Pole piece cutter mechanism and battery cell production device

A pole piece and cutter technology, used in electrode manufacturing, other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of poor stacking accuracy, affecting the quality of cells, and high probability of powder drop, and reduce powder drop. rate, improve the coincidence accuracy, and improve the quality of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

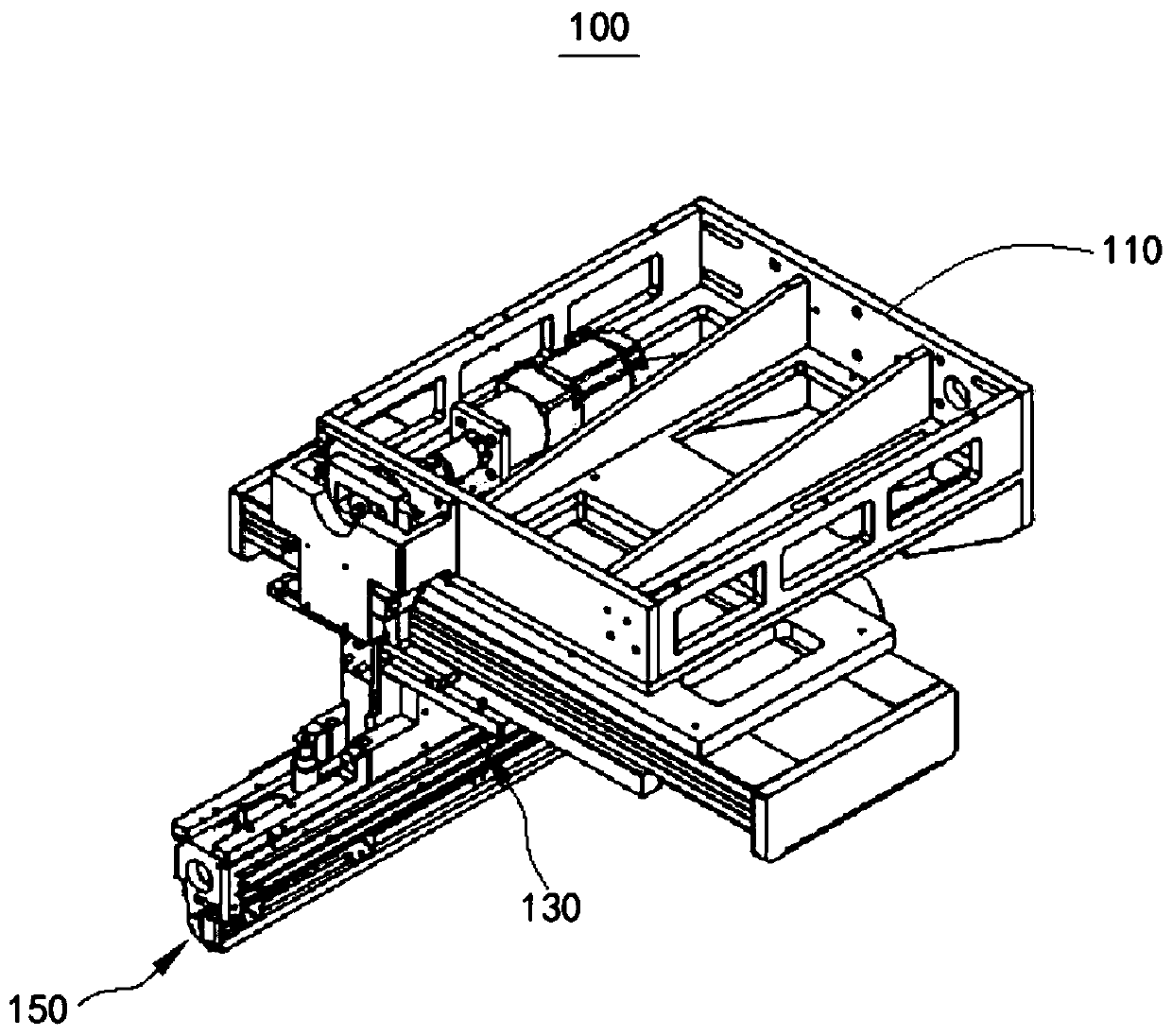

[0035] Please refer to figure 1 As shown, the pole piece cutter mechanism 100 provided in this embodiment is applied to a cell production device. The pole piece cutter mechanism 100 greatly reduces the powder dropping rate of the pole piece by processing the crease marks of the pole piece before stacking, and can improve the overlapping accuracy of the stack, thereby improving the quality of the battery cell.

