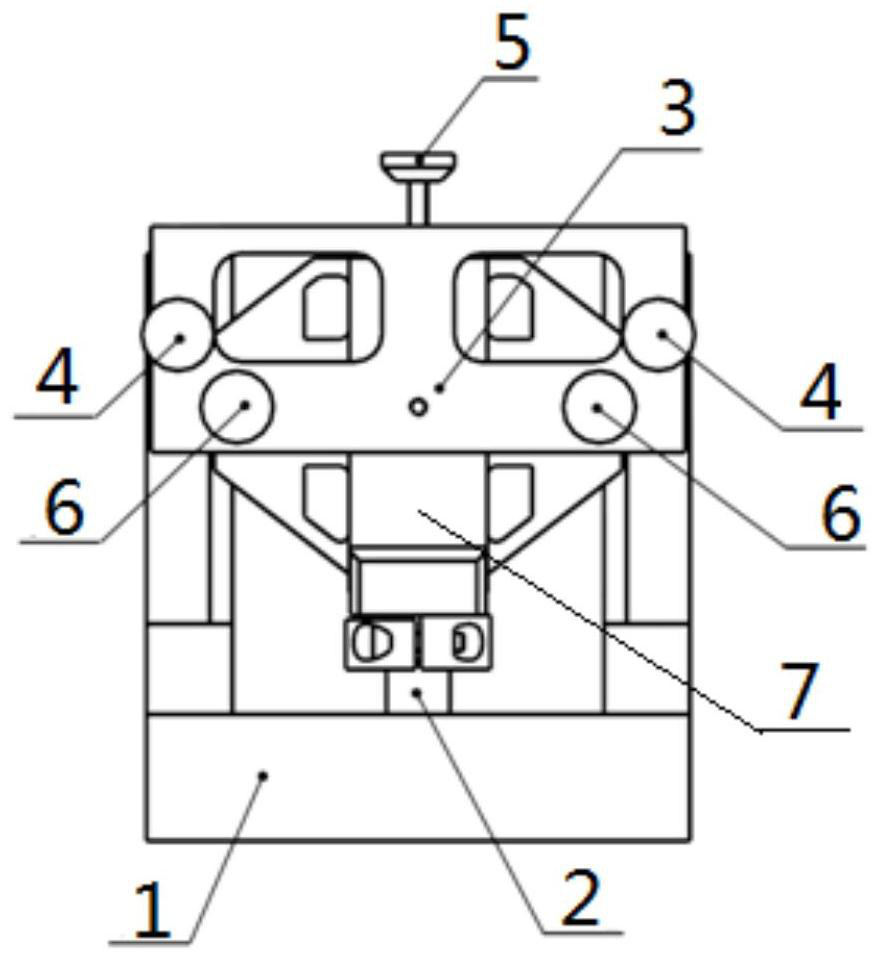

Assembling device of wireless charging coil module

PendingCN111799078AEffective positioningEasy to placeInductances/transformers/magnets manufactureStructural engineeringMechanical engineering

The invention discloses an assembling device of a wireless charging coil module. The assembling device comprises a lower platform, an elastic pressing part and a rotating part. A positioning base table is installed at the front end of the lower platform, the rear end of the lower platform is perpendicularly connected with a vertical frame, a plurality of positioning pins are arranged in the middleof the positioning base table and can be inserted into first positioning holes of the assembling carrier, and guide shafts on the positioning base table are in sliding fit with linear bearings. Two buffer guide shafts are fixed on a moving plate of an assembly cylinder of the elastic pressing part, buffer springs sleeve the outer walls of the middles of the buffer guide shafts, and linear bearings are fixed at two ends of an upper main plate respectively. The rotating part comprises two parallel lugs, a rotating air cylinder is fixed to the inner side face of one lug, one end of the upper sucker is fixed to an output rotary disc of the rotating air cylinder, and the other end of the upper sucker is rotationally connected with the other lug. The device has the effects of being automatic inassembling, high in speed and high in yield.

Owner:LINGSHENGCHENG TECH JIANGSU CO LTD

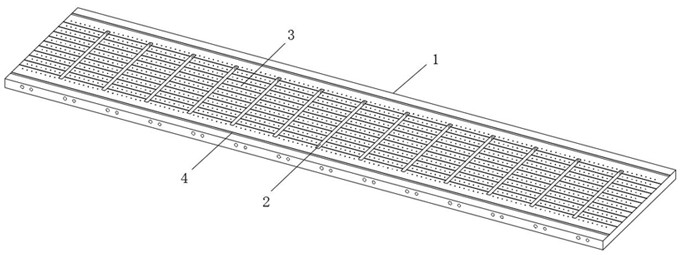

Bottom plate welding device and battery string production equipment

InactiveCN113275687ASmall diameterHigh position coincidence accuracyFinal product manufactureHeating appliancesSilver pasteElectrical battery

The invention provides a welding bottom plate device and battery string production equipment, and relates to the technical field of battery string production. The welding bottom plate device comprises a welding bottom plate body, a plurality of parallel welding wire tail clamping jaw receding grooves are formed in the upper surface of the welding bottom plate body, a plurality of battery piece negative pressure adsorption holes distributed in a rectangular array are formed in the surface of the welding bottom plate body in a penetrating mode, and high-temperature-resistant strong magnet pre-buried grooves are formed in the upper surface of the welding bottom plate body and located on the two sides of the welding wire tail clamping jaw receding groove. According to the bottom plate welding device and the battery string production equipment, a welding wire positioning groove is formed in a welding bottom plate, welding wires are accurately positioned, the position coincidence precision of main grid lines and the welding wires of a battery piece is higher, the width of the main grid lines on the front face and the back face of the battery piece can be smaller, silver paste is saved, the diameter of the welding wires can be reduced, the welding wires with the same weight can be machined to be longer, more battery strings can be welded, and the use cost of the battery piece and the welding wires is greatly reduced.

