Patents

Literature

33results about How to "Will not affect shipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

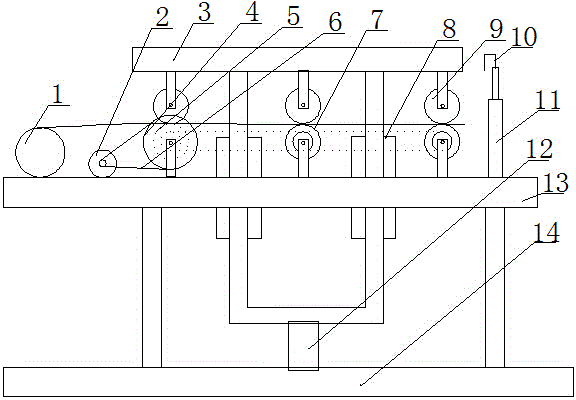

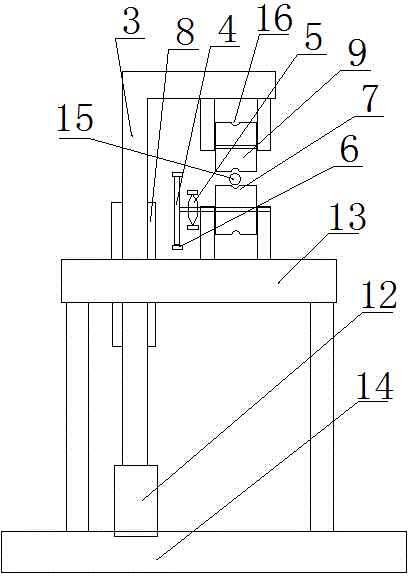

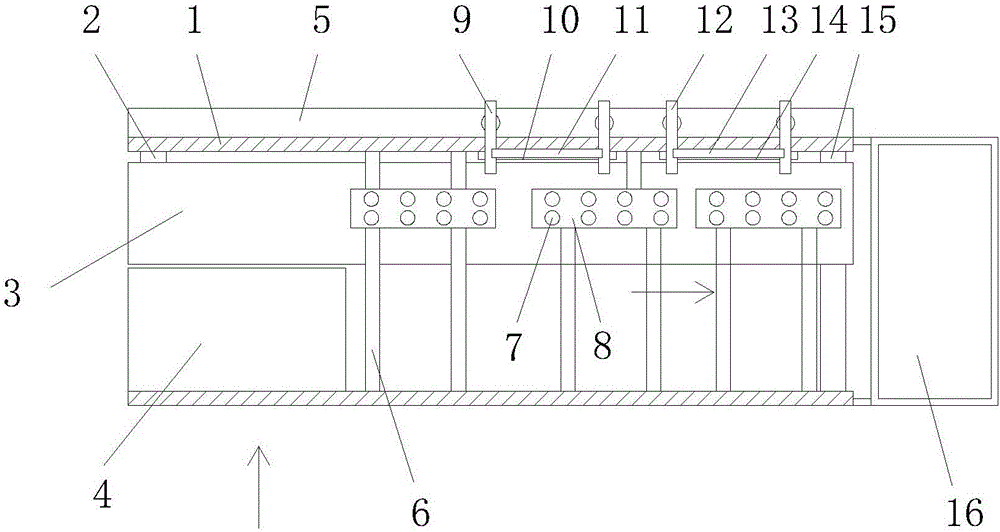

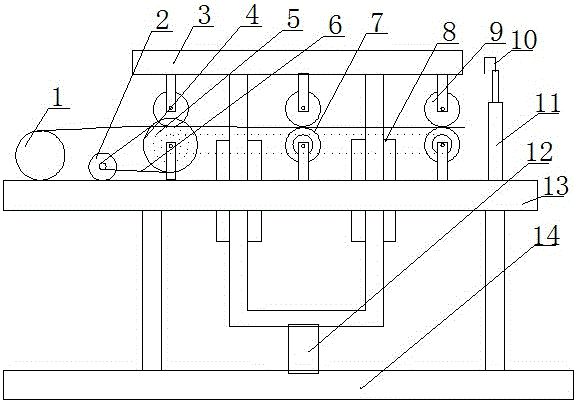

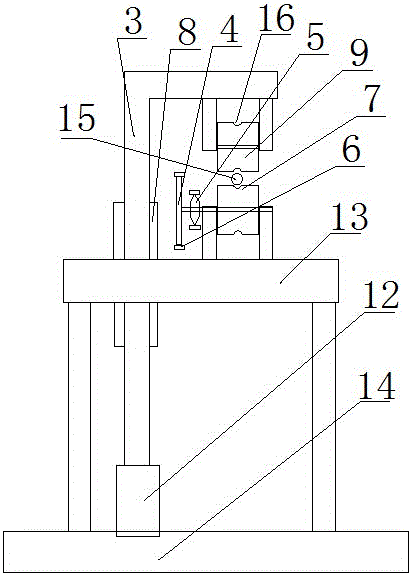

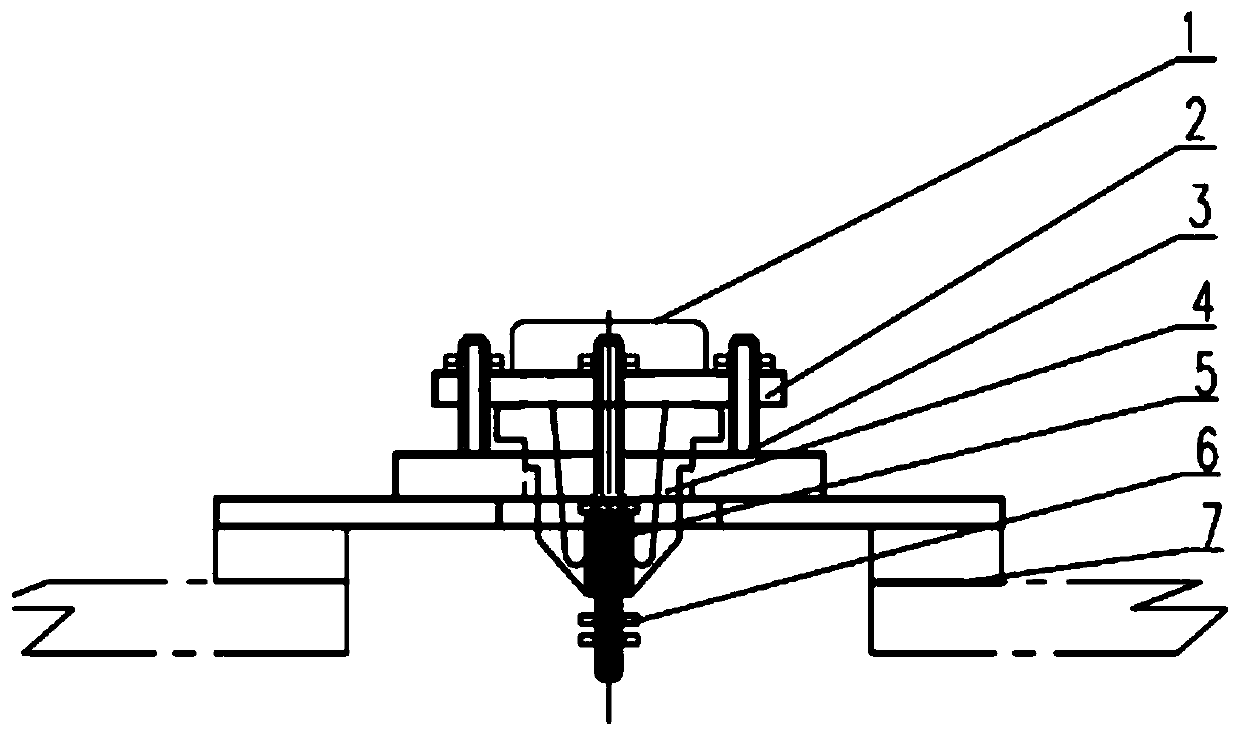

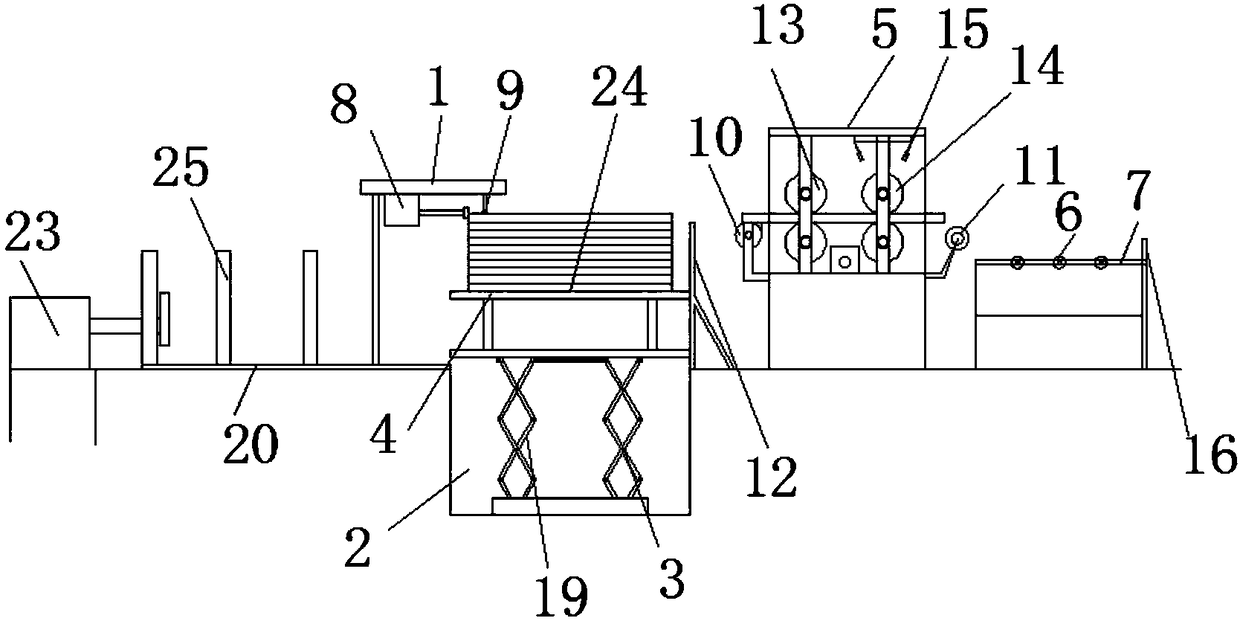

Combined integrated type glue coating and edge cutting device and control method

ActiveCN105835141APrevent deviationHigh degree of automationProfiling/shaping machinesAdhesive application devicesEngineeringAutomation

