Preparation method of silicon-carbon negative electrode slurry, silicon-carbon negative electrode plate and lithium battery

A technology of negative electrode slurry and silicon carbon, which is applied in the preparation of silicon carbon negative electrode, silicon carbon negative electrode slurry, silicon carbon negative electrode and lithium battery, which can solve the problems of difficult mixing evenly, electrode powder dropping, and long homogenization time To achieve the effect of improving the peeling force, reducing the powder dropping rate and saving the homogenization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

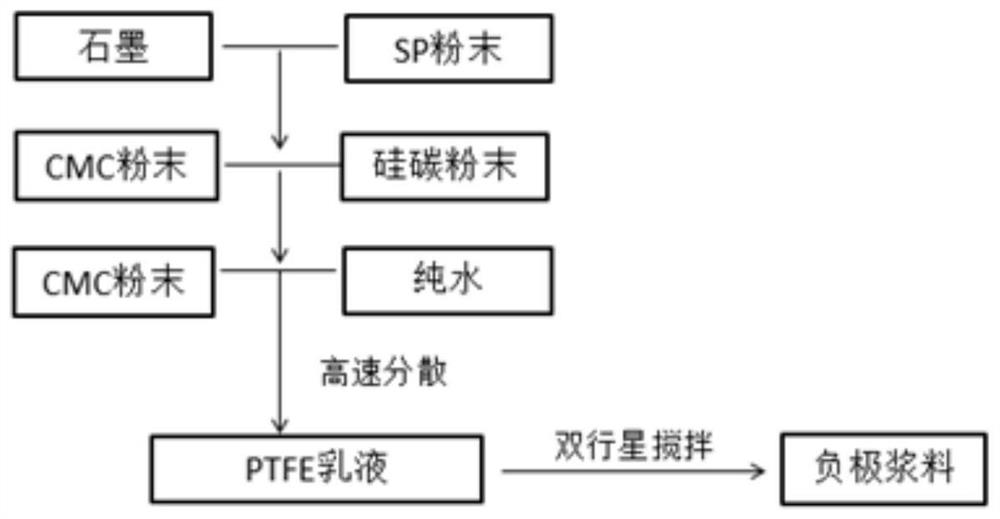

[0061] In a specific embodiment, the present invention provides a method for preparing a silicon-carbon negative electrode slurry, which specifically includes the following steps:

[0062] (1) Mix and stir graphite particles and conductive agent at a revolution speed of 8-12rpm and a dispersion speed of 480-520rpm for 12-18min to obtain the first mixed powder, wherein the conductive agent includes Super-P, acetylene black, graphene, conductive Any one or a combination of at least two of carbon black, conductive graphite or carbon nanotubes;

[0063] (2) Add silicon carbon powder and part of sodium carboxymethyl cellulose to the first mixed powder in step (1), and carry out the first step for 12 to 18 minutes at a revolution speed of 8 to 12 rpm and a dispersion speed of 480 to 520 rpm. Stir to obtain the second mixed powder, the mass ratio of the silicon carbon powder and the negative electrode active material in the second mixed powder is (78~88):(12~22), then the remaining s...

Embodiment 1

[0070] A silicon carbon negative electrode sheet is provided in this embodiment, such as figure 1 Shown, its preparation method specifically comprises the following steps:

[0071] (1) Graphite particles and Super-P powder were mixed and stirred for 15 minutes at a revolution speed of 10 rpm and a dispersion speed of 500 rpm to obtain the first mixed powder;

[0072] (2) Add silicon carbon powder and sodium carboxymethylcellulose powder accounting for 50% of the total mass of sodium carboxymethylcellulose (CMC) in the first mixed powder of step (1), and be 10rpm with revolution speed, Dispersion speed is 500rpm and carries out the first stirring of 15min, obtains the second mixed powder, the mass ratio of silicon carbon powder and graphite particle in the second mixed powder is 85:15, then remaining 50% sodium carboxymethyl cellulose The powder is sprayed into the second mixed powder at a speed of 1L / min, and pure water is sprayed into the second mixed powder at a flow rate o...

Embodiment 2

[0075] This embodiment provides a silicon carbon negative electrode sheet, and its preparation method specifically includes the following steps:

[0076] (1) Graphite particles and acetylene black powder were mixed and stirred for 12 minutes at a revolution speed of 8 rpm and a dispersion speed of 480 pm to obtain the first mixed powder;

[0077] (2) Add silicon carbon powder and sodium carboxymethylcellulose powder accounting for 35% of the total mass of sodium carboxymethylcellulose (CMC) in the first mixed powder of step (1), and be 8rpm with revolution speed, Dispersion speed was 480rpm and carried out the first stirring for 12min to obtain the second mixed powder, the mass ratio of silicon carbon powder and graphite particles in the second mixed powder was 78:22, and then the remaining sodium carboxymethyl cellulose was mixed with 0.8L The speed of / min is sprayed into the second mixed powder, and pure water is sprayed into the second mixed powder at the flow rate of 0.8L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com