Patents

Literature

92results about How to "Improve anti-deformation ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

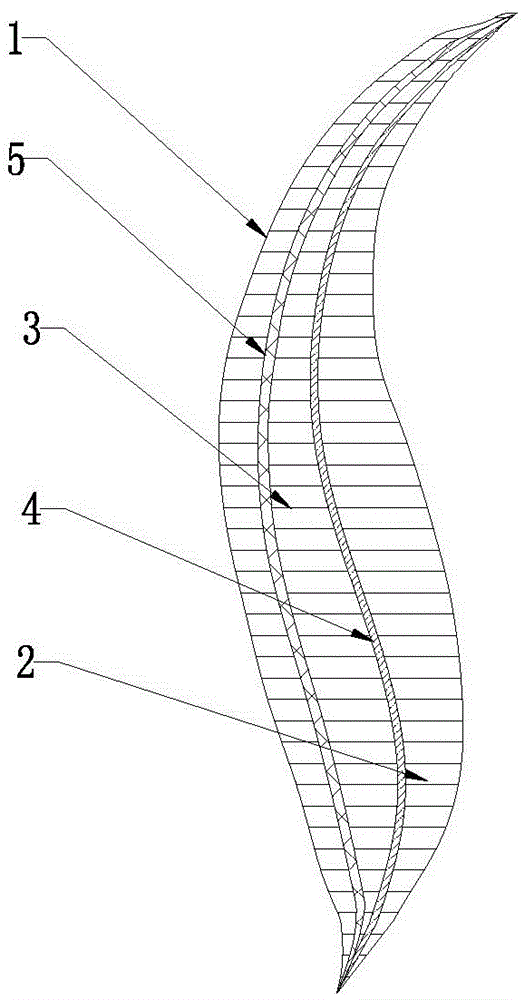

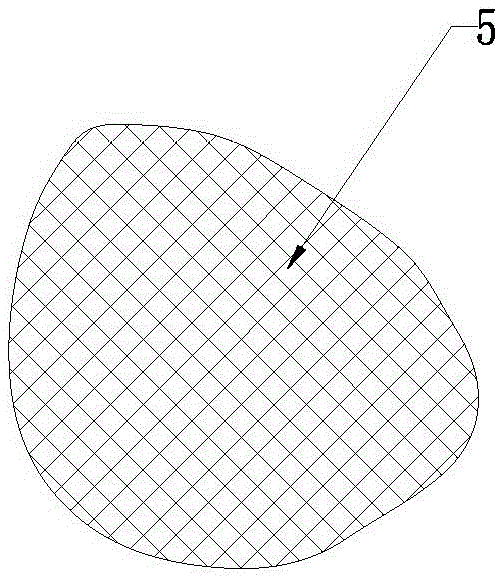

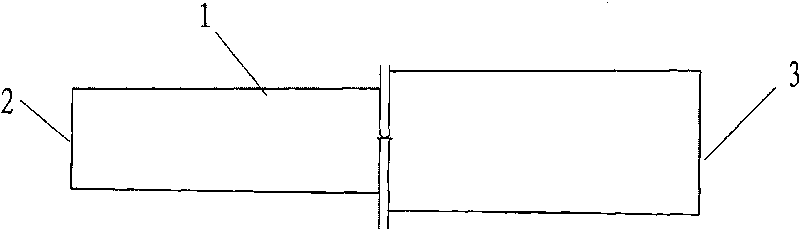

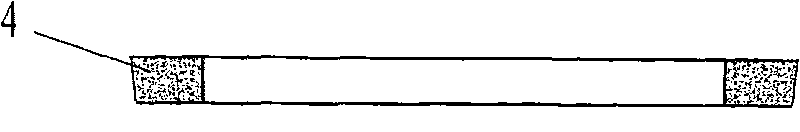

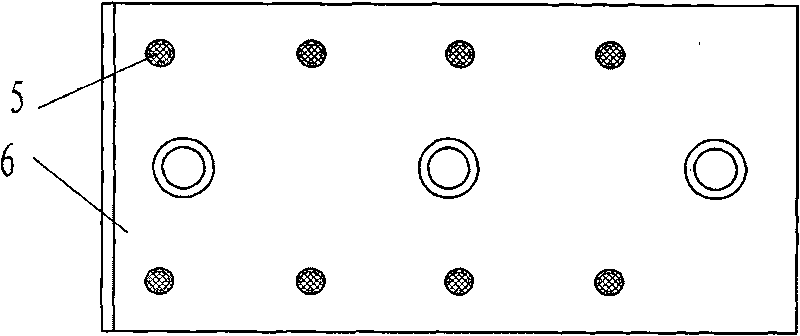

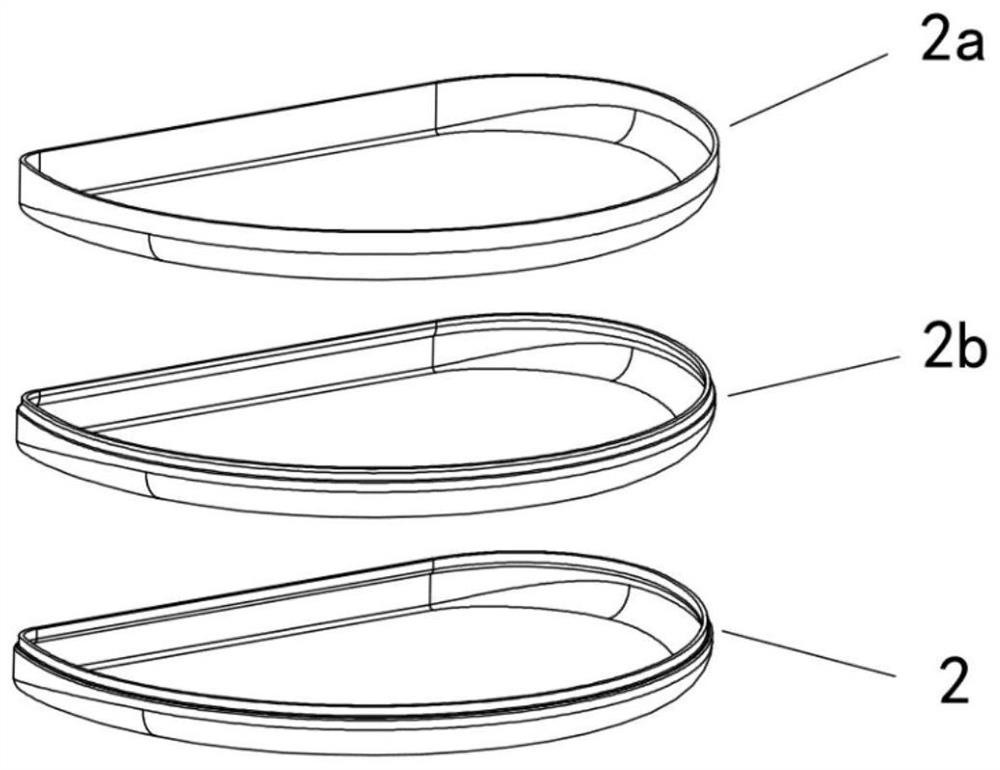

Vertical cotton breathable bra cup pad with silica gel net and preparation method thereof

The invention relates to the technical field of bra cup pad, and specifically relates to a vertical cotton breathable bra cup pad with a silica gel net and a preparation method thereof. The vertical cotton breathable bra cup pad comprises a vertical cotton outer layer and a vertical cotton inner layer; a vertical cotton interlayer is arranged between the vertical cotton outer layer and the vertical cotton inner layer; an adhesive layer is arranged between the vertical cotton interlayer and the vertical cotton inner layer; and a silica gel net layer is arranged between the vertical cotton outer layer and the vertical cotton interlayer. The vertical cotton breathable bra cup pad is prepared by a combined technology of hot pressing and cold pressing. The pad is made of vertical cotton, and is light, comfortable, and breathable. A silica gel layer is arranged between vertical cotton layers, the performance of the pad on resisting water washing is enhanced, the anti-collapse effect is good, three-dimensional effect of the cup pad is long-lasting and stable, and the deformation is difficult to happen.

Owner:HONGJI UNDERWEAR CO LTD

Wicker product anti-pest and anti-mildew method capable of enhancing wicker knitting capacity

InactiveCN106003333ALoose organizational structureLow ash contentWood treatment detailsCane mechanical workingHigh humidityEngineering

The invention discloses a wicker product anti-pest and anti-mildew method capable of enhancing wicker knitting capacity. The method includes the following steps of (1) wicker peeling, (2) softening treatment, (3) wicker knitting and (4) anti-pest and anti-mildew treatment. By the adoption of the method, all the steps are matched scientifically and reasonably, and wicker products manufactured are good in anti-pest and anti-mildew effect. Compared with the prior art, the service life under the conventional using condition can be prolonged by about 20%, and the service life under the high-humidity condition can be prolonged by over 50%. Moreover, using stability is good, anti-deformation capacity is high, and the use value is good.

Owner:阜南县猛发工艺品有限公司

Drawing process of conical ductile cast-iron pipe

The invention discloses a drawing process of a conical ductile cast-iron pipe cast by devices, including a sand mold core, a cast-iron core frame, pipe-drawing calipers, a casting mold and a centrifugal pipe-casting machine. The drawing process comprises the following steps: firstly, putting the dotted casting mold in the centrifugal pipe-casting machine; leading cooling water to the outer wall of the casting mold; mounting the casting mold in the centrifugal pipe-casting machine; mounting the sand mold core on the cast-iron core frame; arranging the cast-iron core frame in the bearing port of the casting mold; pouring molten iron in the fan-shaped ladle of the centrifugal pipe-casting machine; then, starting the automatic pipe-drawing system of the centrifugal pipe-casting machine; drawing to mold; and drawing out the conical ductile cast-iron pipe with the pipe-drawing calipers. In the pipe-drawing process, the drawing speed curve of the automatic pipe-drawing system of the centrifugal pipe-casting machine adopts segmental control, and the rotating speed of a casting rotating DC (Direct Current) motor gradually increases and ranges from 800r / min to 1700r / min. The process enables the pipe body of the conical ductile cast-iron pipe to have even wall thickness and internal compact structure and accord with the use performance requirements.