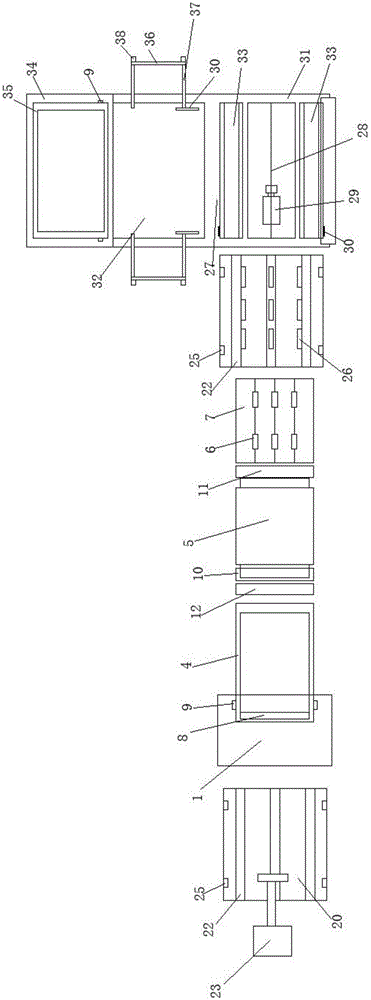

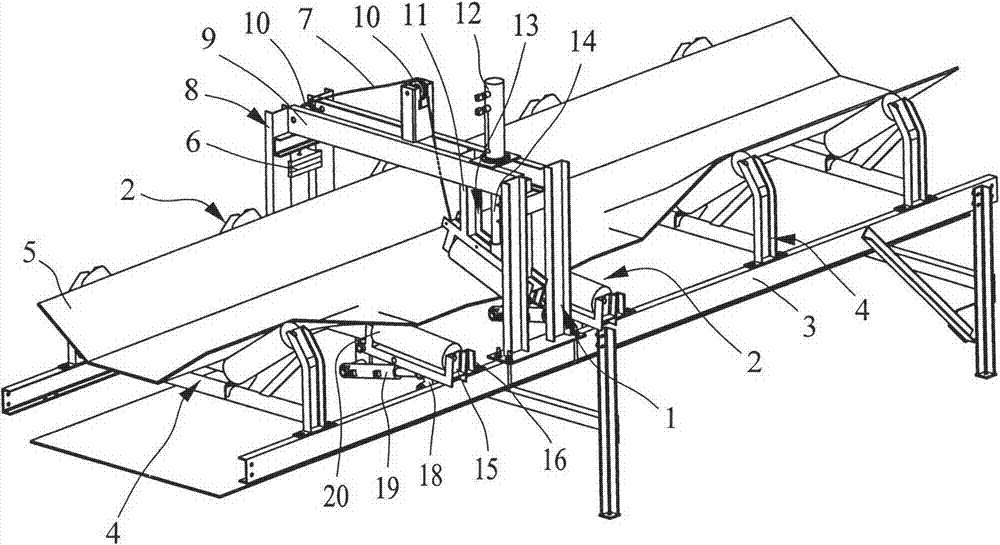

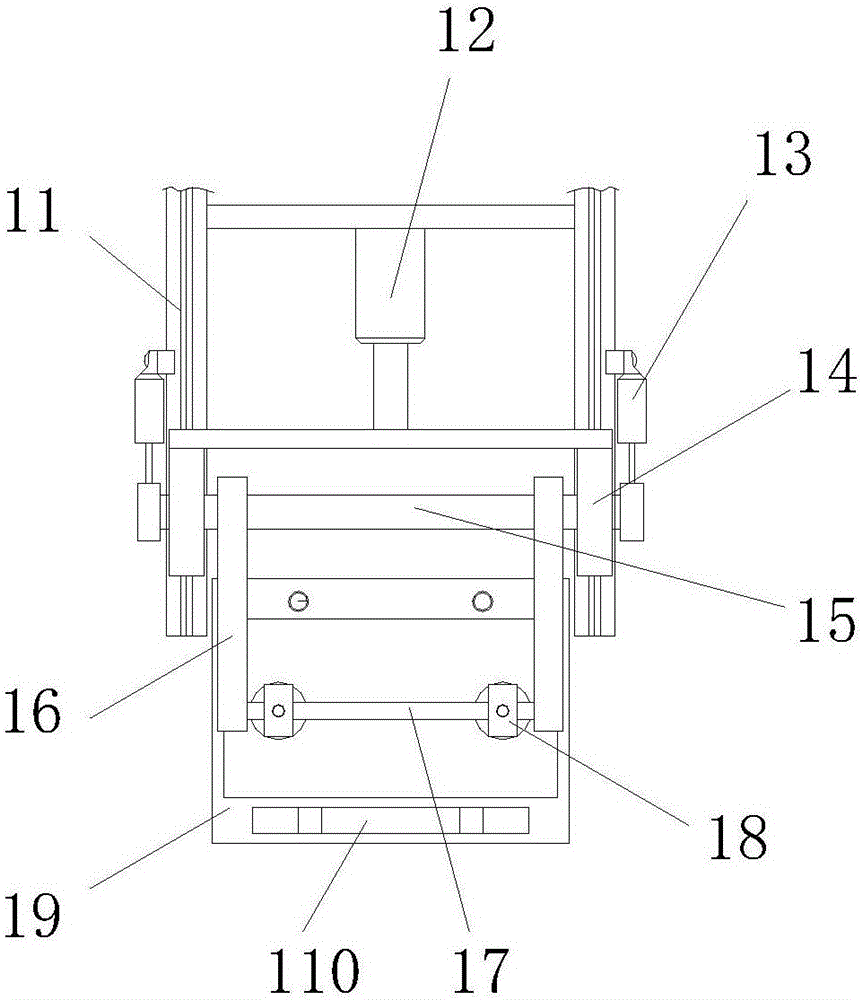

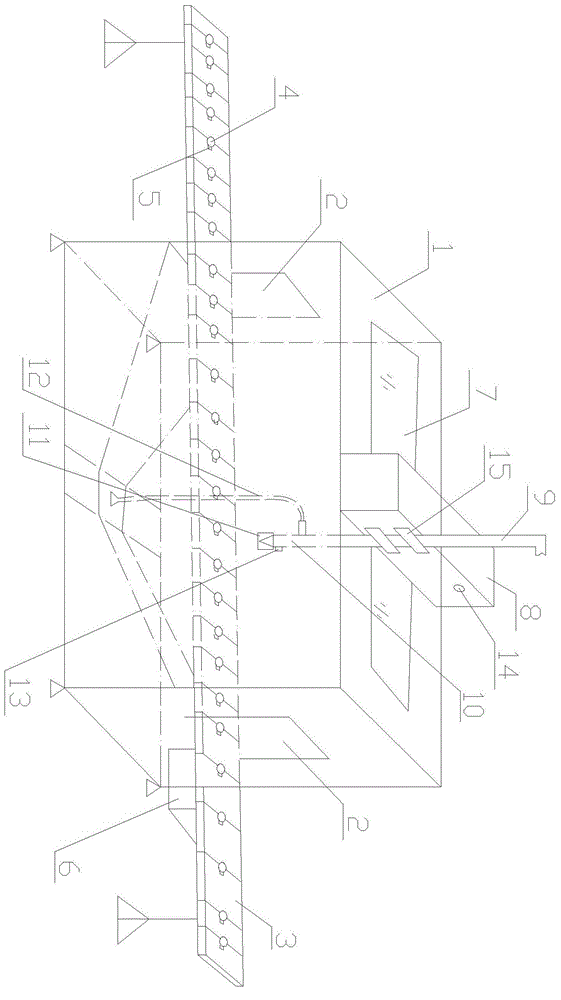

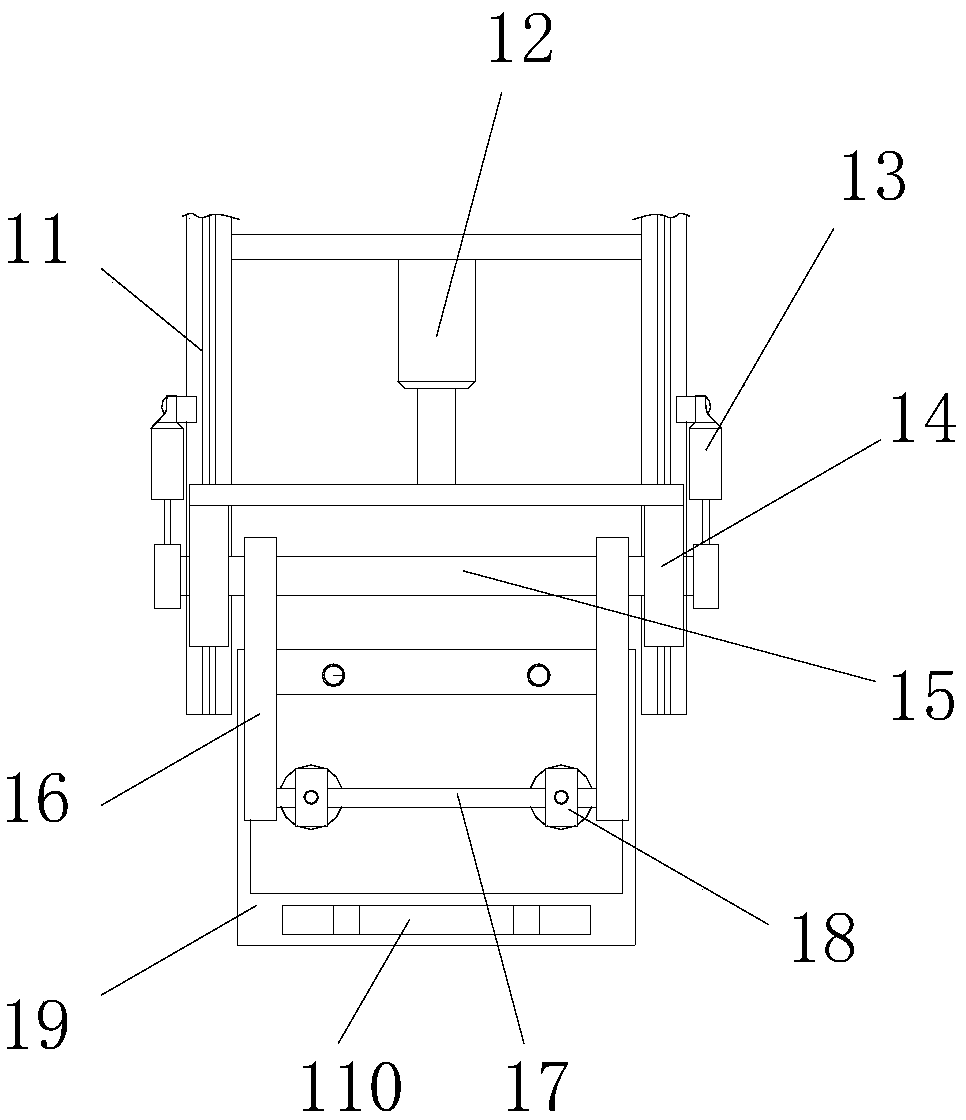

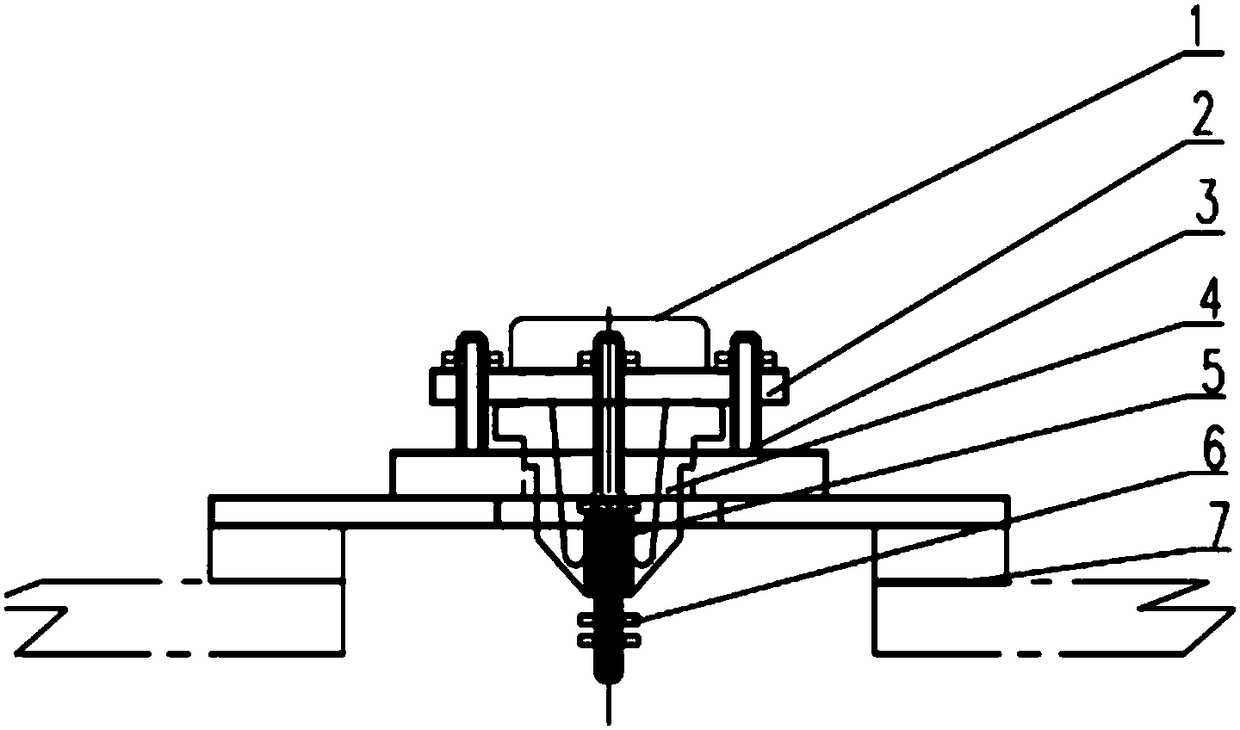

The invention provides a combined integrated type glue coating and edge cutting device and a control method and relates to the field of plate processing equipment. The combined integrated type glue coating and edge cutting device comprises a glue coating device and an edge cutting device and further comprises two segments of feeding mechanisms, namely, a first feeding mechanism and a second feeding mechanism; the first feeding mechanism is located on the left side of a glue coating mechanism; the second feeding mechanism is located between the glue coating device and the edge cutting device; each feeding mechanism comprises a material frame, a sliding rail and a sliding groove; each sliding groove is installed at the bottom of the corresponding material frame; the sliding rails are laid on the ground and connected with the sliding grooves in a matched manner; each material frame is provided with a plurality of supporting rollers; air cylinder push rods are further arranged; the air cylinder push rod at the front end is located on the left side of the first feeding mechanism; and a material frame supporting roller on the second feeding mechanism is further connected with a transmission device. The combined integrated type glue coating and edge cutting device is reasonable in structural design, the glue coating device and an edge cutting mechanism are connected through the corresponding feeding mechanism, the automation degree of the device is improved, and the production efficiency is improved.