Owner:深圳光远智能装备股份有限公司

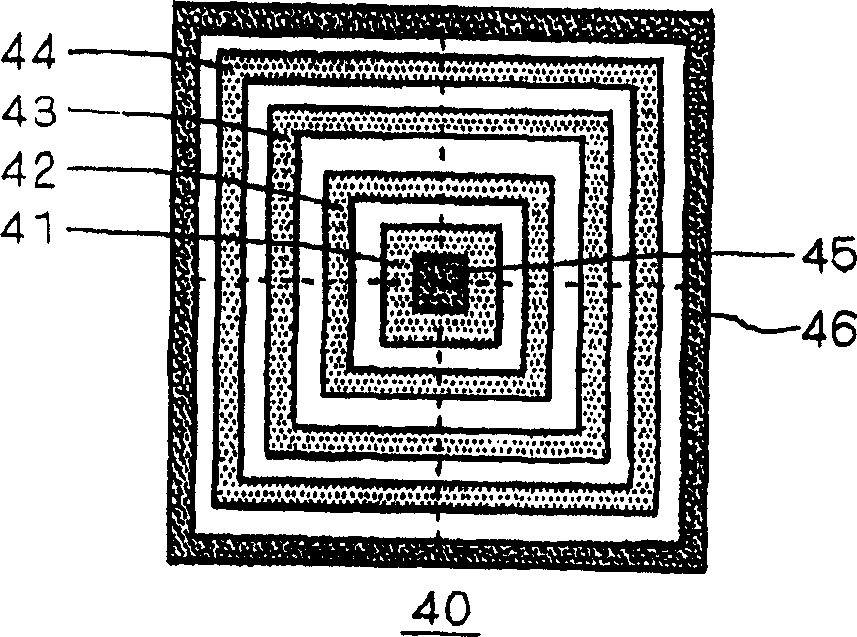

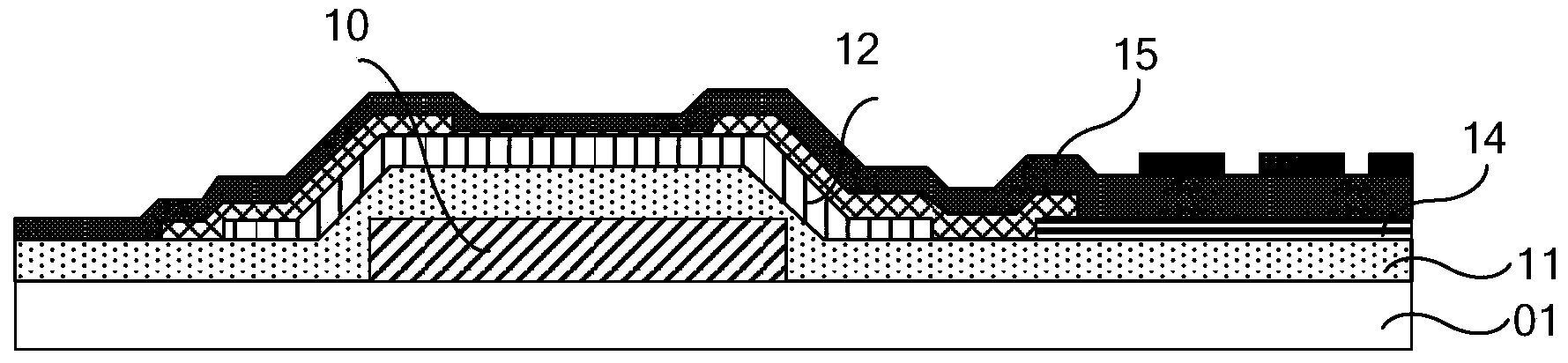

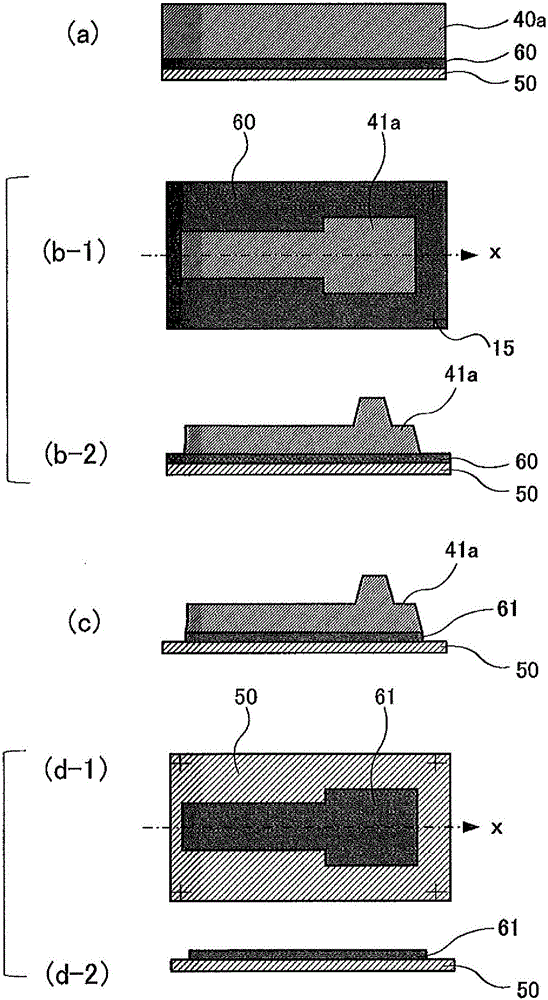

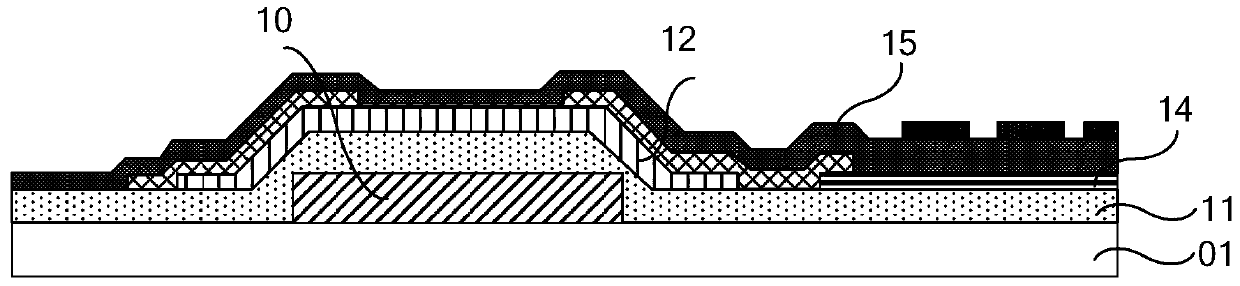

Substrate, alignment mark manufacturing method thereof and display device

ActiveCN103715179AImprove visibilityImprove coincidence accuracySemiconductor/solid-state device detailsSolid-state devicesVisibilityDisplay device

The embodiment of the invention provides a substrate, an alignment mark manufacturing method thereof and a display device, and relates to the display technical field. With the substrate, the alignment mark manufacturing method thereof and the display device of the invention adopted, the visibility of the alignment mark can be improved. The substrate includes a first film layer and a second film layer positioned on the surface of the first film layer; at least one alignment mark exists between the first film layer and the second film layer; and the thickness of a portion of the second film layer which is corresponding to the position of the alignment mark is smaller than the thickness of portions of the second film layer which are corresponding to positions except the position of the alignment mark.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Printing accuracy detection system

InactiveCN108407479ATransmission speed adjustmentEasy to insertOther printing apparatusMetal working apparatusPunchingEngineering

The invention relates to the field of printing, in particular to a printing accuracy detection system which comprises a printing device. The printing device comprises a case, a first printing roller and a second printing roller, wherein an inlet and an outlet are formed in the case; a first conveying wheel and a second conveying wheel are located on the inlet of the case; a first printing roller and a second printing roller are horizontally and rotatably arranged in the case and are in parallel; a first installation hole is formed in the side surface of the first printing roller; a first punching cutter is arranged in the first installation hole; a first tension spring is arranged between the first punching cutter and the first installation hole; a second installation hole is formed in theside surface of the first printing roller; a second punching cutter is arranged in the second installation hole; and a second tension spring is arranged between the second punching cutter and the second installation hole. According to the scheme, positions of printed multi-layer bills can be detected, and the processing accuracy of the bills is improved.