Owner:ANYANG IRON & STEEL

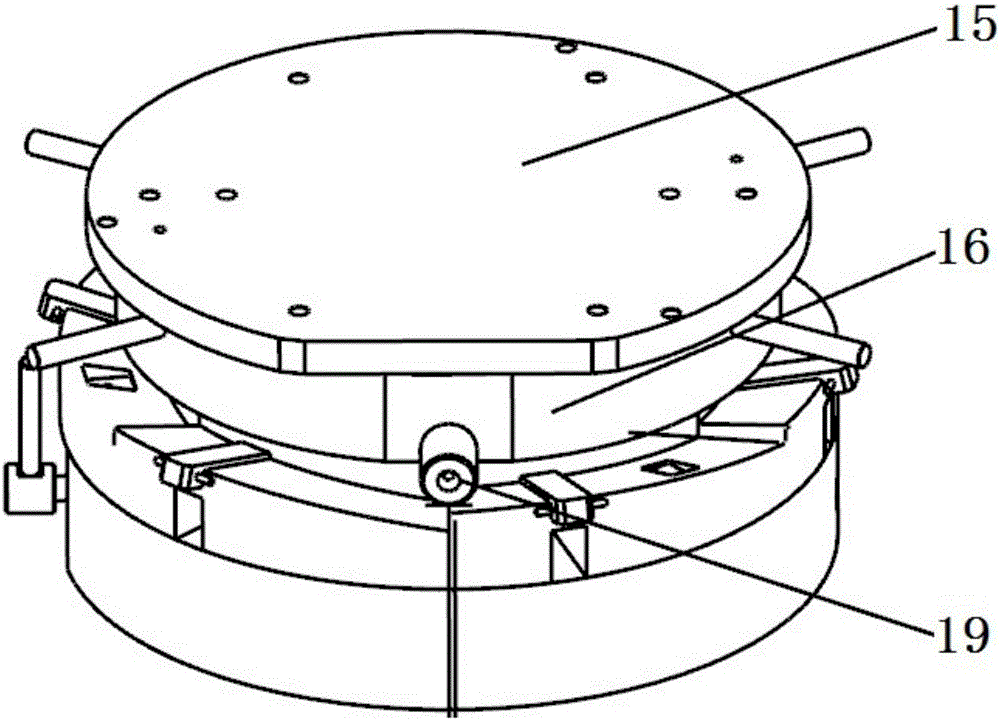

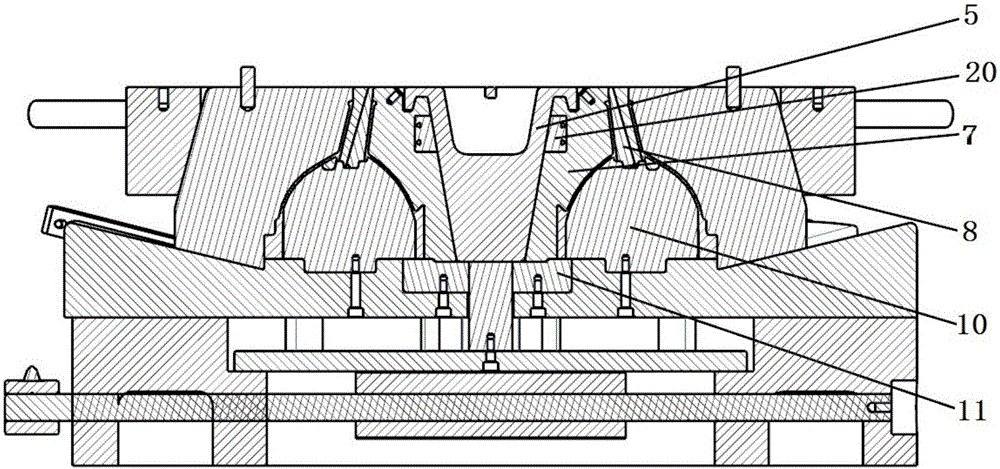

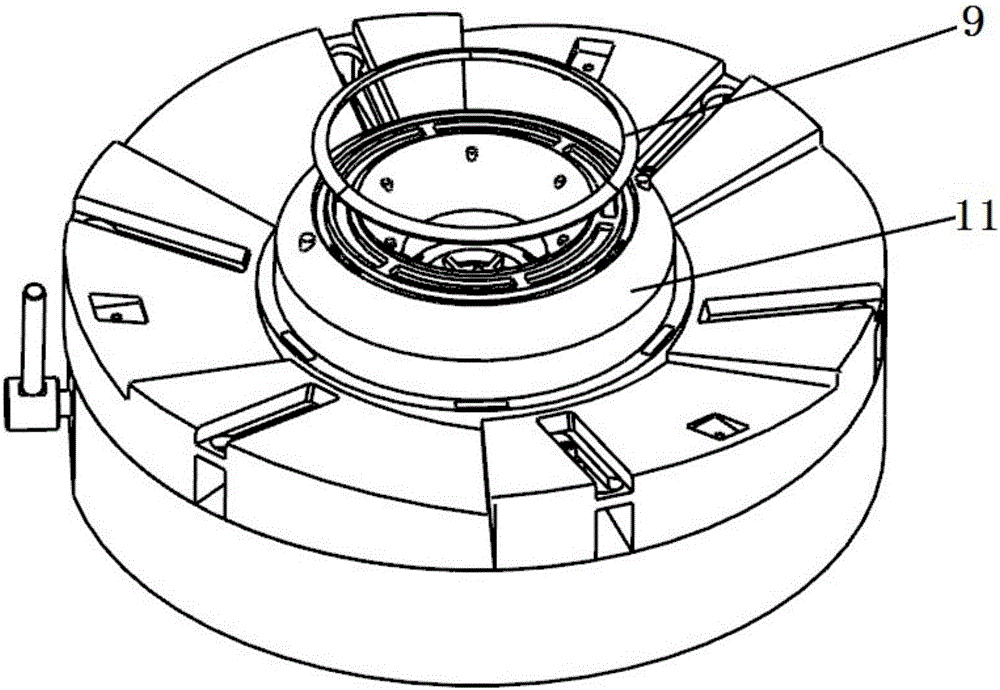

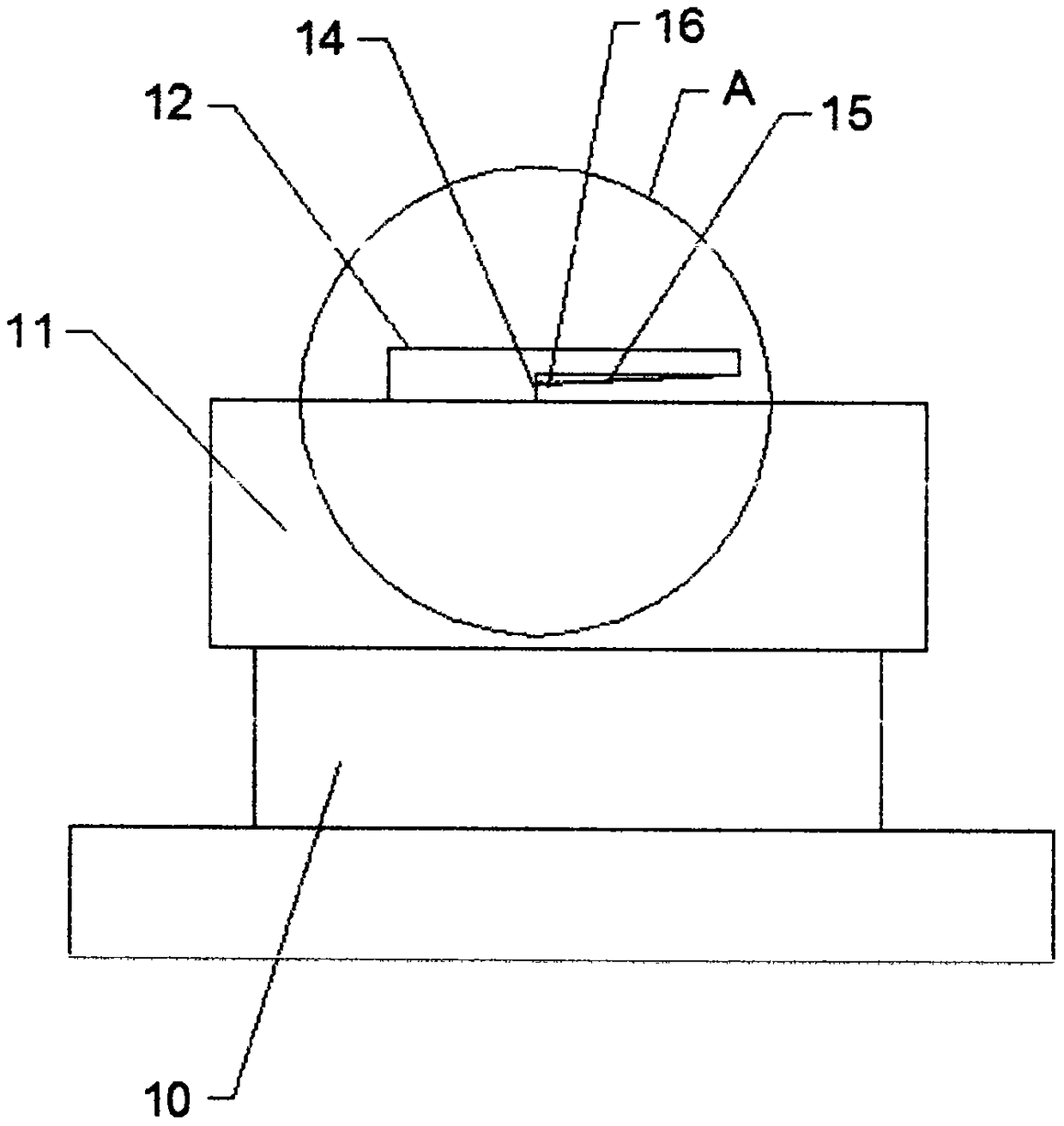

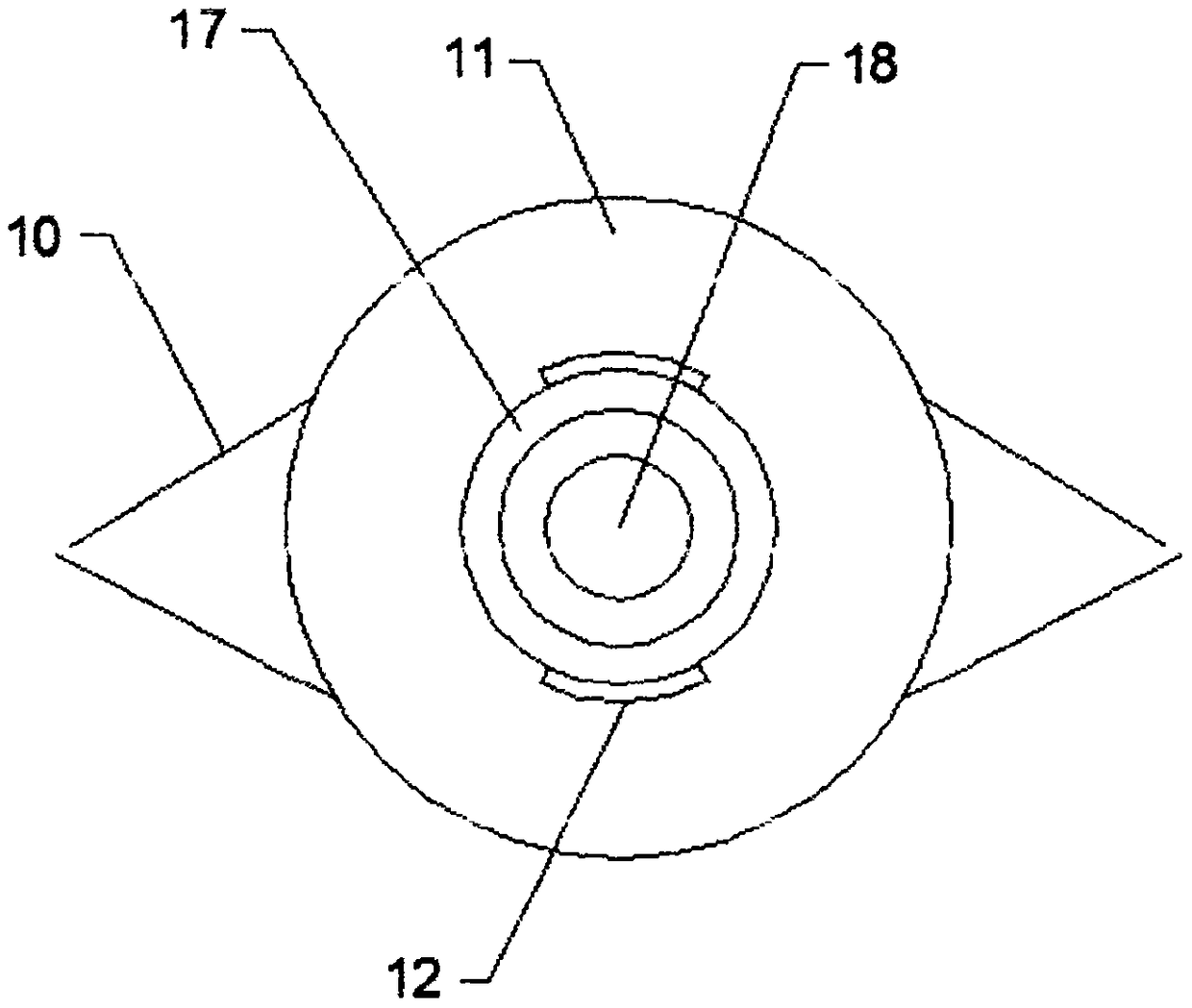

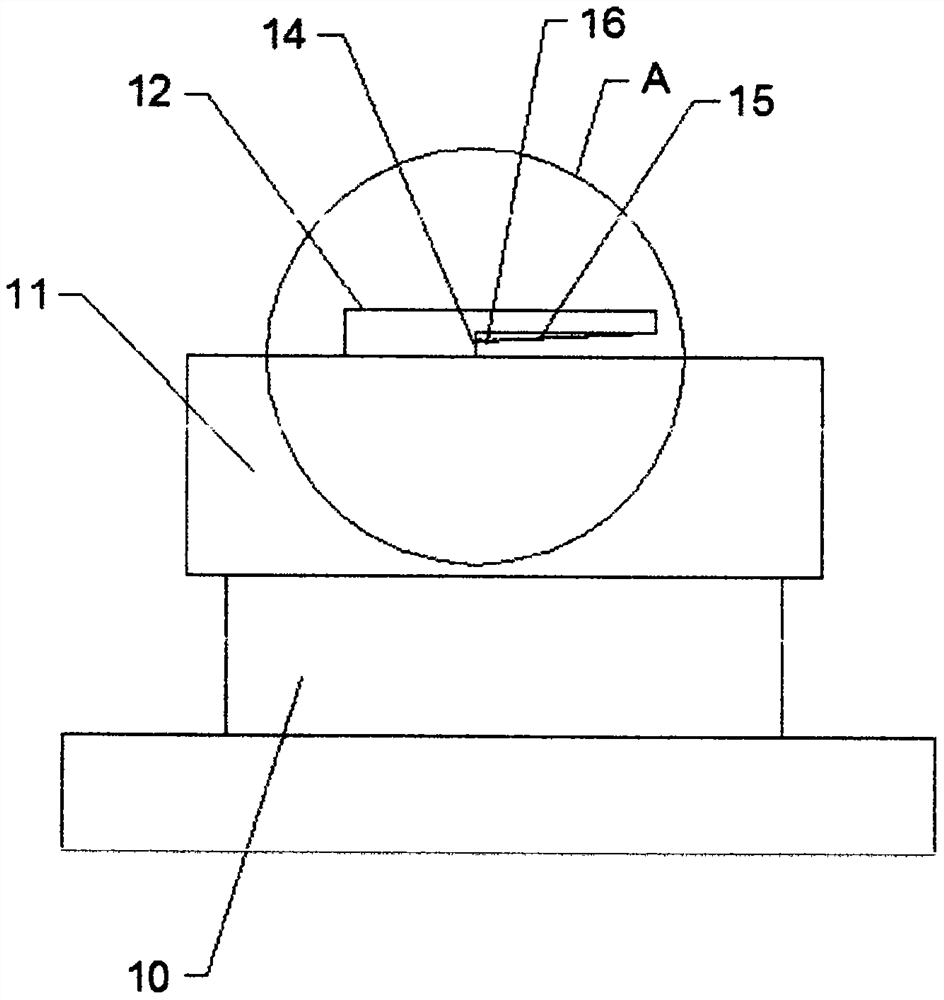

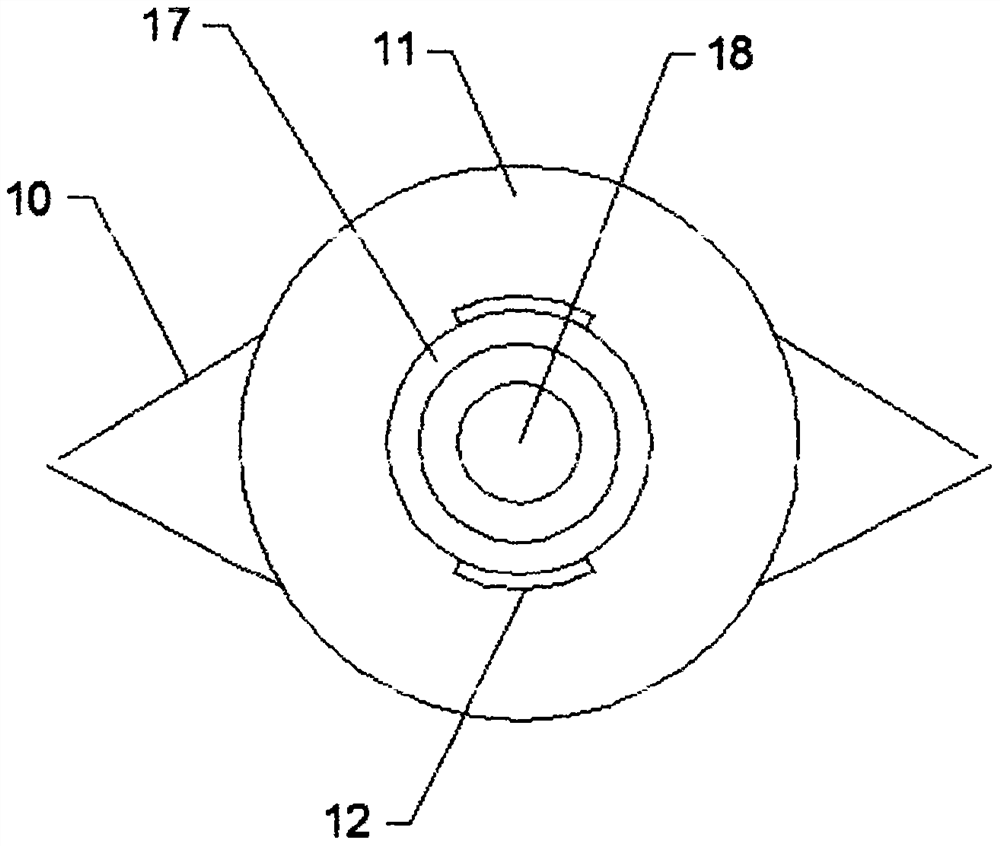

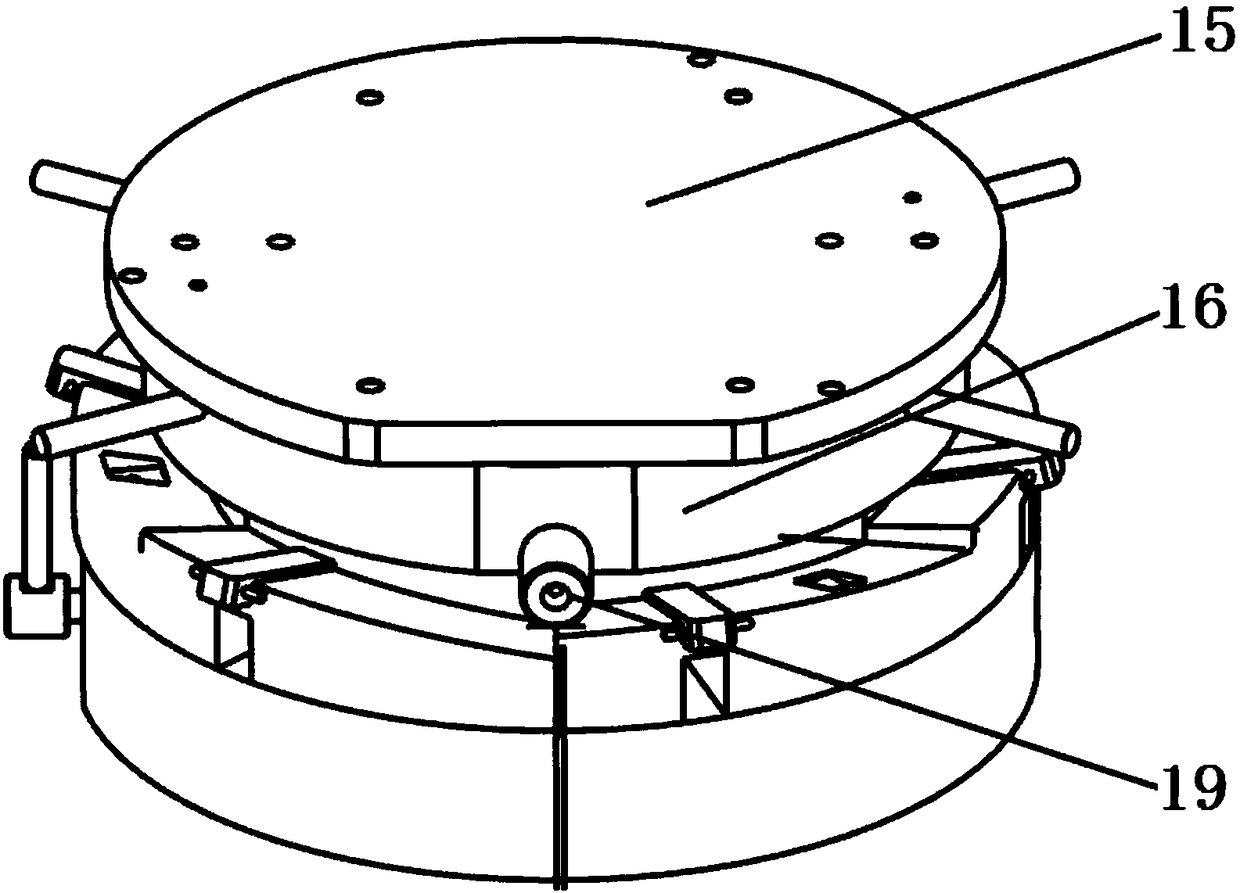

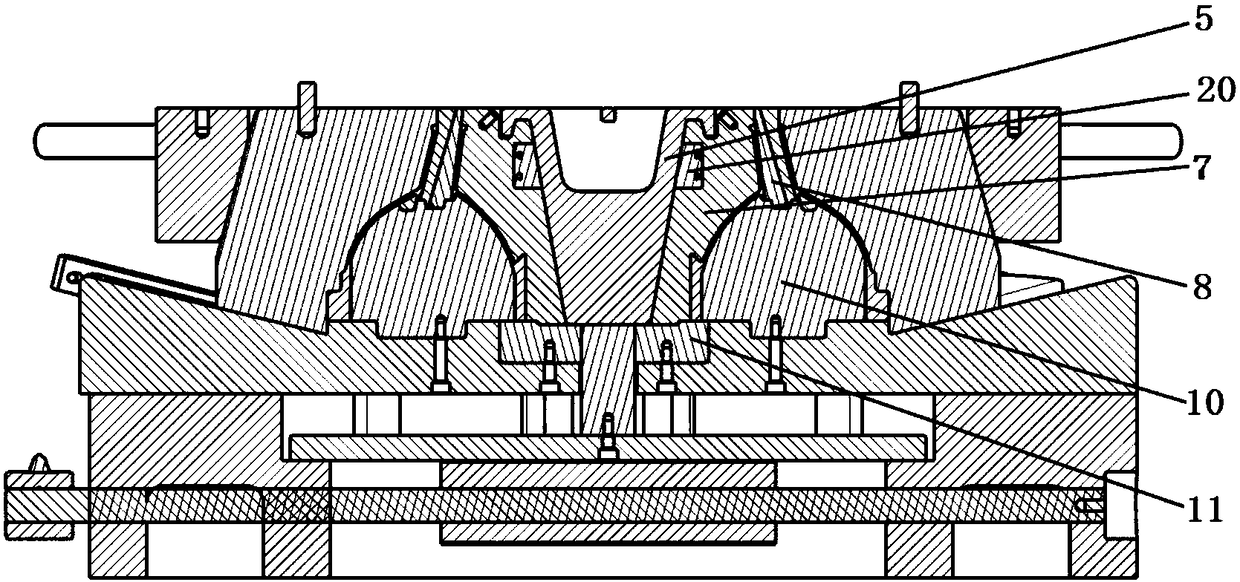

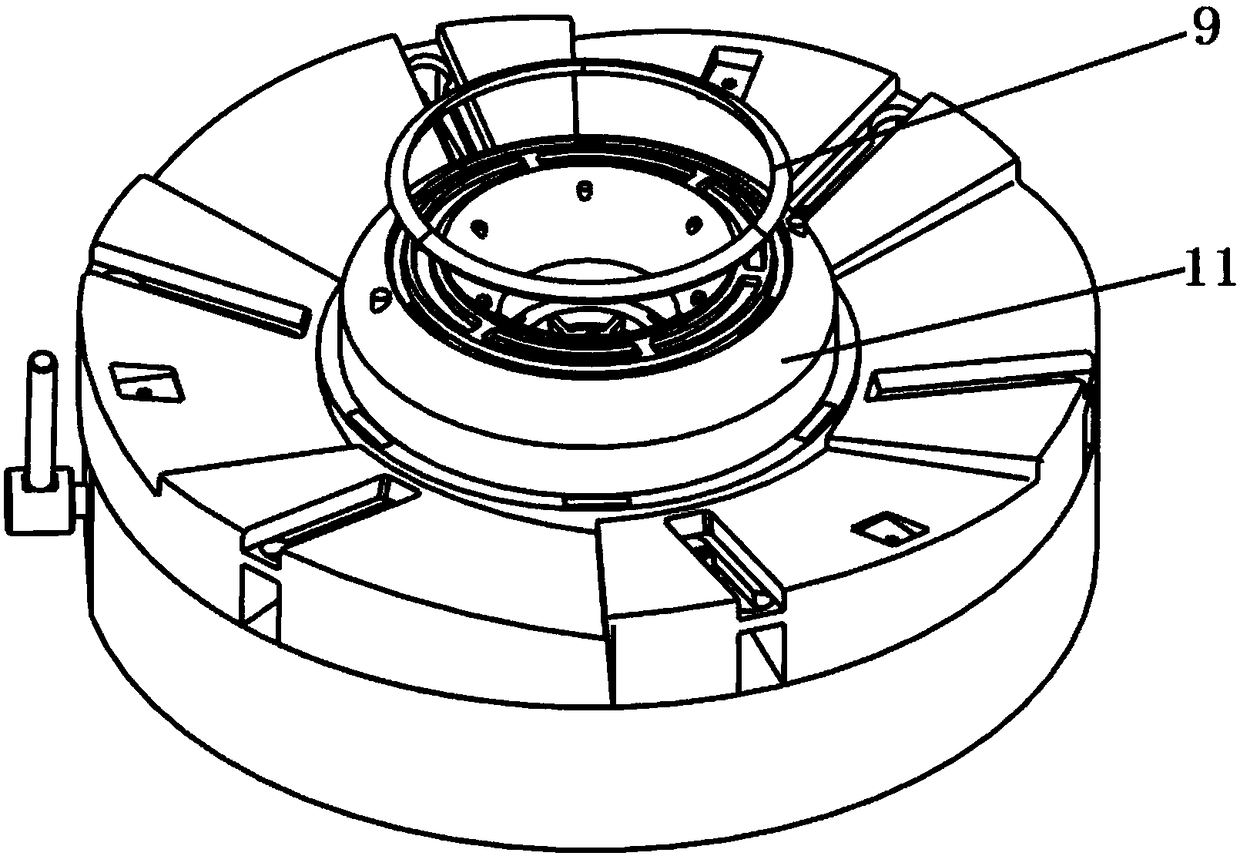

Integrally casting mold for aero-engine diffuser

ActiveCN106623772ASolve the deformationSolve problems such as damageFoundry moulding apparatusWaxCasting mold

The invention discloses an integrally casting mold for an aero-engine diffuser. The mold comprises a pedestal and an upper cover plate, wherein an inner ring-shaped cavity structure of the diffuser is integrally formed between the pedestal and the upper cover plate, a frustum cone-shaped loose core is arranged at the center position of the inner ring-shaped cavity structure, a wax injection nozzle communicating with the inner ring-shaped cavity is arranged on the inner ring-shaped cavity structure; and an ejection structure for ejecting the molded diffuser is arranged at the bottom of the inner ring-shaped cavity structure. According to the mold provided by the invention, the diffuser cast can be integrally formed into a ring at a time without subsequent wax molding adhesion, and the problem of reverse pulling of the wax on the mold can be solved, and forming of the aero-engine diffuser with the thick wall is ensured.

