A high-precision image stabilization mirror bonding device and method

A technology of bonding device and mirror, applied in installation, instrumentation, optics, etc., can solve the problems of poor precision, poor consistency, weak strength, etc., to improve the yield, reduce adverse effects, and facilitate mass production and processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

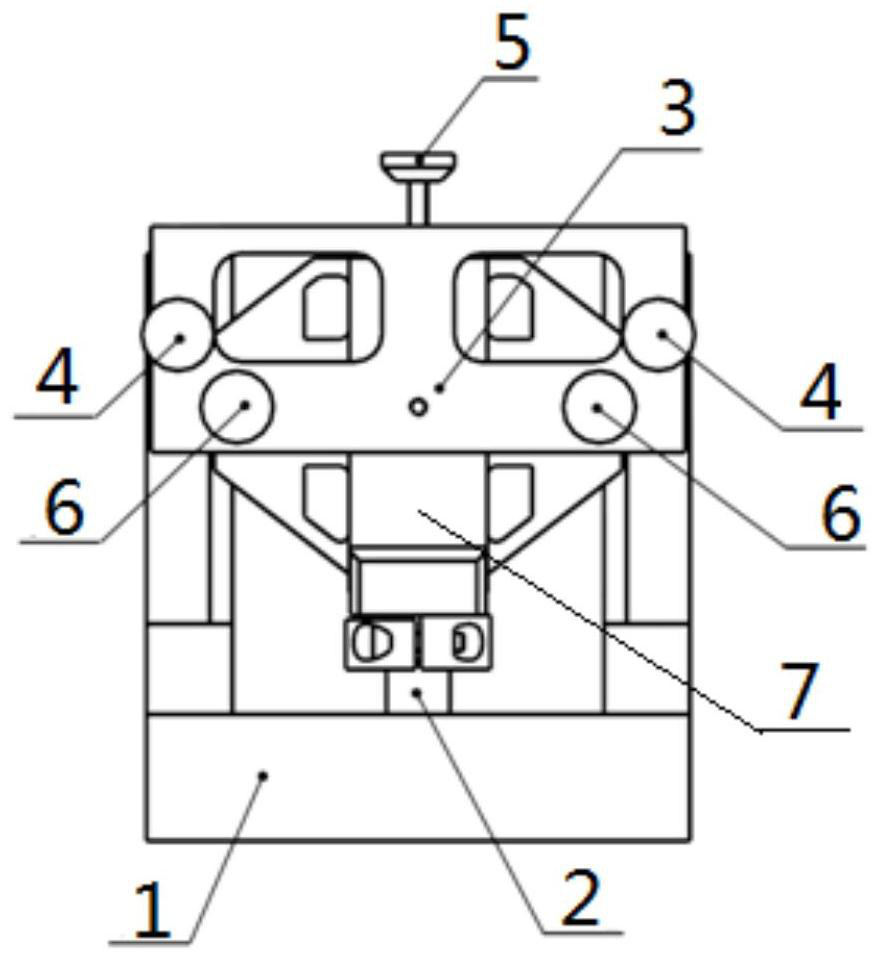

[0036] In combination with the above technical solution, in this embodiment, further, a second adjustment screw and a third adjustment screw are arranged on the adjustment pressure plate; the second adjustment screw is used to adjust the reflector on the mirror holder and the The contact accuracy of the base, the third adjusting screw is used to adjust the contact accuracy between the pressure plate and the mirror holder.

[0037] When using the high-precision image stabilization mirror bonding device described in this embodiment to bond the mirror, the two bonding surfaces of the mirror are coated with adhesive, and the mirror is inserted into the recess of the mirror holder. In the mouth; after the adjusting pressure plate and the base are fixedly connected by the first adjusting screw, the second adjusting screw is rotated so that the bottom end of the reflector is in close contact with the bottom surface of the notch of the mirror holder, and the rotating The third adjusti...