Owner:ANHUI DONGPING WOOD GRP

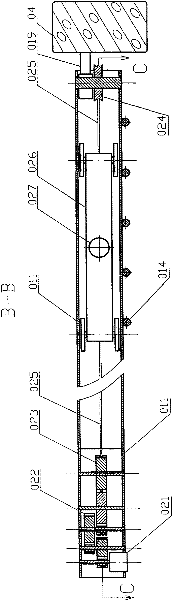

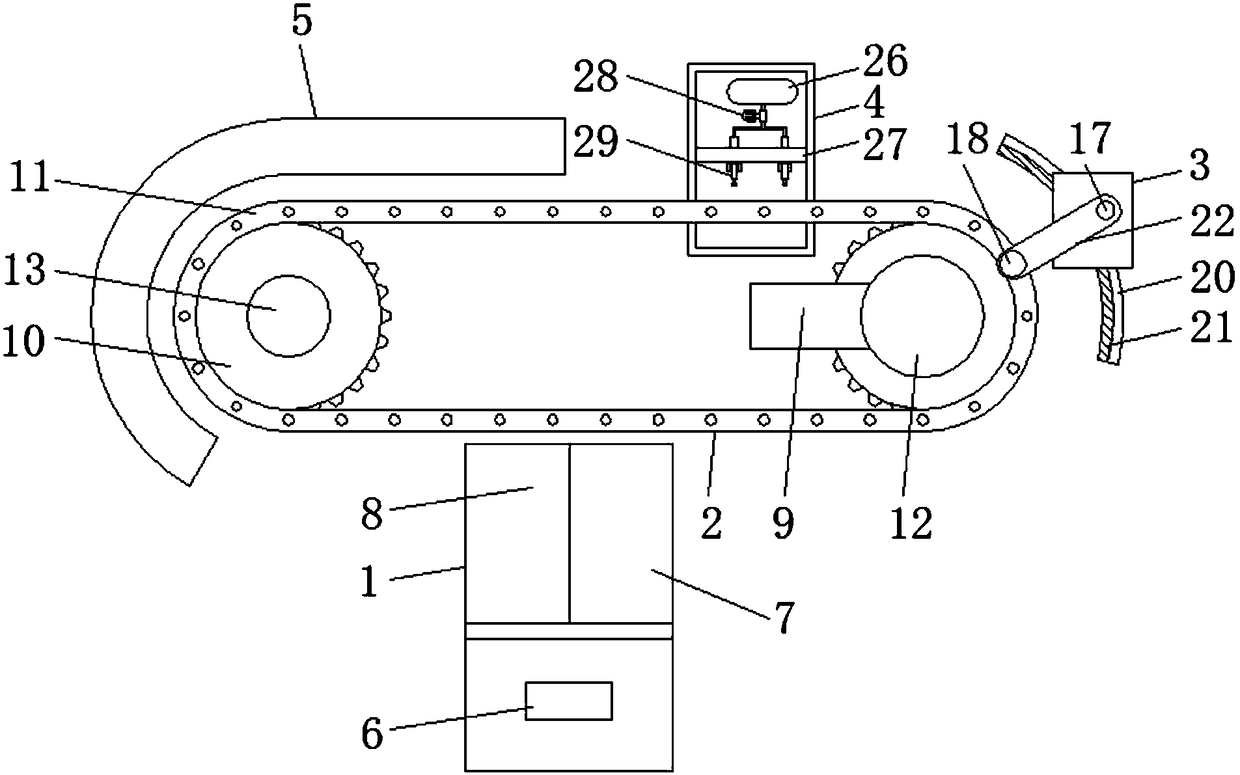

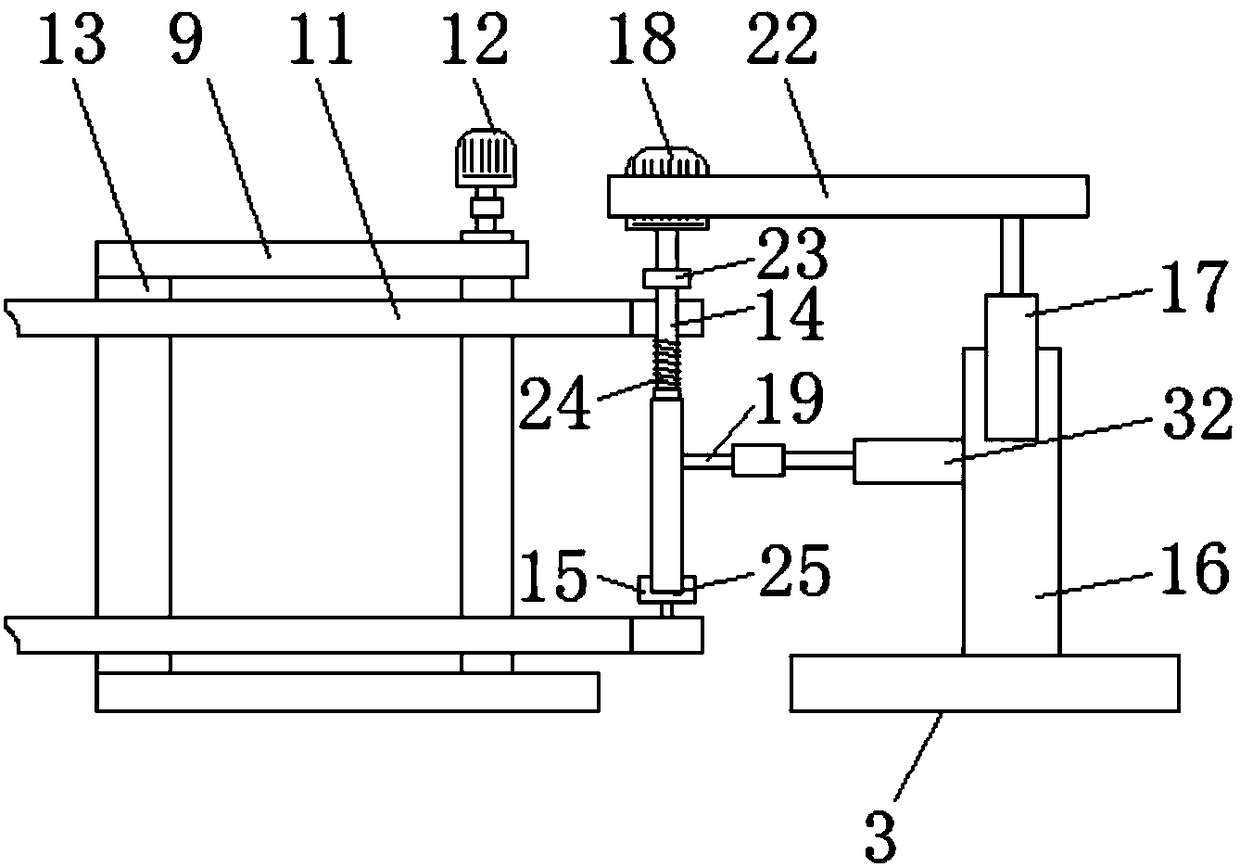

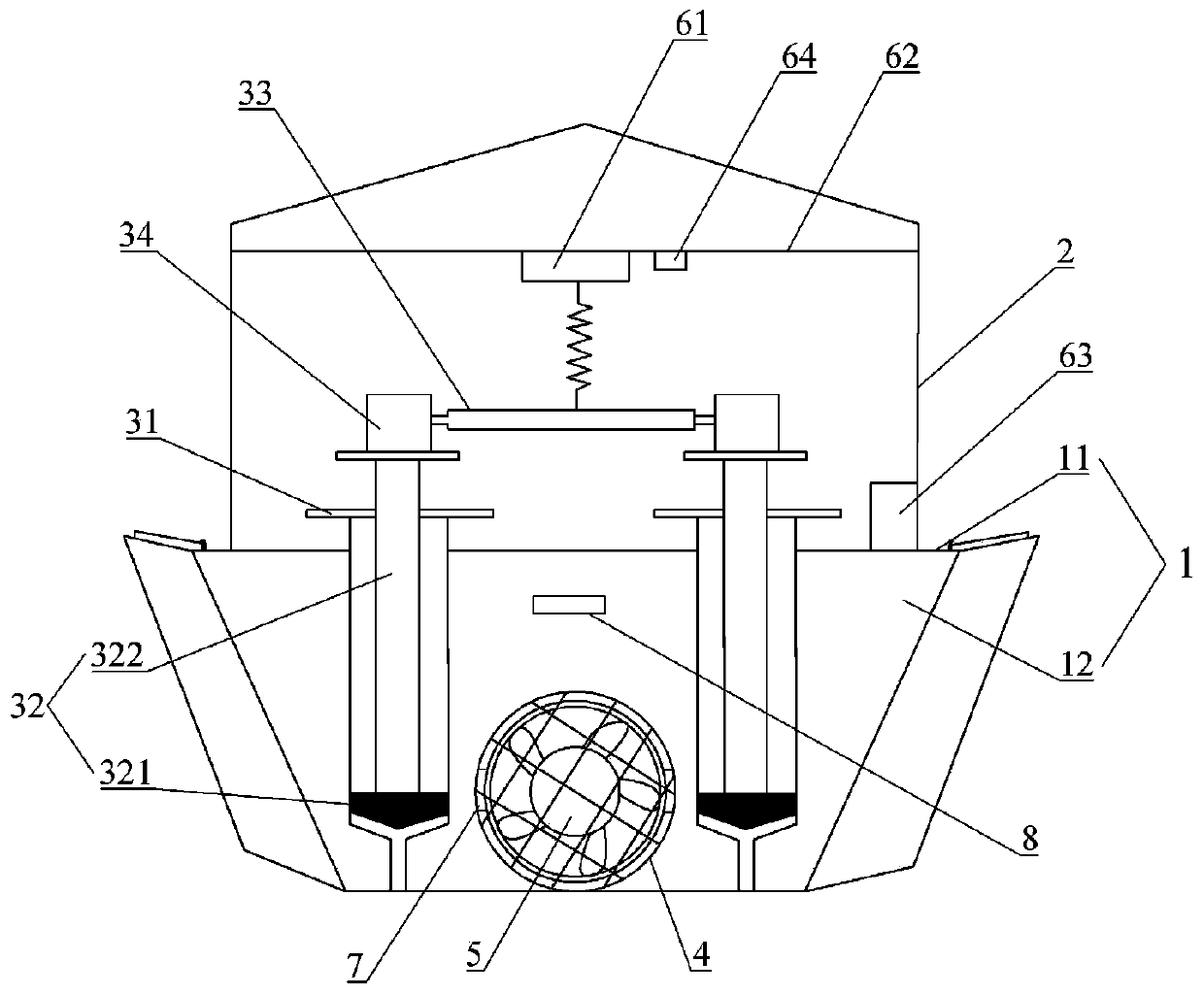

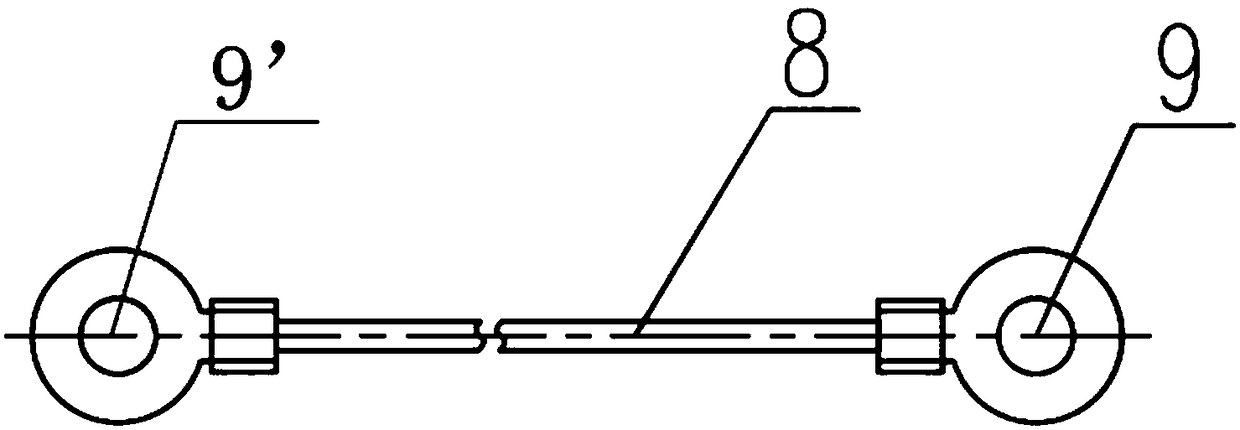

Conveying belt accumulated water removing device of belt conveyer

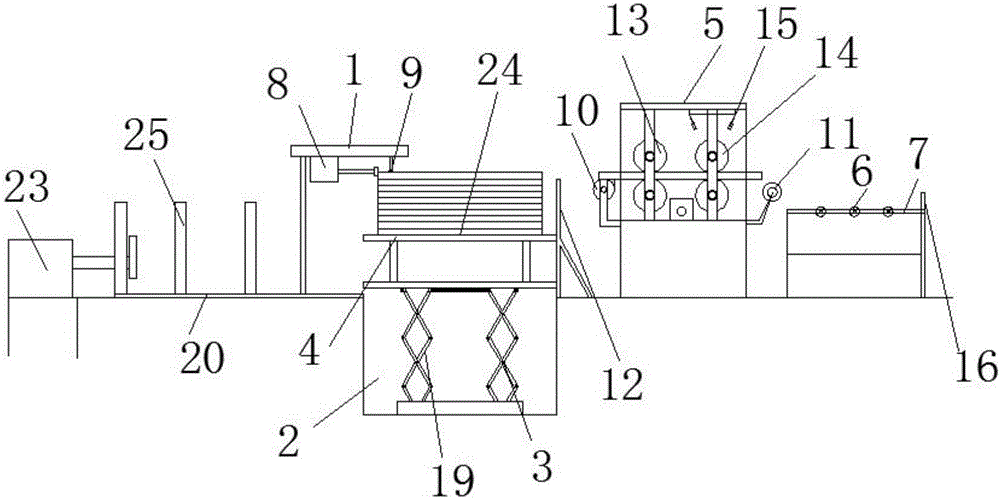

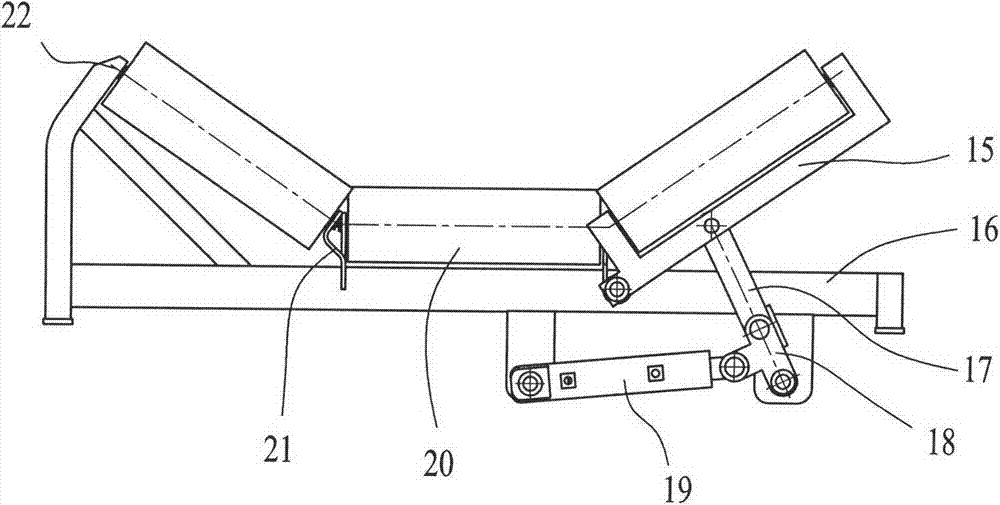

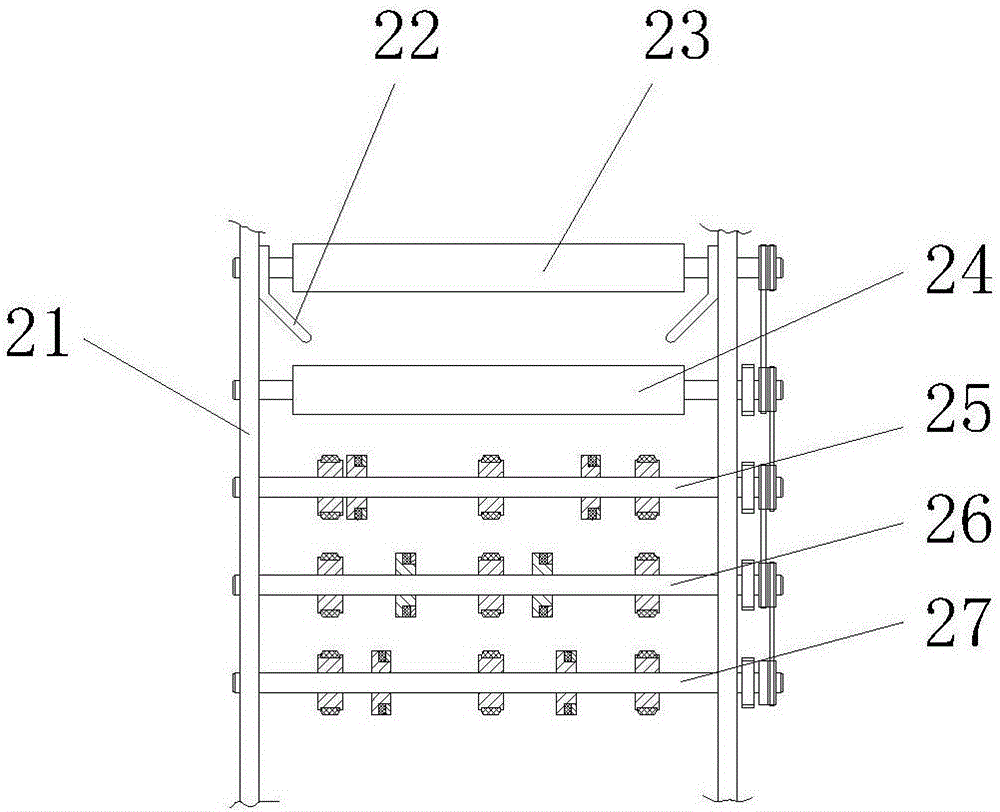

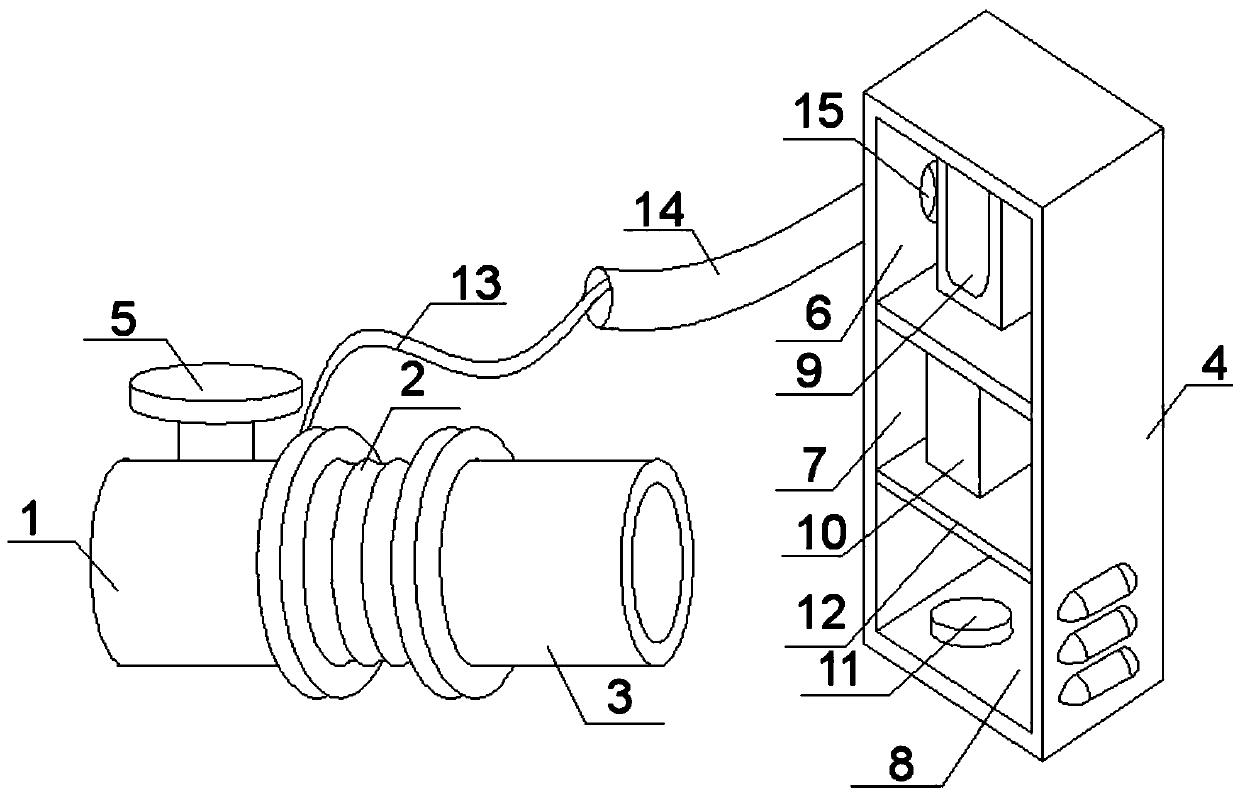

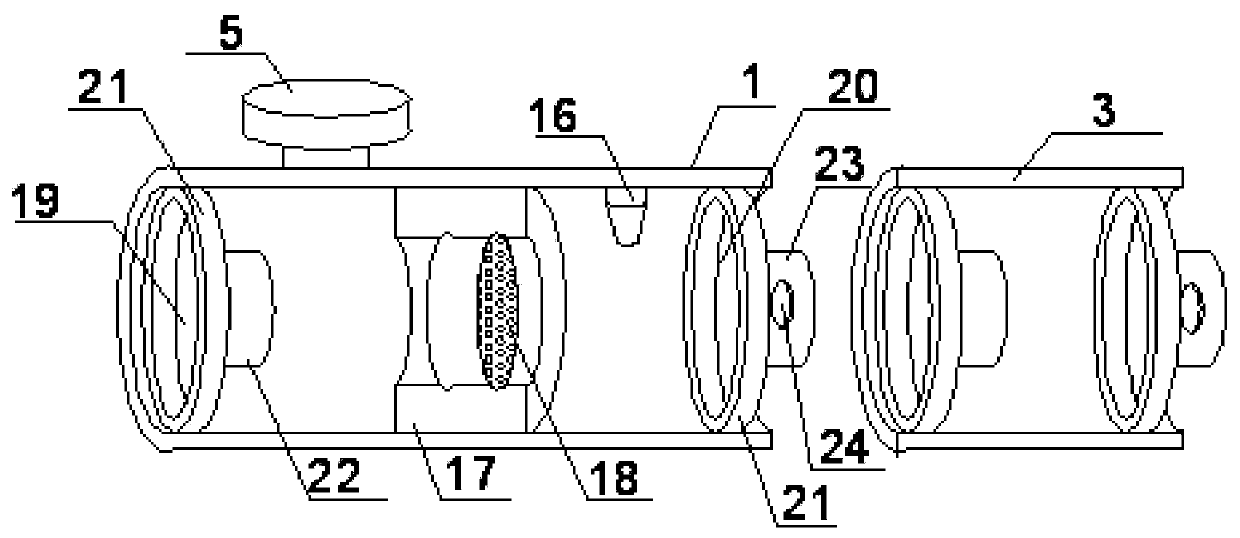

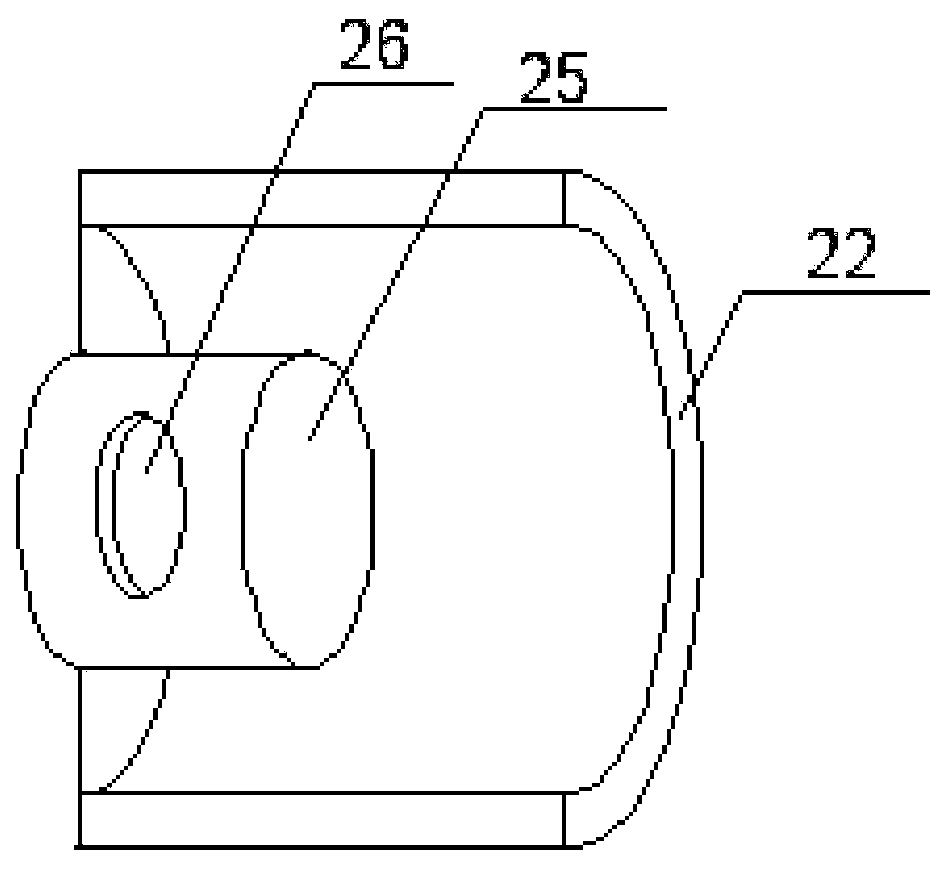

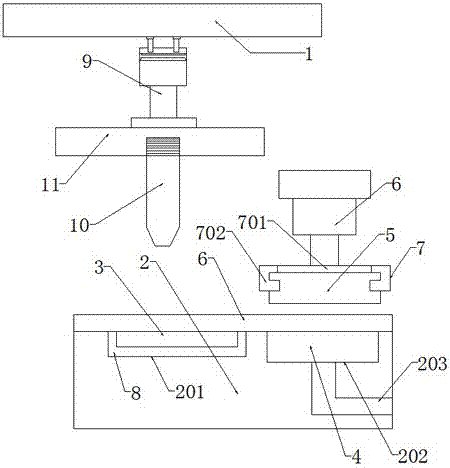

A conveying belt accumulated water removing device of a belt conveyer comprises a belt pressing device (1) and an adjustable groove angle carrier roller group (2) which are installed on a middle frame of the conveyer. A linear driver (12) is installed on a cross beam (9) of a gantry type installing frame of the belt pressing device, a pushing rod (14) is connected with a belt pressing unit (13) under the cross beam, and the belt pressing unit is connected with a counter weight (6) through a steel wire rope (7) wound on a guiding pulley (10). One end of a hinge-side carrier roller frame (15) of the adjustable groove angle carrier roller group is hinged to a fixing base frame (16), the hinge-side carrier roller frame is hinged to a connecting rod 1 (17), the connecting rod 1 is hinged to a connecting rod 2 (18), and the connecting rod 2 is hinged to the fixing base frame, so that a four-connecting-rod mechanism is formed. Two ends of a linear driver (19) are respectively hinged to the fixing base frame and the connecting rod 2. When accumulated water is removed, the linear driver (12) and the linear driver (19) acts, a side carrier roller of the adjustable groove angle carrier roller group is laid flat, the belt pressing unit presses the edge of a conveying belt downward, the conveying belt deforms, and the accumulated water flows out.

Owner:CHINA UNIV OF MINING & TECH +3

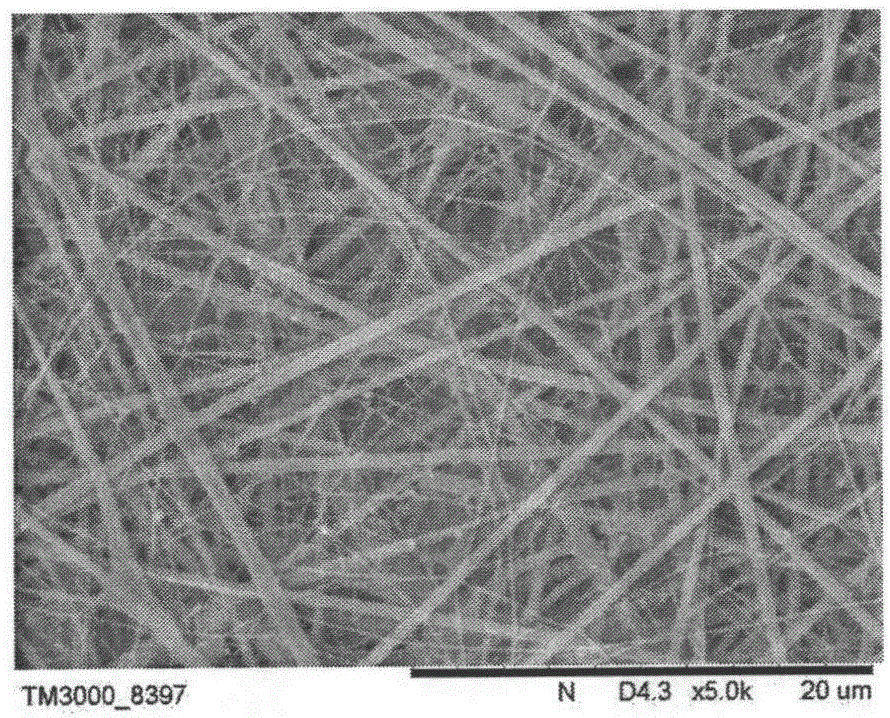

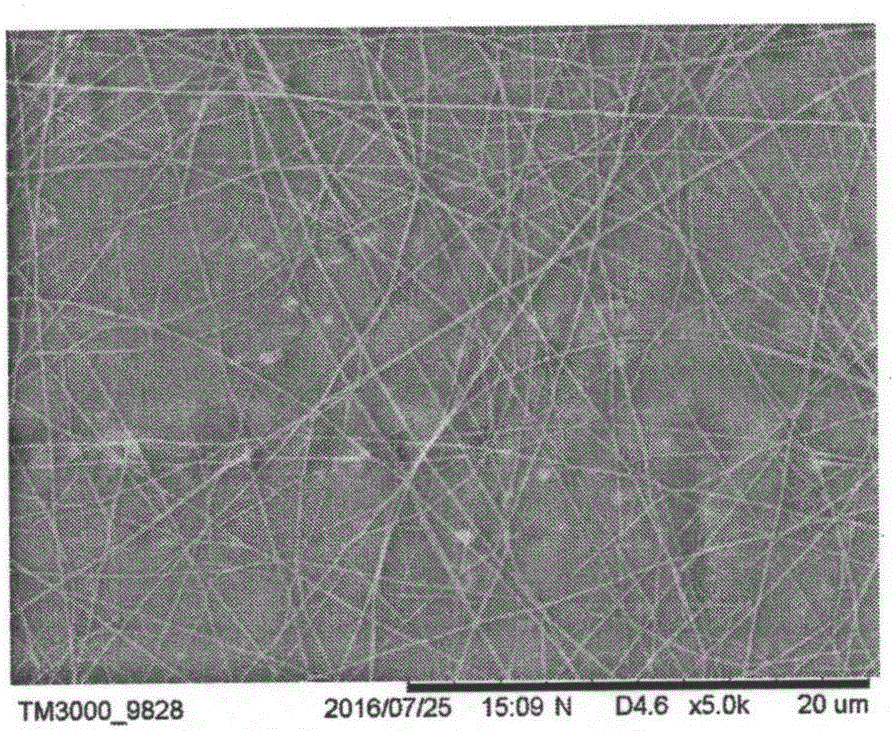

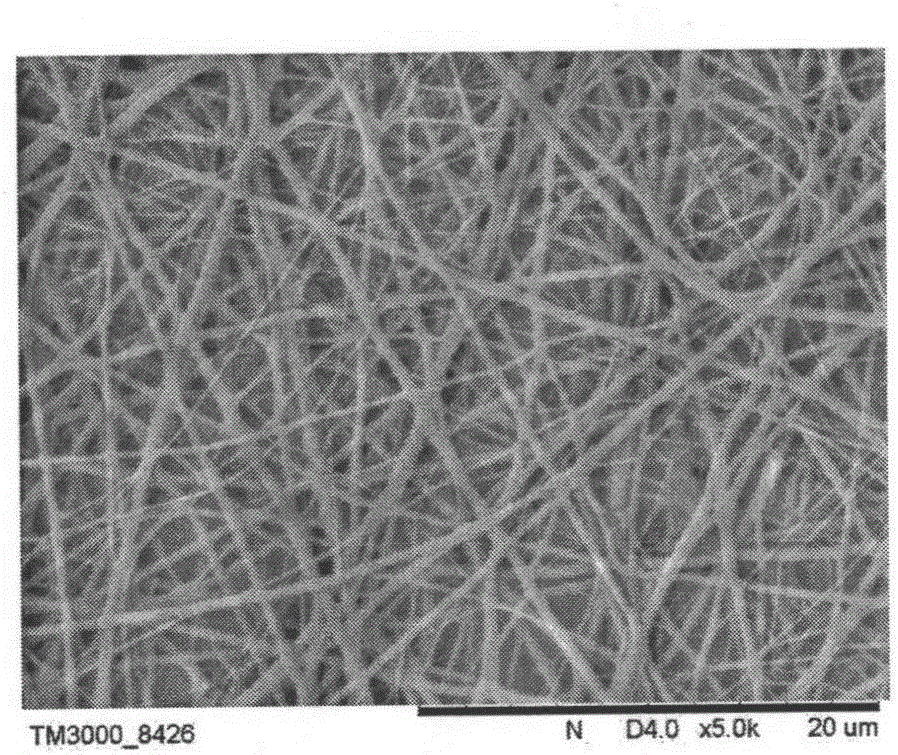

Blue shark fishskin collagen periodontium guided regeneration nanofiber membrane and preparing method thereof

InactiveCN106421903AHigh porosityImprove connectivityFilament/thread formingTissue regenerationCell adhesionElectrospinning