Owner:AECC AVIATION POWER CO LTD

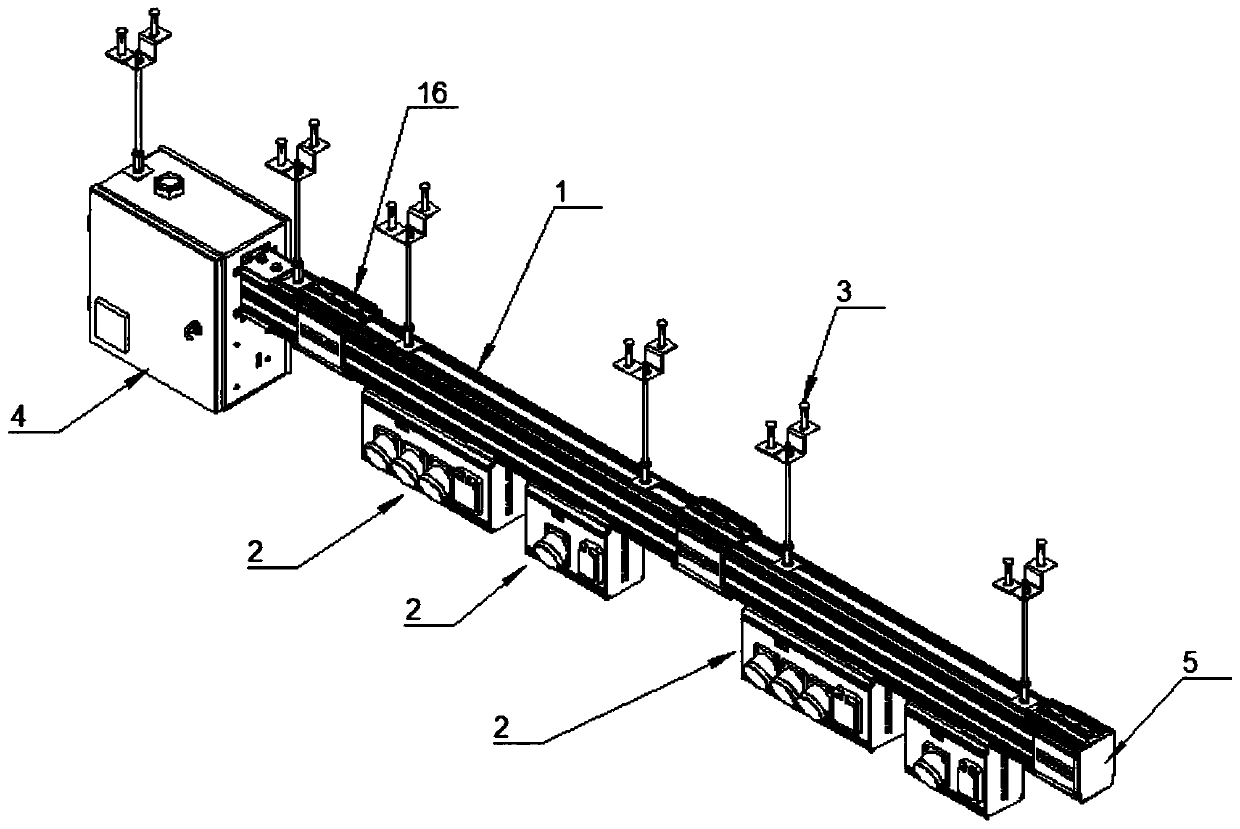

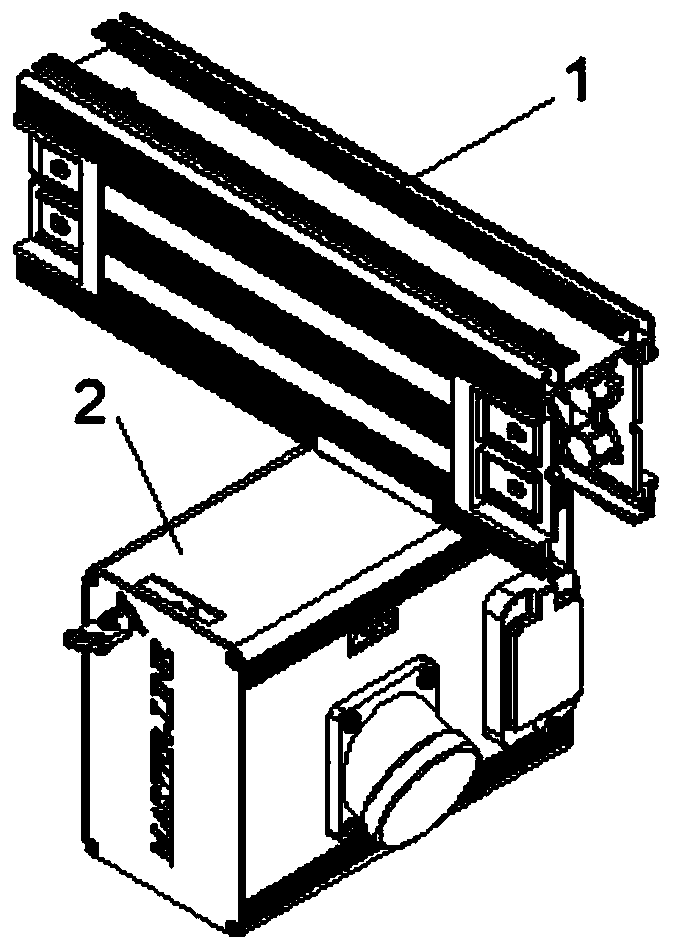

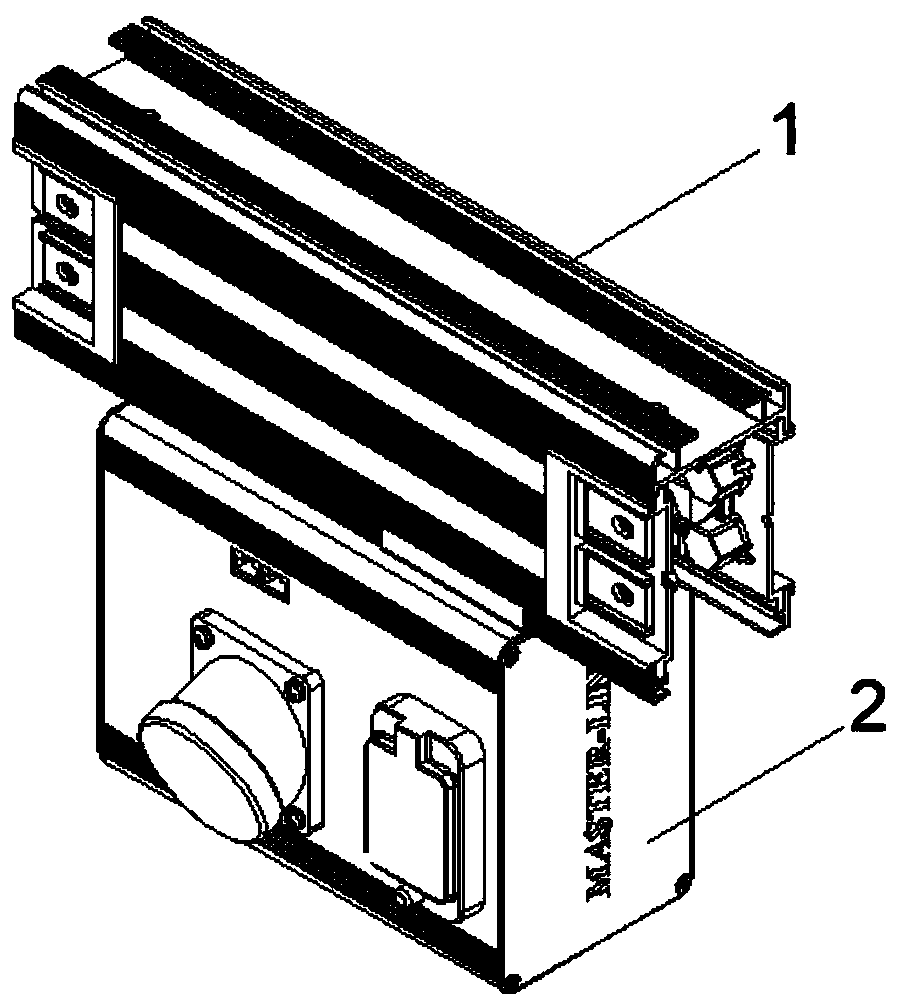

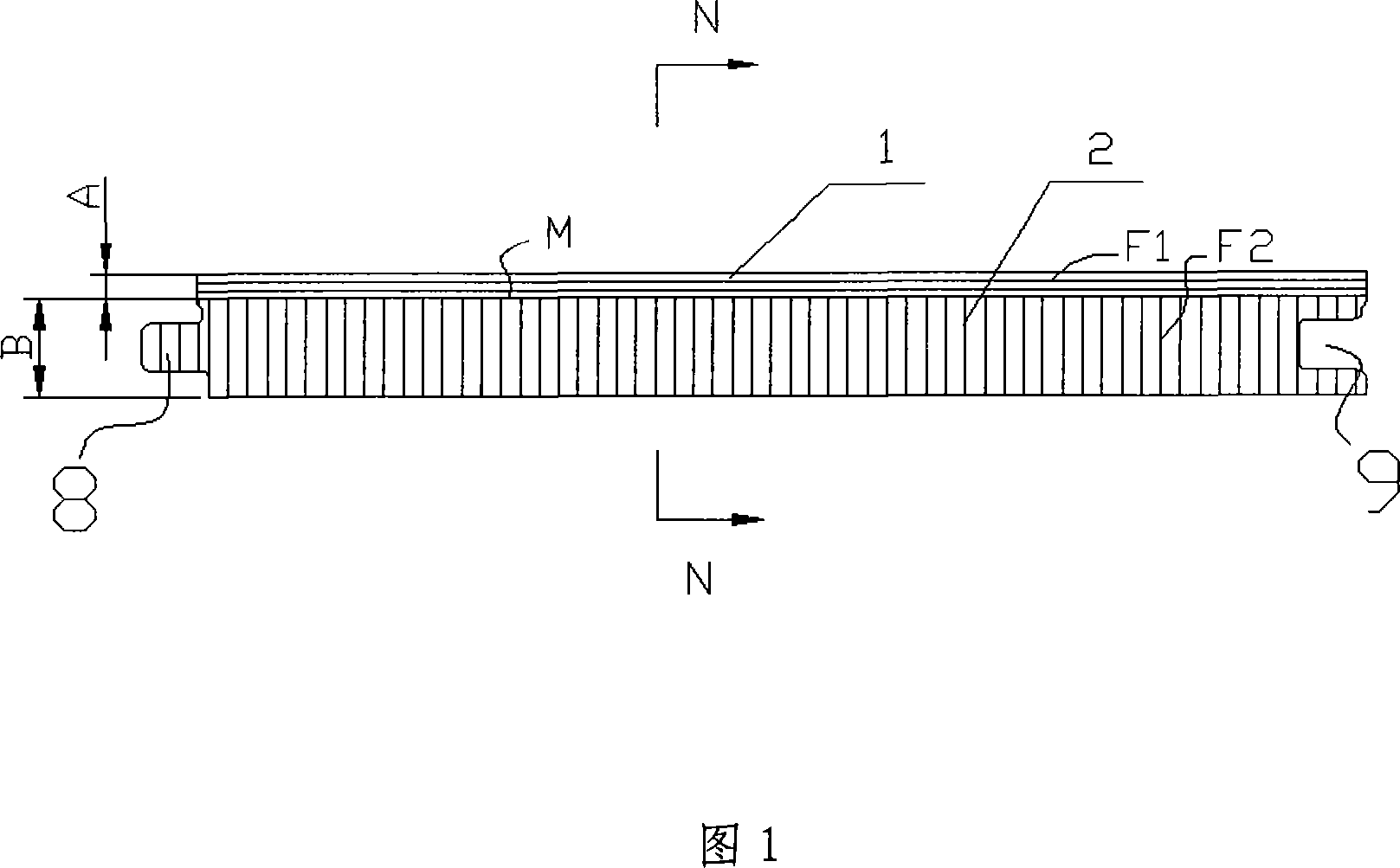

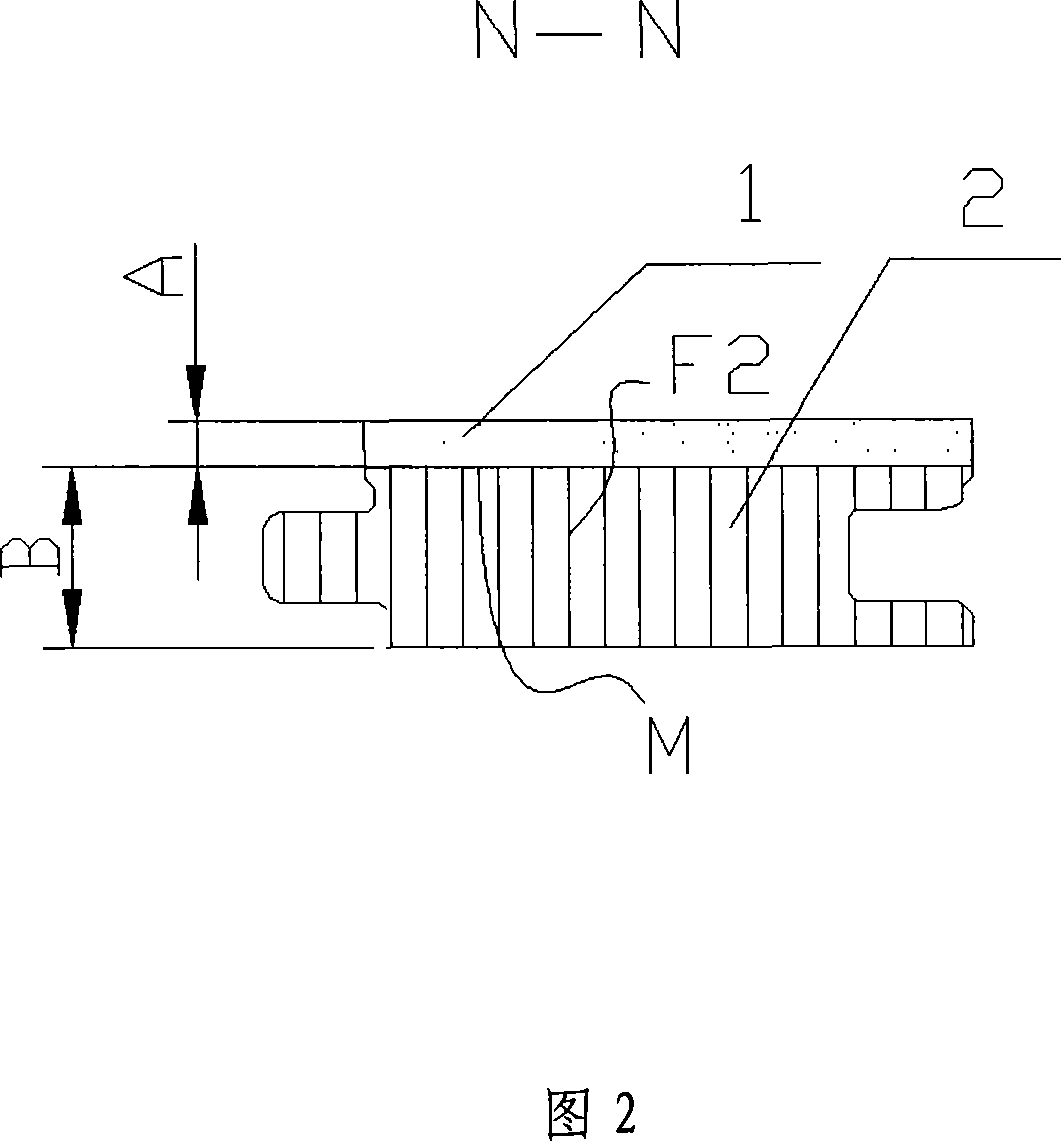

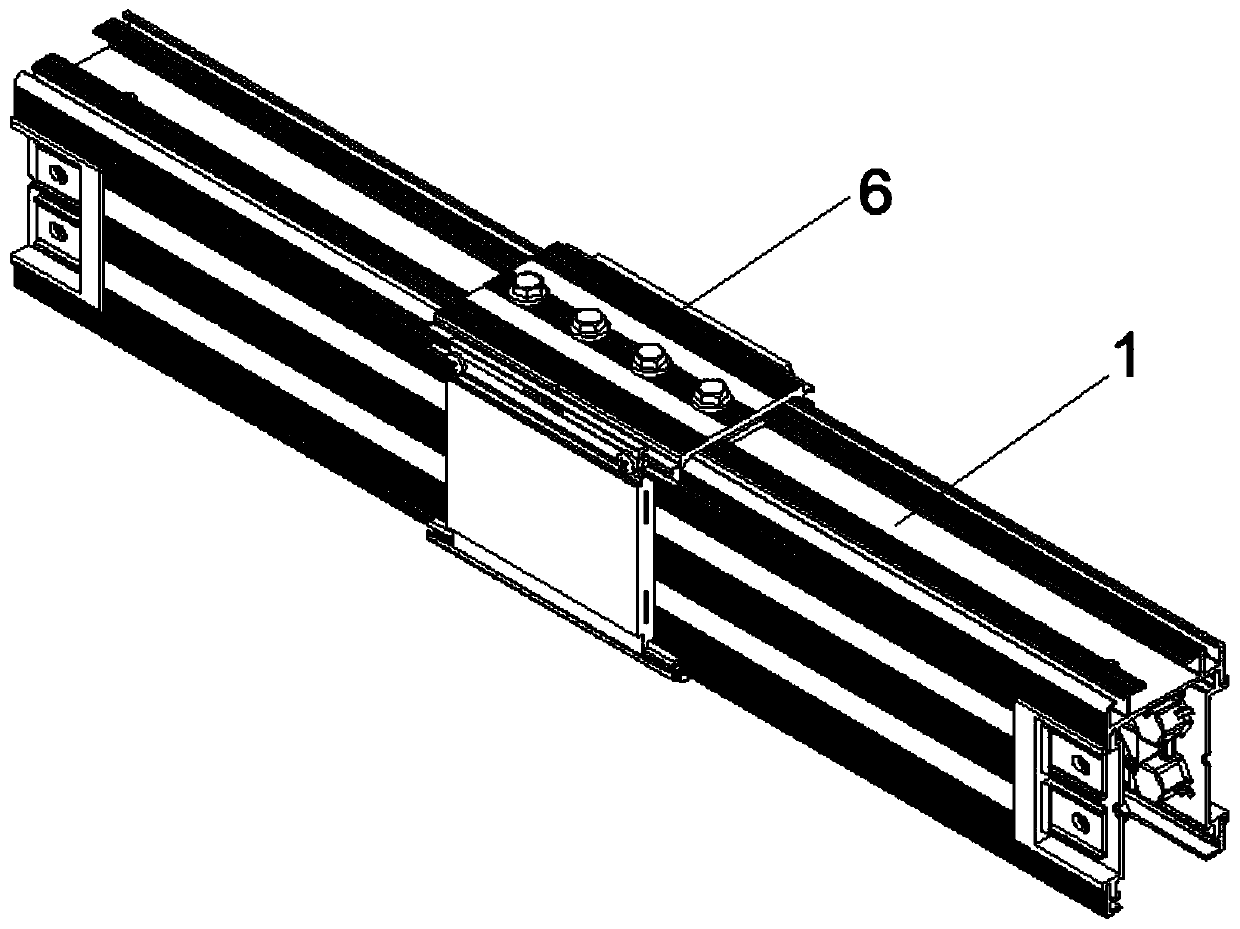

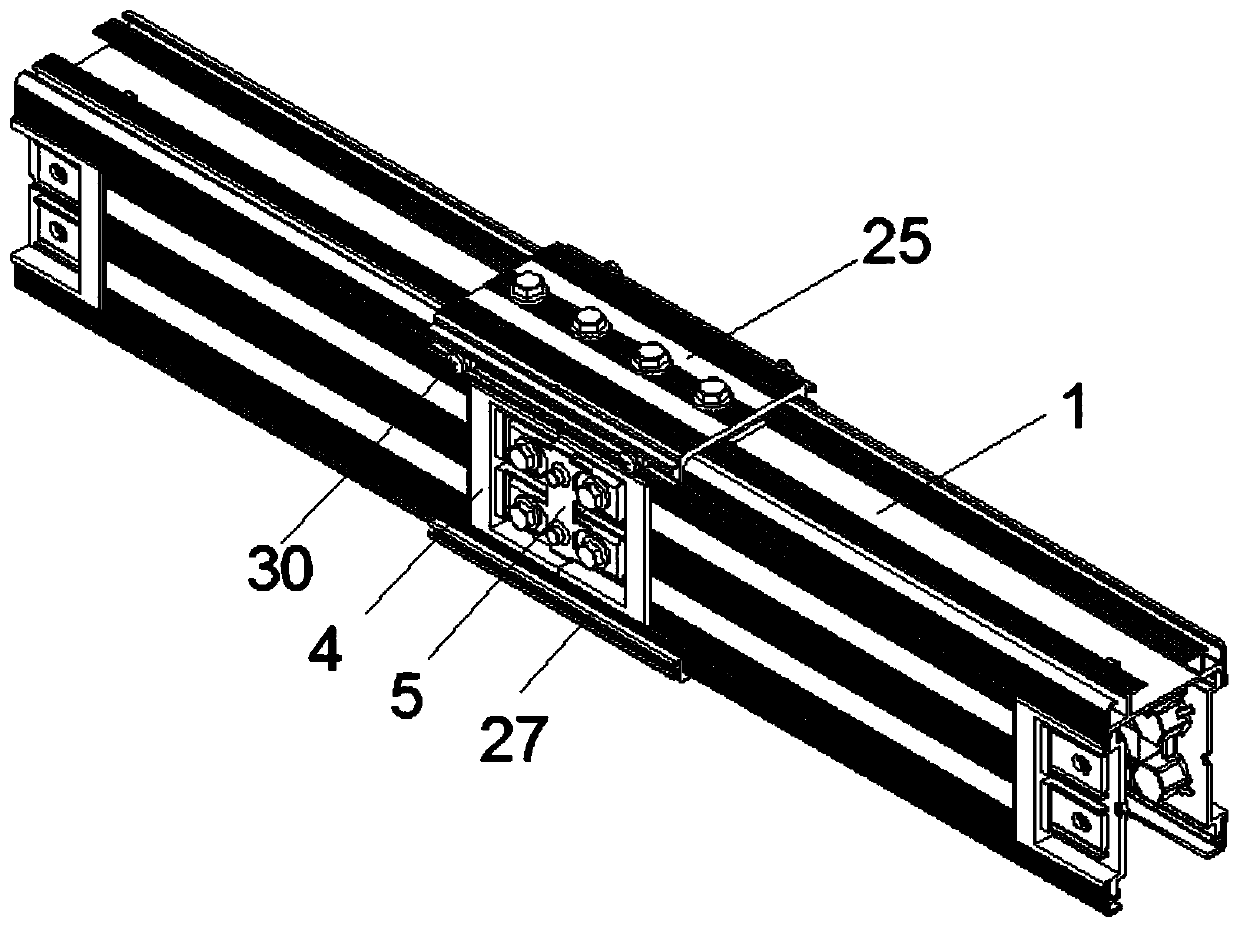

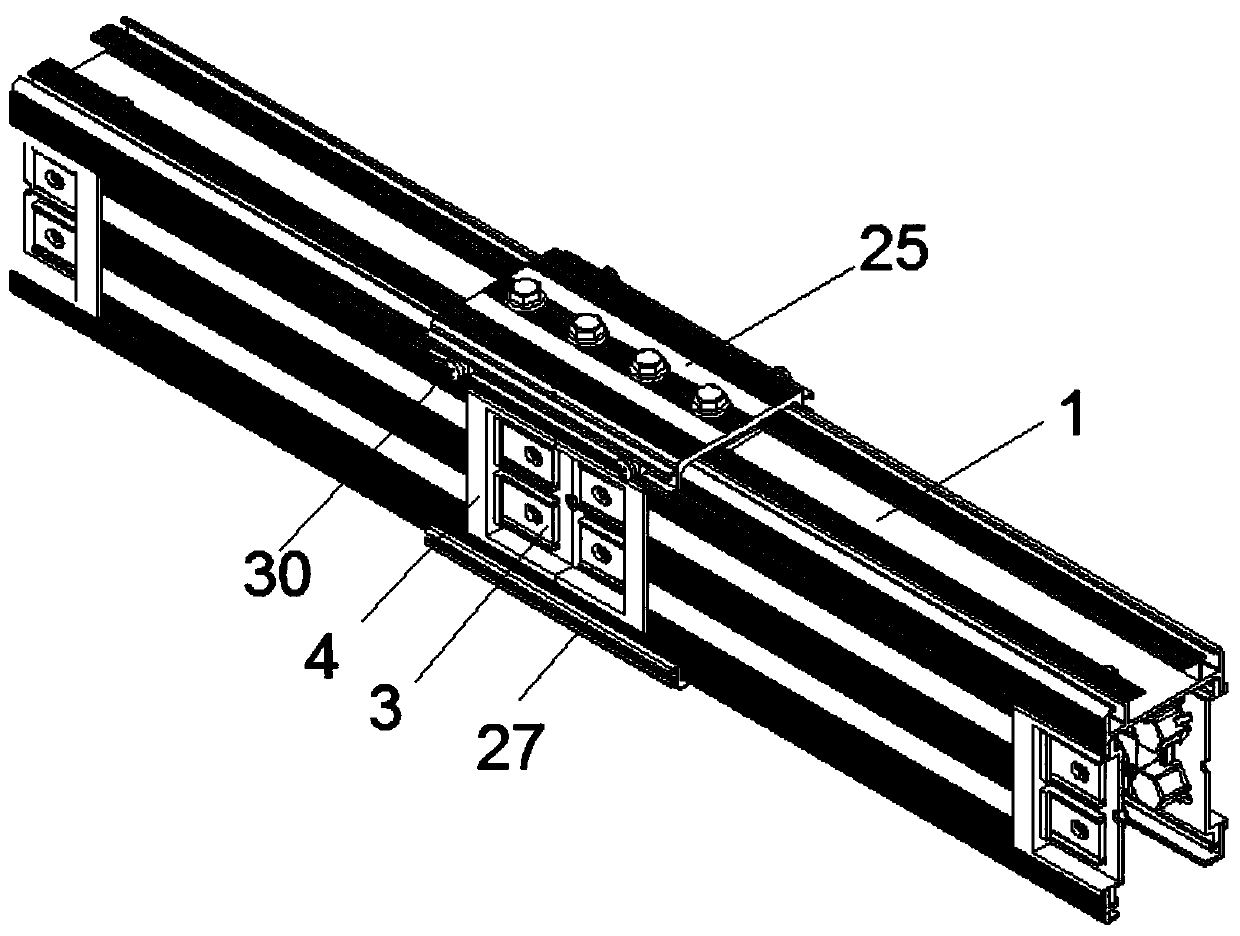

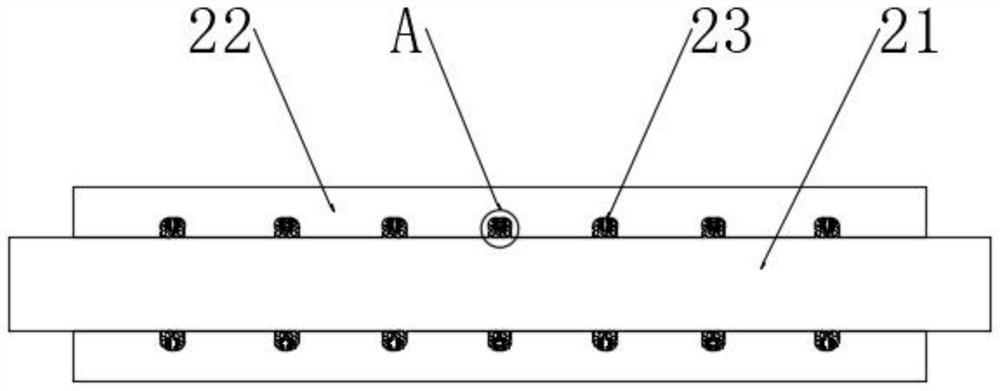

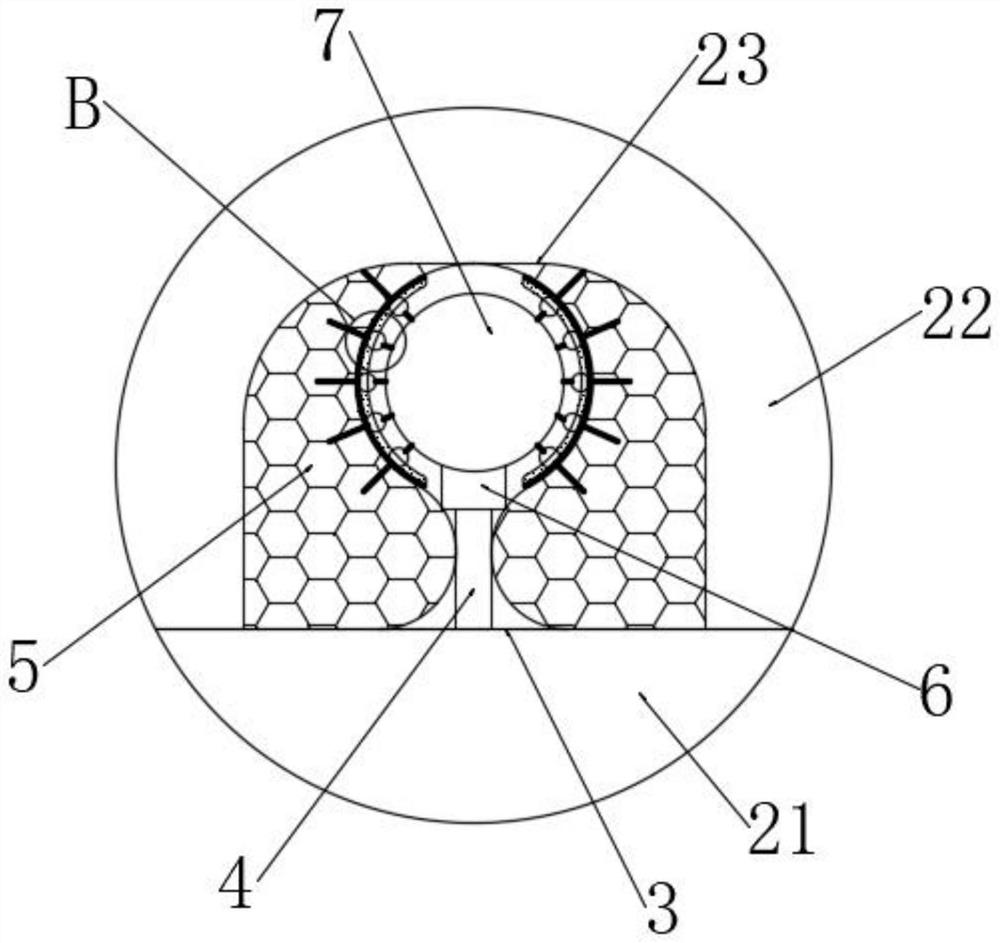

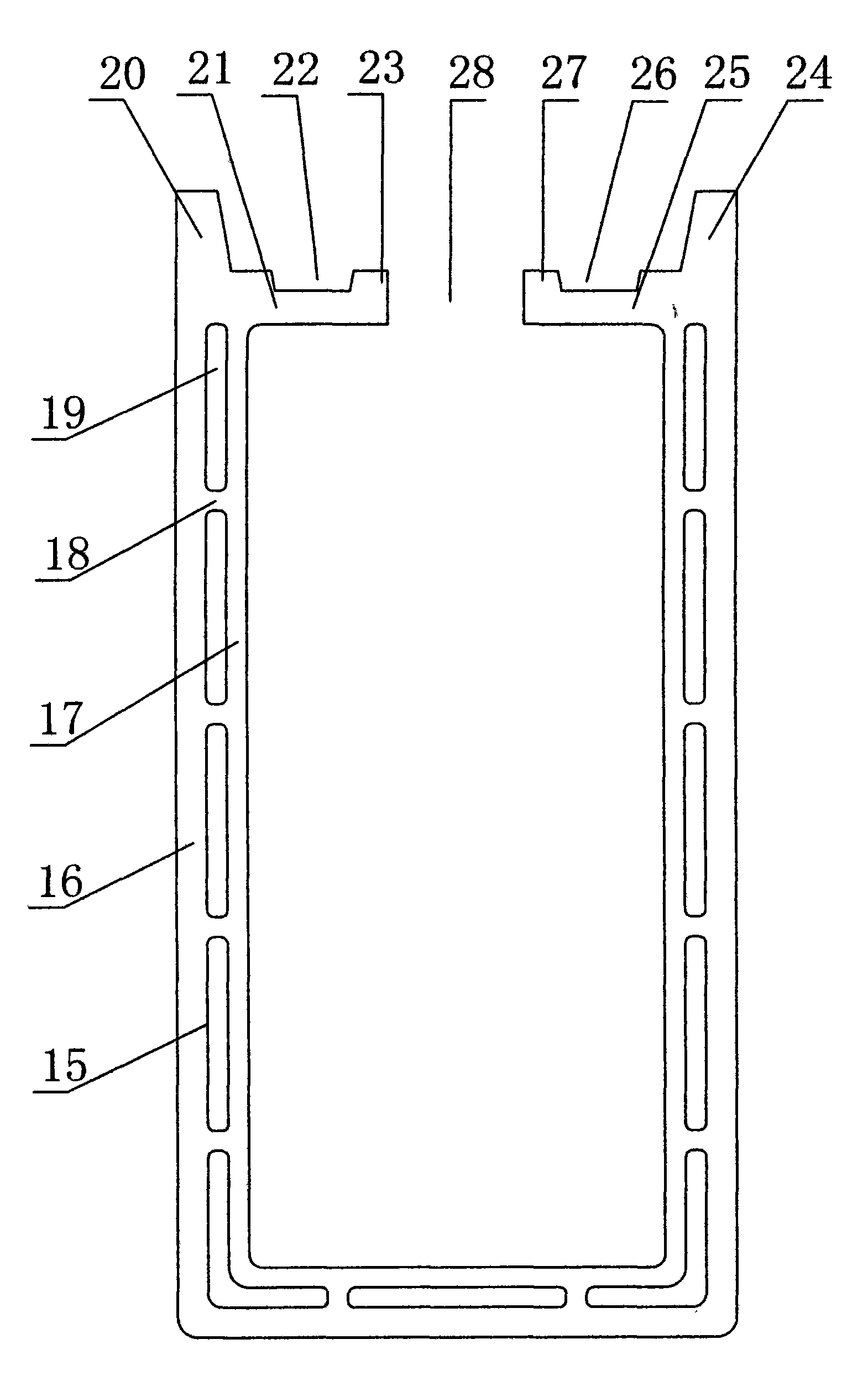

Safety type bus duct digital system

ActiveCN109904812AImprove structural strengthImprove insulation safetyCooling bus-bar installationsTotally enclosed bus-bar installationsEmbedded system

The invention discloses a safety type bus duct digital system. The safety type bus duct digital system comprises a bus duct, an inserting box, a starting end box, a termination end cover and a bus duct hoisting part, and is characterized in that one end of the bus duct is connected with the starting end box; the other end of the bus duct is fixedly provided with the termination end cover; the topof the bus duct is hoisted at the top of a wall through a bus duct hoisting piece; and the bottom of the bus duct is inserted with the inserting box. The safety type bus duct digital system is high inoverall structural strength, simple and convenient in mounting method, rapid to mount, high in overall structure safety performance, simple in part manufacturing process and low in whole structure production cost.