Owner:重庆华康印务有限公司

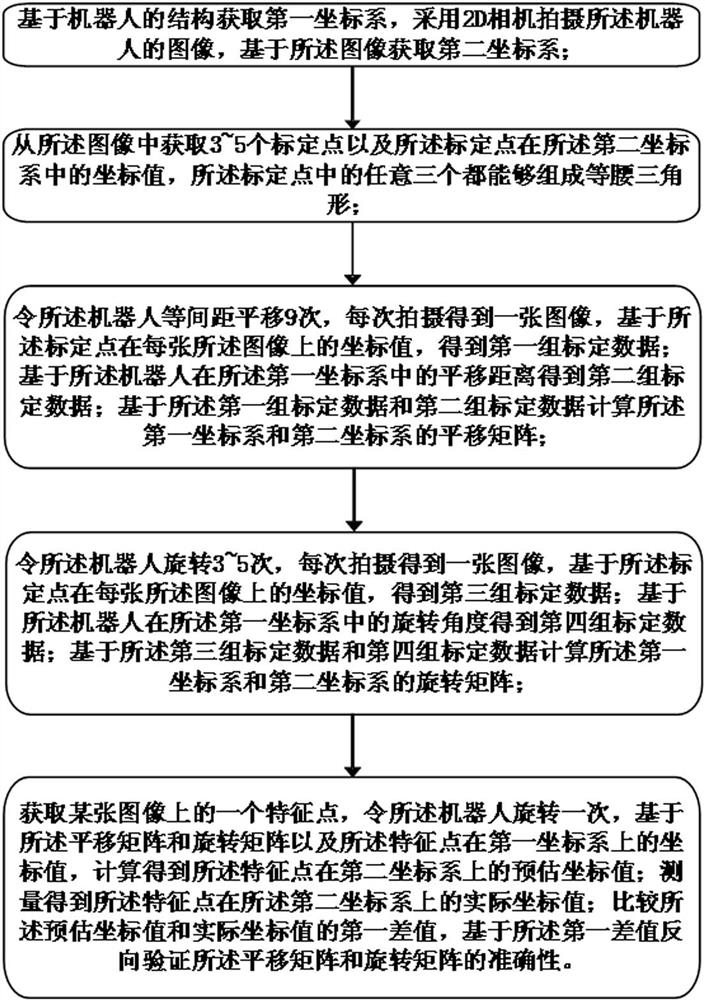

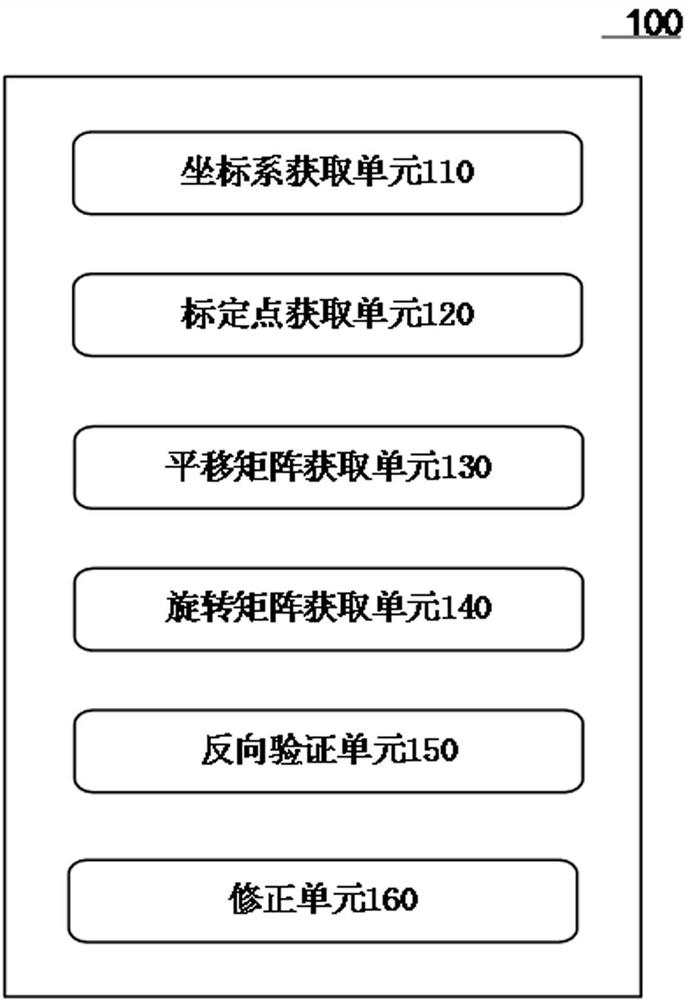

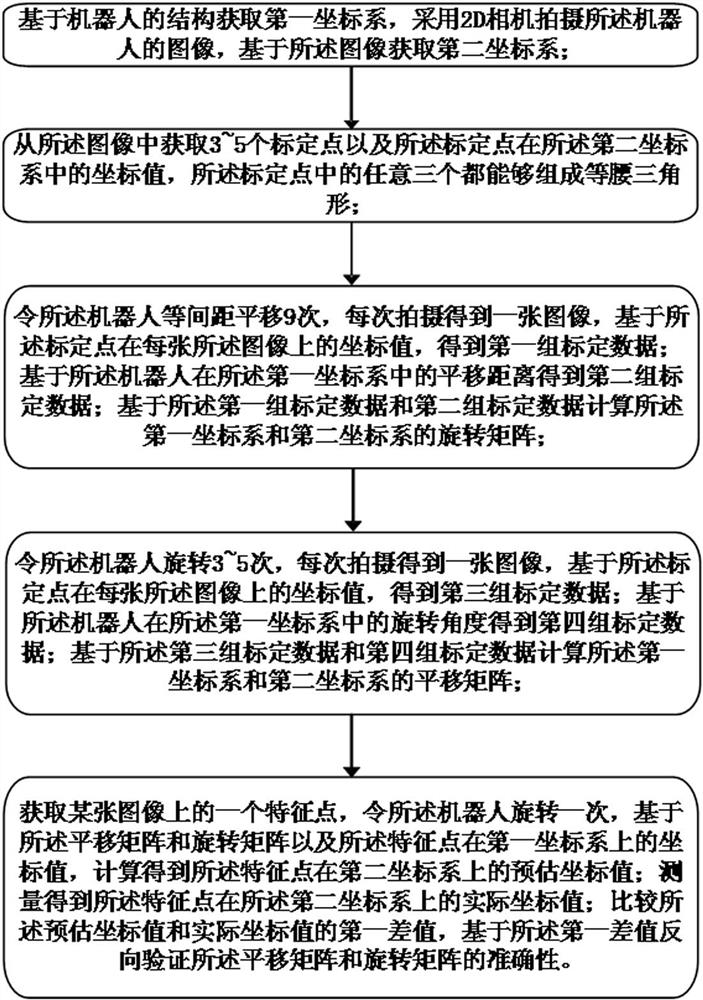

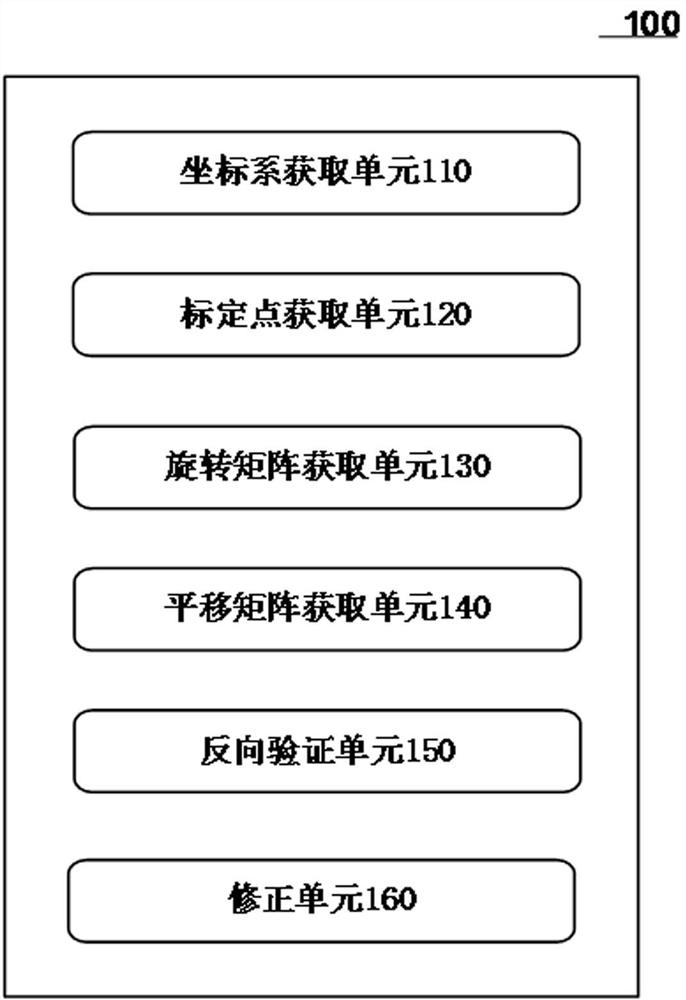

Coordinate system coincidence calibration method and system

ActiveCN113524204AReduce mistakesImprove coincidence accuracyProgramme-controlled manipulatorComputer visionVisual system

The invention relates to a coordinate system coincidence calibration method and system. The method comprises the steps that a first coordinate system is acquired based on the structure of a robot, and a second coordinate system is acquired based on a shot image of the robot; calibration points are acquired from the image, and any three of the calibration points can form an isosceles triangle; the robot is made to translate at equal intervals, and translation matrixes of the first coordinate system and the second coordinate system are calculated based on a first set of acquired calibration data and a second set of acquired calibration data; the robot is made to rotate, and rotation matrixes of the first coordinate system and the second coordinate system are calculated based on a third set of acquired calibration data and a fourth set of acquired calibration data; a feature point on a certain image is acquired, and an estimated coordinate value of the feature point on the second coordinate system is calculated; an actual coordinate value of the feature point is obtained through measurement; and the estimated coordinate value and the actual coordinate value are compared to reversely verify the accuracy of the translation matrixes and the rotation matrixes. Through the coordinate system coincidence calibration method and system, errors of an image vision system can be reduced, the coincidence degree of a camera coordinate system and a robot coordinate system is increased, and then part assembling precision is improved.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

A centering mechanism for horizontal ultra-high pressure sterilization equipment

InactiveCN105077509BHigh Straight and Etc.Improve coincidence accuracyFood preservationUltra high pressureTurning frames

The invention provides a horizontal-type ultra-high pressure sterilization equipment aligning mechanism. According to the horizontal-type ultra-high pressure sterilization equipment aligning mechanism, cylinder bodies (1-1), trolley guide rail beams (1-2), aligning positioning blocks (1-3) and a frame (1) are connected into a whole, the axis of the left cylinder body (1-1) and the axis of the right cylinder body (1-1) are on the same straight line, and circle centers of concaved circular cambered surfaces of the left aligning positioning block (1-3) and the right aligning positioning block (1-3) and the axes of the left cylinder body (1-1) and the right cylinder body (1-1) are on the same straight line; the cylinder bodies (1-1) are matched with piston-type plugs (2) to form hydraulic oil cylinders, and the axes of the left piston-type plug (2) and the right piston-type plug (2) are on the same straight line; an ultra-high pressure barrel body (4) is fixed to a trolley frame (5) through barrel body fixing seats (3), the trolley frame (5) is pulled by a lead screw nut mechanism driven by a servo motor to move along guide rails on the trolley guide rail beams (1-2), positioning is achieved through contact between the barrel body fixing seats (3) and the aligning positioning blocks (1-3), and the situation that the axis of the ultra-high pressure barrel body (4) and the axes of the left piston-type plug (2) and the right piston-type plug (2) are on the same straight line is achieved.

