Thin-wall vulcanized rubber tube reshaping mould and manufacture method thereof

A technology of vulcanized rubber and molds, which is applied in the direction of coating, etc., can solve the problems of high technical difficulty, long manufacturing cycle, and difficult deformation control, and achieve the effects of reducing technical difficulty, strong anti-deformation ability, and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

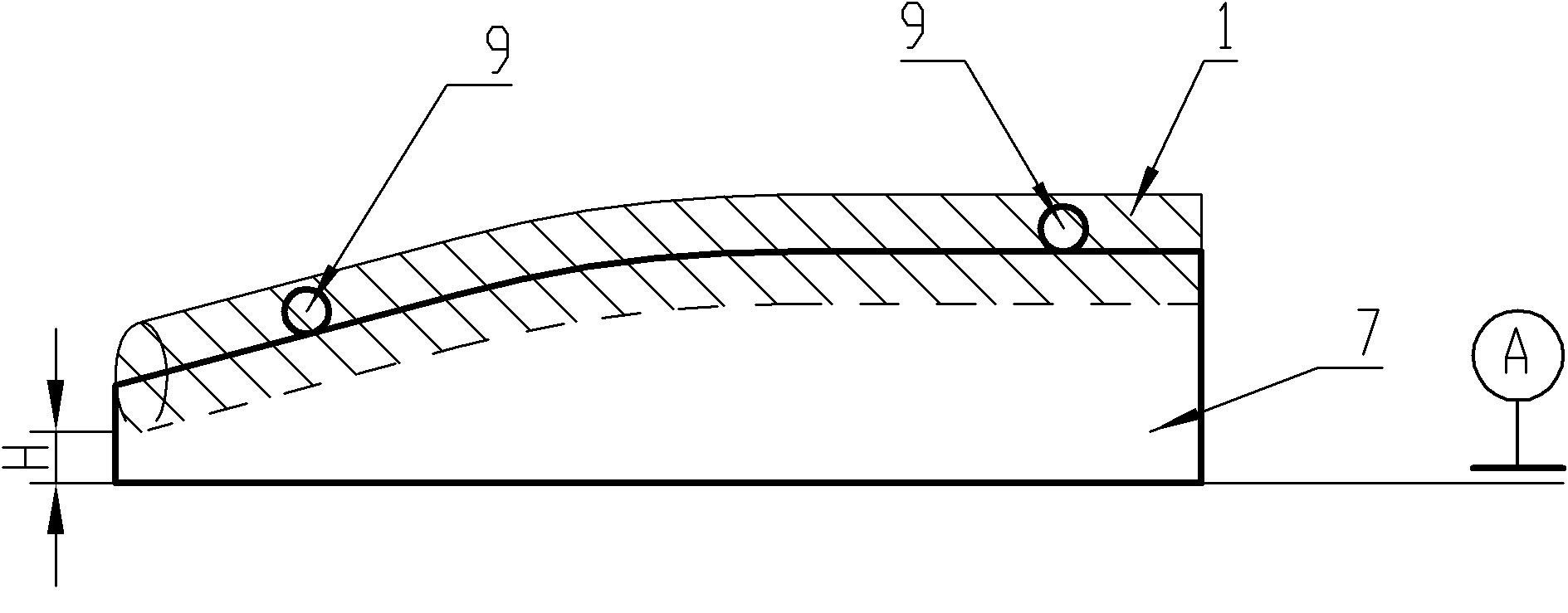

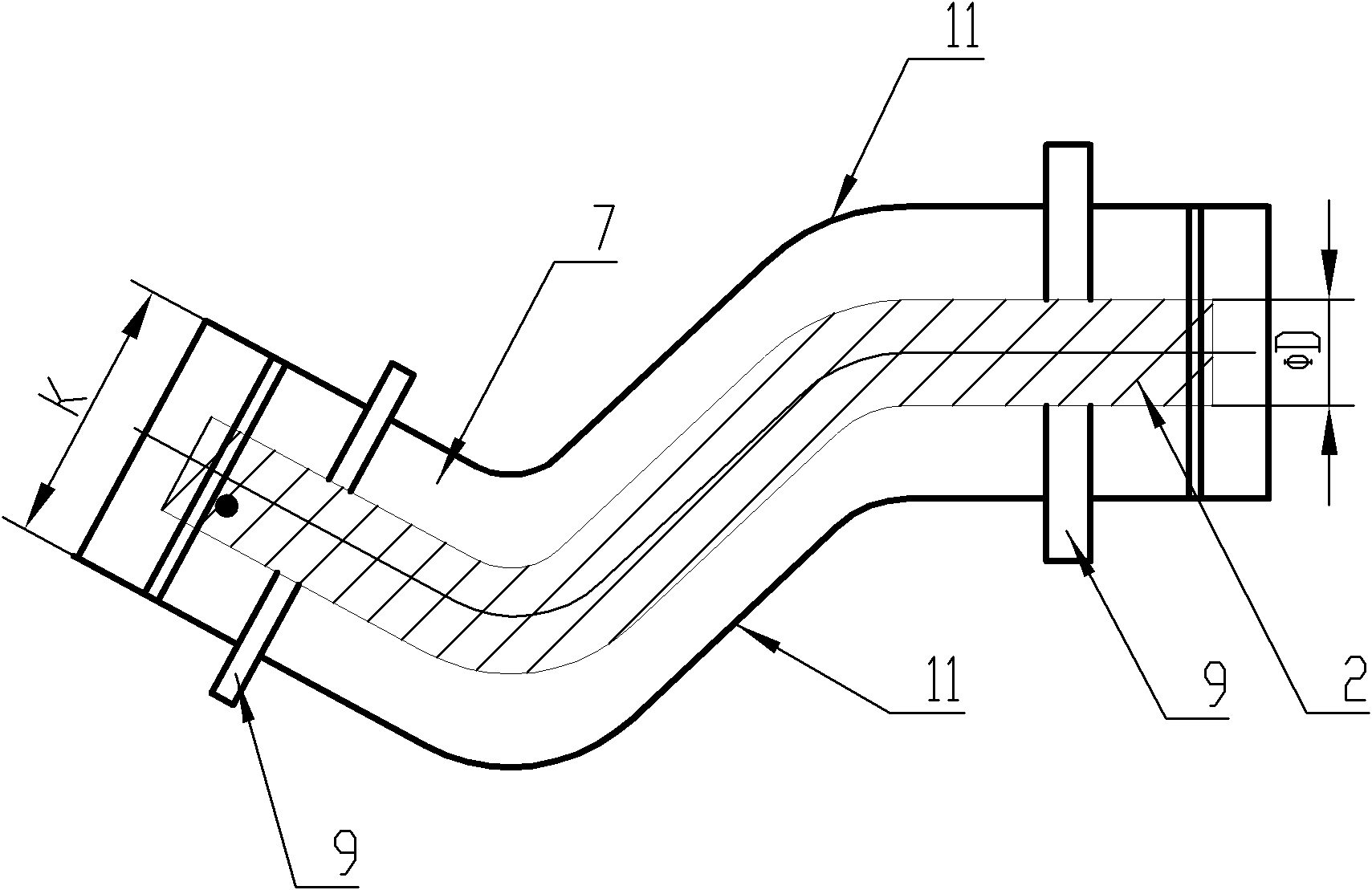

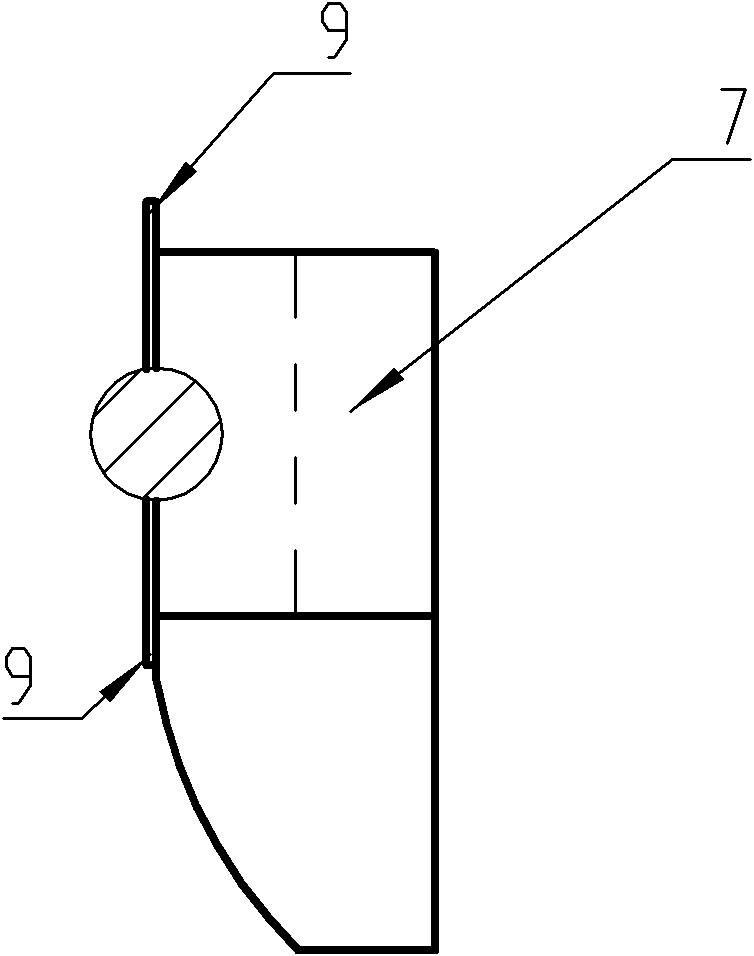

[0044] The present invention will be further described below in conjunction with accompanying drawing. like Figure 1-11As shown, a thin-walled vulcanized rubber hose shaping mold includes a mold cavity 7, a marking pen rotating device, two cutting blade rotating devices and a base 30; the mold cavity 7 is composed of a bottom plate 4 and a left side plate 3 , the right side plate 12, the front vertical plate 8 and the rear vertical plate 13, are combined into a whole by welding respectively, and fixed on the base 30; on the base 30;

[0045] The left side plate 3 and the right side plate 12 in the mold tire cavity 7 are welded with the curved sides of the left and right sides of the bottom plate 4 respectively; the front vertical plate 8 and the rear vertical plate in the mold tire cavity 7 13 are respectively welded to the front end and the rear end of the base plate 4, the left side plate 3 and the right side plate 12;

[0046] The described marking pen rotating and movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com