Owner:镇江西格玛电气有限公司

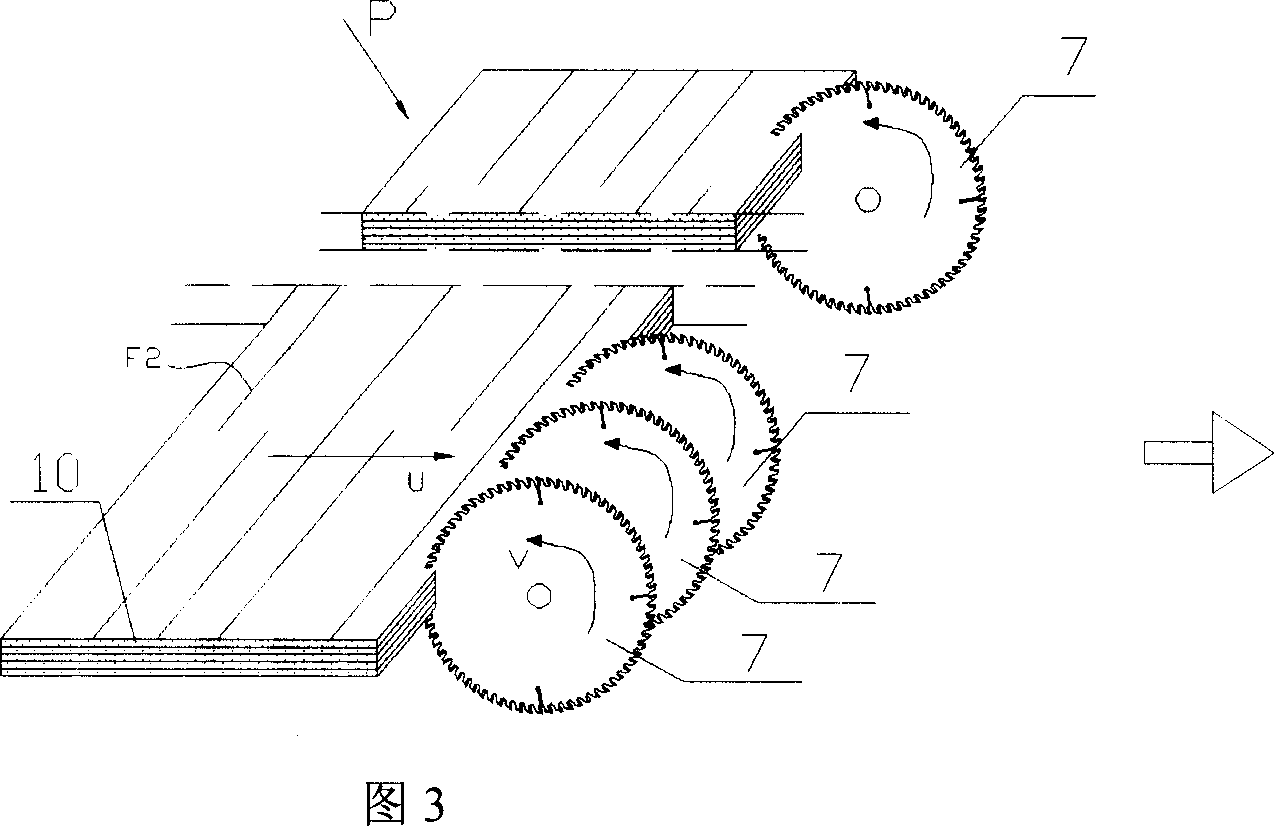

Floor and its production method and its uses as ground heat floor

PendingCN101054852AImprove anti-deformation abilityImprove the crack resistance of the surface plateWood working apparatusFlooringLathCivil engineering

The invention provides a warpproof floor and manufacturing process thereof. This floor comprises a face board and a base material, the surface of base material is timber cross section, radial section or staggered section of timber cross section and radial section. The method of this floor comprises the steps of cementing the face board and the base material together; the base material is prepared according to the following methods: after sawing the single board laminated wood transversely or longitudinally to lath, the side of the lath is applied glue, a plurality of lath are made by lateral pressures again, or after sawing plywood to lath, the side of the lath is applied glue, a plurality of lath are made by lateral pressures again. This floor has good dimensional stability, and can prevent radically warp deform in use and eliminate crazing phenomenon in use.

Owner:NANJING FORESTRY UNIV

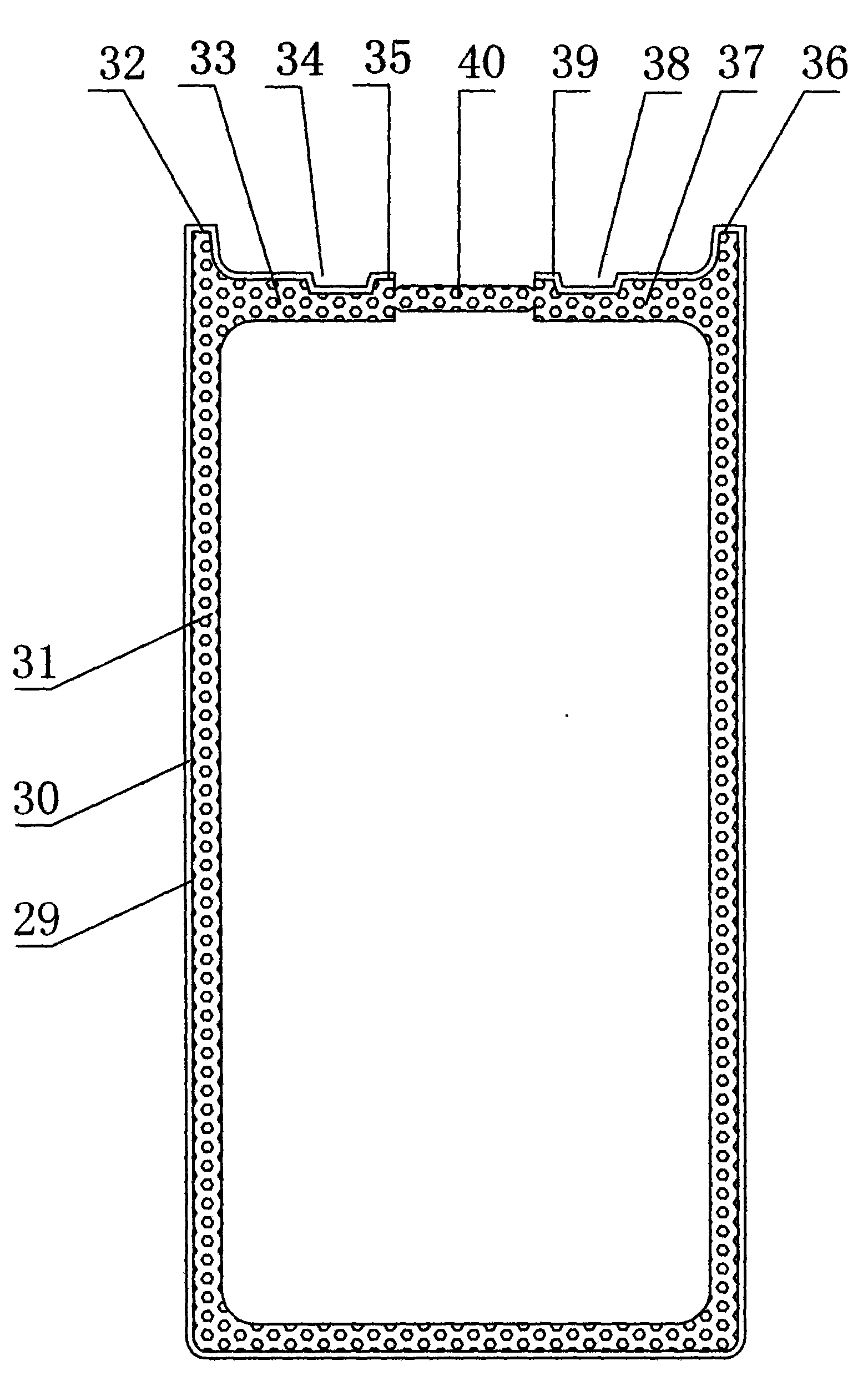

Door body of refrigerator freezer room

InactiveCN102042735AAvoid deformationDeformation force preventionDomestic cooling apparatusLighting and heating apparatusInsulation layerEngineering

The invention relates to a door body of a refrigerator freezer room, which comprises a door panel, a door inner chamber, an upper positioning plate, a lower positioning plate and a foam insulation layer as well as a stiffening plate made of a plurality of bamboo rods, wherein the stiffening plate is parallel to the door inner chamber, and an included angle with the plane is formed and is less than or equal to 90 degrees and is greater than or equal to 0 degree. Because of the adoption of such structure, the stiffening plate made of the bamboo rods has toughness so as to effectively neutralize bending deformation force of the door panel and the door inner chamber and keep the original shape of the door so that the door body is prevented from deforming; the stiffening plate made of the bamboo rods has a plurality of bamboo joints which can enforce the combination force between the foam insulation layer and the stiffening plate so that the door body has high integrality and the function of deformation prevention is increased. Compared with metal stiffening plates in the prior art, the stiffening plate made of the bamboo rods has good toughness, high deformation-resistant capability, low cost and light weight.

Owner:孙维荣

Method for increasing duck egg hatching rate

The invention discloses a method for increasing the duck egg hatching rate. The method is characterized by comprising the steps of 1, hatching egg selection, wherein the hatching egg weight, eggshell mass, vibrating sound and storage time are screened; 2, sterilization, wherein chinaberry leaves and azadirachta indica leaves are adopted as main extraction raw materials, pulverization, cooking and concentration are performed to obtain a plant sterilizing solution, and hatching eggs are soaked with the solution to be sterilized; 3, hatching bed laying, wherein matrix components are subjected to high-temperature sterilization, then, a hatching bed is laid, and upper and lower fluorescent lamps and a lower ventilation system are arranged; 4, hatching, wherein water is added into the plant sterilizing solution for dilution, the solution is sprayed one time every day, a folic acid solution is used for performing atomization on duck eggs, and the hatching temperature is adjusted. Compared with a control group, according to hatched ducks, the hatching rate is increased by 7.74%, the morbidity rate is lowered by 2.74%, the distortion rate is lowered by 0.50%, and the growth cycle is shortened by 15 d.

Owner:合肥市明航养殖有限公司

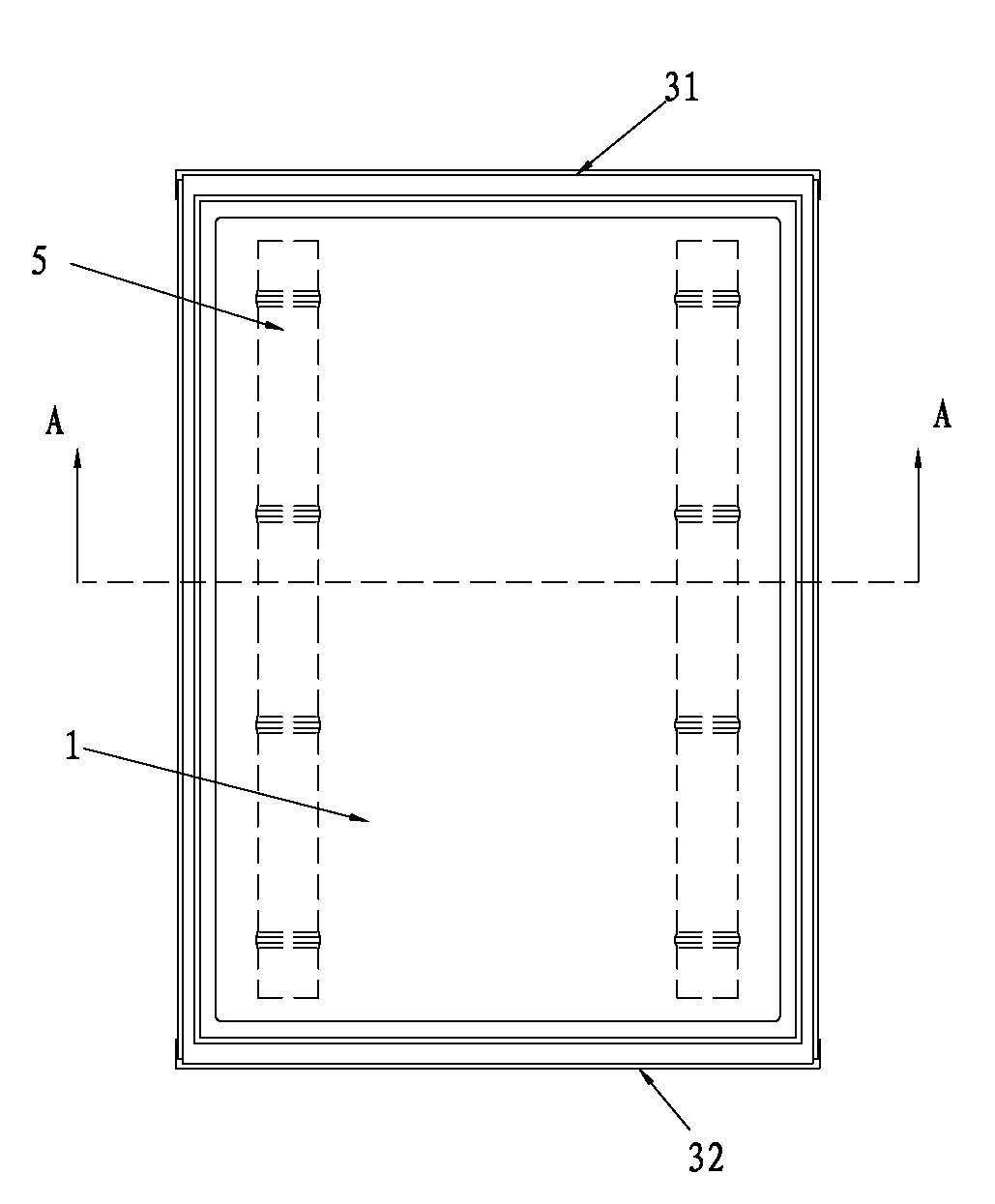

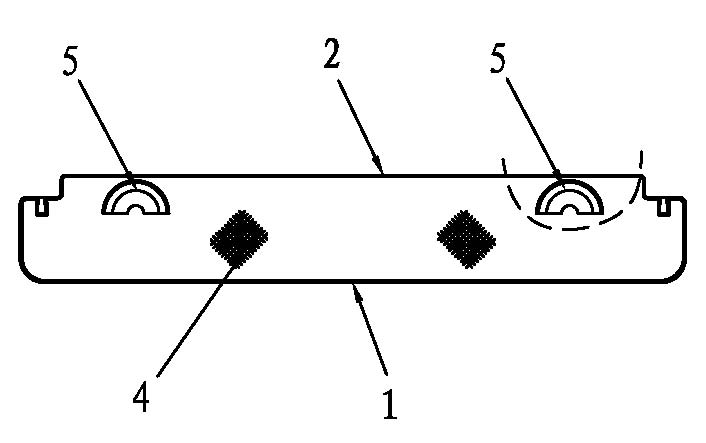

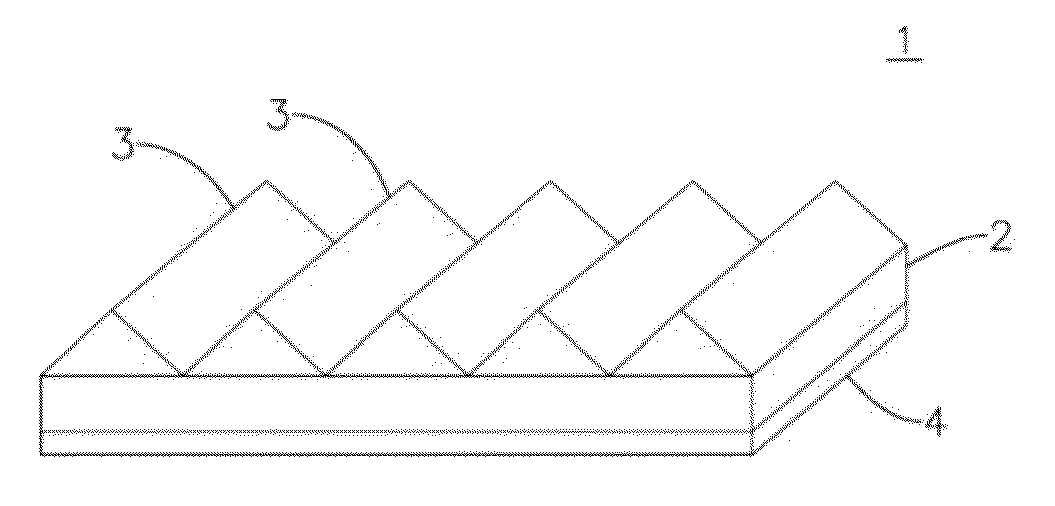

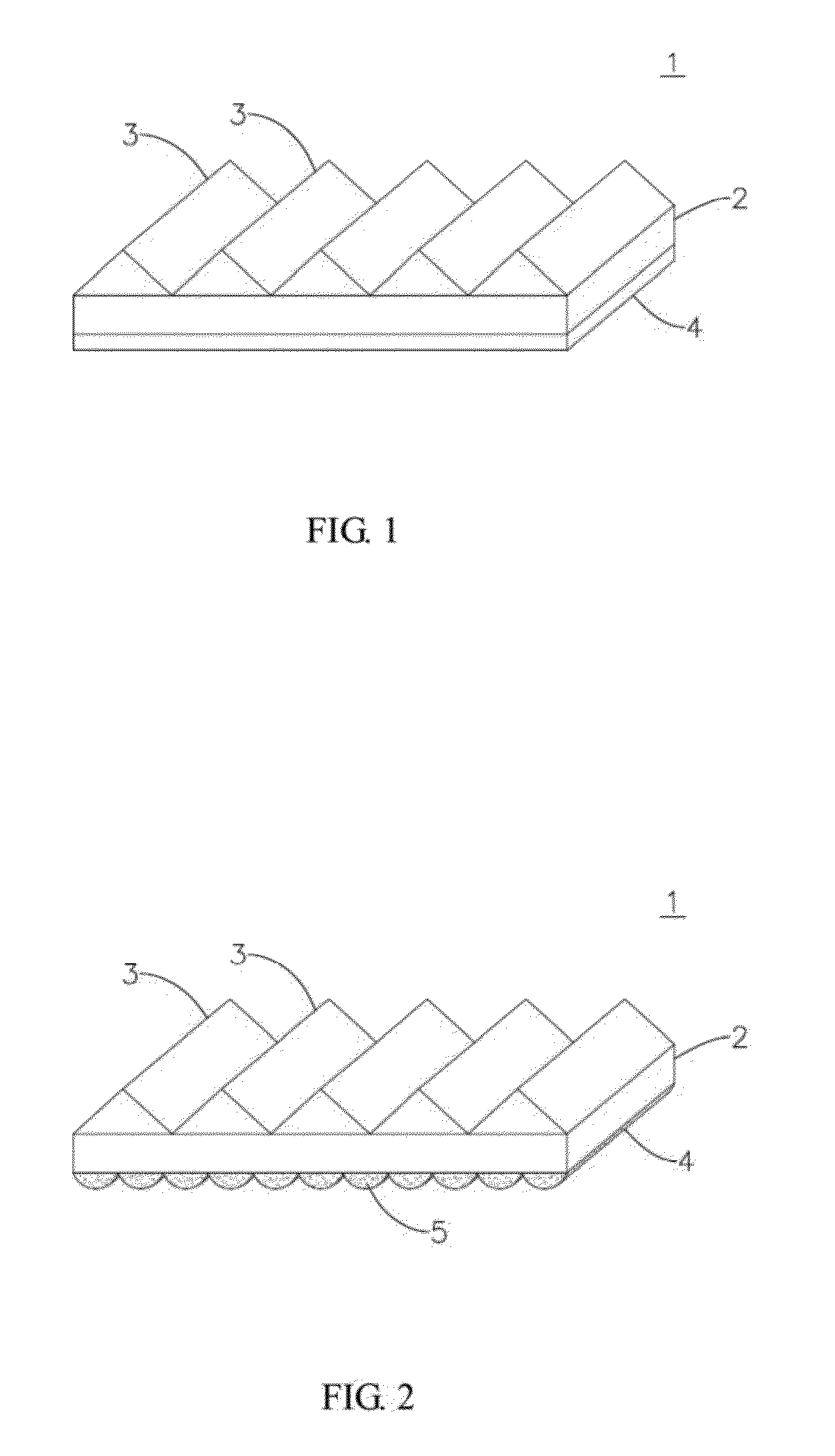

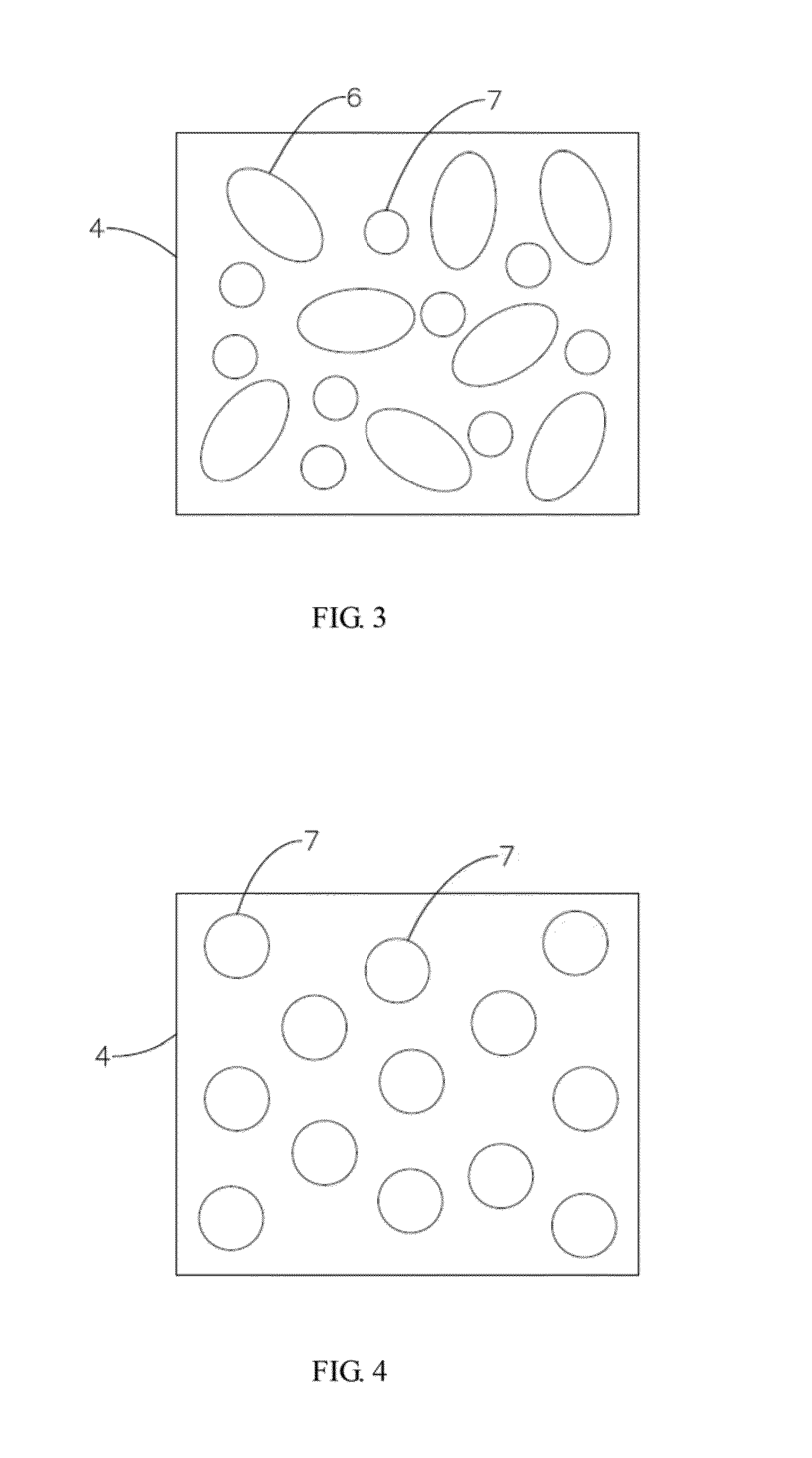

Luminance enhancement film, backlight module and liquid crystal display device

ActiveUS20140133133A1Small sizeImprove anti-deformation abilityProtective devices for lightingIlluminated signsLiquid-crystal displayPrism

The present invention provides a luminance enhancement film which is superior in dimensional stability, thermal stability, and anti-deformation ability. Thus, it can meet the current requirement for thinning LCD apparatuses.With regard to the luminance enhancement film, a prism row structure is formed on a surface of a substrate, and a reinforced layer is formed on the other surface of the substrate. The glass transition temperature of the reinforced layer is in the range from 80° C. to 250° C., and the thickness of that is in the range from 3 μm to 50 μm.