Owner:CHINA AGRI UNIV

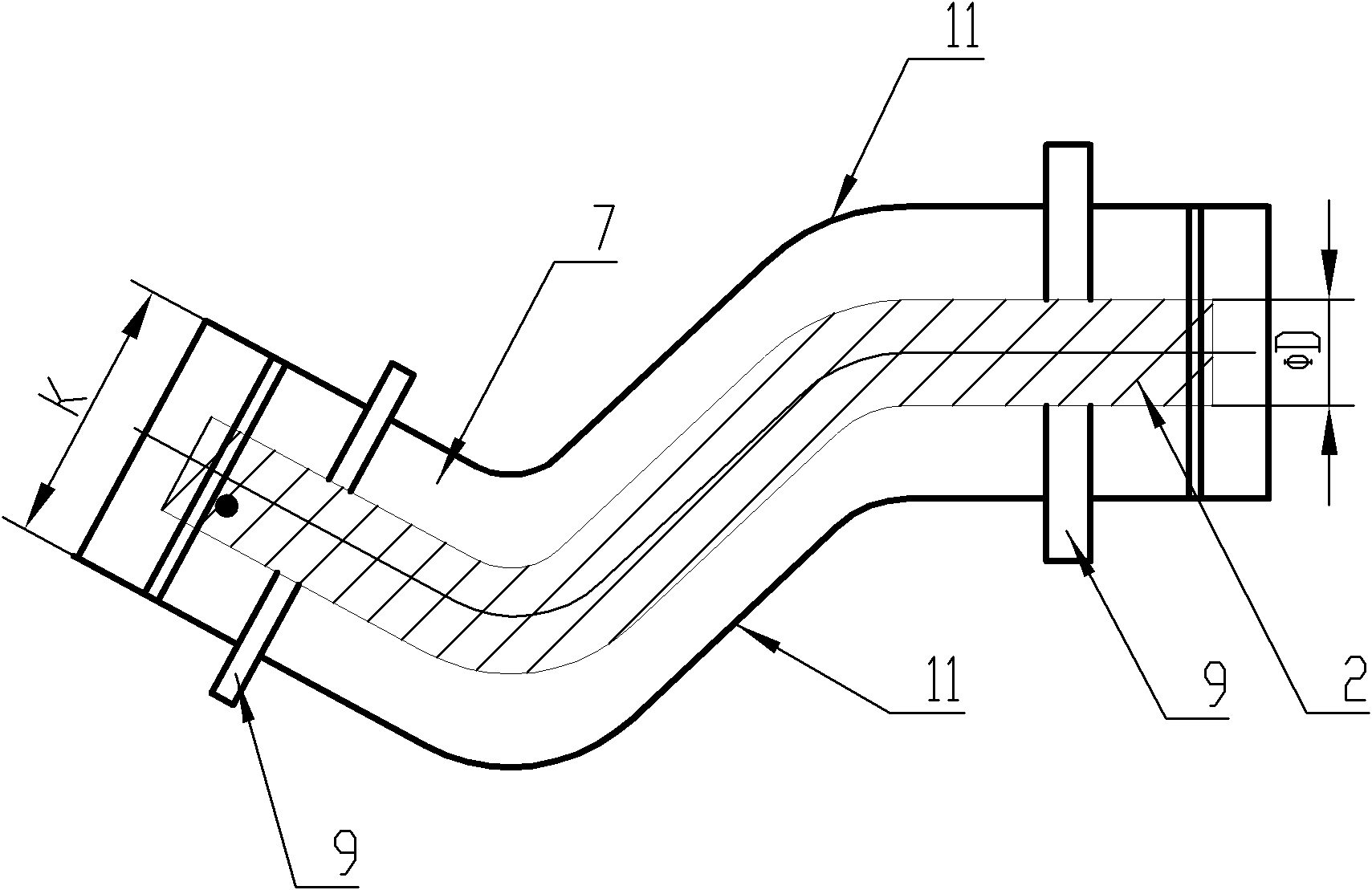

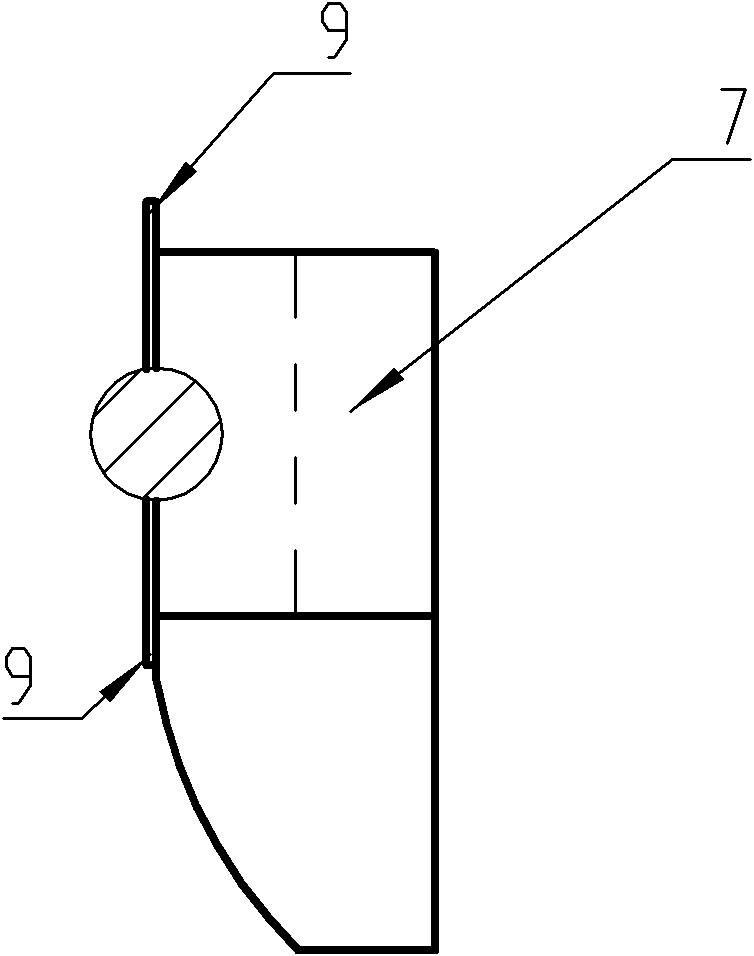

Thin-wall vulcanized rubber tube reshaping mould and manufacture method thereof

InactiveCN102218784BReduce manufacturing costReduce technical difficultyCoatingsWorking environmentEngineering

Owner:大连山元机械制造有限公司

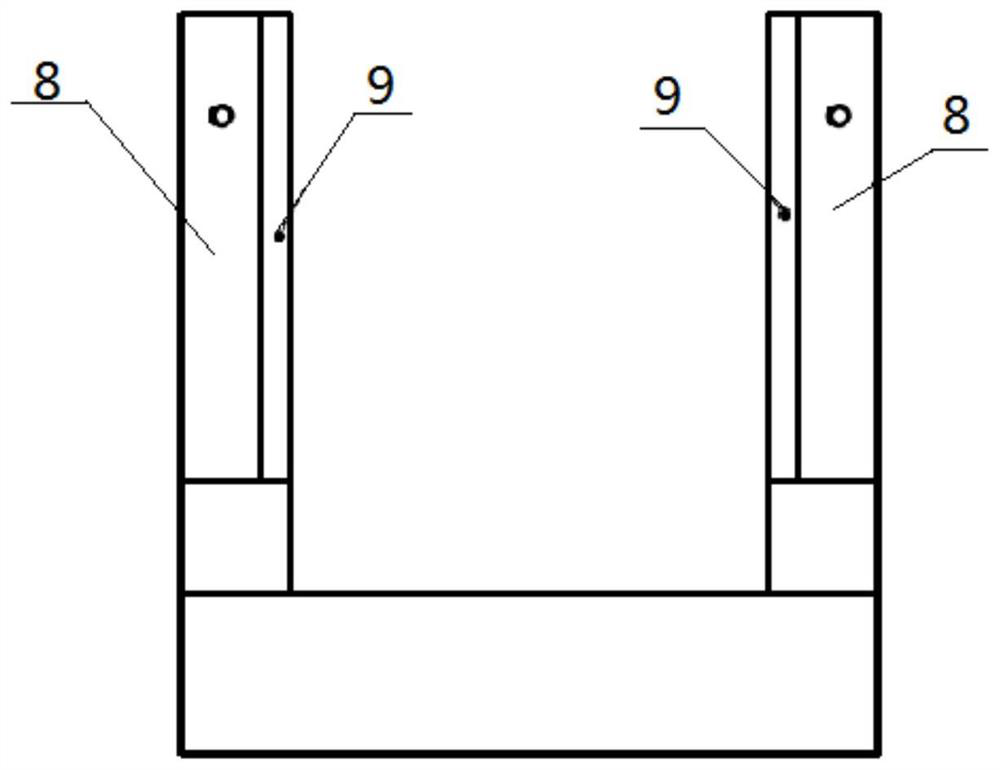

A guiding device for orthopedic surgery

ActiveCN112998809BEasy to drillEasy to operateBone drill guidesOrthopedics surgeryOrthopedic department

The invention relates to the field of orthopedic surgical instruments, and provides a guiding device for orthopedic surgery, which includes a fixed base, a support shaft is arranged inside the fixed base, and a first rotating plate and a second rotating plate are sleeved on the supporting shaft , the first rotating plate is provided with a rotating cavity, and one side of the first rotating plate is provided with a rotating outlet communicating with the rotating cavity, and the top surface of the first rotating plate is provided with a connecting through hole that runs through the rotating cavity and cooperates with the support shaft, The second rotating plate includes a rotating part located in the rotating cavity and sleeved on the support shaft. The side of the rotating part is extended with a connecting part passing through the rotating outlet; the connecting part and the end of the first rotating plate away from the supporting shaft are provided with through Fix the clamping arm of the base, and the two clamping arms are set in mirror image; one end of the clamping arm is provided with a guide assembly, and the other end of the two clamping arms is provided with a control assembly, and the control part of the control assembly is connected to the The clamping arm is hinged; it solves the problem that the structure of the existing drilling guiding device is complex and the guiding accuracy becomes smaller after long-term use.