The invention provides a blue shark fishskin collagen periodontium guided regeneration nanofiber membrane and a preparing method thereof. The preparing method of the blue shark fishskin collagen periodontium guided regeneration nanofiber membrane includes the steps that blue shark fishskin collagen is prepared, and blue shark fishskin collagen or blue shark fishskin collagen and at least one of chitosan and PEO are used for carrying out electrostatic spinning to obtain the blue shark fishskin collagen periodontium guided regeneration nanofiber membrane. The blue shark fishskin collagen and chitosan in use are natural degradable materials and are excellent in biocompatibility and wide in source. The blue shark fishskin collagen periodontium guided regeneration nanofiber membrane prepared through the electrostatic spinning method can simulate the structure and functions of a natural cytoplasmic matrix well. The blue shark fishskin collagen periodontium guided regeneration nanofiber membrane is used for treating periodontium defects and can effectively promote cell adhesion, proliferation and differentiation and promote guided regeneration of periodontium.

Owner:DONGHUA UNIV +2

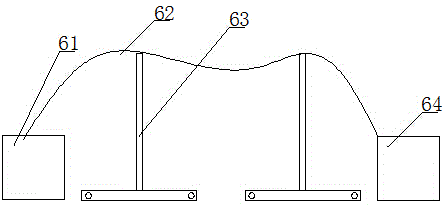

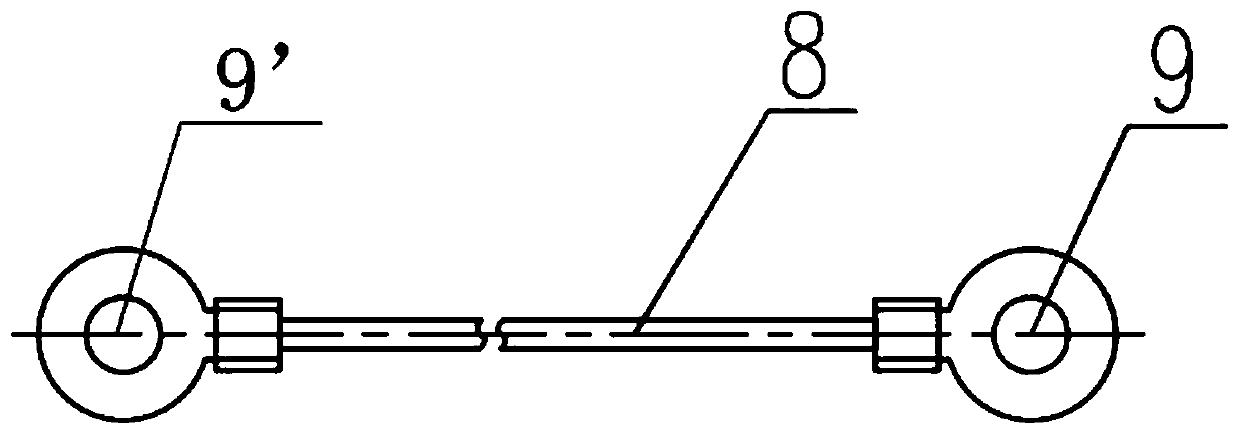

High voltage power transmission and distribution cable road-crossing machine tool and cable erecting method

ActiveCN104158114AWill not affect drivingWill not affect trafficApparatus for overhead lines/cablesWire tensionEngineering

The invention discloses a high voltage power transmission and distribution cable road-crossing machine tool and a cable erecting method. The high voltage power transmission and distribution cable road-crossing machine tool includes a stay wire tension device, a laying tension mechanism, a quick tensioning mechanism, a lead ejection device, a cable pulling rope and at least two wire erecting brackets, wherein a lead and the cable pulling rope are sequentially connected with the cable through a mouse-type wire connector; each wire erecting bracket includes a base, an upright and a wire erecting cross rod. According to the invention, compared with the prior art that the tool needs at least 5 persons for cable erecting, while the machine tool provided by the invention only needs 2 operators and the time consumed is only one fourth of the time consumed in the prior art, more importantly, the lead, the pulling rope and the cable are suspended all the time, thereby not influencing road transportation at all.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

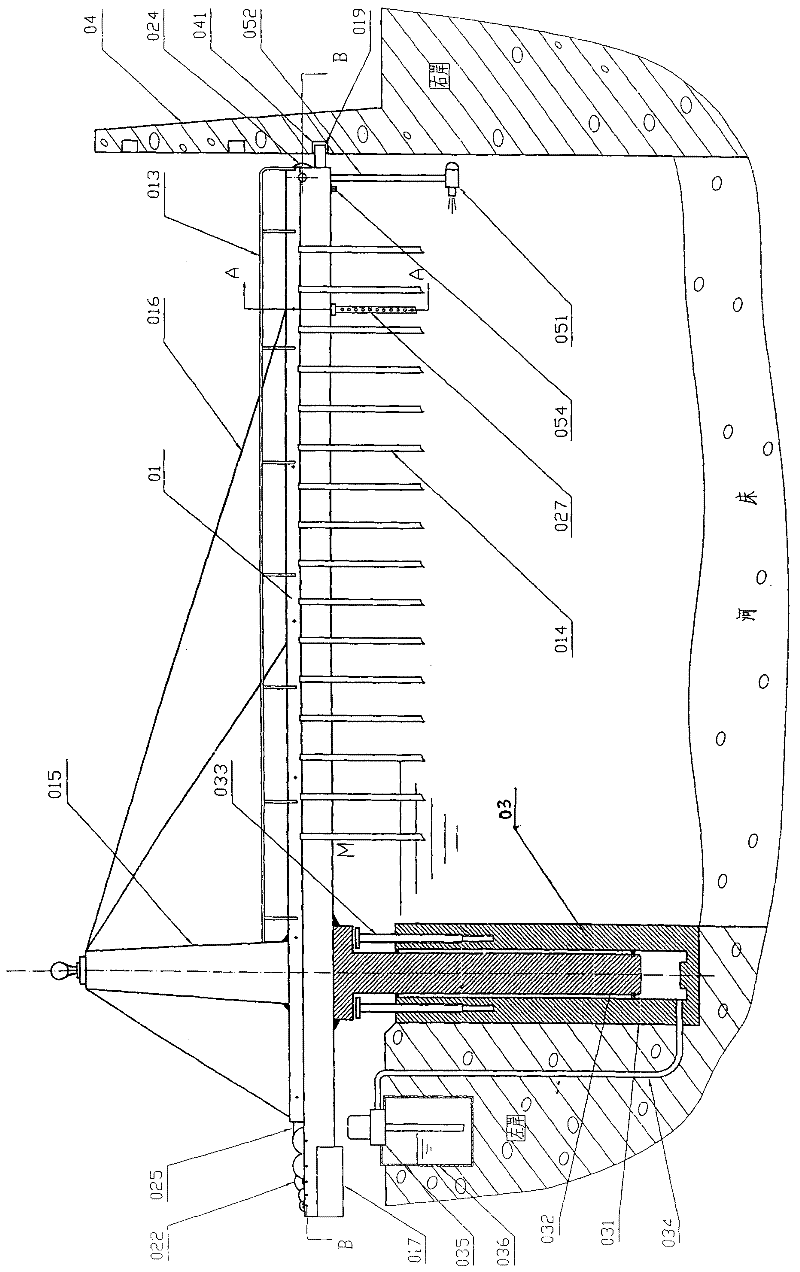

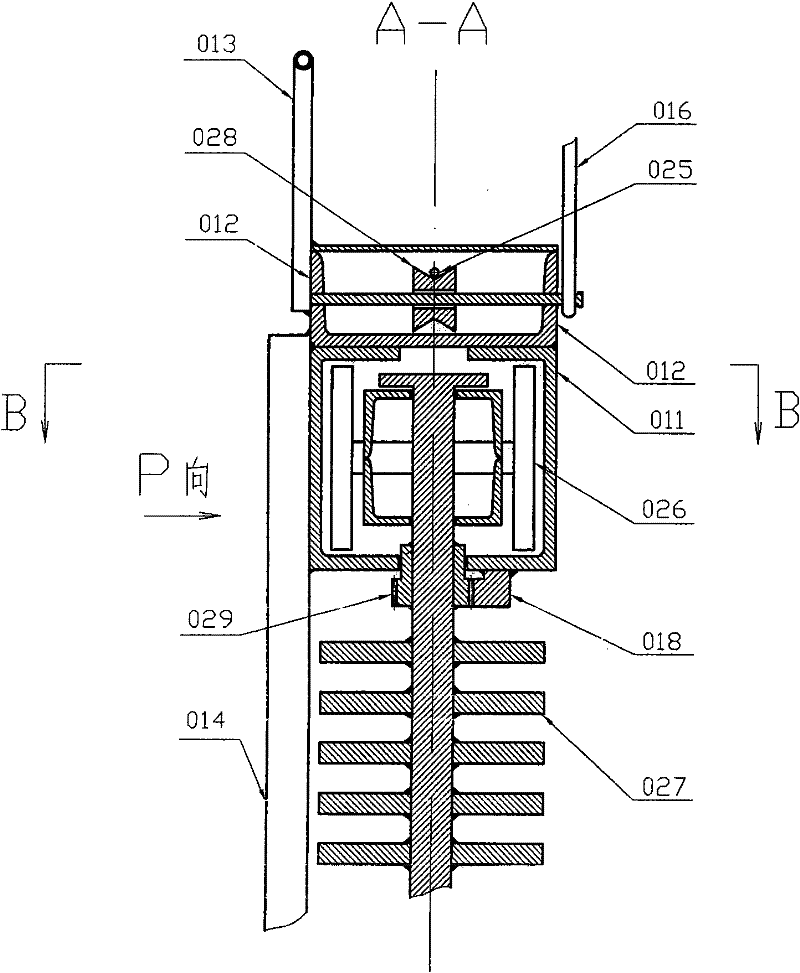

Bridge type cleaning machine

InactiveCN102261057AWill not affect shippingAvoid being floodedWater cleaningGeneral water supply conservationStructural engineeringShore