Owner:UBRIGHT OPTRONICS CORP

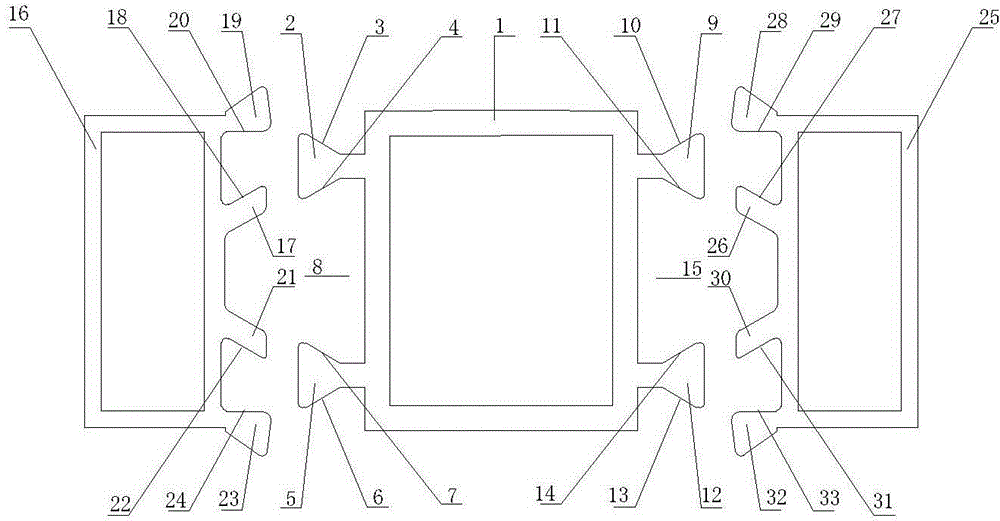

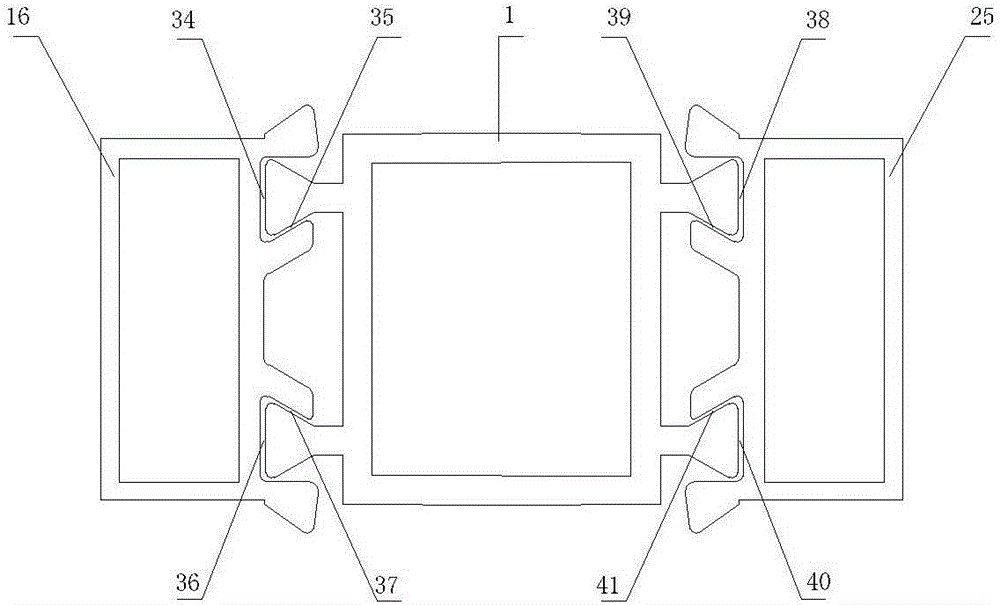

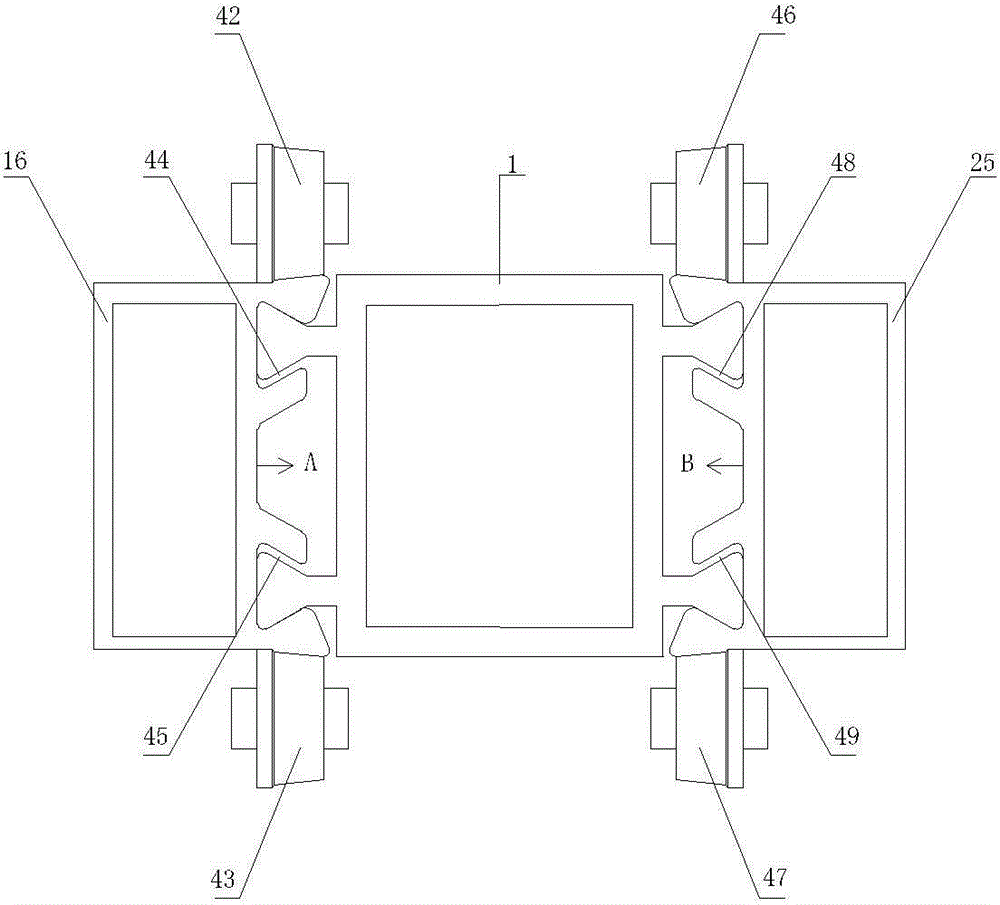

Composite door and window sectional material with combination of internal and external metal sectional materials and middle integral heat-insulation sectional materials

ActiveCN104612538ASolving Flow Heat Transfer ProblemsSolve the deformationDoors/windowsEngineeringPlastic property

Owner:王广武

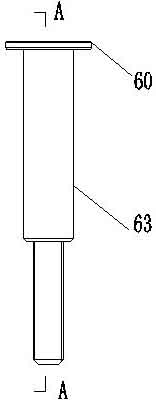

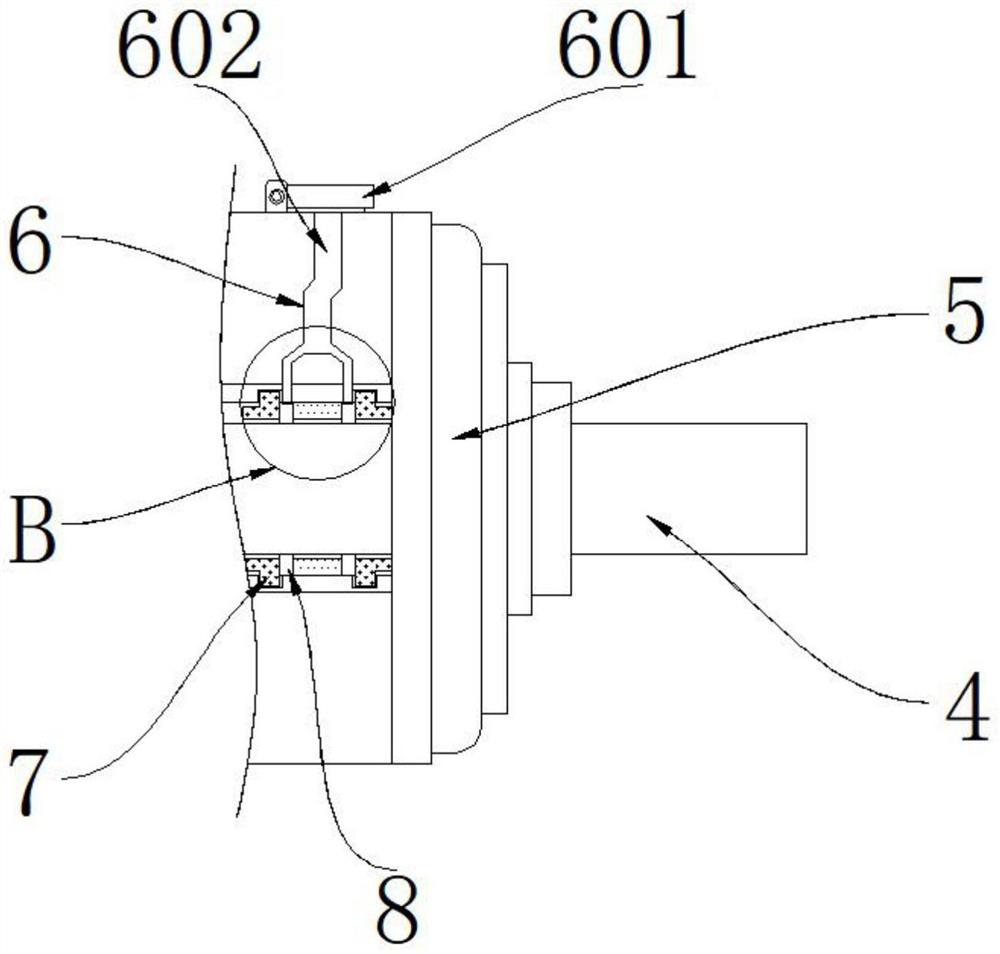

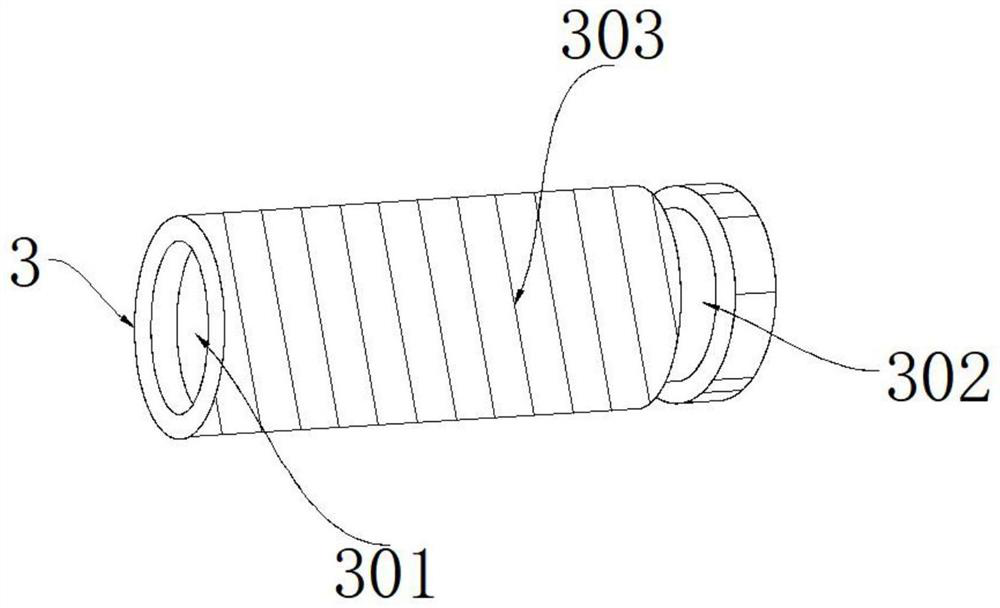

Vacuuming device for rice bags

ActiveCN108910136AAvoid wear and tearImprove anti-deformation abilityPackaging by pressurising/gasifyingEngineeringBreathing

The invention discloses a vacuuming device for rice bags. The vacuuming device comprises an exhaust device and a vacuum orifice device matched with the exhaust device. The vacuuming device is installed in a ventilation opening of a rice bag, the vacuuming device comprises a vacuuming valve base and a vacuuming valve deck installed on the rice bag, the upper end of a exhaust cylinder shell is inserted into a connecting portion, a lifting hole is formed in the middle of a connecting base, the lifting structure is in sliding connection with the lifting hole, the lifting structure is composed of alifting structure body and a reset spring, the lifting body comprises a handle, a connecting rod and an airtight structure, the handle is transversely arranged at the upper end of the connecting rod,a non-woven fabric layer is arranged at the inner side wall of an elastic iron ring, the lower end of an exhaust cylinder suction nozzle is provided with an iron hoop groove matched with the elasticiron ring, and the bottom of the exhaust cylinder is connected with the vacuuming valve deck through a reinforcing structure. According to the vacuuming device for rice bags, the cover device is connected firmly, the service life is long, air leakage can be avoided, and use is convenient.

