Grid line printing method of solar cell

A technology of solar cells and printing methods, which is applied in printing, printing devices, etc., can solve problems such as increased costs, increased component welding debris, and scrapped solar cells, and achieves the effects of improving printing quality, improving efficiency, and improving grid line coincidence accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

[0021] A grid line printing method for solar cells, characterized in that: comprising the following steps:

[0022] 1) Prepare two screens as follows:

[0023] Screen 1#: The entire graphic has only complete auxiliary grid lines and four calibration points, such as figure 1 shown;

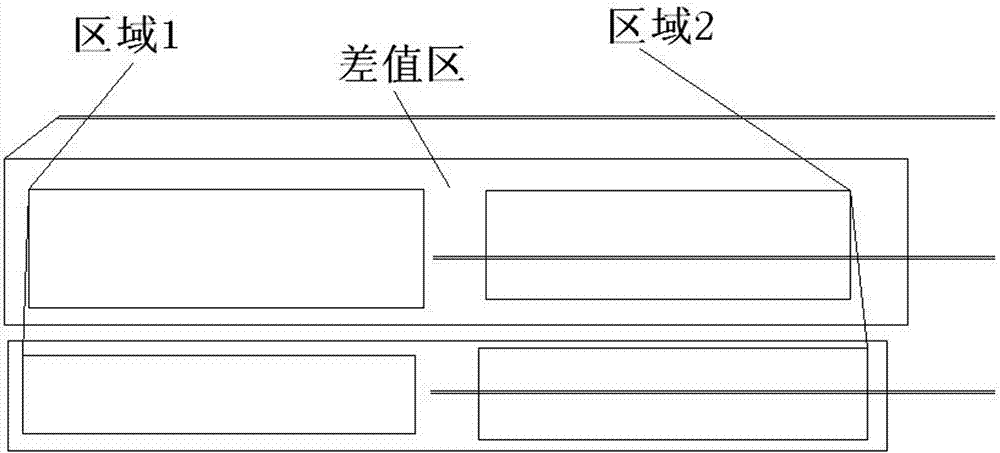

[0024] Screen 2#: The auxiliary grid line perpendicular to the main grid and four calibration electrodes, the four corners of the graphic are second inward, and the third grid line is missing the meaning part, such as figure 2 as shown,

[0025] The two calibration points are complementary, solid circle and ring;

[0026] 2) Use screen 1# to print the solar cell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com