Owner:XIAN HONGHUI HOSPITAL

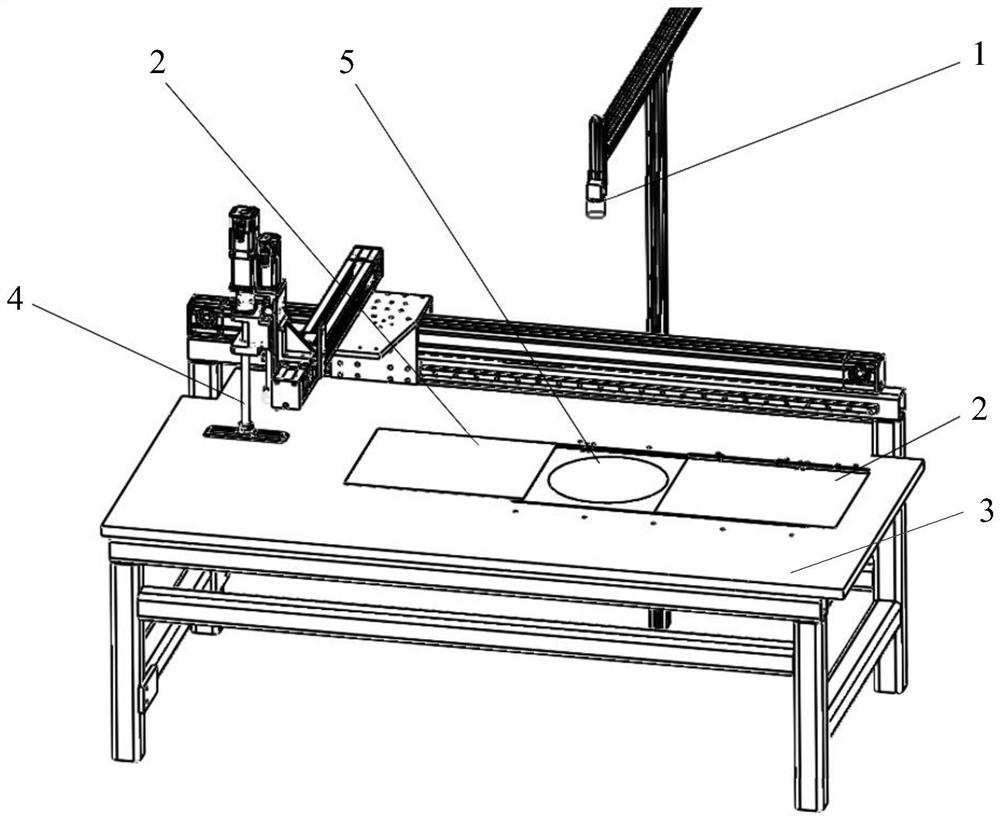

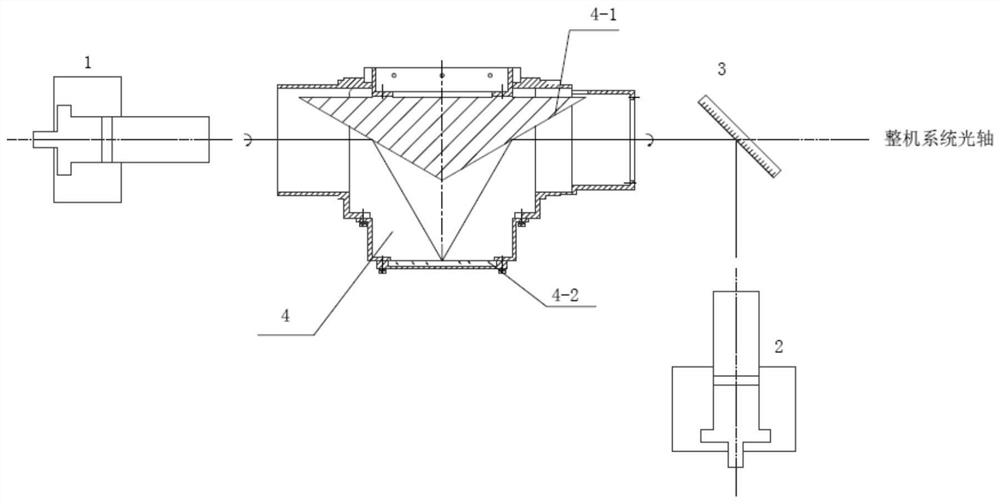

A high-precision image stabilization mirror bonding device and method

ActiveCN109188646BAccurate adhesionImprove coincidence accuracyMountingsMechanical engineeringHigh adhesion

The invention discloses a high-precision image stabilization mirror bonding device and method, and relates to the field of high-precision assembly of optical structures. It includes a base, a mirror holder, a cylindrical pin, an adjustment pressure plate, and a first adjustment screw; wherein: one end of the cylindrical pin is fixedly arranged in a positioning hole at the bottom of the base, and the other end is fixedly connected to the mirror holder; the adjustment pressure plate passes through The first adjusting screw is connected to the upper part of the base, and the adjusting pressure plate is used to control and adjust the position accuracy of the reflector on the mirror holder. The reflector and the mirror holder can be precisely bonded according to the size requirements, thereby improving the coincidence accuracy of the mirror surface and the axis of the mirror holder mounting hole, reducing the adverse effects of manual operation errors, improving the yield, high adhesion strength, and Easy to mass produce and process.

Owner:BEIJING INST OF REMOTE SENSING EQUIP

Coordinate system coincidence calibration method and system

ActiveCN113524204BPrecise conversion relationshipReduce mistakesProgramme-controlled manipulatorEngineeringComputer vision

The invention relates to a coordinate system coincidence calibration method and system. The method includes: acquiring a first coordinate system based on the structure of a robot, acquiring a second coordinate system based on a captured image of the robot; Any three can form an isosceles triangle; make the robot translate at equal intervals, and calculate the rotation matrices of the first and second coordinate systems based on the obtained first and second sets of calibration data; make the robot rotate, based on the obtained third set Calculate the translation matrix of the first and second coordinate systems with the fourth group of calibration data; obtain a feature point on an image, calculate the estimated coordinate value of the feature point on the second coordinate system; measure the actual value of the feature point Coordinate values; compare the estimated and actual coordinate values to back-verify the accuracy of the translation and rotation matrices. The invention can reduce the error of the image vision system, improve the coincidence degree of the camera coordinate system and the robot coordinate system, and then improve the assembly precision of parts.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

Electronic device manufacturing method, display device manufacturing method, photomask manufacturing method and photomask

ActiveCN105892226AImprove coincidence accuracyReduce alignment errorsSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentResistDisplay device

The present invention provides an electronic device manufacturing method, a display device manufacturing method, a photomask manufacturing method and a photomask, which can reduce the alignment errors among layers. The electronic device manufacturing method is characterized by comprising the following steps of forming a first film pattern, and implementing a first photoetching process using a first photomask on a substrate; forming a second film pattern and implementing a second photoetching process using a second photomask, wherein the first and second photomasks comprise a first transfer pattern containing a light transmitting part, a shading part and a semi-light transmitting part, and are the same photomask, or the second photomask is the photomask of the second transfer pattern formed by processing the first transfer pattern possessed by the first photomask.