Owner:ZHEJIANG SHUNFU PRINTING

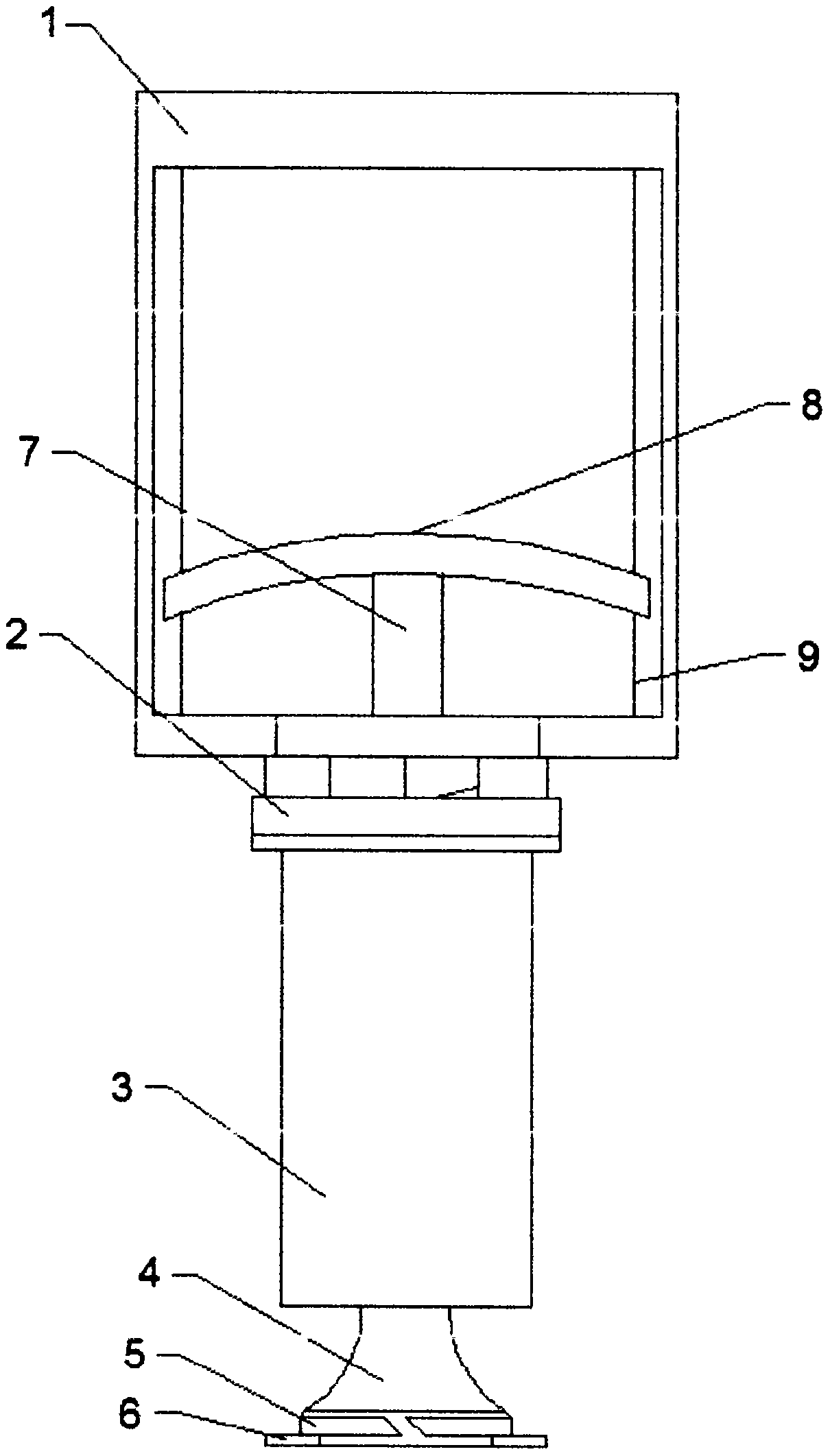

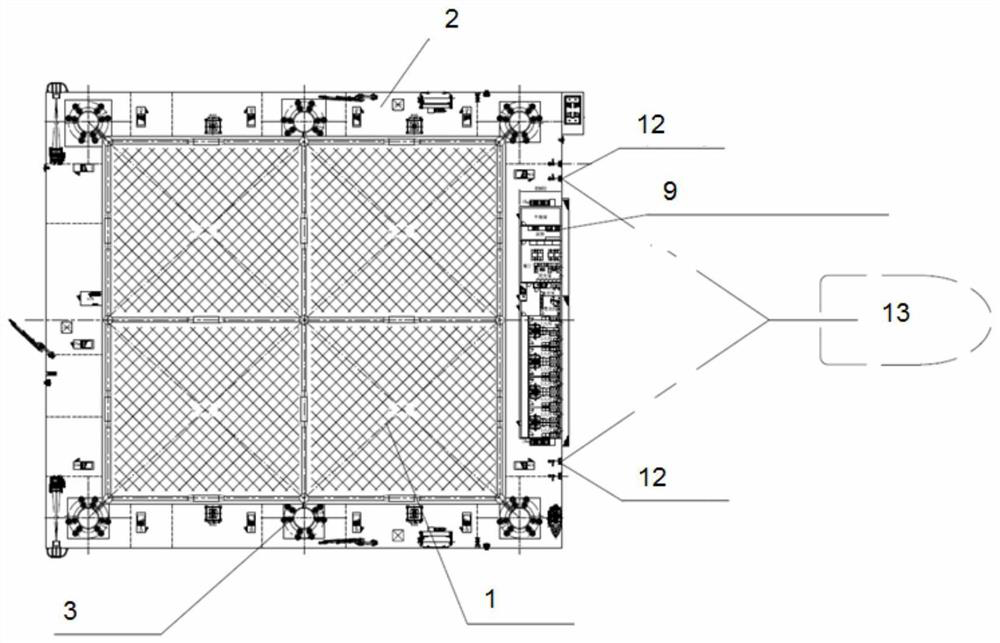

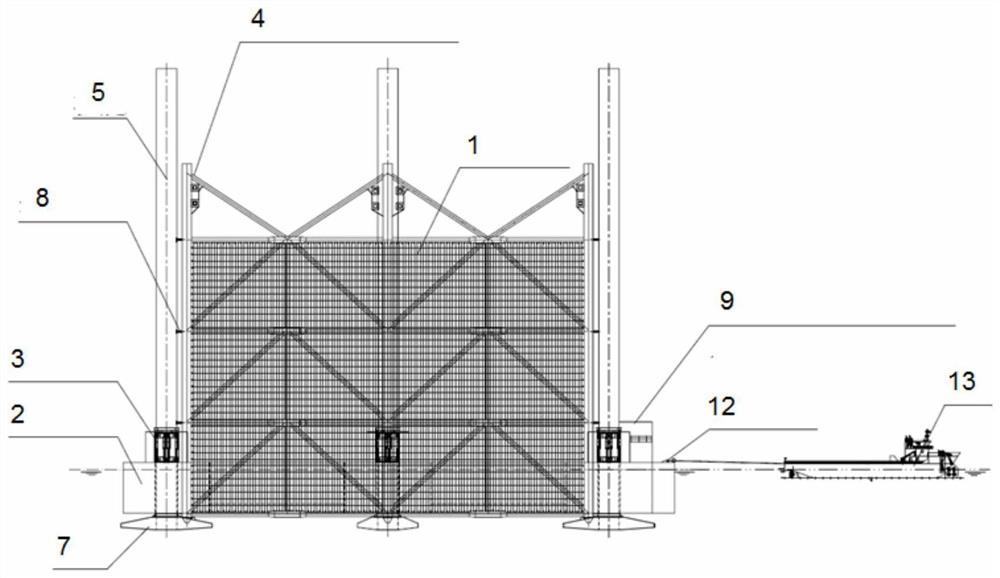

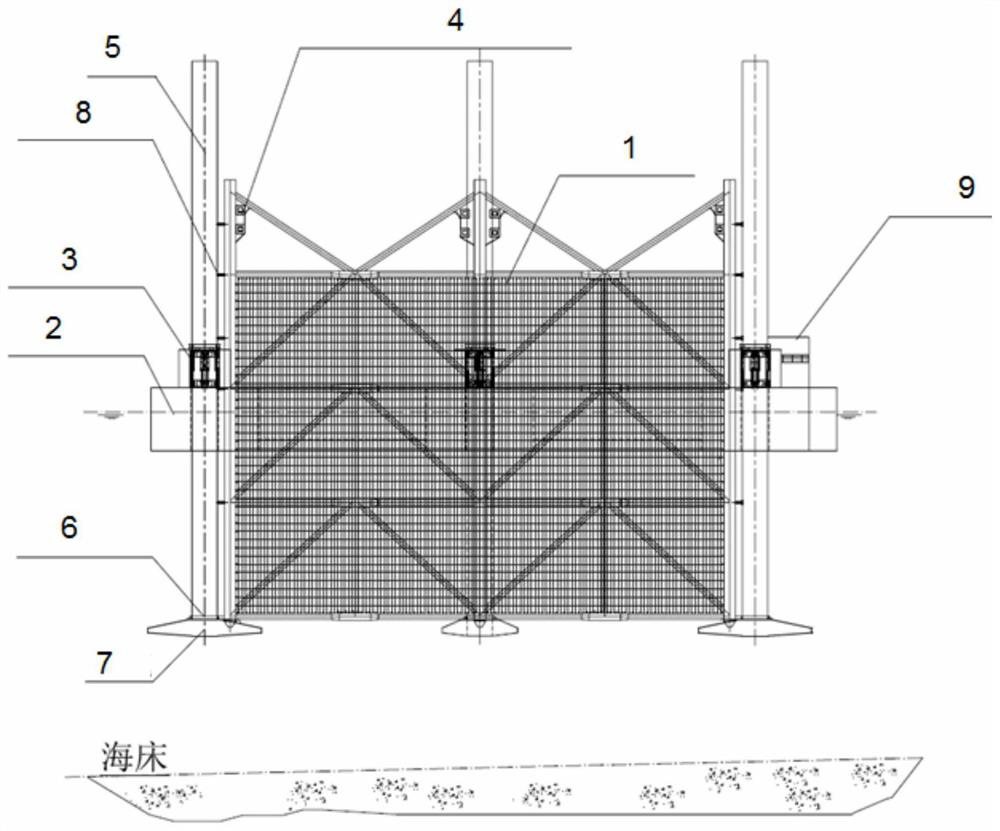

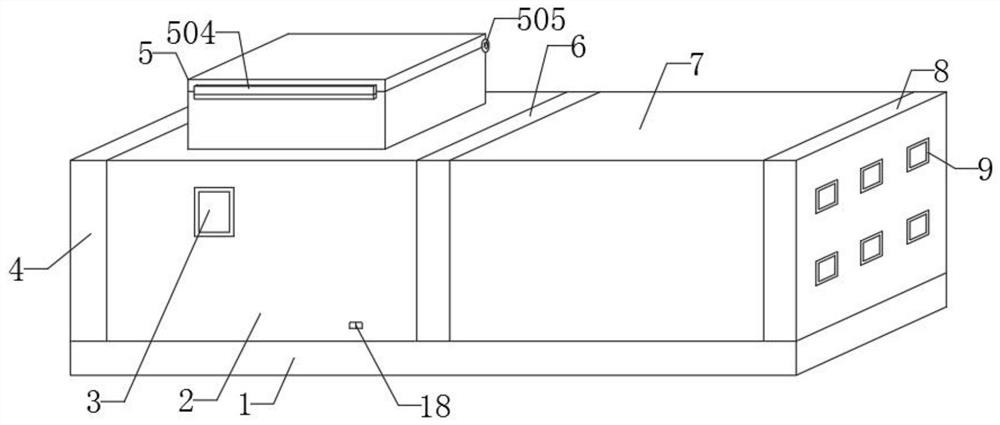

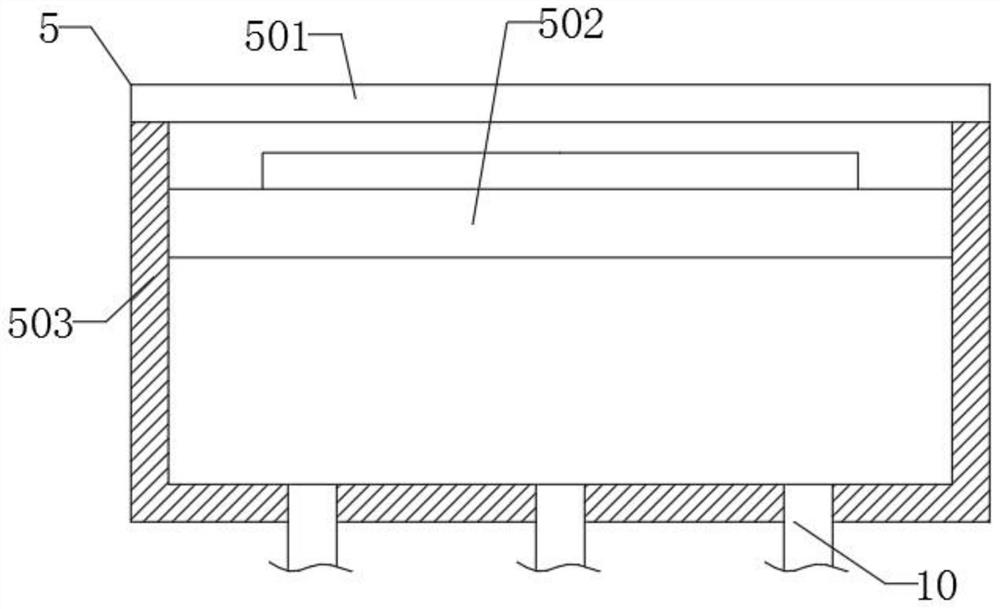

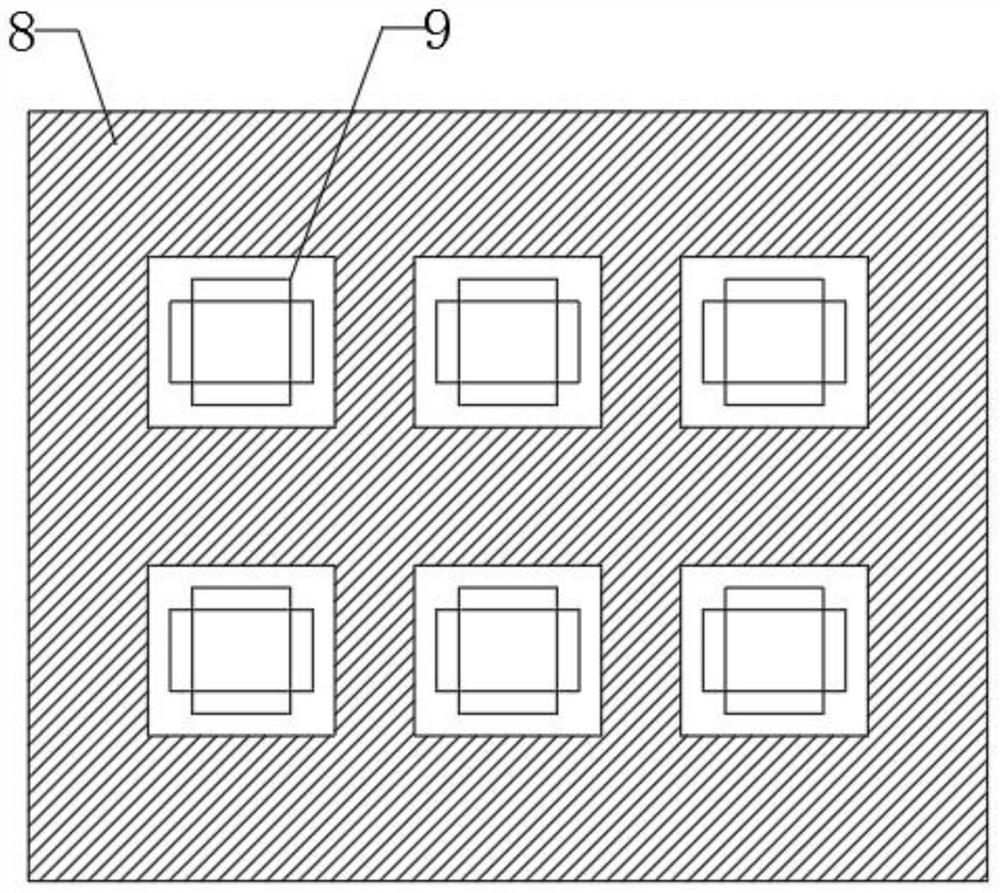

Self-elevating box-type culture platform

PendingCN112715443AImprove anti-deformation abilityReduce fishingClimate change adaptationPisciculture and aquariaStructural engineeringFishery

The invention discloses a self-elevating box-type culture platform which comprises a culture net cage and a structural ship body surrounding the periphery of the culture net cage, wherein the structural ship body comprises a lifting device and a locking system, pile legs penetrate through the structural ship body and are slidably connected with the structural ship body through the lifting device, and pile shoes are arranged at the bottoms of the pile legs; and a locking structure matched with the locking system is arranged on the upper portion of the culture net cage, and a guide structure used for moving up and down along the pile legs of the structural ship body is arranged on the lower portion of the culture net cage. The culture platform has the functions of capable of resisting typhoon, being autonomously positioned and installed on the sea, improving the safety of living and operation of culture personnel and workers, having a large feed storage space, reducing the platform supply period, reducing water in the net cage by independently lifting the net cage, facilitating offshore fish collection and netting cleaning and replacement, protecting the culture net cage during construction and dragging and the like.

Owner:DALIAN SHIPBUILDING IND

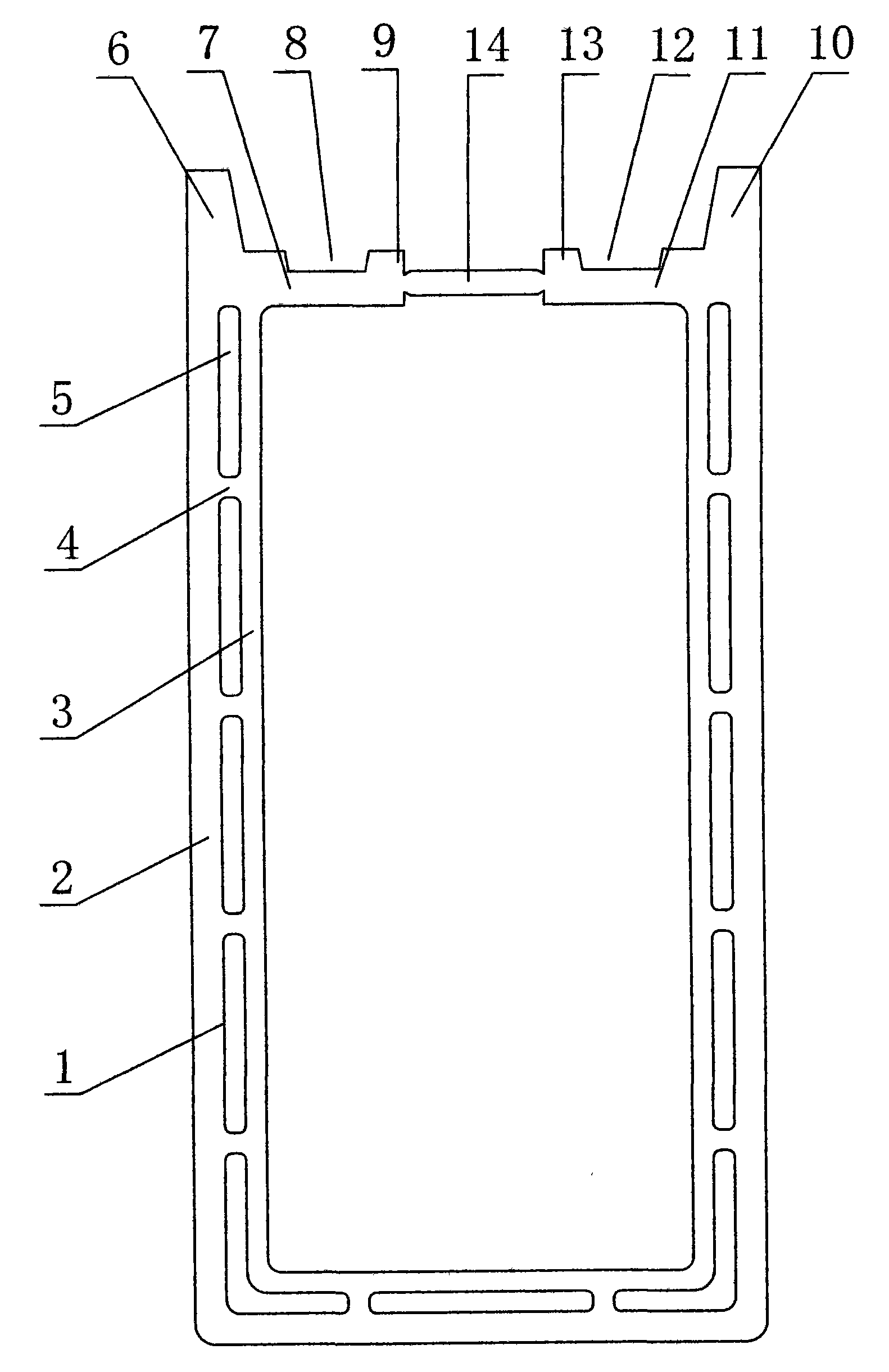

Safe energy-saving bus duct

ActiveCN109904817AImprove stabilityImprove insulation safetyCooling bus-bar installationsTotally enclosed bus-bar installationsManufacturing technologyEmbedded system

The invention discloses a safe energy-saving bus duct comprising a shell, a ground row, a phase row, bus protection pieces, a bus connector and a shell connection structure; the shell comprises a topplate, a side plate, a bus sheath and a bottom buckle plate; the bus protection piece comprises a protection piece base plate, a flange, a bus side limiting block, a bus top limiting block, a clampingstrip, a turn plate and a protection piece sleeve; the bus protection piece is inserted into the slot of the side plate, and clamped into the limiting block on the bottom side of the side plate via aside clamping strip; the bus connector comprises a connection bus, a connector base plate, a connector limiting block, a locating rod and a connector sleeve; the bus connector is arranged between thetwo bus protection pieces; the shell connection structure comprises an upper cover plate, an upper embedding plate, a lower cover plate, a lower embedding plate, a side protection plate and a side protection plate fastening bolt; the two shell sections are fixedly connected via the shell connection structure. The safe energy-saving bus duct provided by the invention is high in whole structural strength, simple and convenient in installation method and fast to install; the whole structure is high in security performance, the manufacturing technology of parts is simple, and the whole structureis low in production cost.

Owner:镇江西格玛电气有限公司

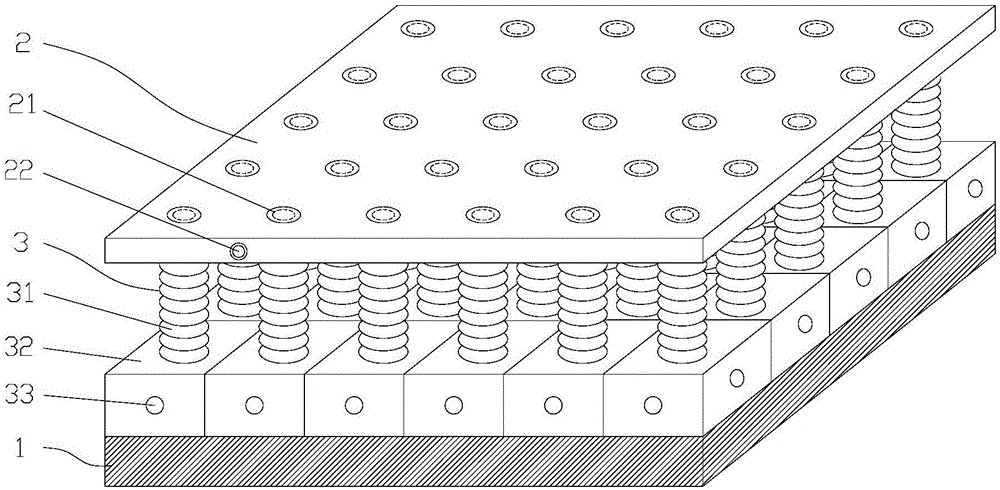

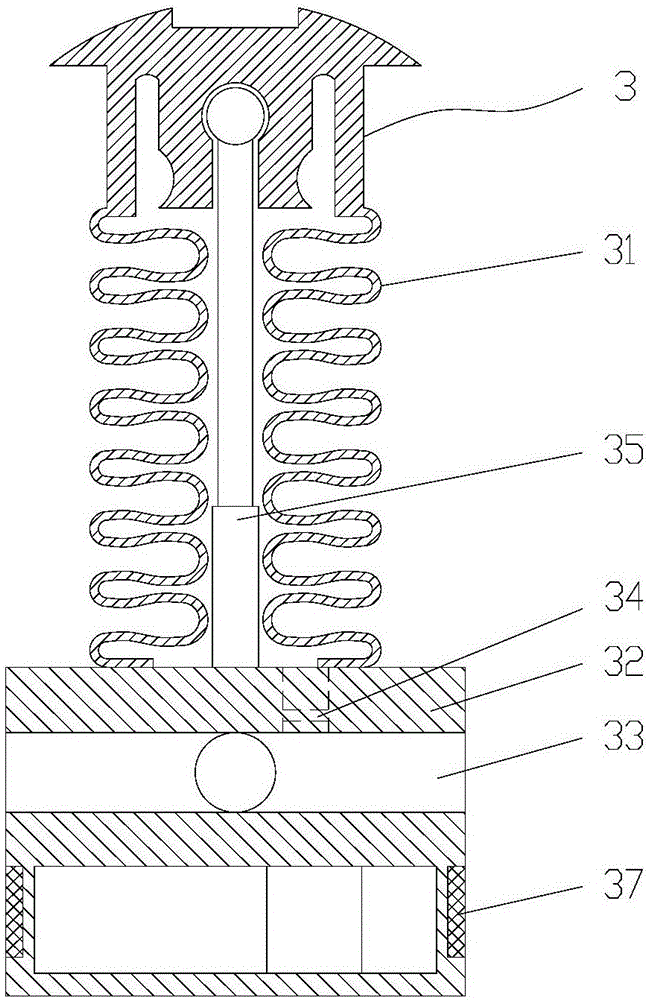

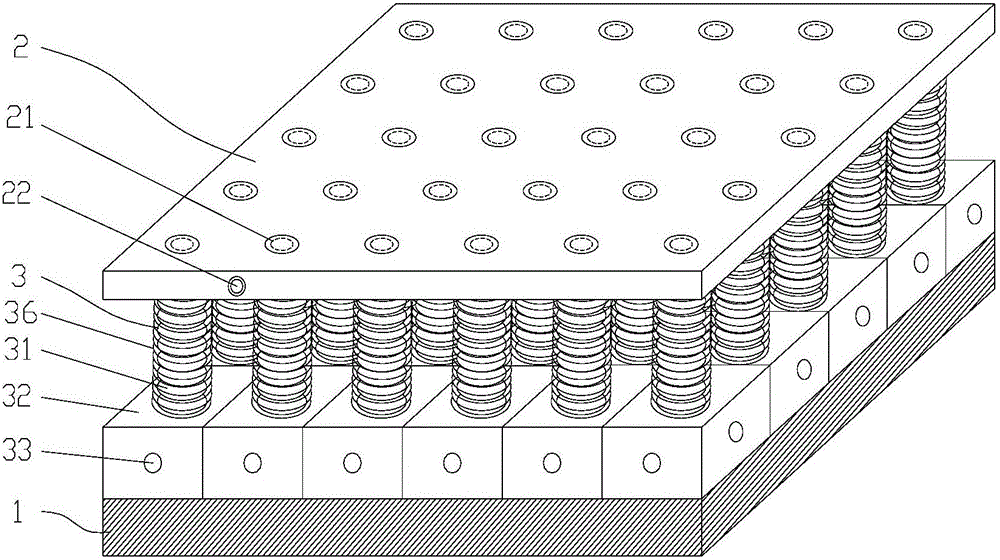

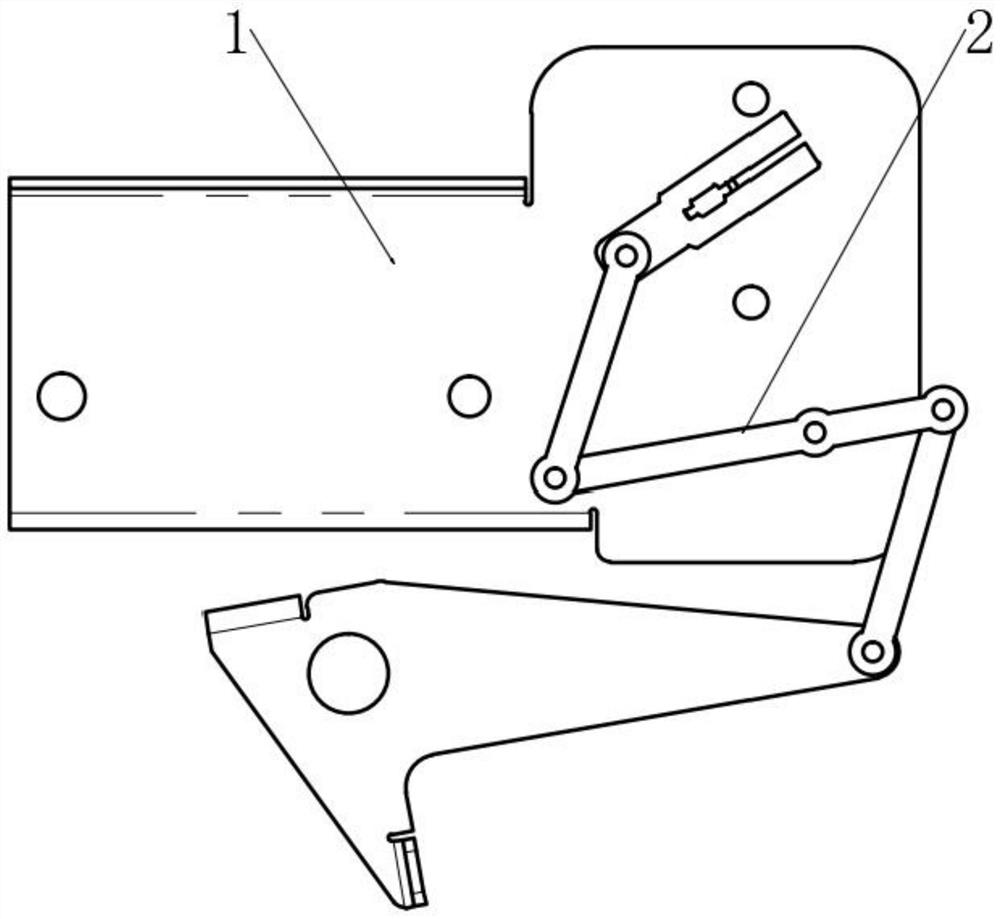

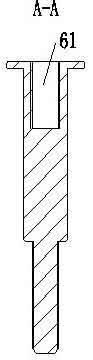

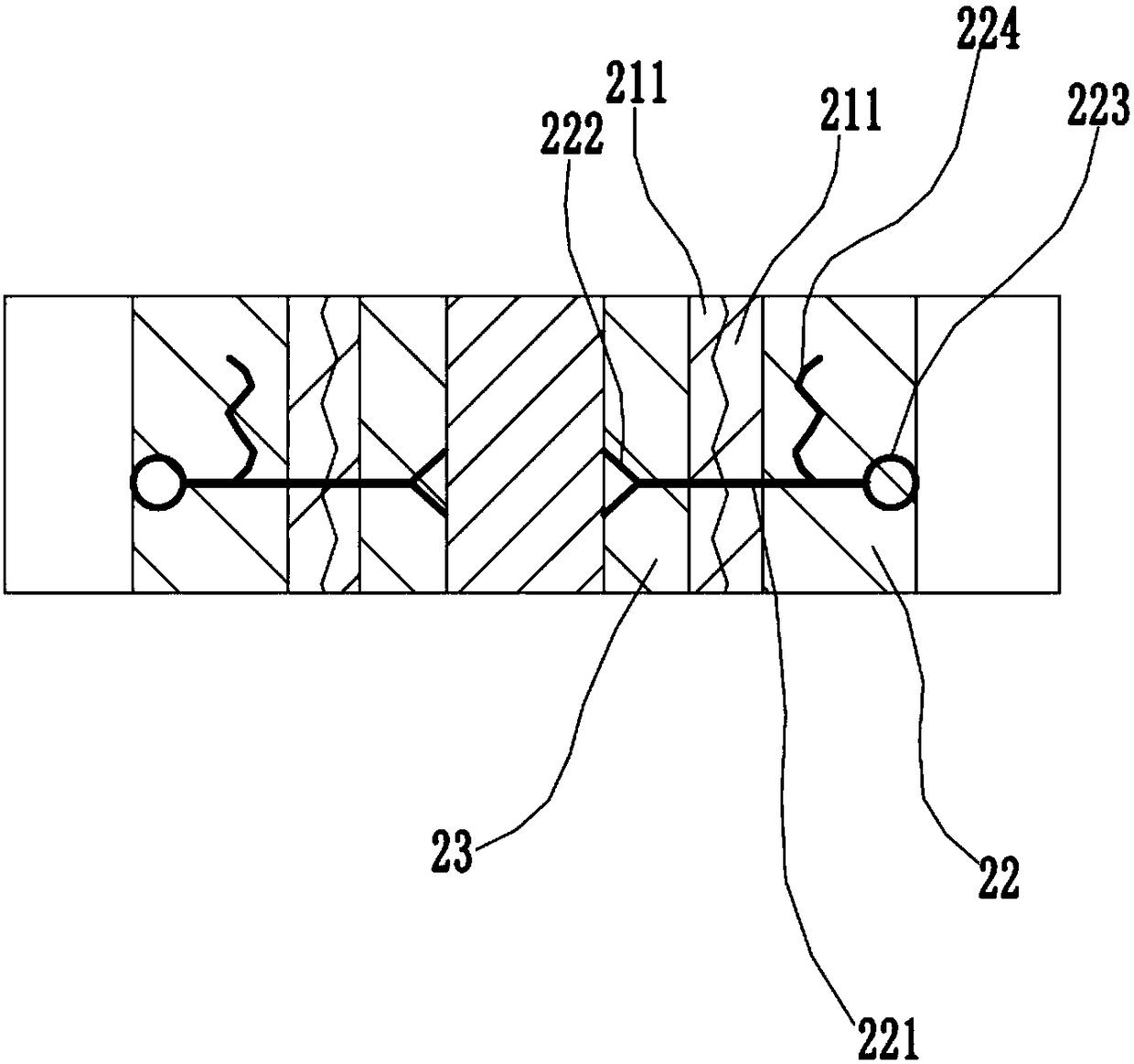

Gradient individually-adjustable three-dimensional air cushion structure for sectional backbone drawing bed

