Coordinate system coincidence calibration method and system

A coincidence calibration and coordinate system technology, which is applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of large error range and difficult to guarantee the accuracy of assembly, so as to improve the coincidence precision, precise coordinate system conversion relationship, reduce effect of error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to describe the technical solution of the above invention in more detail, specific examples are listed below to demonstrate the technical effect; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

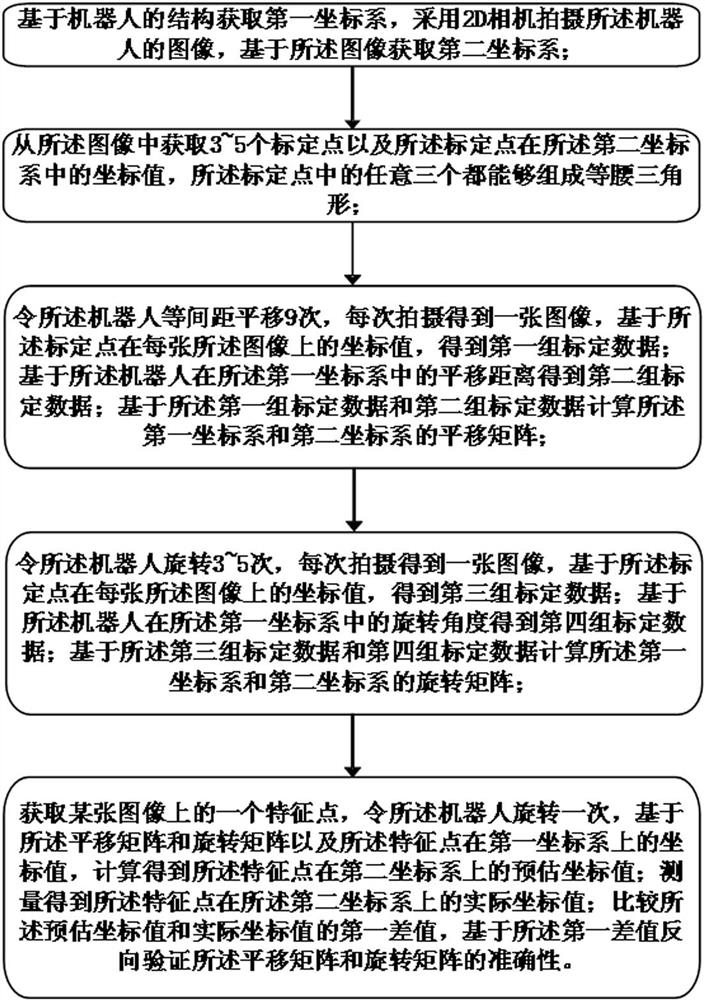

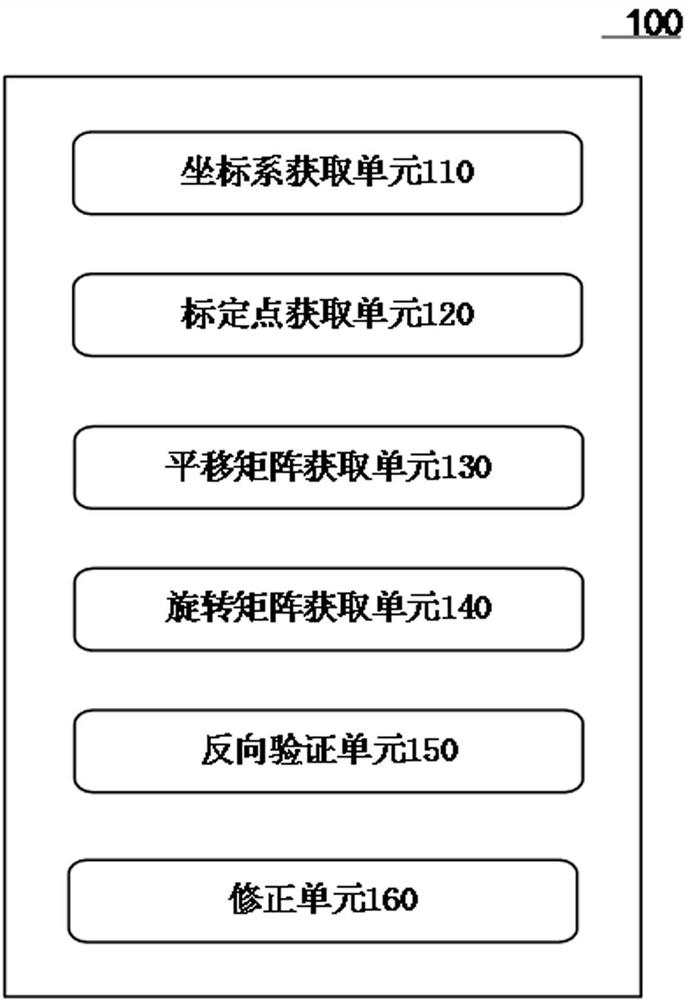

[0030] For the coordinate system coincidence calibration method provided by this invention, please refer to figure 1 , the method includes:

[0031] Step 1: Obtain a first coordinate system based on the structure of the robot, use a 2D camera to capture an image of the robot, and obtain a second coordinate system based on the image. In this embodiment, the first coordinate system is a three-dimensional coordinate system, and the second coordinate system is The two-coordinate system is a two-dimensional coordinate system.

[0032] Step 2: Obtain 3 to 5 calibration points and the coordinate values of the calibration points in the second coordinate system from the image, any thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com