The invention discloses a bridge-type cleaning machine, which belongs to the field of automatic removal devices for floating objects in rivers. The positioning pier on one side of the bank; its structural feature is that the positioning pier is provided with a bridge positioning device for fixing the bridge on the positioning pier, and the bottom side of the bridge is equipped with a trash rack with the lower part placed in the water. There is a longitudinal channel for the reciprocating and linear movement of the cleaning trolley inside, and a cleaning sweep placed in the water for cleaning floating objects is connected to the lower end of the cleaning trolley. The invention can realize full-automatic decontamination work 24 hours a day, and the bridge can be lifted and lowered according to the rise and fall of the river water, and the decontamination efficiency is high. In addition, the bridge can rotate along the lifting pier to leave the river, so it will not affect shipping.

Owner:曾一峰

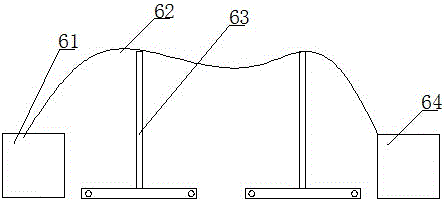

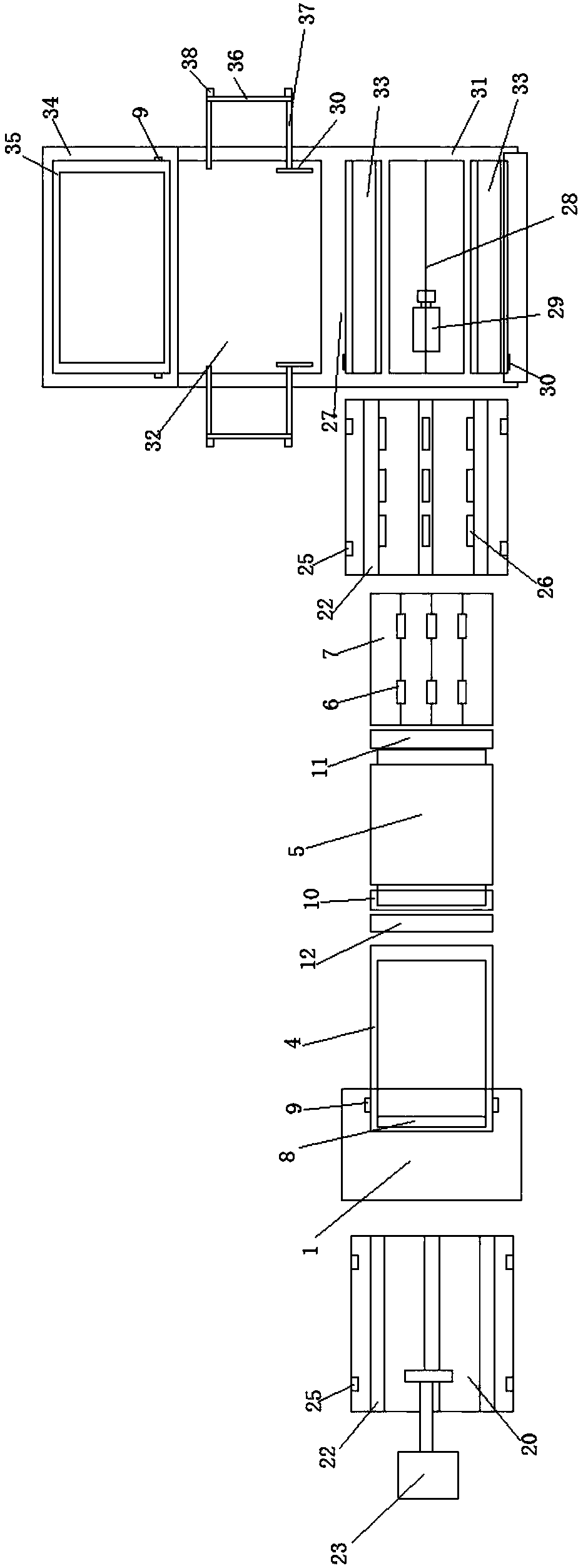

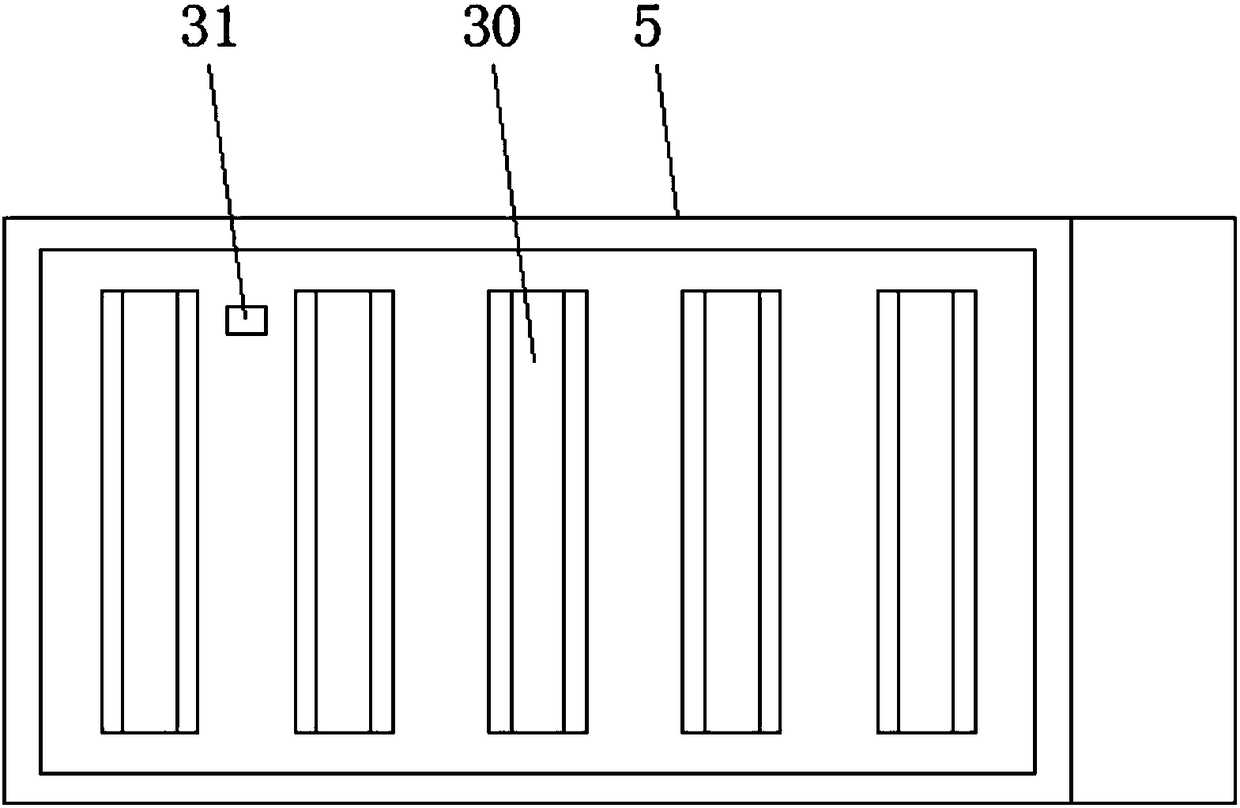

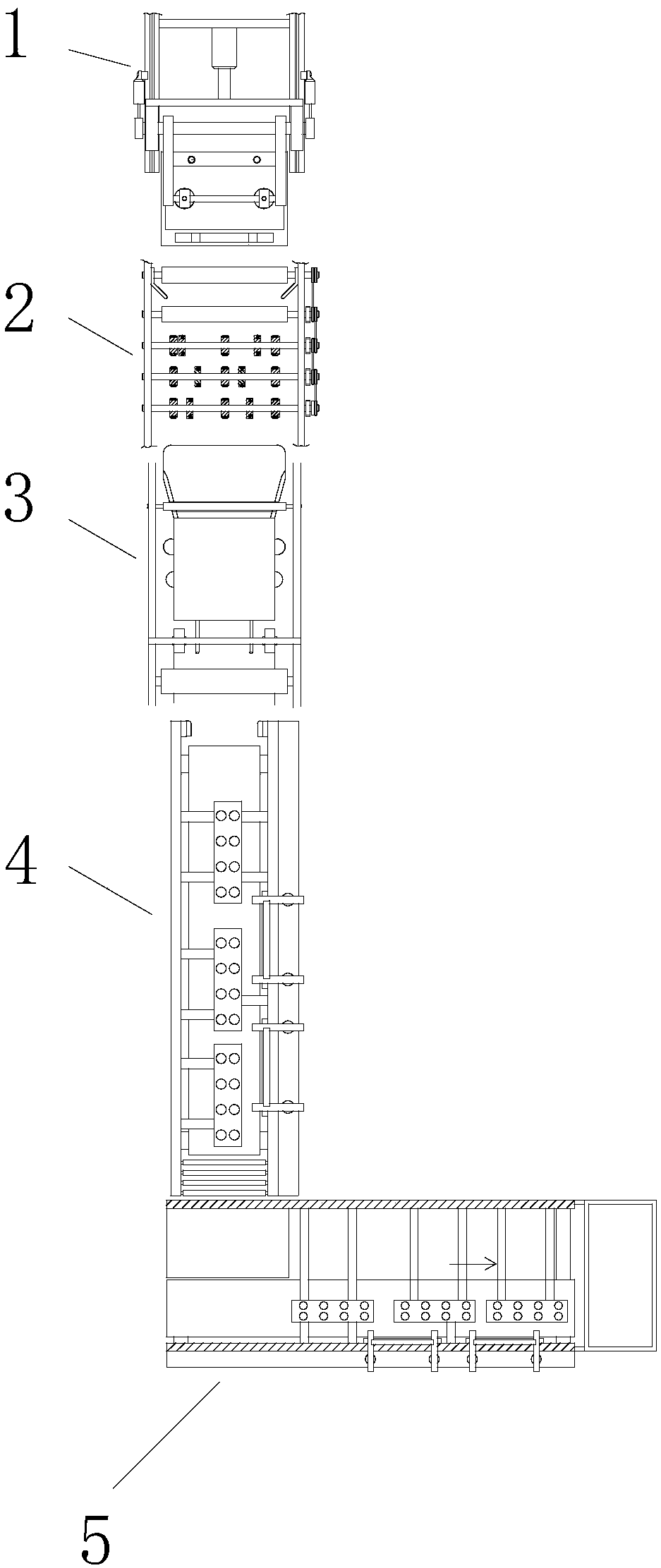

Paper bag package production line equipment

ActiveCN106564214AAvoid overlapping entryPrevent deviationBag making operationsPaper-makingProduction linePulp and paper industry

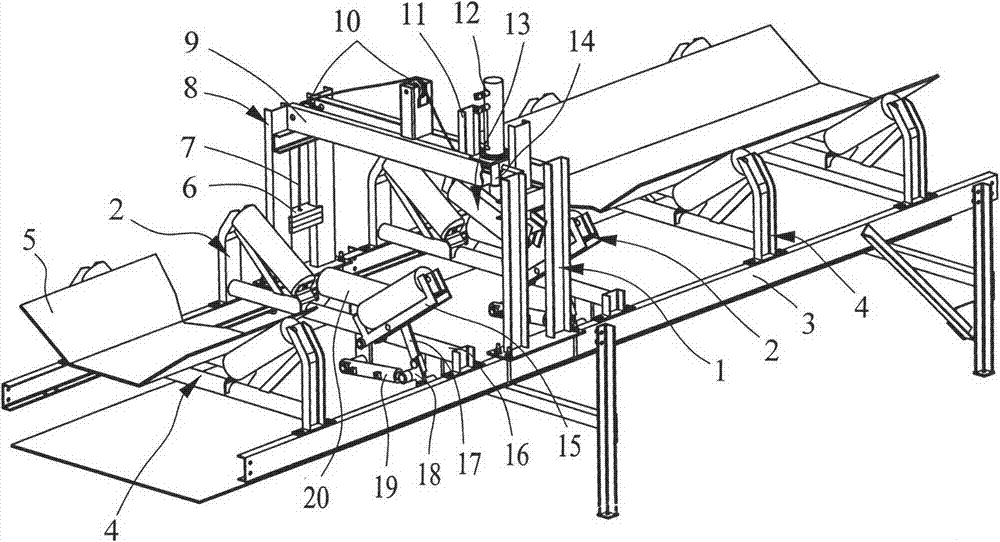

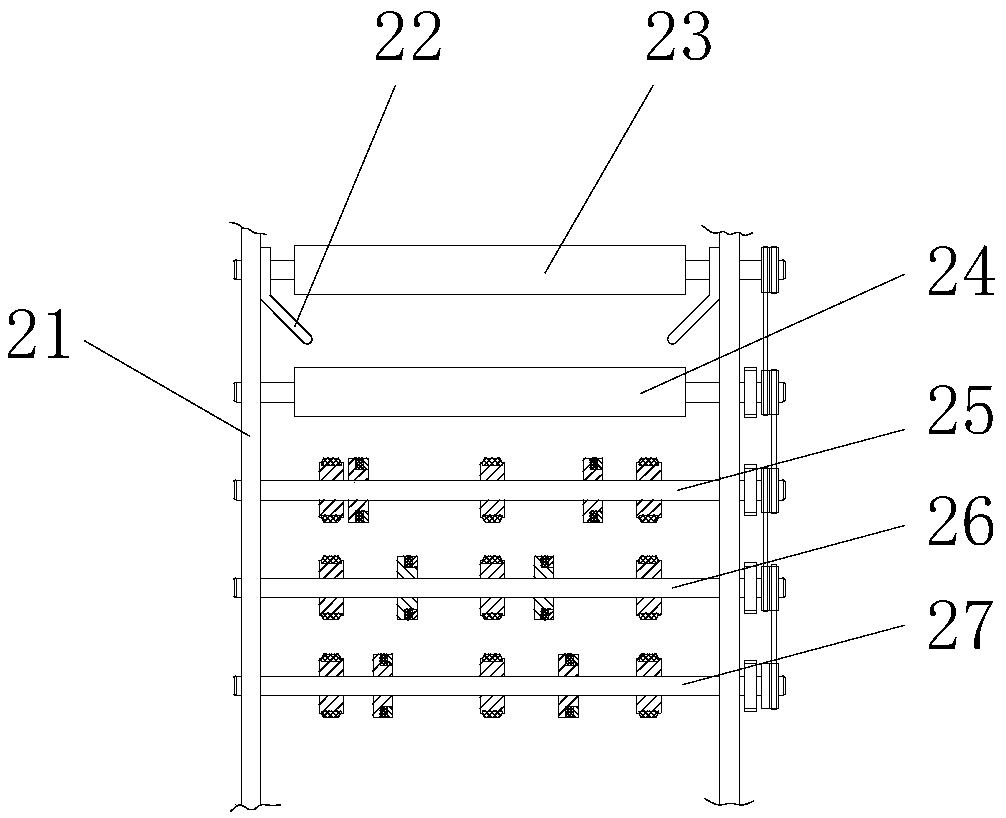

The invention discloses paper bag package production line equipment which comprises a paper suction device, a line folding device, a forming device, an edge sealing device and a bottom sealing device which are sequentially arranged in the production direction; the paper suction device is composed of a paper suction rack and a paper charging lifting device arranged at the front end of the paper suction rack; the line folding device is composed of a rack plate, a pinch roll, a first line folding rotary shaft, a second line folding rotary shaft and a third line folding rotary shaft; the forming device is composed of a forming rack, an edge folding guide plate, a former and a setting roll; the edge sealing device is composed of an edge sealing rack, an edge sealing conveying device, an edge sealing heat sealing device and an edge sealing compaction device; and the bottom sealing device is composed of a bottom sealing rack, a bottom sealing conveying device, a bottom sealing heat sealing device and a bottom sealing compaction device. The paper bag package production line equipment is reasonable in structure arrangement, prevents paper from entering in an overlapping manner, is beneficial to improving the paper transmission efficiency, can effectively carry out centering guide, is accurate in line folding position and good in paper bag forming effect and enables bottom sealing of a paper bag to be firmer, more reliable and complete.