InactiveCN106344244AImprove stabilityImprove anti-deformation abilityChiropractic devicesFractureHuman bodyEngineering

The invention relates to a gradient individually-adjustable three-dimensional air cushion structure for a sectional backbone drawing bed. The three-dimensional air cushion structure comprises an air cushion arranged on the body of the sectional backbone drawing bed, and a plurality of column structures. A plurality of latticed meshes are uniformly distributed in the air cushion. The upper ends of the plurality of column structures are fixedly connected to the plurality of meshes, and the lower ends of the plurality of column structures are mounted on the bed body respectively. The plurality of column structures are driven by a power medium source to stretch and retract independently in the vertical direction. When the plurality of column structures stretch and retract independently respectively, the corresponding parts of the air cushion are driven to rise and fall to adjust the gradient of the air cushion and the bracketing forces for different parts of a human body. The three-dimensional air cushion structure of the invention is applied to the sectional backbone drawing bed; in the treatment process of drawing the backbone of a human body, the stability, anti-deformation capability and use comfort of the air cushion may be improved, and the gradient of each part of the air cushion may be individually adjusted according to different parts of a human body, so that different parts of the human body can be effectively supported.

Owner:FUJIAN UNIV OF TRADITIONAL CHINESE MEDICINE

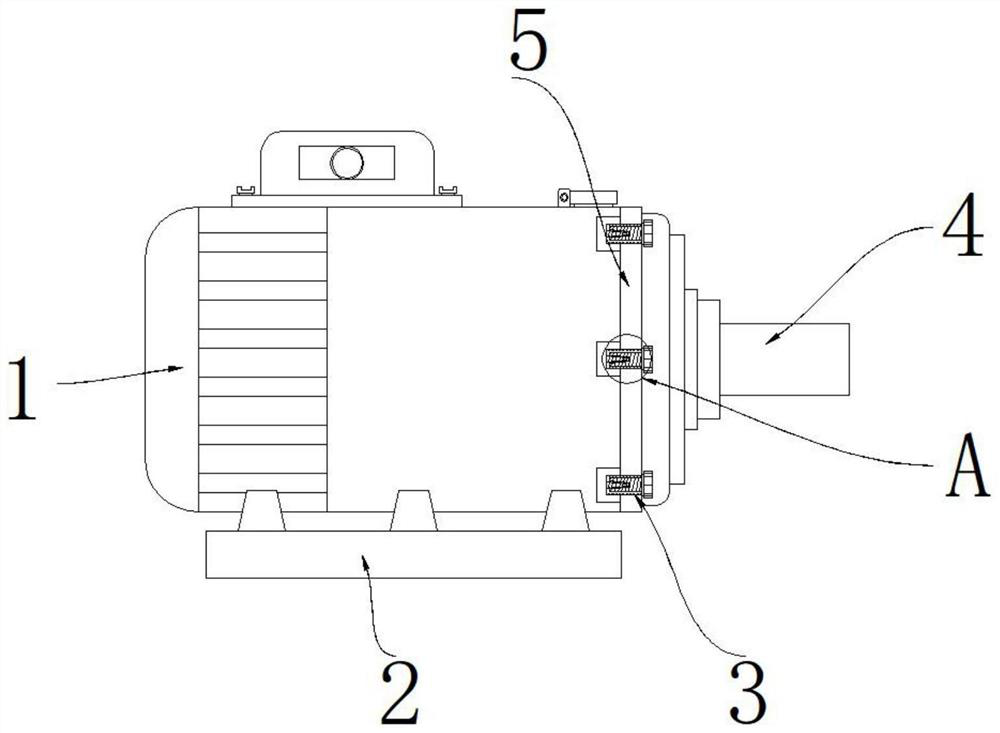

Self-repair type high-precision intelligent variable-frequency speed regulating mechanism

InactiveCN111734538AImprove stabilityPlay a protective effectEngine controllersMachines/enginesThermal dilatationControl engineering

The invention discloses a self-repair type high-precision intelligent variable-frequency speed regulating mechanism which belongs to the technical field of variable-frequency speed regulation. The self-repair type high-precision intelligent variable-frequency speed regulating mechanism can realize that a repair protective sleeve is creatively introduced on an existing multi-connecting-rod mechanism, so that protection effect on connecting rod bodies is achieved, and early-stage micro deformation of the connecting rod bodies can be timely sensed through a repair slot, and therefore, repair workis triggered by sensing a piston rod; a heating way is utilized, so that a thermal expansion repair block arranged in the repair slot is forced to have a thermal expansion phenomenon, and therefore,force capable of balancing deformation is transmitted to the connecting rod bodies, and a deformed area is repaired; and meanwhile, repair work can be timely stopped to prevent reverse deformation caused by excessive repair, so that deformation preventing effect, in a using process, of the connecting rod bodies can be improved, and the deformed area can be properly repaired, and therefore, stability, in a speed regulating process, of the multi-connecting-rod mechanism is greatly improved.

Owner:江苏神驰机电有限公司

U-shaped polymer insulation profile and manufacturing method thereof

InactiveCN104235592AImprove anti-deformation abilityImprove insulation performanceThermal insulationConstructions elementsPolymer insulationEngineering

A U-shaped polymer insulation profile is characterized in that two sides of an open end of a profile body are provided with L-shaped structures, one side of an opening of a horizontal plate of each L-shaped structure is provided with a rectangular or trapezoidal positioning cavity, one end of each horizontal plate is provided with a positioning stopper, an anti-deformation tie bar is arranged between the ends of the adjacent horizontal plates or an opening is arranged between the ends of the adjacent horizontal plates, a vertical plate of each L-shaped structure is in a rectangular or trapezoidal structure, the sidewall of the profile body is composed of an inner layer and an outer layer, and a connective bar and an air insulation chamber are arranged between the inner layer and the outer layer.

Owner:王广武

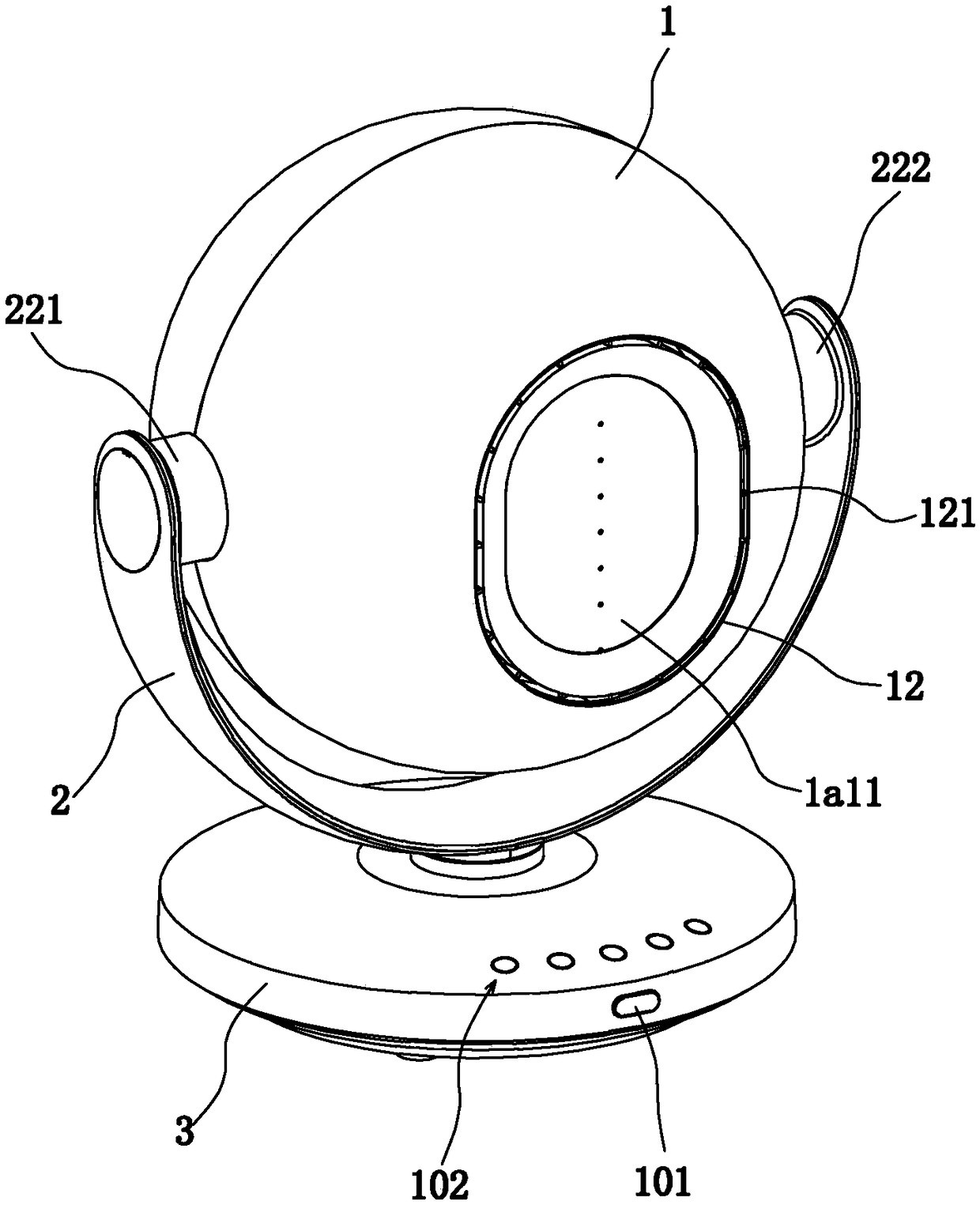

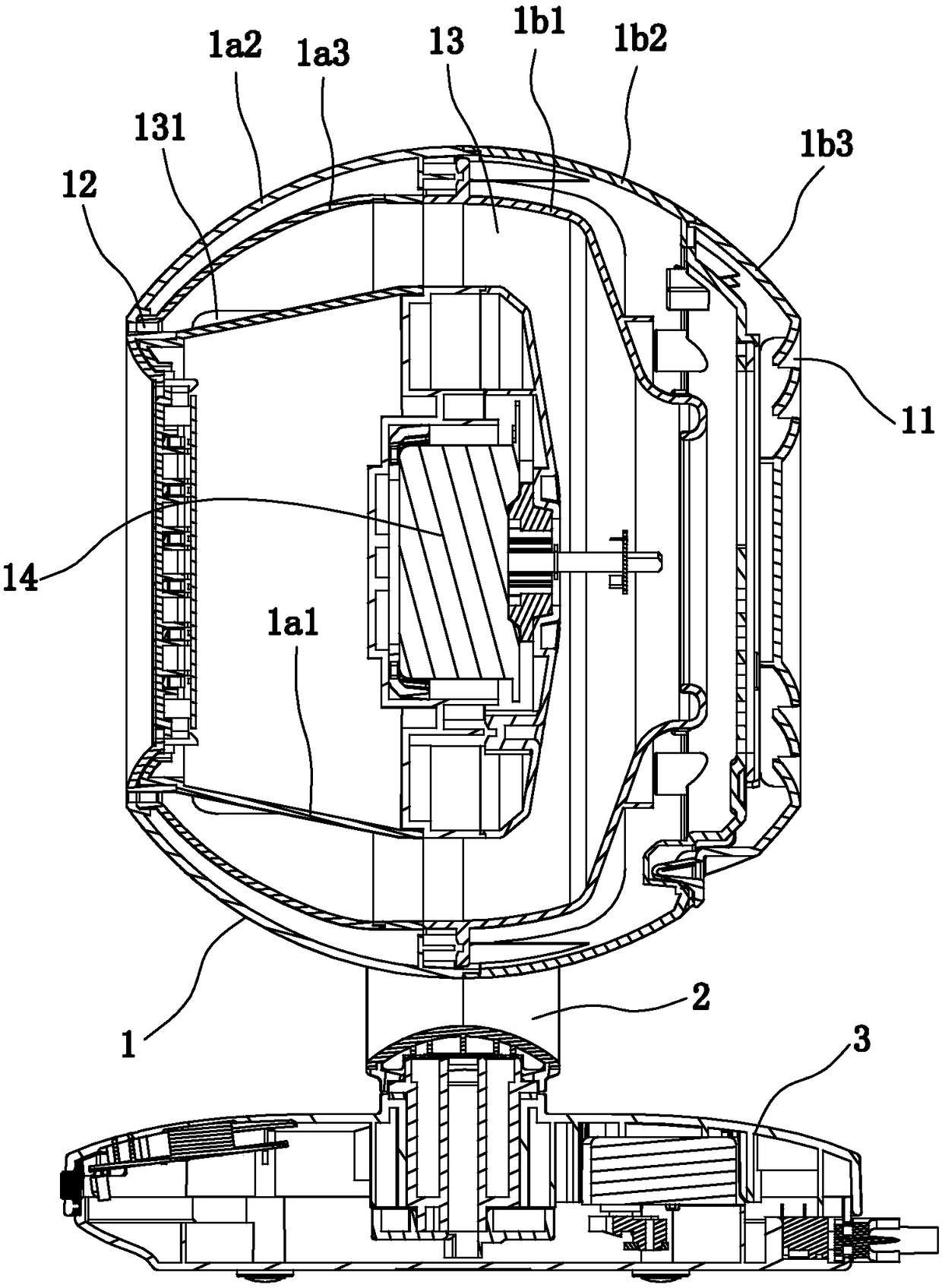

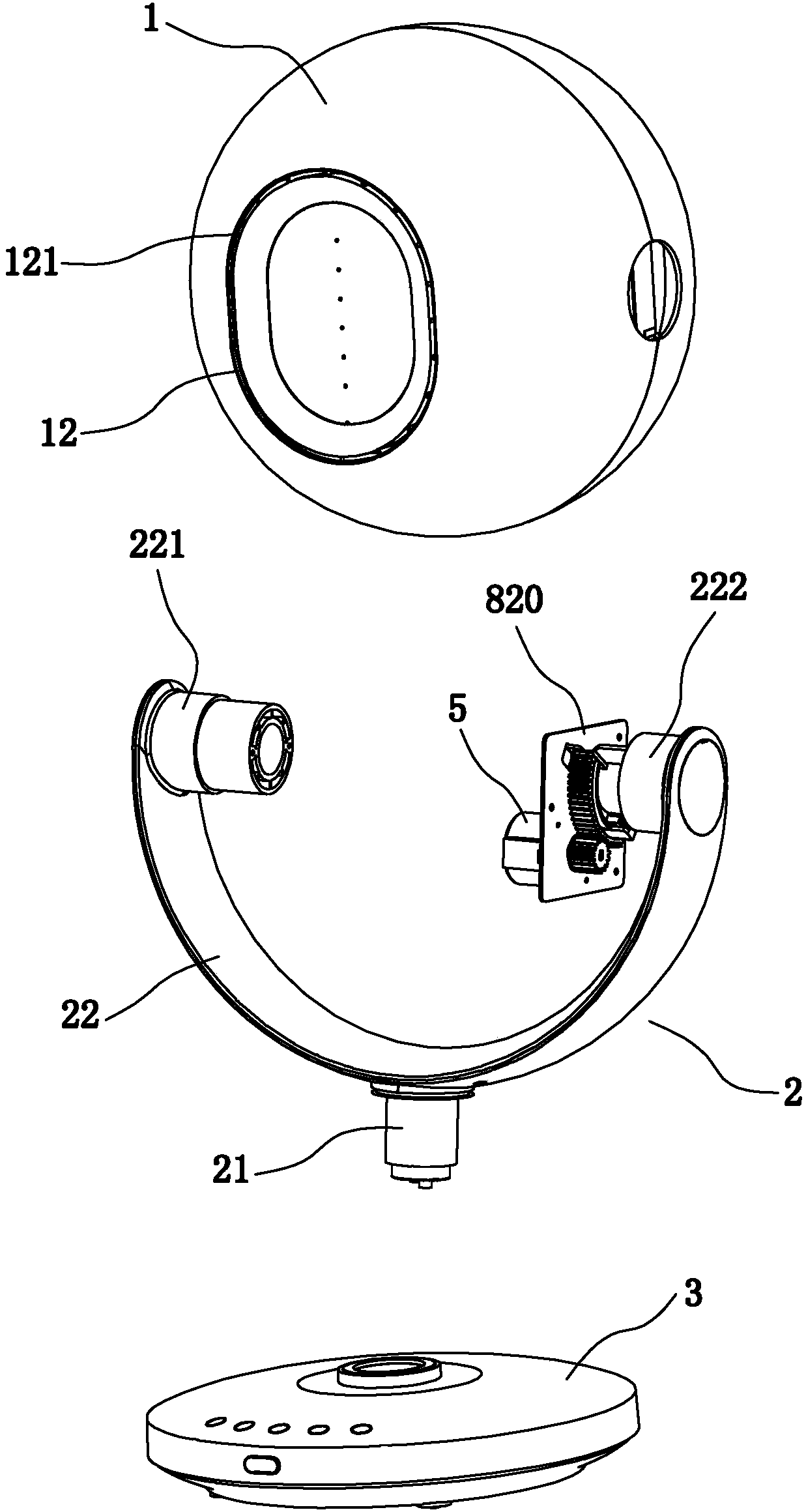

Air supplying device

PendingCN108119379AMeet the demand of air supplyImprove experiencePump componentsPump installationsWaste managementAirflow

The invention relates to an air supplying device which comprises a device main body, a support and a base, wherein the device main body comprises an air sucking inlet, an air blowing outlet and an airflow channel for communicating the air sucking inlet and the air blowing outlet; an air flow generating device is arranged in the air flow channel, the air blowing outlet is in an annular narrow slit, and the air blowing outlet in the annular narrow slit shape perpendicularly extends out in a certain distance from the front end face of the device main body into the device main body; furthermore,a plurality of deformed inhibition parts which are connected with two inner lateral sides of the air blowing outlet are further arranged in the air blowing outlet in the annular narrow slit shape, anda plurality of air flow guiding parts for guiding air flow to the air blowing outlet are arranged in a part, close to the air blowing outlet in the air flow channel. The air supply device disclosed by the invention has the advantages of simple structure, far air supplying distance, high reliability, multidirectional rotation, increased wind area, convenience, practicability and the like.

Owner:ZHEJIANG CROSSBOW BRAND ELECTRIC CO LTD

Highly tenacious nylon monofilament filter cloth modified by radiation grafting of nanocarbon sol and nanographite and preparation method thereof

InactiveCN106390594AImprove densification performanceImprove heat resistanceStain/soil resistant fibresMembrane filtersHeat resistanceFiltration

The invention discloses a highly tenacious nylon monofilament filter cloth modified by radiation grafting of nanocarbon sol and nanographite. The filter cloth comprises, by weight, 100-105 parts of nylon monofilament filter cloth, 3-3.5 parts of nanocarbon sol, 2.7-3 parts of nanographite, 0.8-0.9 part of FeSO4-7H2O, 24-26 parts of Trifluoroethyl acrylate, 1.2-1.5 parts of nano-hydroxyapatite, 3-3.5 parts of polyphenylene sulfide micron powder, 2.8-3.2 parts of flexible SiO2 nanofibers, 1.8-2.1 parts of triallyl Isocyanurate, 24-26 parts of dodecafluoroheptyl methacrylate and suitable amount of water. The invention uses nanocarbon sol to soak the nylon monofilement filter cloth, enhances the density, heat-resistance and friction-resistance of the filter cloth. Through the incorporation of polyphenylene sulfide micron powder to adsorb the nano-hydroxyapatite, enhances the tenacity and filtration precision of the filter cloth. The use of SiO2 nanofiber enhances the tenacity and anti-deformation property of the filter cloth.

Owner:骆华军

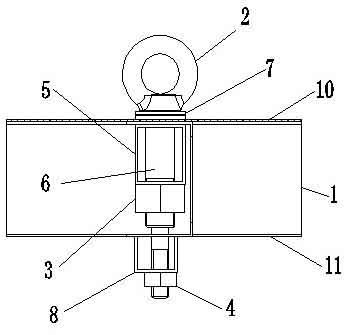

Outdoor cabinet top lifting device

ActiveCN102686073AHigh strengthReduce distortionCasings/cabinets/drawers detailsOperational safetyTop cap

Owner:SUZHOU NEW SEA UNION TELECOM TECH CO LTD

A vacuum device for rice bags

ActiveCN108910136BAvoid wear and tearImprove anti-deformation abilityPackaging by pressurising/gasifyingAgricultural engineeringStructural engineering

The invention discloses a vacuuming device for rice bags. The vacuuming device comprises an exhaust device and a vacuum orifice device matched with the exhaust device. The vacuuming device is installed in a ventilation opening of a rice bag, the vacuuming device comprises a vacuuming valve base and a vacuuming valve deck installed on the rice bag, the upper end of a exhaust cylinder shell is inserted into a connecting portion, a lifting hole is formed in the middle of a connecting base, the lifting structure is in sliding connection with the lifting hole, the lifting structure is composed of alifting structure body and a reset spring, the lifting body comprises a handle, a connecting rod and an airtight structure, the handle is transversely arranged at the upper end of the connecting rod,a non-woven fabric layer is arranged at the inner side wall of an elastic iron ring, the lower end of an exhaust cylinder suction nozzle is provided with an iron hoop groove matched with the elasticiron ring, and the bottom of the exhaust cylinder is connected with the vacuuming valve deck through a reinforcing structure. According to the vacuuming device for rice bags, the cover device is connected firmly, the service life is long, air leakage can be avoided, and use is convenient.