Owner:HOYA CORP

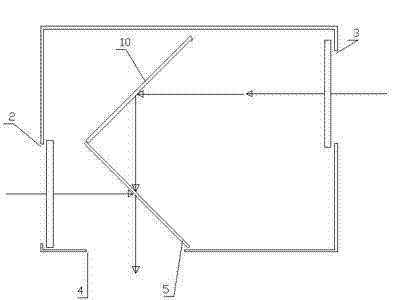

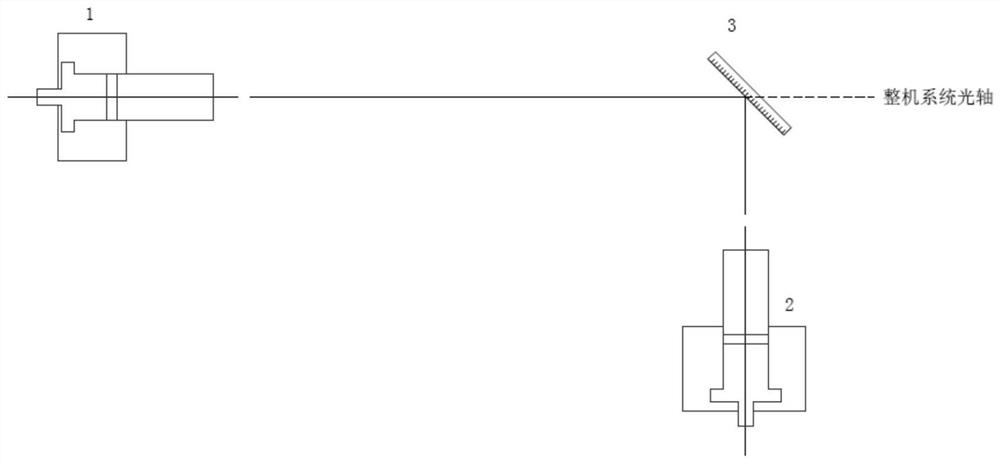

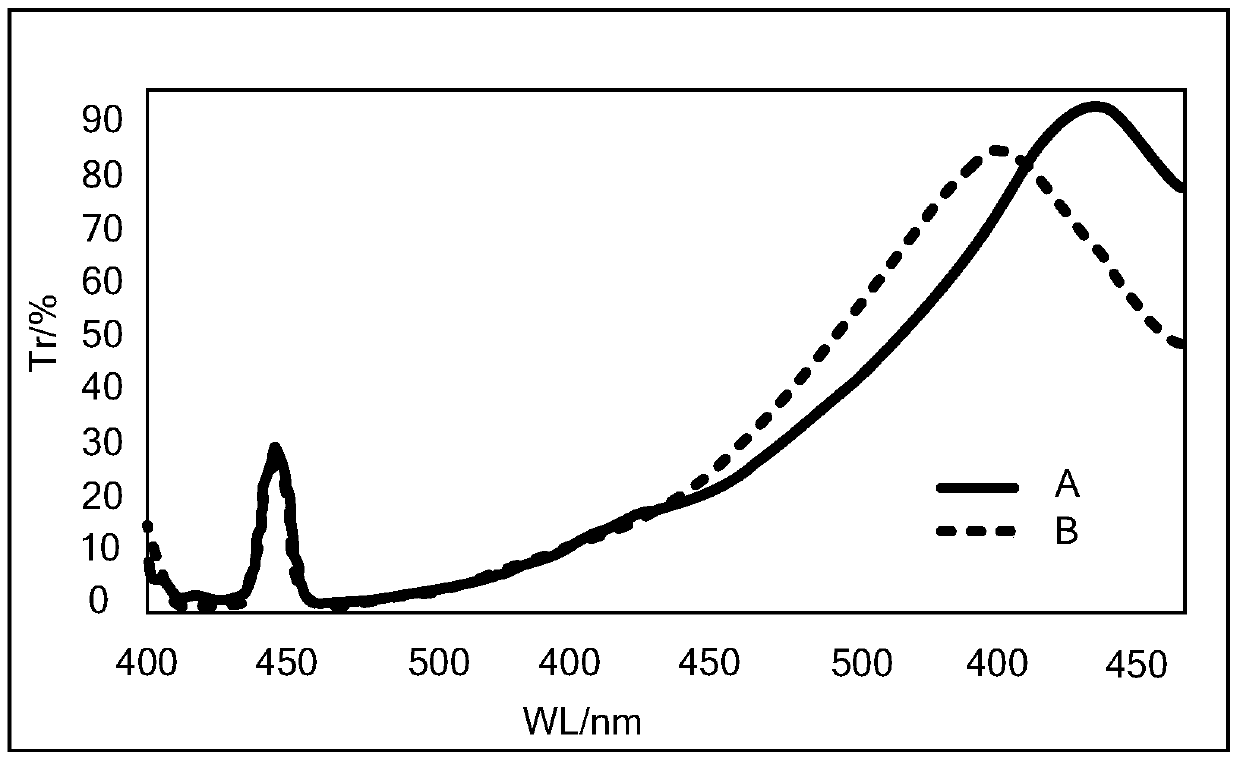

Bidirectional shooting device

InactiveCN102096280BTwo-way photography realizedLow costCamera body detailsOptical elementsOptical axisLight reflection

The invention discloses a bidirectional shooting device, which is characterized by comprising a shell, a first window, a second window, a shooting window, a one-way photoscope and a mirror array, wherein the one-way photoscope is used for reflecting light entering from the first window onto the shooting window by using the reflective panel of the one-way photoscope; the mirror array is used for changing the light path of light entering from the second window so as to make the light pass through the one-way photoscope from the illuminating surface of the one-way photoscope and enter the shooting window; the first window and the second window are parallel with each other; the shooting window is positioned between the first window and the second window; and the first window and the second window are provided with a controllable shading device respectively. By the bidirectional shooting device, bidirectional shooting is realized, two images in opposite directions can be shot by one shooting platform, cost is saved, coaxial bidirectional shooting can be realized, target images on the same straight line on both sides can be shot by a single camera, and optical axis superposition accuracy is high.

Owner:广州创孚检测电子设备有限公司

Overlap sewing device

ActiveCN107419442BSimplify complexityImprove coincidence accuracyWork-feeding meansSewing-machine control devicesStructural engineeringManipulator

The invention discloses an overlapping sewing device which comprises a feeding plate, a storage plate, a driving device, a visual system, a rotating device and a manipulator. The feeding plate and the storage place are used for supporting cut parts, the driving device is used for driving the corresponding feeding plate to move to a position above or far away from the storage plate, the visual system is used for recognizing the positions of the cut parts placed on the feeding plate and recognizing the positions of the cut parts placed on the storage plate, the rotating device is used for controlling the storage plate to rotate according to recognition results of the visual system, so that the angle of one cut part on the storage place is adjusted to be as same as that of another cut part on an adjacent layer above the cut part, and the manipulator is used for moving one cut part on the feeding plate to be aligned to another cut part on an adjacent layer under the cut part according to the recognition results of the visual system and rotating results of the rotating device. The rotating device is matched with the manipulator to adjust relative positions of the cut parts, program setting complexity in the manipulator can be simplified, operation time is reduced, and overlapping accuracy of the cut parts is improved.

Owner:JACK SEWING MASCH CO LTD

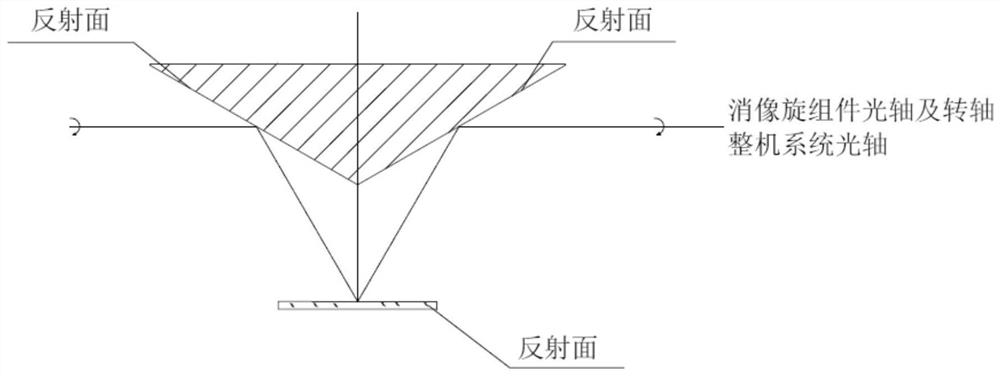

An optical correction method for reflective deimage rotation components of aerospace optical remote sensing instruments

ActiveCN111736361BCalibration is fast and accurateImprove calibration accuracyMountingsOptical reflectionOptical axis

The invention discloses an optical correction method for a reflection-type anti-image rotation component of an aerospace optical remote sensing instrument. Two internal focusing telescopes that are coaxial with each other and coincide with the optical axis of the whole machine are used to align the rotating shafts at both ends of the anti-image rotation component respectively. The center can quickly adjust and coincide the rotation axis of the image elimination rotator assembly with the optical axis of the whole system, and accurately judge and correct the relative position between the internal optical reflection surfaces of the image elimination rotator assembly. Optical correction of the three-axis coincidence of the optical axis of the machine system. When the anti-image rotation assembly rotates, the included angle between the shaking of the image point around the axis and the optical axis of the whole system is better than 10". The advantage of the present invention is that the method of the present invention quickly and accurately corrects the reflective anti-image rotation assembly of the aerospace optical remote sensing instrument, By improving the coincidence accuracy of the optical axis of the inner focusing telescope, the optical axis of the whole machine system and the rotation axis of the image elimination rotation assembly, the correction accuracy of the image elimination rotation assembly can be improved.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