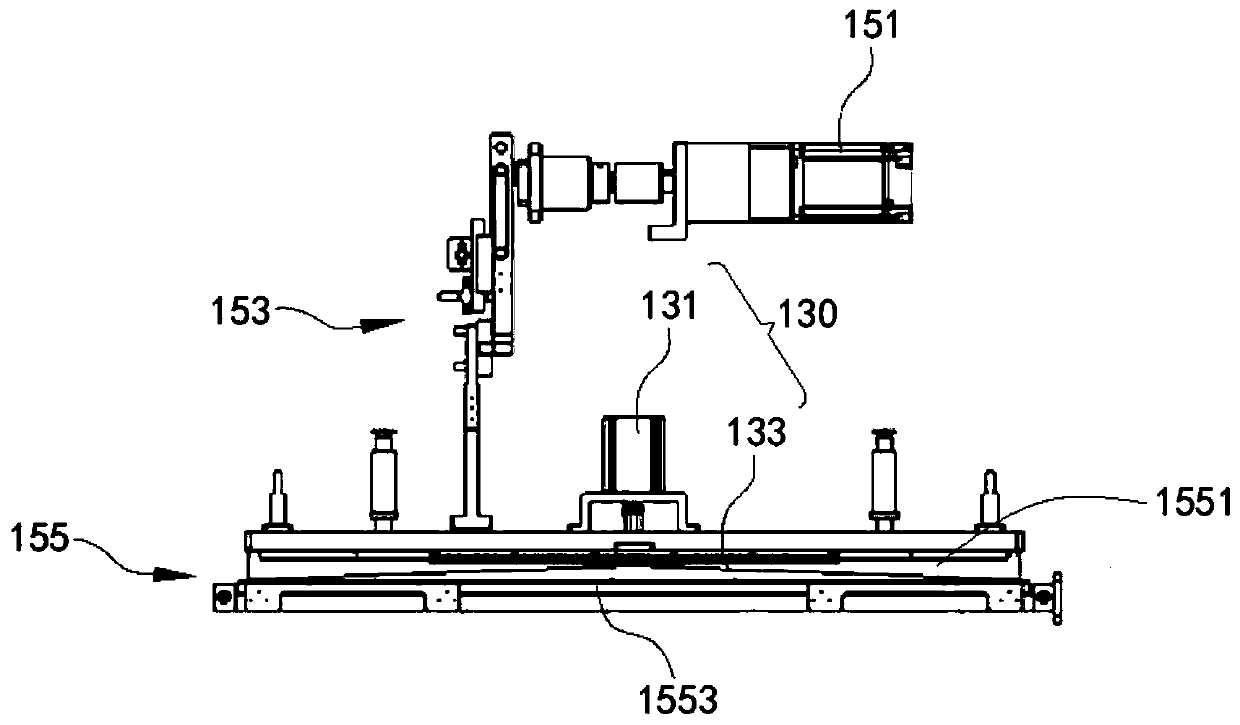

[0036] The pole piece cutter mechanism 100 provided in this embodiment includes a frame 110, a crease assembly 130 and a cutting assembly 150. The crease assembly 130 and the cutting assembly 150 are respectively arranged on the frame 110, and the frame 110 is installed in practical applications. Assembled and fixed with other working mechanisms of the cell production device, the frame 110 is used to carry pole pieces, and the pole pieces move along a preset direction on the frame 110 under the action of the pole piece conveying mechanism.

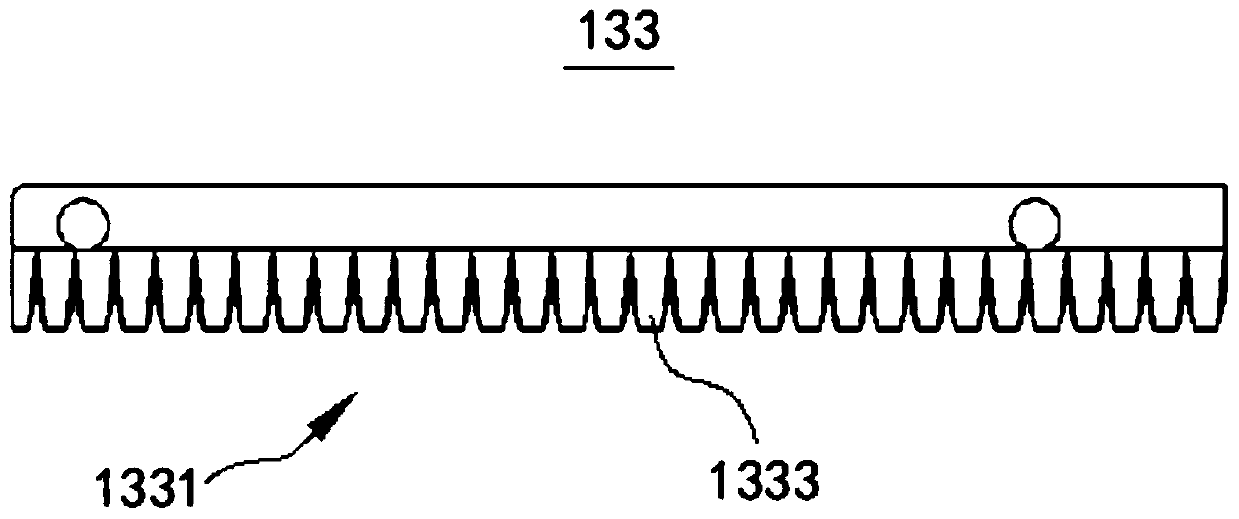

[0037] The crease assembly ...

no. 2 example

[0053] This embodiment provides a cell production device, including a pole piece conveying mechanism, a stacking mechanism, and the pole piece cutter mechanism 100 provided in the first embodiment.

[0054] The pole piece cutter mechanism 100 avoids multiple cutting of the pole piece, greatly reduces the powder dropping rate of the pole piece, and forms multiple creases on the pole piece, which is convenient for the lamination process of the lamination mechanism , which improves the overlapping accuracy of the laminations, thereby improving the quality of the output cells. Therefore, the cell production device provided in this embodiment can produce cells with higher quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com