Owner:烟台中科恩吉科创新产业园管理有限公司

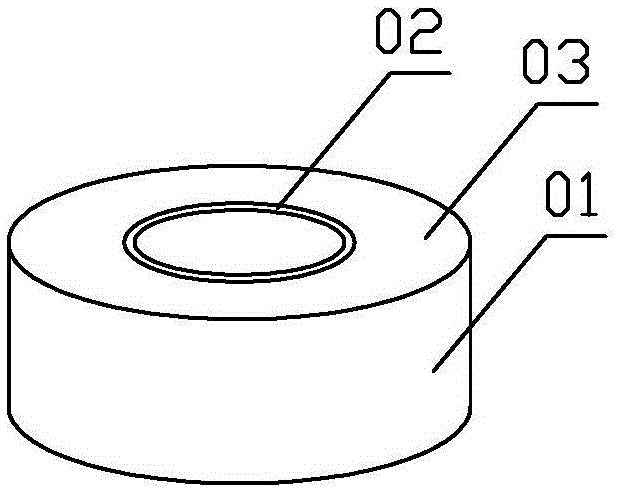

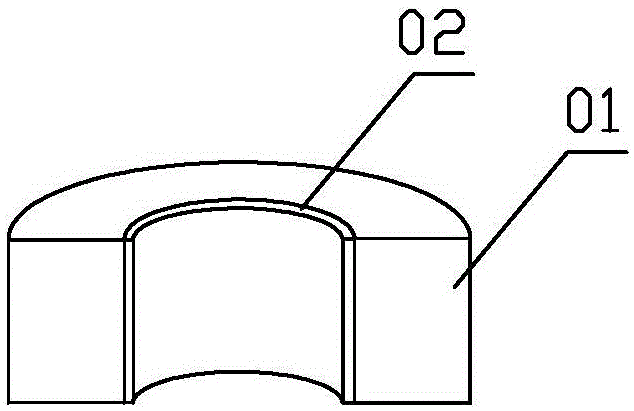

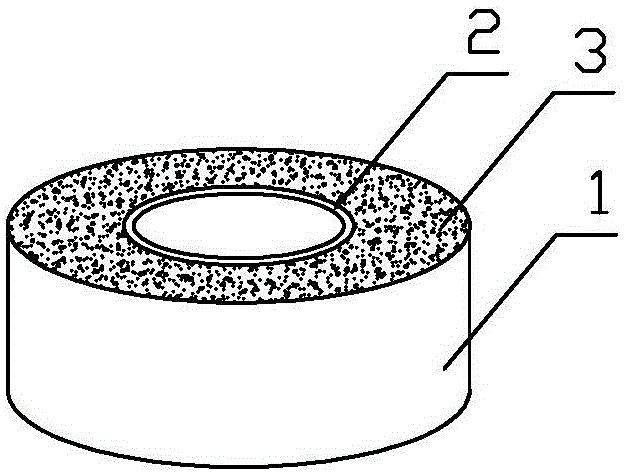

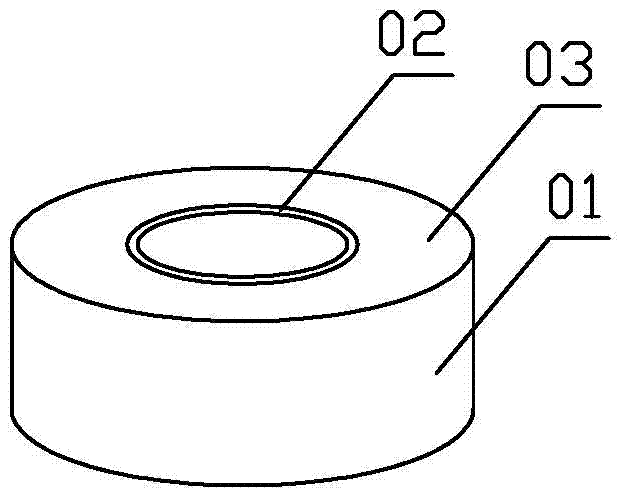

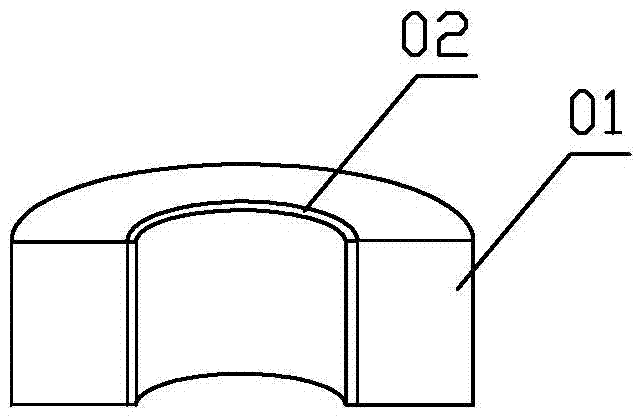

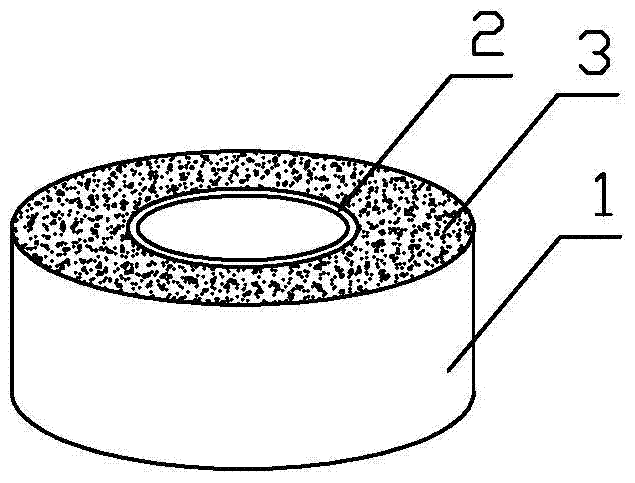

Processing method for packing tape

ActiveCN105017981AWill not affect normal useNo extra weightFilm/foil adhesivesEngineeringPlastic film

The invention provides a processing method for a packing tape with better user experience. No right-angled corners are available at the upper and lower ends of a produced tape, so that a user is not cut, and meanwhile, the end face of a tape coil is not sticky, so that the tape is more convenient to take and use. The processing method comprises the following main steps: adding a tape raw material acrylic acid into an emulsification tank for emulsification; then putting the emulsified raw material into a reaction pot to be heated to prepare glue; then adding the glue into a coating machine; mounting a plastic thin film coil on the coating machine and smearing the glue to a plastic thin film through the coating machine to prepare a mother coil; pipe-cutting the mother coil through a pipe cutter; stripping the successfully pipe-cut tape through a stripping machine to obtain coils of tapes; polishing the upper and lower inner corners of a paper element of the stripped tape by using a polishing machine; polishing the right-angled corners with the inner corners to bevels or arc-shaped faces; and uniformly adhering paper element powder left when the right-angled corners are polished to the end face of the tape coil of the tape to prepare a finished product packing tape.

Owner:广东宝兰山新材料科技有限公司

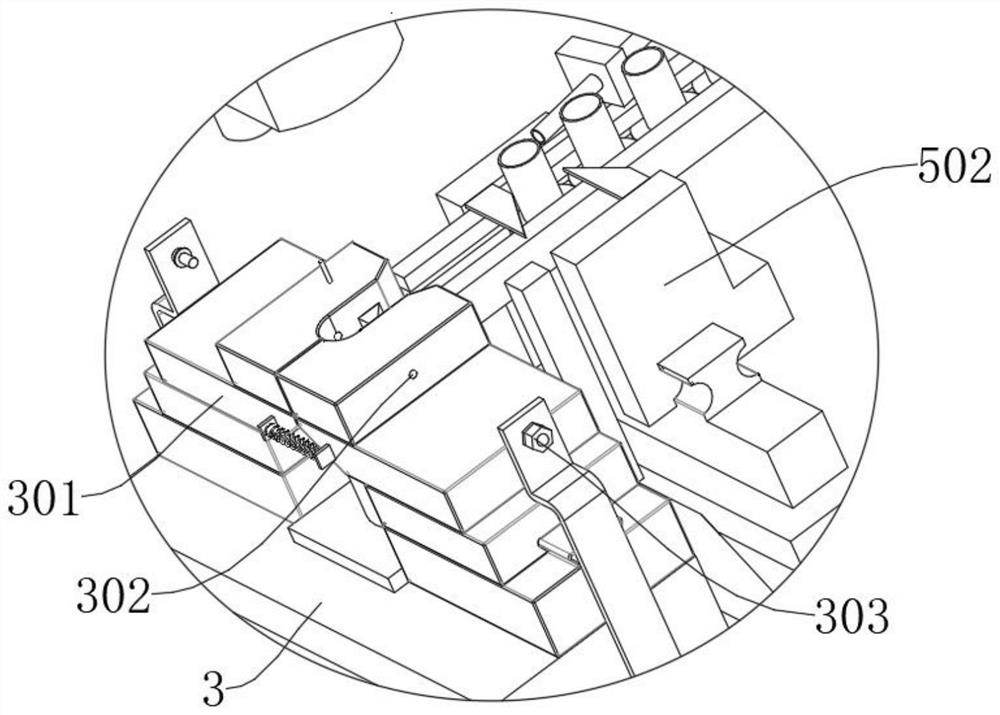

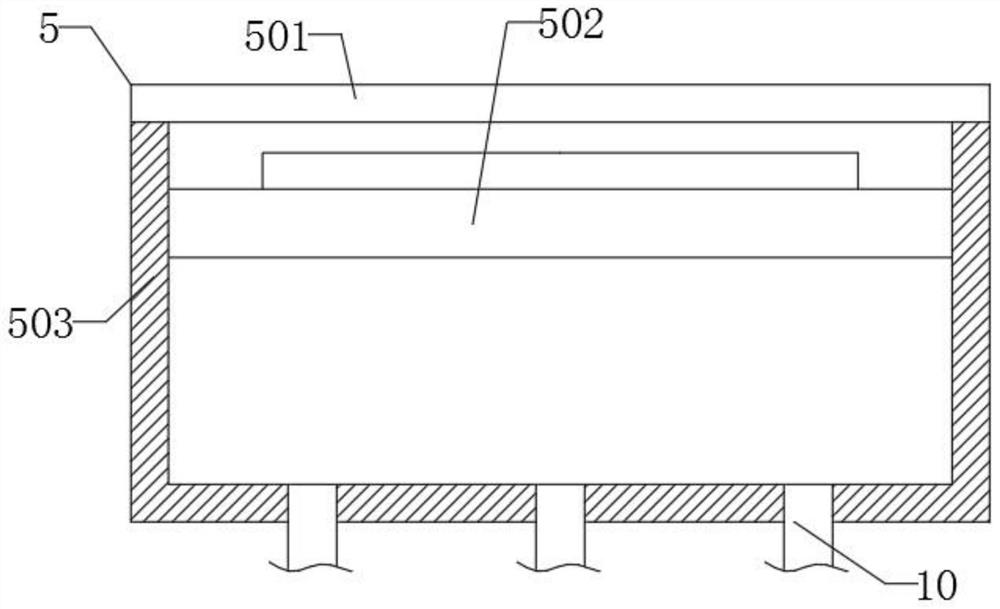

Paper packaging bag bottom sealing device

InactiveCN106476325AWill not affect shippingAvoid self openingBag making operationsPaper-makingEngineeringMechanical engineering