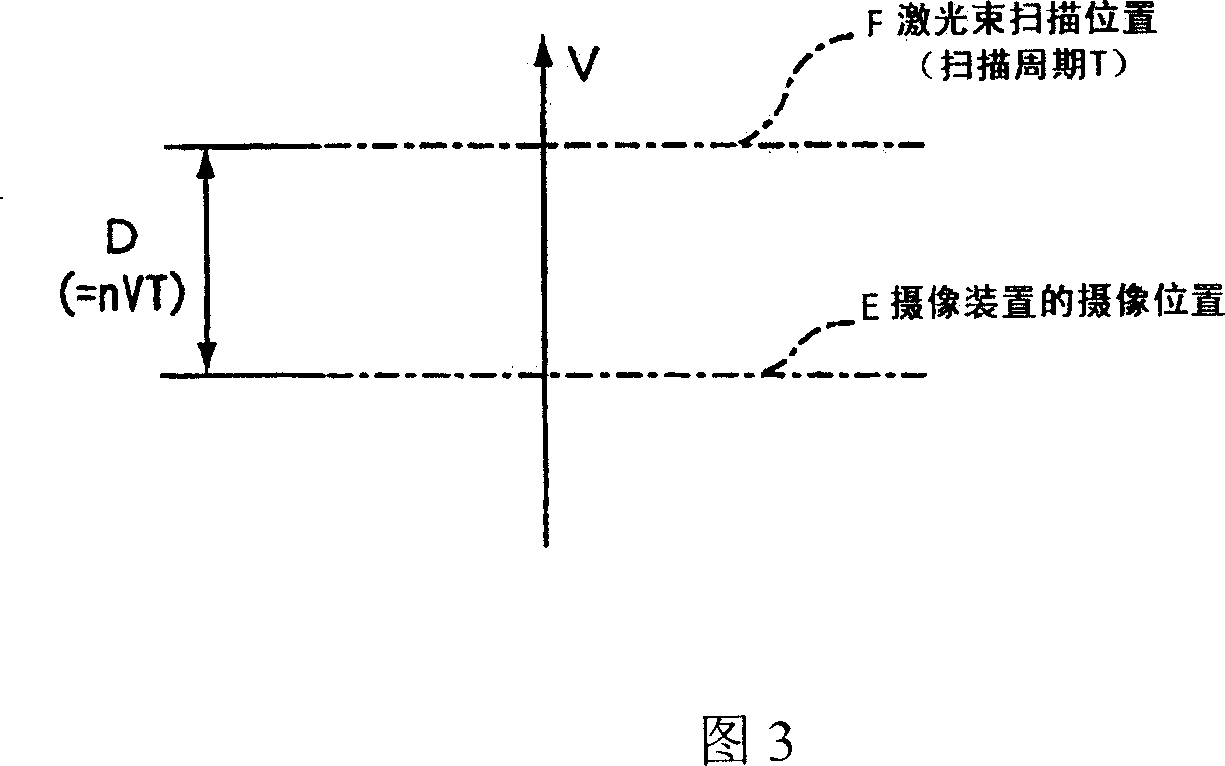

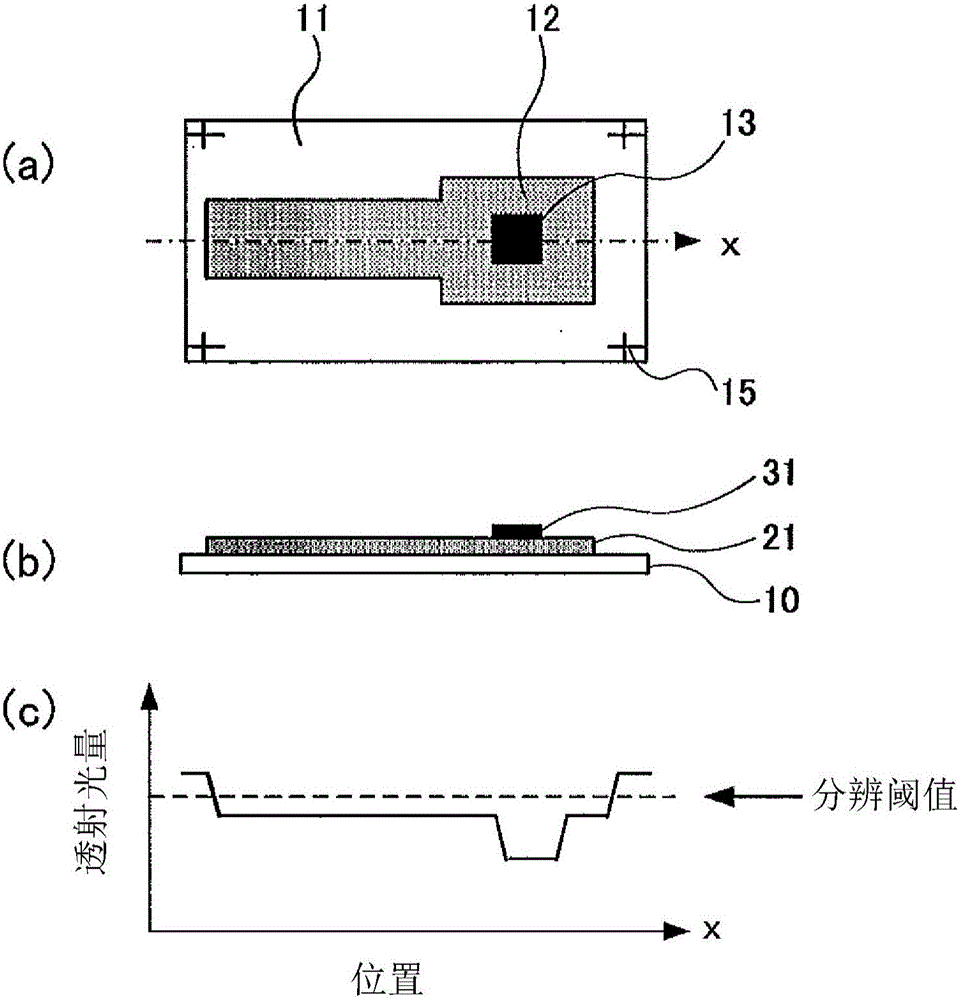

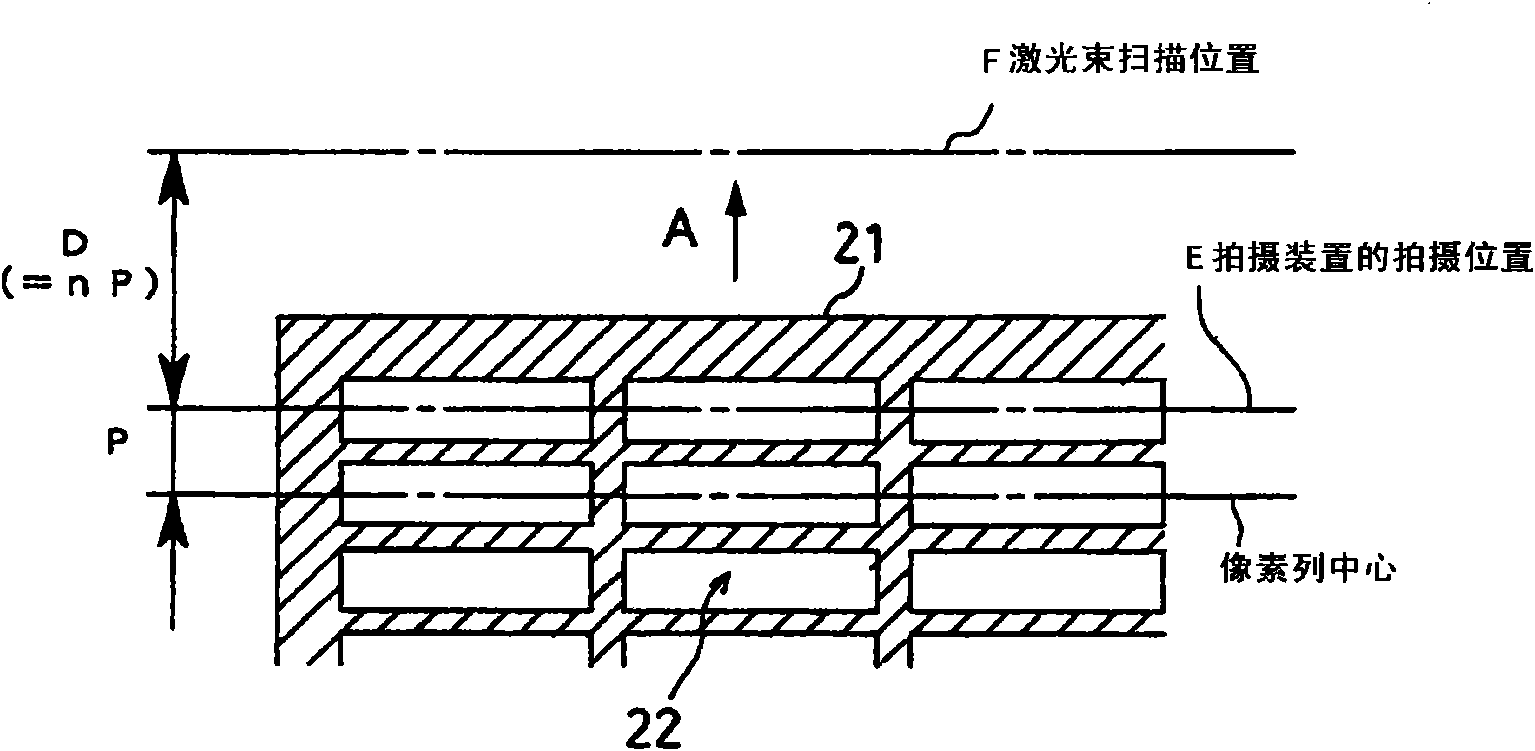

Exposure apparatus

InactiveCN1947069BImprove coincidence accuracyEliminates the problem of decreased coincidence accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight beamImage detection

An exposure apparatus (1) relatively scans a glass board (8) with laser beams irradiated from an exposure optical system (3) in a direction orthogonally intersecting a shifting direction (arrow A) of the glass board, and exposes a functional pattern at a prescribed pitch on the glass board (8). The exposure apparatus is provided with an image pickup means (5) for picking up an image of a pixel ofa black matrix previously formed on the glass board (8), and an optical system control means (7), which performs a prescribed image process to the pixel image data obtained by the image pickup means (5), a defect is removed from a pixel row image in one scanning area of the laser beams to generate a defect-free pixel row image, detects a reference position of exposure start or completion in the defect-free pixel row image, and controls laser beam irradiation start or irradiation stop of the laser beams, having the reference position as a reference. Thus, alignment accuracy of the functional pattern is improved and cost increase of the exposure apparatus is suppressed.