Owner:ZHEJIANG SHUNFU PRINTING

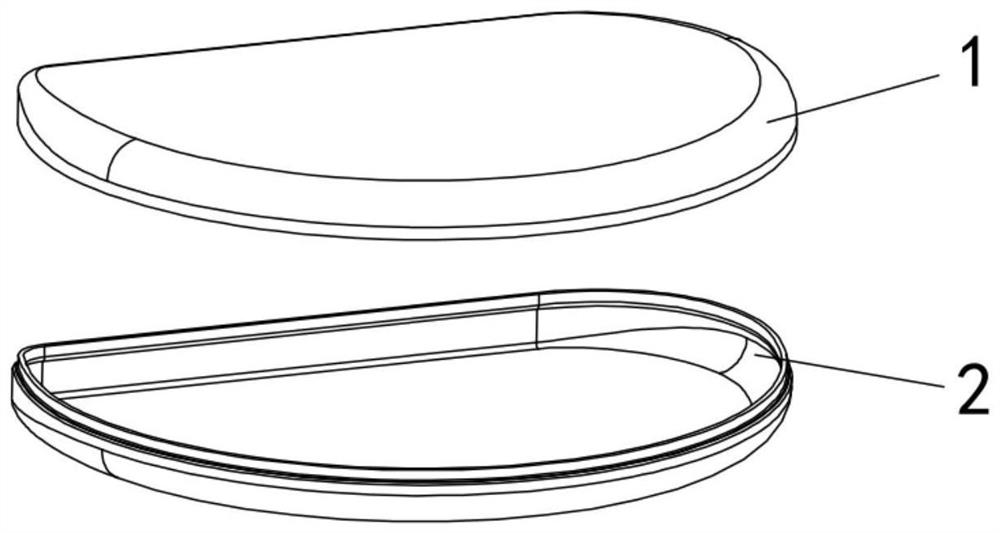

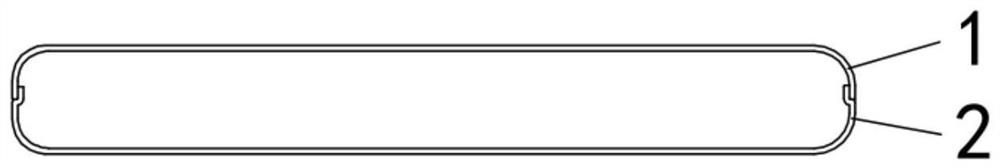

Metal shell structure of implantable medical device and forming method

ActiveCN112974641AHigh strengthImprove anti-deformation abilityShaping toolsHeart stimulatorsPhysicsLaser soldering

The invention discloses a metal shell structure of an implantable medical device and a forming method, and relates to the field of medical instruments. The metal shell structure comprises a lower shell used for containing a battery and a PCBA module and an upper shell in sealing fit with the lower shell; the outer contour of the upper shell and the outer contour of the lower shell are in irregular shapes defined by arc sections and straight line sections; a convex spigot structure shrinking inwards is arranged at an opening of the lower shell; and the opening of the upper shell is arranged on the convex spigot structure of the lower shell in a sleeving manner and then sealed through laser welding. A female die, a pre-necking die and a necking forming die used for forming of the lower shell are further designed, the brand-new lower shell forming method is adopted, the operation steps are simple, the positioning frequency is small, and high forming efficiency and precision are achieved. By means of the manufactured convex spigot structure of the lower shell, the strength of the necking portion of the lower shell can be improved, positioning and assembling of the upper shell and the lower shell are facilitated, and meanwhile lasers can be prevented from penetrating through gaps.

Owner:丹源医学科技(杭州)有限公司

Method for producing water-proof damp-proof door plate

InactiveCN105583917AImprove waterproof and moisture-proof performanceImprove toughnessLaminationLamination apparatusEmulsionSorptivity

The invention discloses a method for producing a water-proof damp-proof door plate. The method includes the following steps: a first step: performing steaming and boiling on a log, and then performing rotary-cut on the log to obtain single-layer plates; a second step: drying the single-layer plates, and performing solid-compressing forming; a third step: cutting the single-layer plates into the plates with a required specification after solid-compressing forming; a fourth step: coating double surfaces of the single-layer plates with glue, coating one surface of the outermost plate with the glue, hot-pressing the single-layer plates through a hot press, performing once forming to obtain a multi-layer plate; a fifth step: soaking the multi-layer plate in a water-proof protective emulsion, pulling the multi-layer plate out of the emulsion, draining off the emulsion on the surfaces of the multi-layer plate, and drying the multi-layer plate; a sixth step: defining the thickness of the dried multi-layer plate and sanding the dried multi-layer plate, and performing natural health; and a seventh step: painting the multi-layer plate after natural health to obtain a finished product. The method can effectively improve the water-proof and damp-proof performance of the door plate, improve the tenacity and an anti-deformation effect of the door plate, can effectively prevent the door plate from cracks, and reduce the water absorption of a wooden door.

Owner:HEILONGJIANG HUAXIN FURNITURE

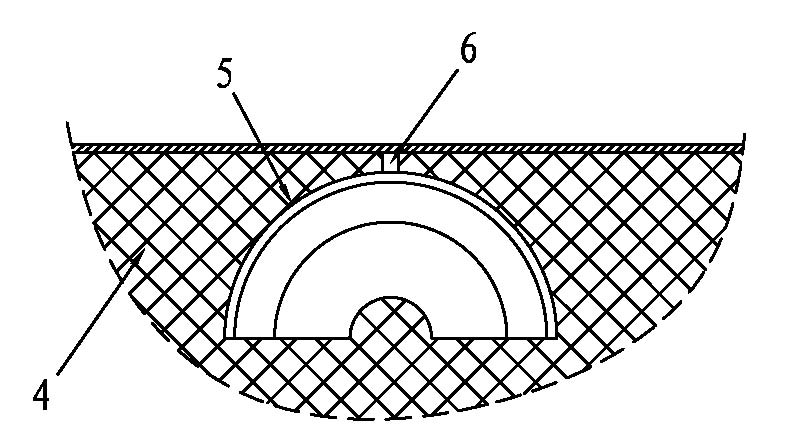

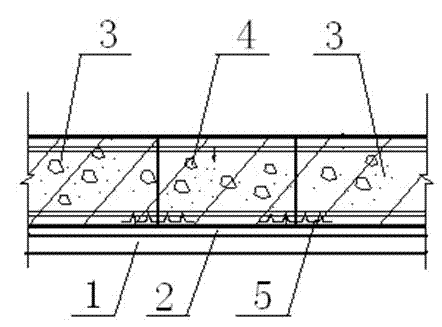

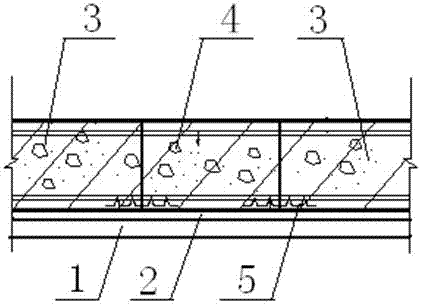

Manufacturing method and structure of post-poured strip of underground building

InactiveCN102454173AImprove waterproof performanceImprove water leakageArtificial islandsProtective foundationBasementElectrolysis

The invention discloses a manufacturing method and a structure of a post-poured strip of an underground building. After the construction of a basement pit baseplate cushion layer (1) finishes, a layer of waterproof coiled material (2) is laid on the basement pit baseplate cushion layer (1), then an externally-adhered waterstop (5) is pre-embedded on the waterproof coiled material (2) and the joint of main structure (3) to be made and the post-poured strip (4), and the main structure (3) is poured by adopting a conventional process; after the concrete of the main structure (3) has the age of six weeks, the concrete at the joint of the main structure (3) and the post-poured strip (4) is roughened, and then shrinkage-compensating concrete is used to pour to obtain the post-poured strip. The post-poured strip has the advantages of good water and seepage prevention performance, simple structure and convenience for construction. The post-poured strip is particularly suitable for the basement baseplates and side walls of the semi-underground power transforming and rectifying room in an electrolysis workshop when the geological condition of a foundation is good and the underground water level is high.

Owner:GUIYANG AL-MG DESIGN & RES INST

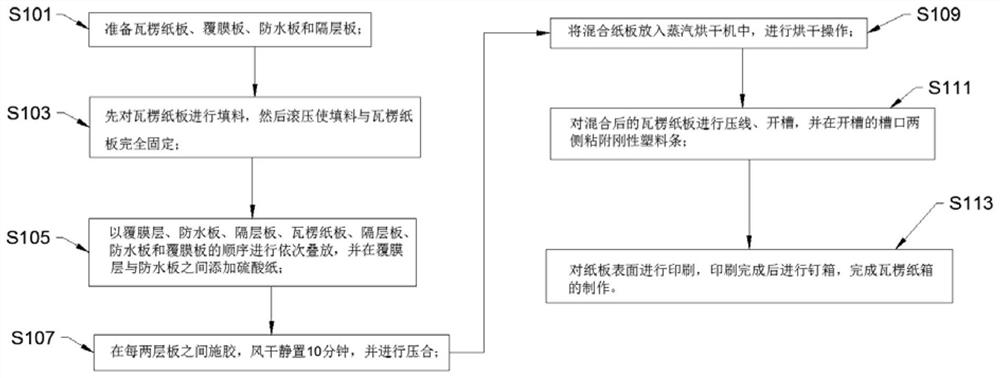

Production process of anti-deformation corrugated carton

PendingCN112810228AReduce weightHigh strengthPaper-makingBox making operationsChemistryProcess engineering

The invention discloses a production process of an anti-deformation corrugated carton. The production process of the anti-deformation corrugated carton comprises the following steps: step 1, preparing a corrugated paperboard, film-coated boards, waterproof boards and interlayer boards; step 2, filling the corrugated paperboard with filler, and then conducting rolling to enable the filler and the corrugated paperboard to be completely fixed; step 3, stacking the film-coated layer, the waterproof board, the interlayer board, the corrugated paperboard, the interlayer board, the waterproof board and the film-coated board in sequence, and adding vegetable parchment between the film-coated layer and the waterproof board; step 4, applying glue between every two layers of boards, conducting air drying and waiting for 10 minutes, and performing pressing; step 5, putting the mixed paperboard into a steam dryer to be dried; and step 6, conducting line pressing and grooving on the mixed corrugated paperboard, and adhering rigid plastic strips to two sides of a groove opening of the groove. The beneficial effects are that the strength of the whole box body can be further enhanced by mixing and pressing the five layers of board bodies so that the possibility of extrusion deformation is prevented.

Owner:张伟

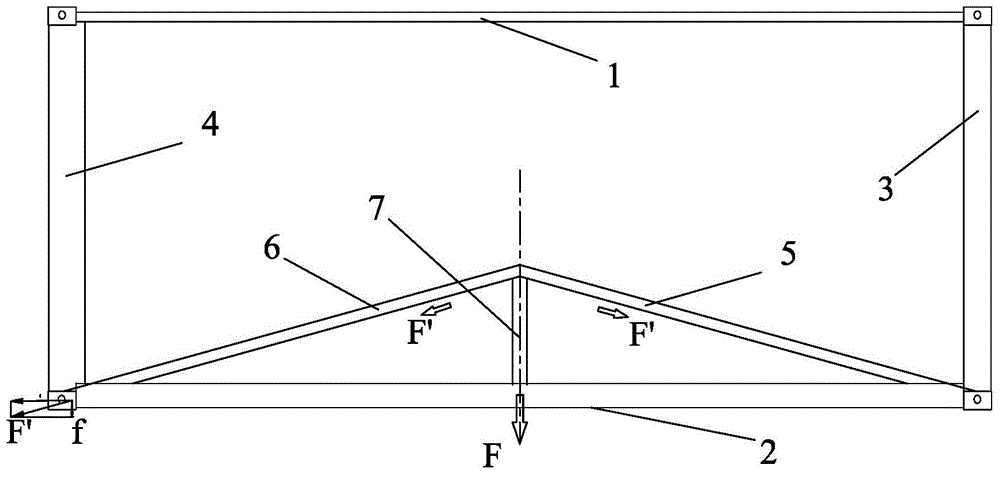

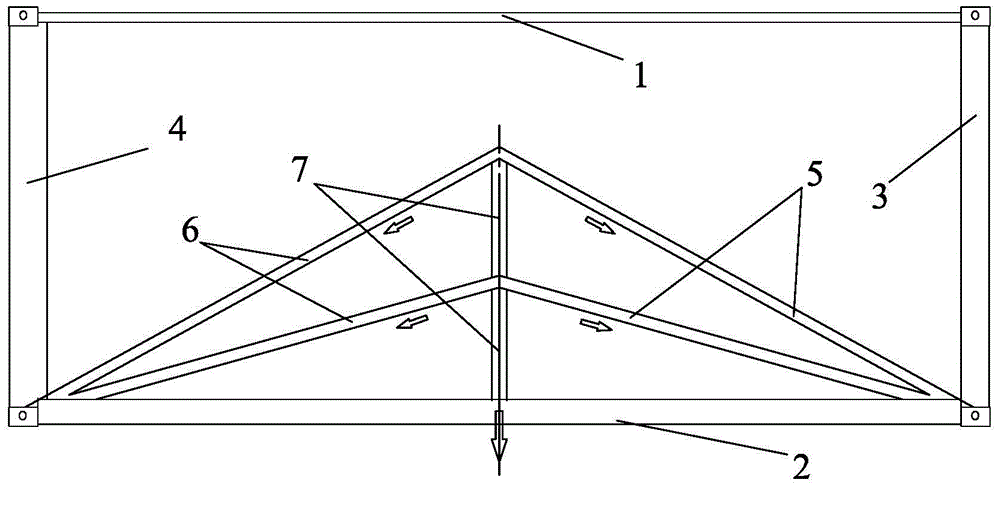

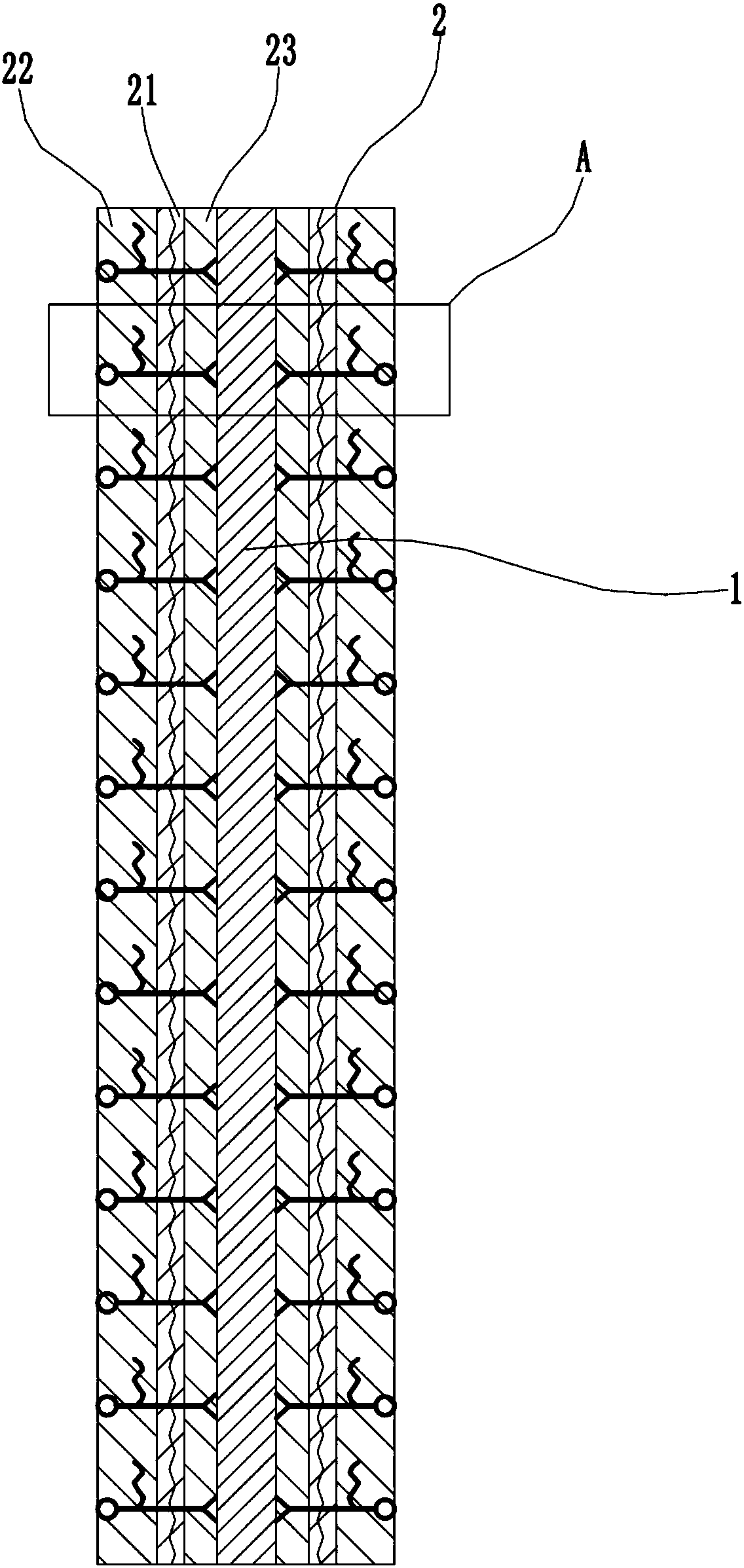

Anti-deformation container and container-type prefabricated house as well as container bottom beam deformation prevention device

PendingCN106144292ASolve the profile strength problemImprove carrying capacityLarge containersSmall buildingsEngineeringEnergy conservation

The invention discloses an anti-deformation container and a container-type prefabricated house as well as a container bottom beam deformation prevention device. The anti-deformation container and the prefabricated house are characterized in that a side framework is internally provided with a bottom beam deformation prevention structure capable of forming a stable geometrical shape; a bottom beam and an anti-deformation stiffening beam are connected in a vertical limiting manner by virtue of a suspension structure; the intermediate load of the bottom beam is dispersed to two sides by virtue of the bottom beam deformation prevention structure so as to restrict the bottom beam from bearing and bending downwards. The bottom beam deformation prevention device comprises the bottom beam deformation prevention structure which can be connected with the container bottom beam in a vertical limiting manner; two ends of the bottom beam deformation prevention structure are supported on container bottom frameworks on two sides of the bottom beam; the intermediate load of the bottom beam is dispersed to two sides by virtue of the deformation prevention structure so as to restrict the bottom beam from bearing and bending downwards. The container and the prefabricated house are capable of greatly improving the bearing capacity of the bottom beam; the bottom beam deformation prevention device can be used for refitting the container or prefabricated house so as to enhance the bearing capacity of the bottom beam, even transforming a waste container into a container which meets the requirements, and conforming to the industrial concept of energy conservation and emission reduction.

Owner:吴丽华

High-toughness carbon nanotube modified carbon fiber reinforced paper-based friction material and preparation method thereof

InactiveCN106351058AImprove heat resistanceDisadvantages of customer service poor thermal stabilityInorganic fibres/flakesOther chemical processesBorideCarbon fibers

The invention discloses a high-toughness carbon nanotube modified carbon fiber reinforced paper-based friction material. The high-toughness carbon nanotube modified carbon fiber reinforced paper-based friction material is prepared from the following raw materials in parts by weight: 1.1 to 1.4 parts of nano copper powder, 52 to 54 parts of carbon fibers, 27 to 28 parts of bamboo fibers, 3.5 to 4 parts of carbon nanotube, 2.3 to 2.8 parts of full-vulcanized nano powder carboxy terminated nitrile rubber, 5 to 5.5 parts of aramid pulp, 1.3 to 1.5 parts of silane coupling agent kh-550, 3 to 3.5 parts of cerous nitrate, 14 to 15 parts of zirconium boride, 10 to 12 parts of cashew nut shell oil modified phenolic resin with the solid content of 20 percent, 1.2 to 1.5 parts of nano-hydroxyapatite, 3 to 3.5 parts of polyphenylene sulfide micro-grade powder, 2.8 to 3.2 parts of flexible SiO2 nano fibers and a proper amount of water. According to the high-toughness carbon nanotube modified carbon fiber reinforced paper-based friction material disclosed by the invention, by using the polyphenylene sulfide micro-grade powder and the nano-hydroxyapatite, the toughness and the wear resistance of the friction material are improved; by using the flexible SiO2 nano fibers, the toughness and the deformation resistance are improved.

Owner:胡仲胜

Customized hardcover space indoor sound-absorbing inorganic keel combined-type partition wall structure

The invention provides a customized hardcover space indoor sound-absorbing inorganic keel combined-type partition wall structure which comprises a keel base frame. Two face plate components are laid on the two opposite faces of the keel base frame; the face plate components comprise first face plates which are mounted on the keel base frame; each first face plate comprises two first face plate units which are oppositely arranged, wherein the two first face plate units are engaged through a tooth-shaped face; second face plates are mounted on the first face plates and each internally provided with a plurality of first ribs; and one ends of the first ribs penetrate through the first face plates to be connected with the keel base frame. According to the customized hardcover space indoor sound-absorbing inorganic keel combined-type partition wall structure, the problem that in the prior art, a partition wall is poor in strength and noise-reduction effect can be effectively solved.

Owner:SUZHOU MEIRUIDE BUILDING DECORATION CO LTD

Anti-deformation treatment equipment and treatment method for wooden door frame

ActiveCN112621950BWill not affect shippingReduce moisture contentMagnetic wood treatmentWood treatment detailsMagnetic tension forceEngineering

The invention discloses a wooden door frame anti-deformation treatment device and a treatment method, which belong to the technical field of wooden door frame treatment, and comprise a first box body, one end of the first box body is provided with a first sealing material passing plate, and the other side of the first box body One end is provided with a second box body, a second sealing plate is provided between the first box body and the second box body, the other end of the second box is provided with a third sealing plate, and the first sealing plate 1. Both the second sealing material passing plate and the third sealing material passing plate are provided with material passing devices. The invention can increase the sealing performance of the device when transporting the wooden door frame by setting the feeding device, and at the same time, it will not affect the transportation of the wooden door frame. By setting the electric heating block and the magnetic fluid, the wooden door frame can be baked by the electric heating block Dry, by injecting magnetic fluid, under the action of magnetic force, the performance of the magnetic fluid can be increased, the water content of the wooden door frame can be reduced, and the anti-deformation ability of the wooden door frame can be increased through the magnetic fluid.

Owner:安徽龙鼎家居工贸有限公司

An integral casting mold for an aero-engine diffuser

ActiveCN106623772BImprove casting precisionIncrease productivityFoundry moulding apparatusDilatorCasting mold

The invention discloses an integrally casting mold for an aero-engine diffuser. The mold comprises a pedestal and an upper cover plate, wherein an inner ring-shaped cavity structure of the diffuser is integrally formed between the pedestal and the upper cover plate, a frustum cone-shaped loose core is arranged at the center position of the inner ring-shaped cavity structure, a wax injection nozzle communicating with the inner ring-shaped cavity is arranged on the inner ring-shaped cavity structure; and an ejection structure for ejecting the molded diffuser is arranged at the bottom of the inner ring-shaped cavity structure. According to the mold provided by the invention, the diffuser cast can be integrally formed into a ring at a time without subsequent wax molding adhesion, and the problem of reverse pulling of the wax on the mold can be solved, and forming of the aero-engine diffuser with the thick wall is ensured.

Owner:AECC AVIATION POWER CO LTD

Durable high-efficiency high-power permanent magnet engine suitable for working in various environments

PendingCN114001240ARelease the jamming phenomenonPromote repairMachine framesEngine bedsProcess engineeringMechanical engineering

The invention discloses a durable high-efficiency high-power permanent magnet engine suitable for working in various environments, which comprises an engine body, a base and a connecting shaft, wherein the engine body is installed at the top end of the base, the engine body and the base are integrally designed, an end cover is installed at one end of the engine body, one end of the end cover is uniformly provided with dismounting structures, one end of the end cover is provided with a connecting shaft, one end of the connecting shaft is arranged in the engine body, one end in the engine body is provided with a cavity, the cavity is internally provided with a positioning block, and the two sides of the positioning block are both provided with sealing gaskets. According to the invention, the sealing cover is installed at one end of the top of the engine body, the sealing cover is pulled, lubricating oil is injected into the cavity through a main oil injection pipeline and a branch oil injection pipelines, and under the action of the lubricating oil, friction between the connecting shaft and the positioning block can be reduced, abrasion of the connecting shaft is delayed, and the durability of the connecting shaft is improved.

Owner:贵州中联氢能能源设计研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com