Owner:GUANGDE COLORFUL ZEBRA PACKAGE TECH

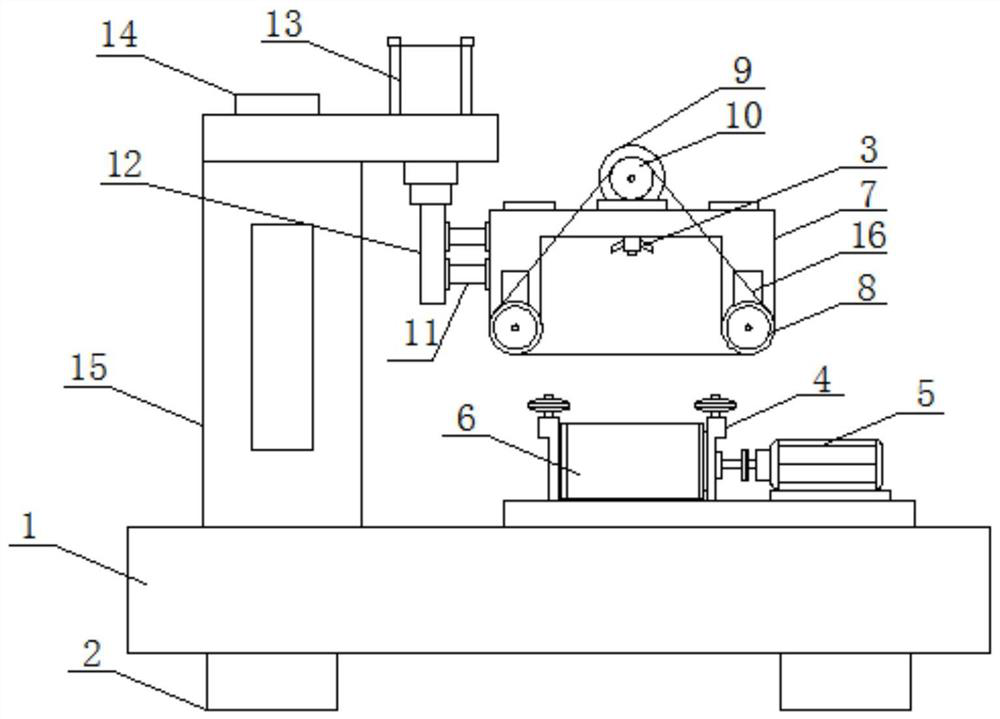

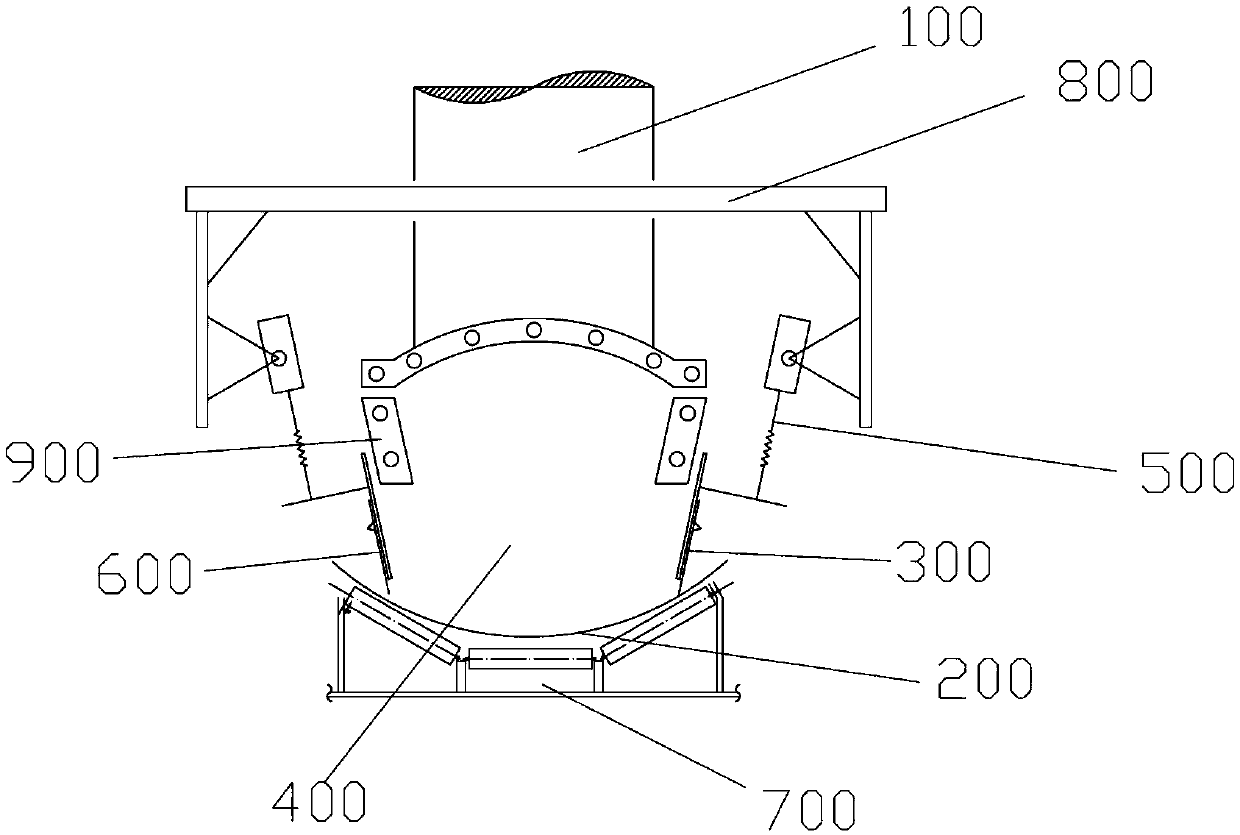

Monocrystalline silicon rod cutting device and cutting method thereof

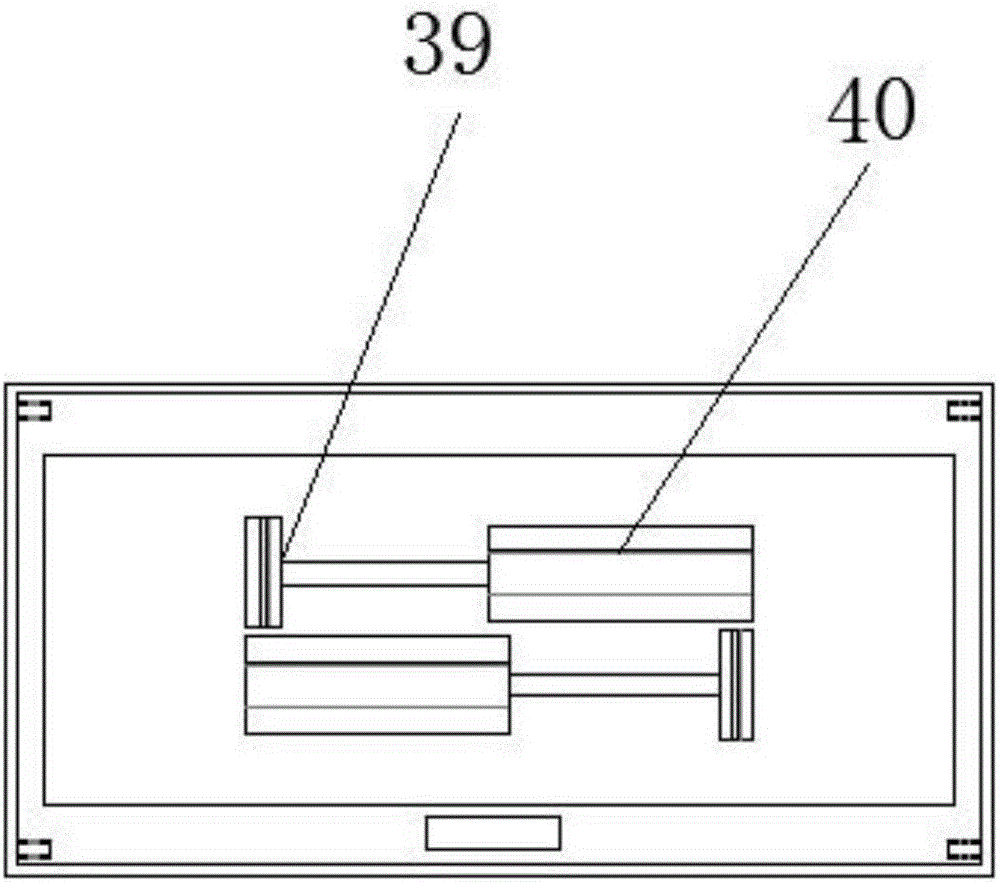

InactiveCN112277178AWill not affect shippingThe truncation operation is simple and efficientWorking accessoriesFine working devicesElectric machineryStructural engineering

The invention discloses a monocrystalline silicon rod cutting device in the technical field of monocrystalline silicon. An operation table is arranged on the right side of the top of a base, wherein aconveying motor is installed on the right side of the top of the operation table; two clamping devices of the same structure are symmetrically arranged on the left side of the top of the operation table; a conveying belt is arranged between the two clamping devices through a rotating shaft rod; and the power end of the left side of the conveying motor penetrates through one clamping device to beconnected with the rotating shaft rod on the conveying belt. According to the device, a monocrystalline silicon rod to be machined can be clamped through two auxiliary wheels, conveying of the monocrystalline silicon rod on the conveying belt cannot be influenced, and the conveying stability cannot be influenced while clamping is carried out; through cooperation of power rollers and auxiliary rollers which are arranged in a triangular shape, a diamond wire running at a high speed has good stability; and through cooperation of a hydraulic device, the cutting operation of the monocrystalline silicon rod becomes simple and efficient.