Owner:V TECH CO LTD

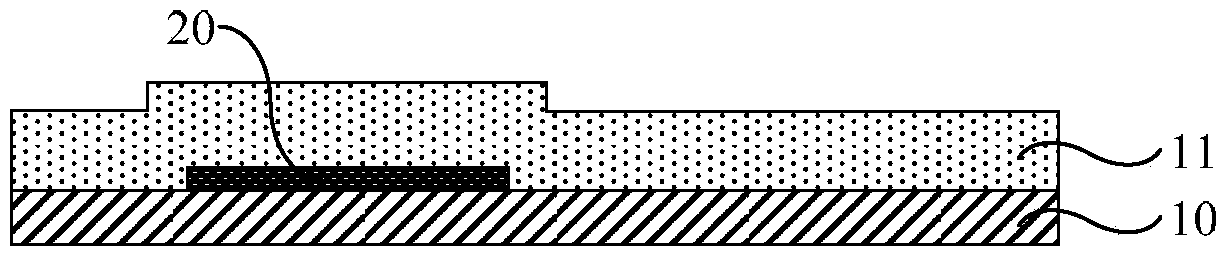

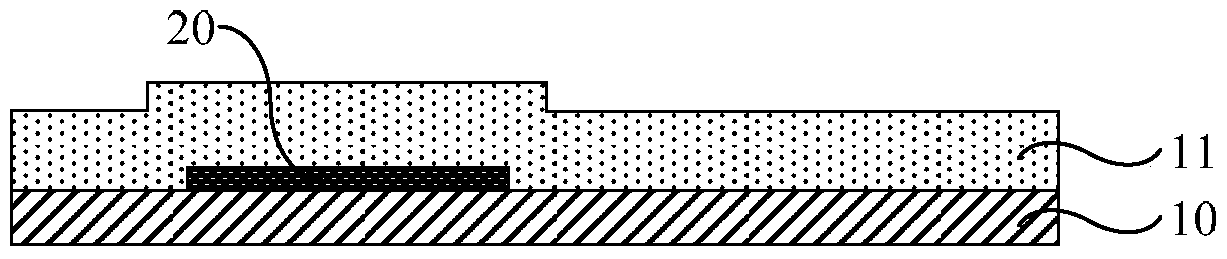

Solid-state imaging device, manufacturing method thereof, and electronic device

InactiveCN102479794BImprove coincidence accuracySuppression of lens aberrationTelevision system detailsColor television detailsSolid massEngineering

The present invention relates to a solid-state imaging device, a manufacturing method thereof, and an electronic device using the solid-state imaging device. The solid-state imaging device includes: a supporting substrate including a concave portion; a solid-state imaging chip bonded to the supporting substrate to seal the concave portion in a viewing angle region of the solid-state imaging chip; and a stress film formed on the solid-state imaging chip. on the surface of the solid-state imaging chip; and an imaging surface in which the viewing angle area is bent toward the concave portion by the stress of the stress film. In the present invention, by bending the viewing angle area, the coincidence accuracy between the center of the viewing angle area and the optical center of the imaging lens system is improved, and the suppression of lens aberration is enhanced.

Owner:SONY SEMICON SOLUTIONS CORP

Exposure apparatus

InactiveCN101846889AImprove coincidence accuracyEliminates the problem of decreased coincidence accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusLight beamOptoelectronics

An exposure apparatus (1) relatively scans a glass board (8) with laser beams irradiated from an exposure optical system (3) in a direction orthogonally intersecting a shifting direction (arrow A) of the glass board, and exposes a functional pattern at a prescribed pitch on the glass board (8). The exposure apparatus is provided with an image pickup means (5) for picking up an image of a pixel of a black matrix previously formed on the glass board (8), and an optical system control means (7), which performs a prescribed image process to the pixel image data obtained by the image pickup means (5), a defect is removed from a pixel row image in one scanning area of the laser beams to generate a defect-free pixel row image, detects a reference position of exposure start or completion in the defect-free pixel row image, and controls laser beam irradiation start or irradiation stop of the laser beams, having the reference position as a reference. Thus, alignment accuracy of the functional pattern is improved and cost increase of the exposure apparatus is suppressed.

Owner:V TECH CO LTD

Guiding device for orthopedic surgery

ActiveCN112998809AEasy to drillEasy to operateBone drill guidesOrthopedics surgeryOrthopedic department

The invention relates to the field of orthopedic surgical instruments, and provides a guiding device for orthopedic surgery, the guiding device comprises a fixed base, a support shaft is arranged in the fixed base, a first rotating plate and a second rotating plate sleeve the support shaft, a rotating cavity is arranged in the first rotating plate, and a rotating outlet communicated with the rotating cavity is formed in one side of the first rotating plate; a connecting through hole penetrating through the rotating cavity and matched with the supporting shaft is formed in the top face of the first rotating plate, the second rotating plate comprises a rotating part located in the rotating cavity and arranged on the supporting shaft in a sleeving mode, and a connecting part penetrating through the rotating outlet extends from the side face of the rotating part; clamping connecting arms penetrating through the fixed base are arranged at the ends, away from the supporting shaft, of the connecting part and the first rotating plate correspondingly, and the two clamping connecting arms are arranged in a mirror image mode; a guide assembly is arranged at one end of each clamping connecting arm, a control assembly is arranged between the other ends of the two clamping connecting arms, and the control part of the control assembly is hinged to the clamping connecting arms; the problems that an existing drilling guide device is complex in structure, and the guide precision is reduced after long-time use are solved.

Owner:XIAN HONGHUI HOSPITAL

A substrate and a manufacturing method of an alignment mark, and a display device

ActiveCN103715179BImprove visibilityImprove coincidence accuracySemiconductor/solid-state device detailsSolid-state devicesVisibilityDisplay device

The embodiment of the invention provides a substrate, an alignment mark manufacturing method thereof and a display device, and relates to the display technical field. With the substrate, the alignment mark manufacturing method thereof and the display device of the invention adopted, the visibility of the alignment mark can be improved. The substrate includes a first film layer and a second film layer positioned on the surface of the first film layer; at least one alignment mark exists between the first film layer and the second film layer; and the thickness of a portion of the second film layer which is corresponding to the position of the alignment mark is smaller than the thickness of portions of the second film layer which are corresponding to positions except the position of the alignment mark.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Overturning overlapping machine

PendingCN109348396AImprove work efficiencyImprove coincidence accuracyElectrical transducersDrive wheelPressure stabilization

The invention discloses an overturning overlapping machine which comprises a base electric box. A supporting plate is arranged at the rear end of the upper surface of the base electric box; a slidingplate is arranged in the front of the supporting plate; a driving device is arranged on the supporting plate; a left plate is arranged at the left front end of the sliding plate; a right plate is arranged at the right front end of the sliding plate; a rotary cylinder is arranged on the right plate; a driving wheel is arranged on the right end face of the rotary cylinder; a driven shaft is arrangedon the right plate; a driven wheel is arranged at the right end of the driven shaft; the left end of the driven shaft is connected with the left plate; the driving wheel is connected with the drivenwheel by a synchronous belt; a sound film tool clamping jaw is arranged on the driven shaft between the left plate and the right plate; a product tool is arranged on the base electric box; a tool pressure stabilization cylinder is arranged on the right side of the product tool; a UV (ultraviolet) irradiation mechanism is arranged below the product tool; and a sound film tool detection sensor is arranged at the left side of the product tool. According to the invention, by integrating both the manual overturning action and the UV irradiation process onto one machine, overturning and UV irradiation can be completed, so that working efficiency, overlapping accuracy of the product and stability of the product are improved.

Owner:广州鸿冠星智能设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com