Embodiment 2

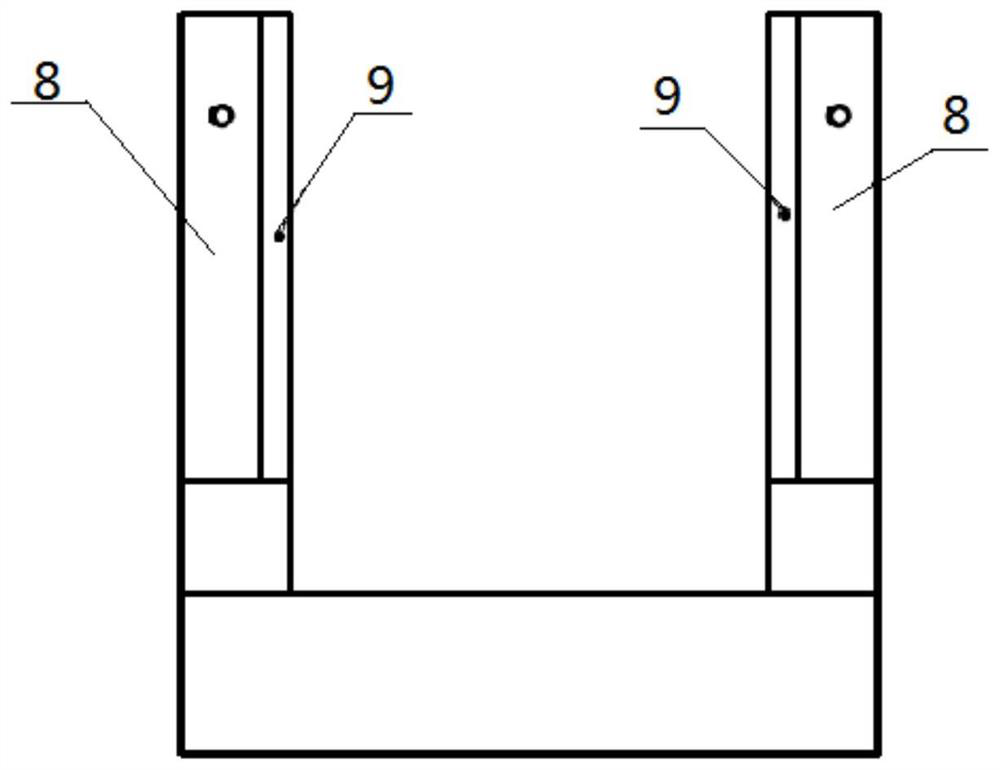

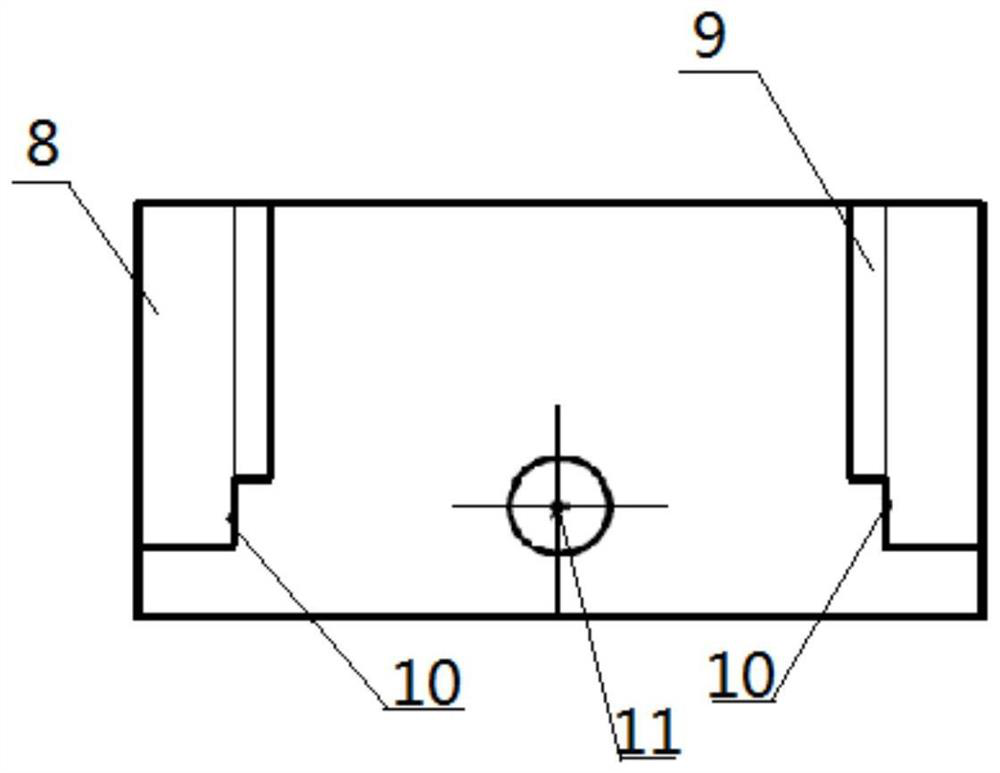

[0039] In combination with the above-mentioned technical solution, in this embodiment, further, the two ends of the base are respectively provided with adjusting platen fixing devices 8, and the two ends of the adjusting platen are respectively fixed with the adjusting platen fixing device 8 by first adjusting screws. connect. Further, positioning devices 9 are fixedly arranged on the inside of the adjusting platen fixing device 8, and the adjusting platen fixing device 8 protrudes from the positioning device 9, so that the adjusting platen fixing device 9 and the positioning device 8 An L-shaped limiting surface is formed between them. Further, the two ends of the base are respectively provided with limiting devices 10, and each of the limiting devices 10 is perpendicular to and intersects with the positioning device 9 and the fixing device 8 of the adjusting platen located at the same end of the base, that is, the limiting The device 10 cooperates with the L-shaped limiting...

Embodiment 3

[0042]In combination with the above technical solution, in this embodiment, a positioning lens 12 is also included, and the positioning lens includes a first positioning surface 13, a second positioning surface 14 and a third positioning surface 15, and the first positioning surface is located on the second positioning surface. Between the positioning surface and the third positioning surface, the two ends of the first positioning surface are respectively in close contact with the positioning devices at both ends of the base, and the second positioning surface and the third positioning surface are respectively in contact with the concave of the mirror holder. The upper and lower surfaces of the mouth are in close contact.

[0043] Further, the distance h1 between the second positioning surface and the third positioning surface on the positioning lens is 4.2mm, the tolerance is -0.02mm to -0.04mm, the distance between the first positioning surface and the second positioning surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com