Owner:江苏晶品新能源股份有限公司

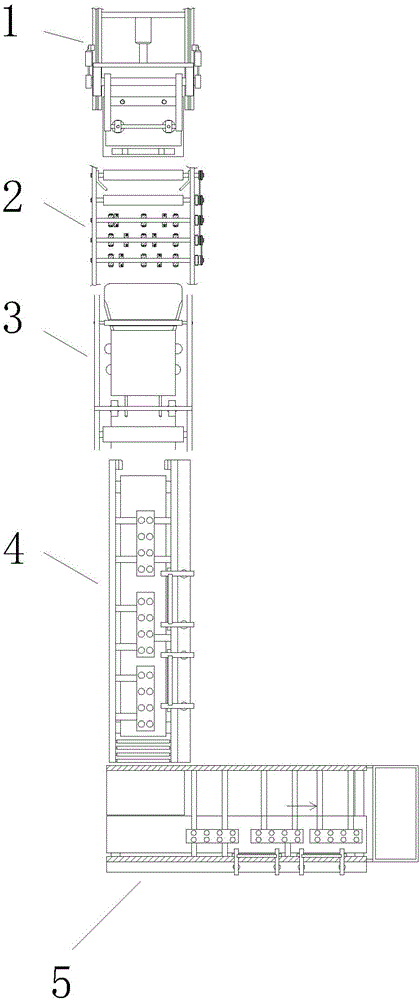

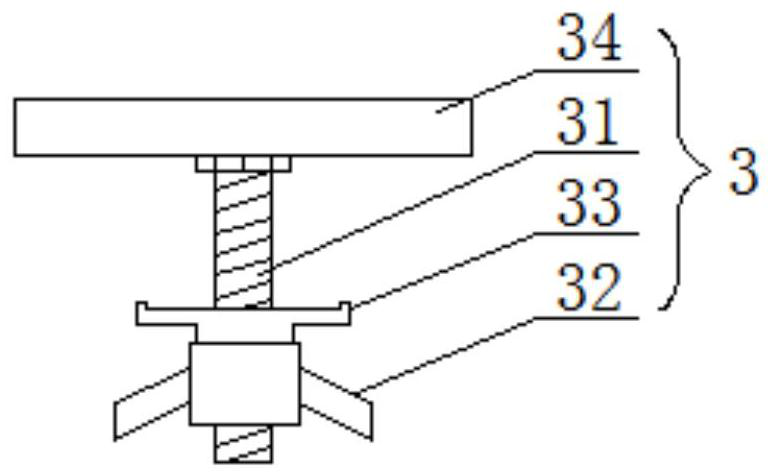

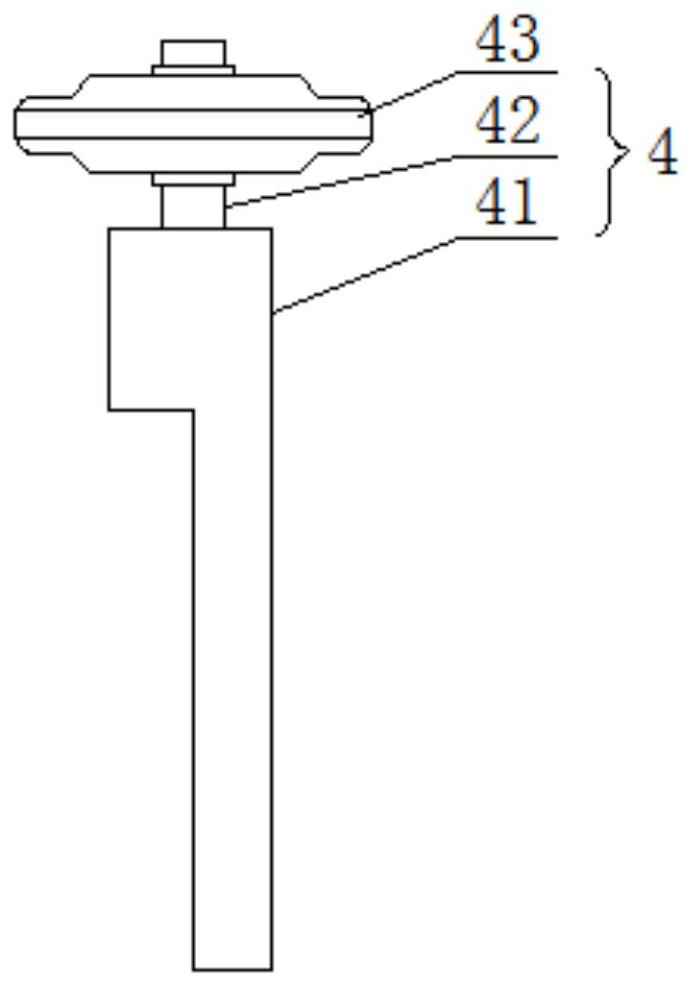

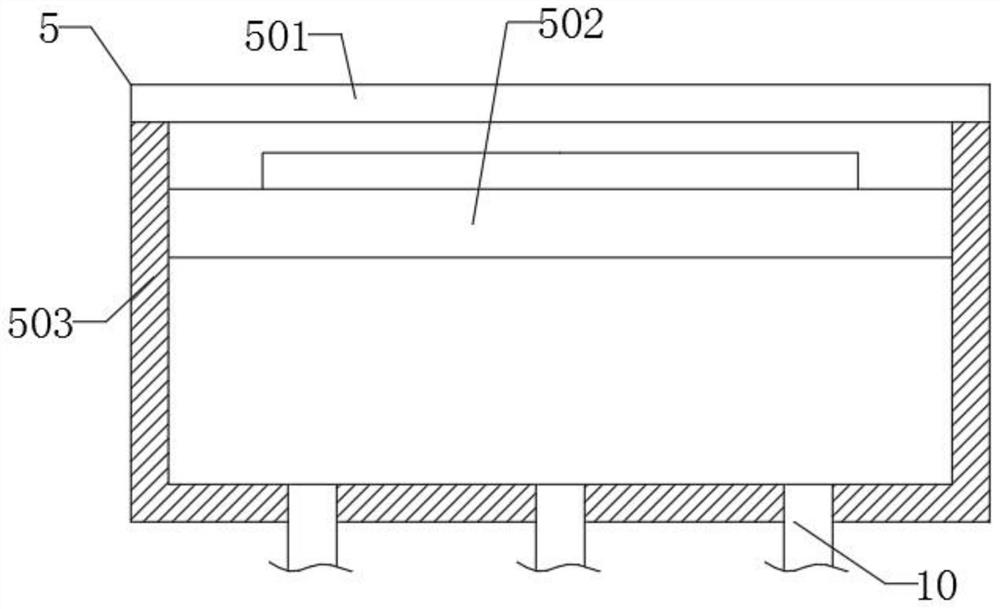

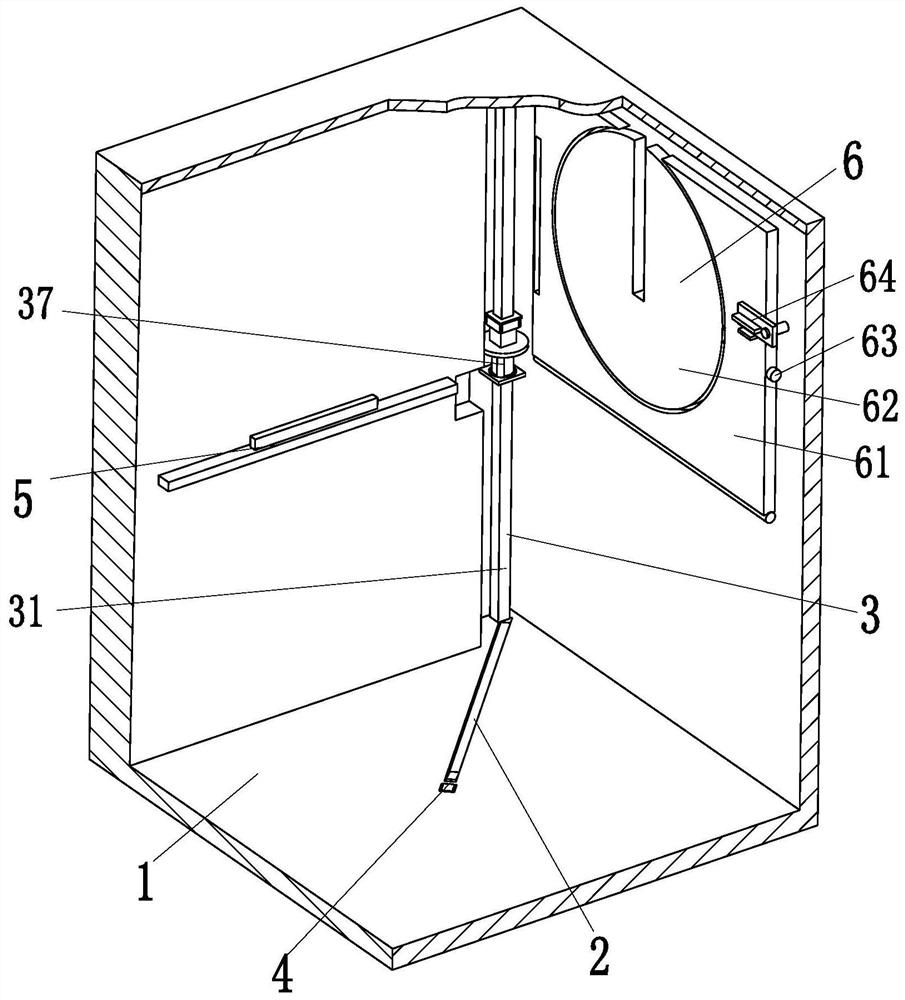

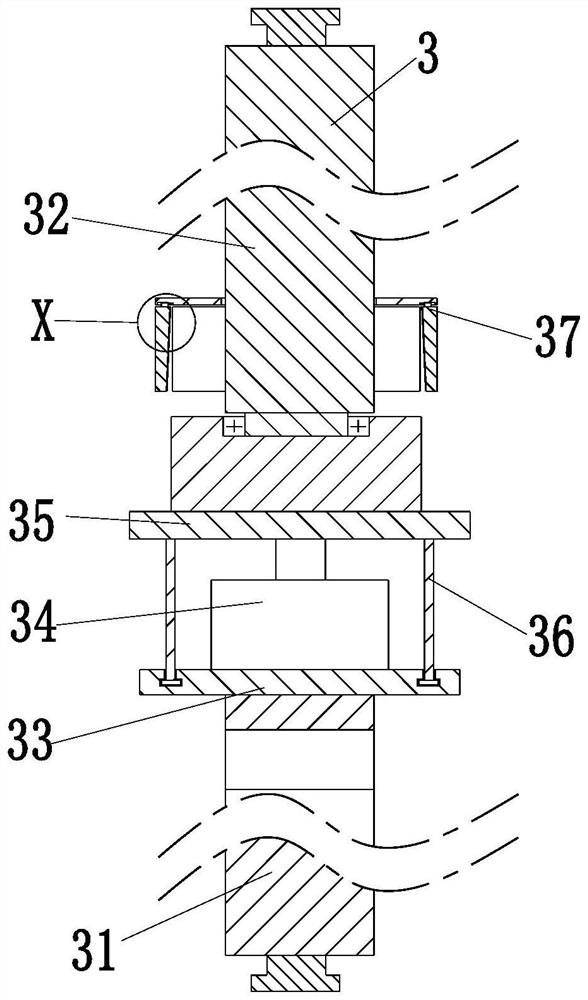

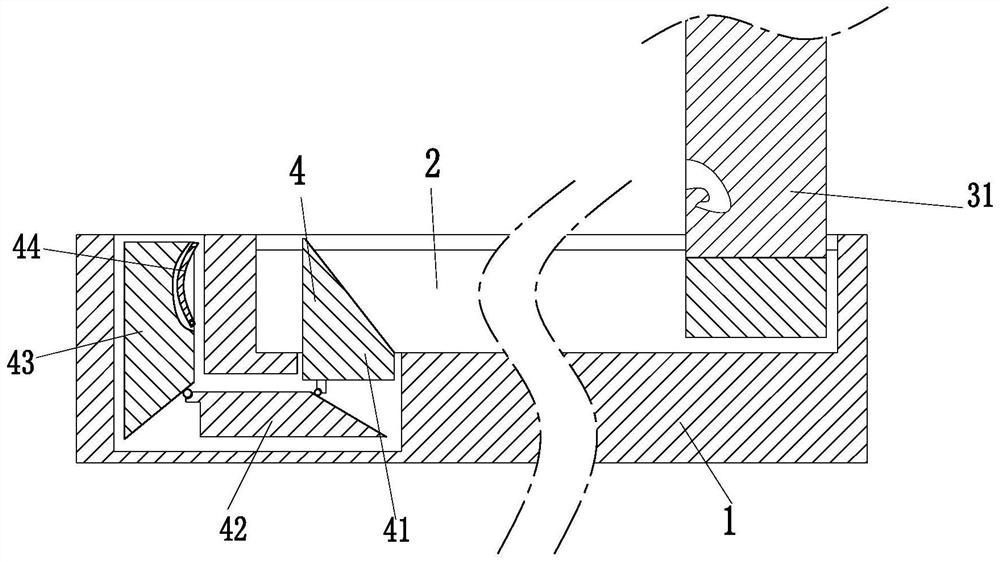

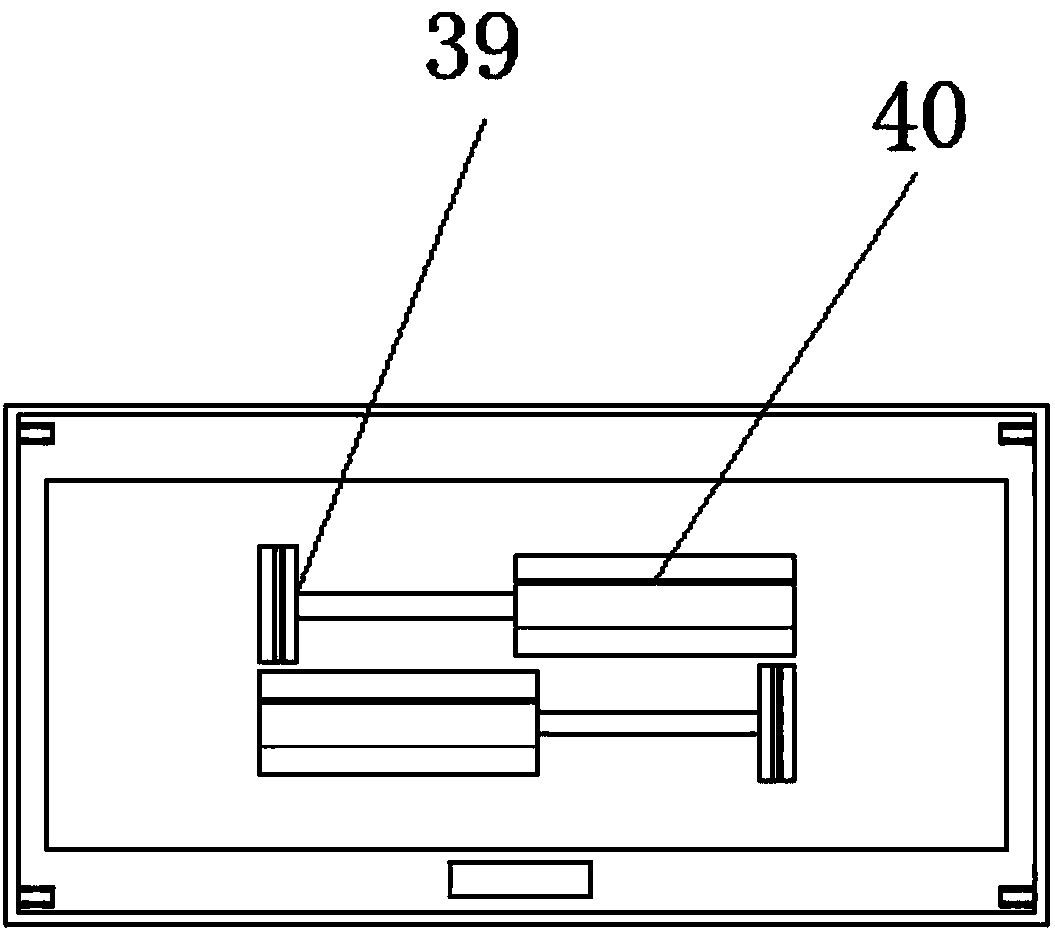

Car of temporary freight elevator of high-rise building

ActiveCN110921464AWill not affect shippingAvoid hard-to-remove situationsBuilding liftsStructural engineeringControl theory

The invention relates to a car of a temporary freight elevator of a high-rise building. The car comprises a car body, two sliding slots, a supporting and rotating device, a positioning device, a positioning block and an interlayer unit. The two sliding slots are formed in the upper and lower ends of the car body, the supporting and rotating device is arranged between the two sliding slots, the positioning device is arranged in the sliding slot in the lower side of the car body, the positioning block is mounted in the middle of the left end of the car body, and the interlayer unit is arranged at the back end of the car body. The car can solve the problems that when cargoes are stacked, it is often needed to place small parts and relatively light cargoes above, staff needs to select the placing positions of the cargoes by way of observation or weighing, the cargoes in the relatively high positions may collapse, and when the stacked cargoes need to be unloaded from different floors, it isneeded to take out front cargoes when the rear cargoes in the car are taken out, and then the front cargoes are placed again after the rear cargoes are taken out.

Owner:马双斌

A high-voltage power transmission and distribution cable cross-road erection machine tool and wiring method

ActiveCN104158114BWill not affect drivingWill not affect trafficApparatus for overhead lines/cablesEngineeringHigh pressure

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY +1

Moving type material guiding groove

PendingCN108674925APrevent material from splashingWill not affect shippingConveyorsConveyor partsMechanical engineering

The application discloses a moving type material guiding groove, which is arranged on the outlet of a blanking pipe. The outlet of the blanking pipe is over against a conveyor belt, the outlet of theblanking pipe is oppositely provided with moving baffles at both sides of the conveyor belt, the upper ends of the moving baffles are inclined outwards, a material guiding groove is formed between thetwo oppositely arranged moving baffles, an electric push rod is fixedly mounted on the back of each moving baffle, and the electric push rods move along inclined directions of the moving baffles. Themoving type material guiding groove has the advantages that the moving baffles are lifted when materials are supplied, the conveying of the materials is not affected, and the moving baffles are descended when discharging is needed to prevent the materials from splashing.

Owner:张家港华兴能源工程有限公司

Double-column adsorption purification process for natural gas

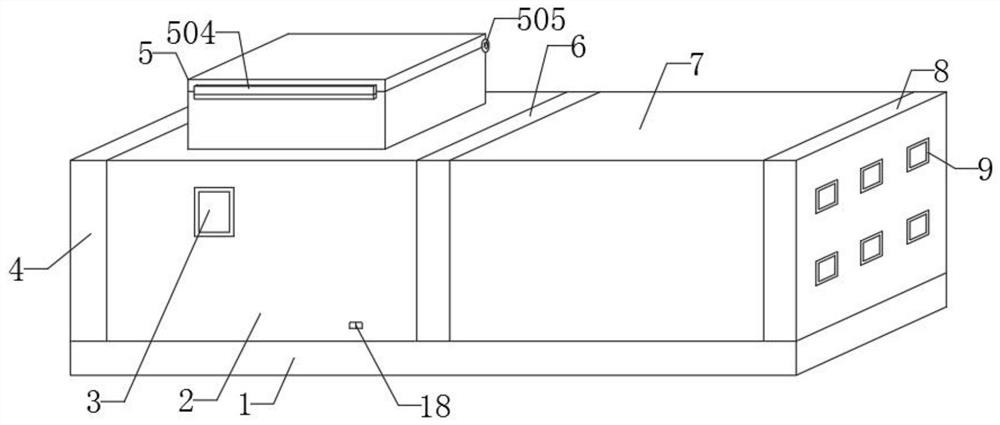

ActiveCN110437905AWill not affect shippingDispersed particle separationGaseous fuelsMolecular sieveProcess engineering

The invention discloses a double-column adsorption purification process for natural gas. A device comprises: an adsorption pipeline, a communication pipeline, a conveying pipeline and an electrical cabinet, wherein two ends of the communication pipeline are respectively communicated with the adsorption pipeline and the conveying pipeline; an electronic one-way valve is mounted on the adsorption pipeline; an adsorption module and a moisture detection probe are arranged in the adsorption pipeline; the moisture detection probe is connected with the electrical cabinet through a data line; and theelectrical cabinet is connected with the electronic one-way valve through a data line. According to the device, through the disconnected connection of the adsorption pipeline and the conveying pipeline, when the molecular sieve in the adsorption pipeline is regenerated, the standby adsorption pipeline can be connected to the conveying pipeline; therefore, the regeneration process of the molecularsieve does not influence natural gas transportation.

Owner:芜湖中燃城市燃气发展有限公司

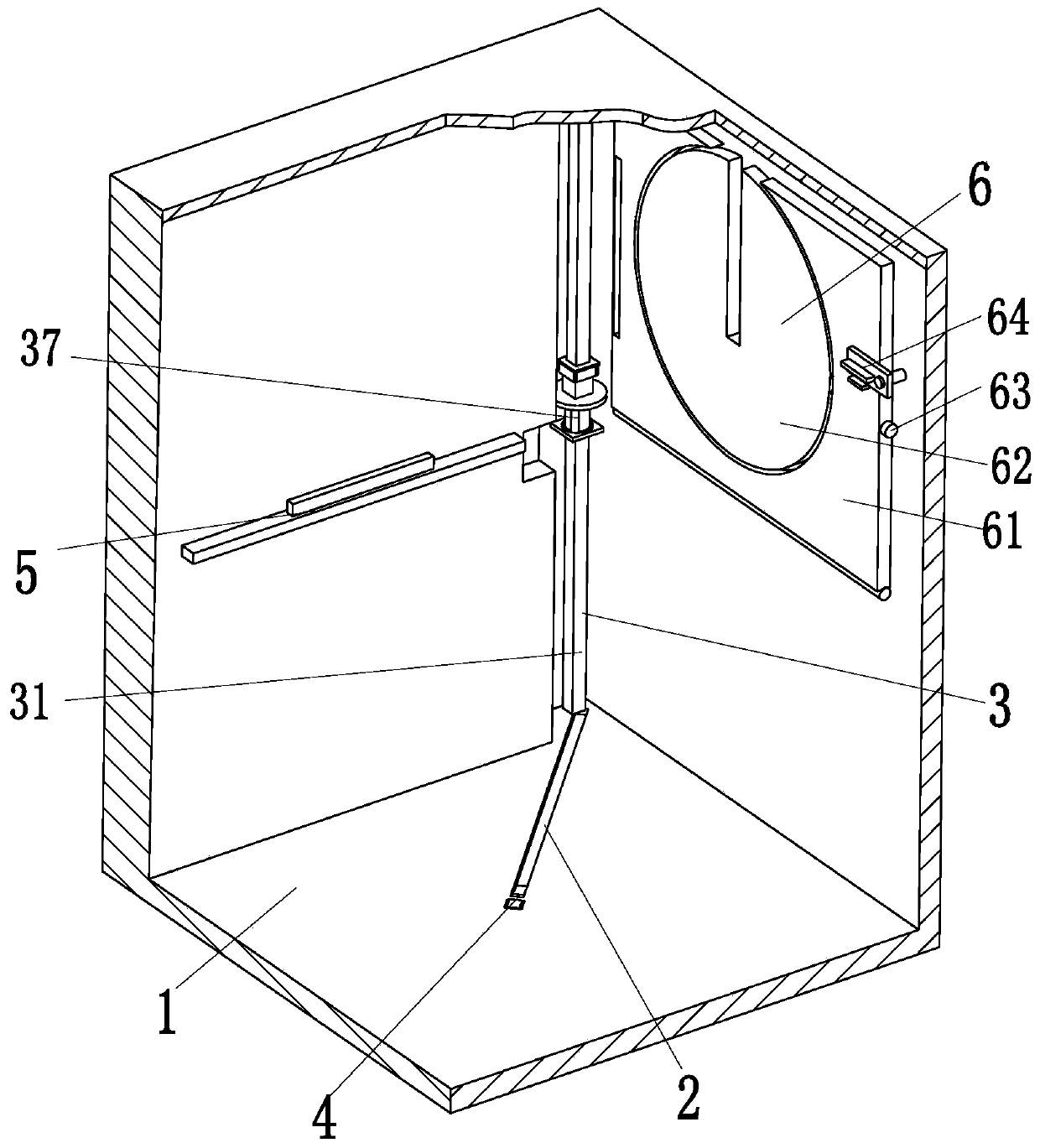

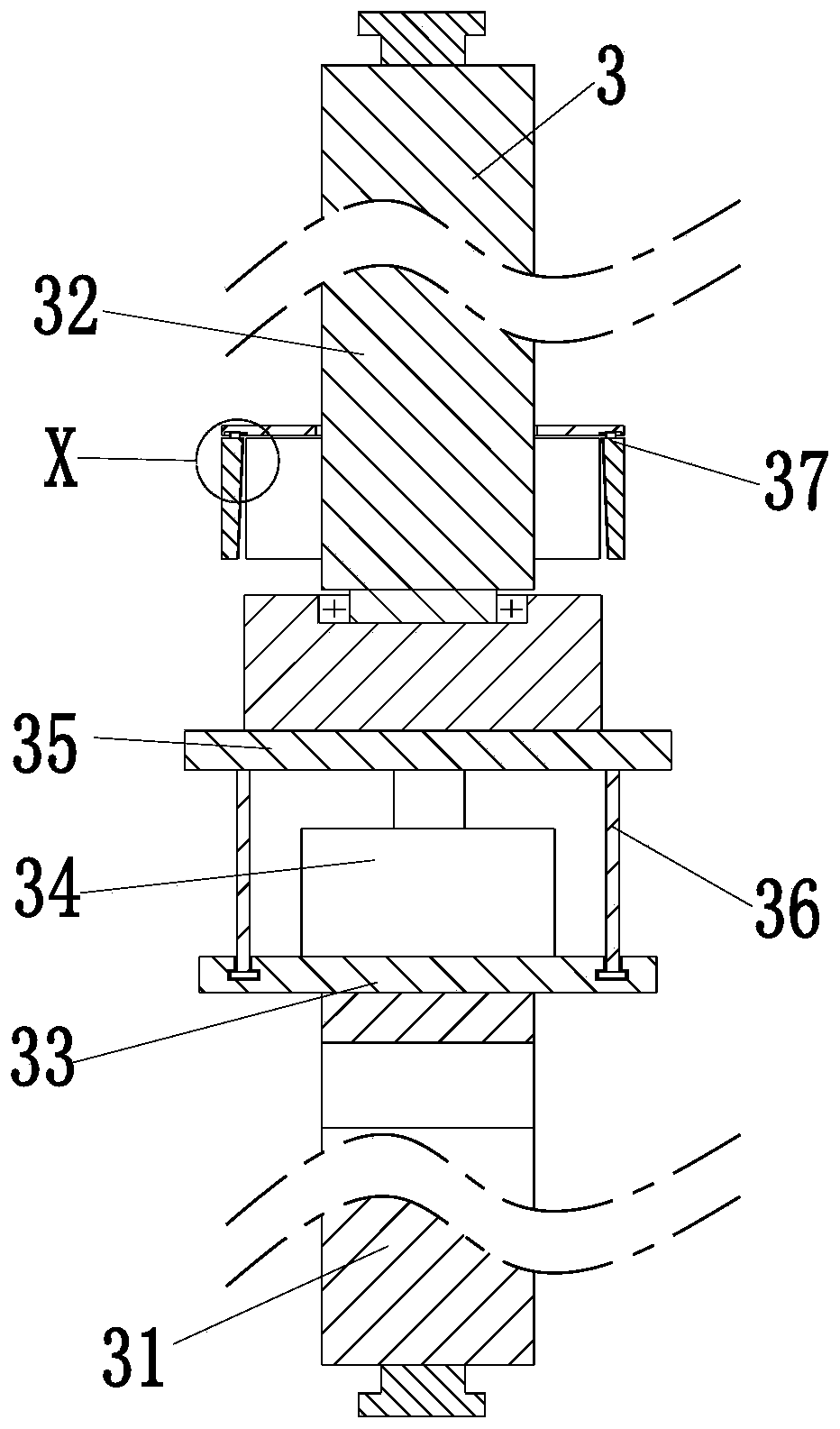

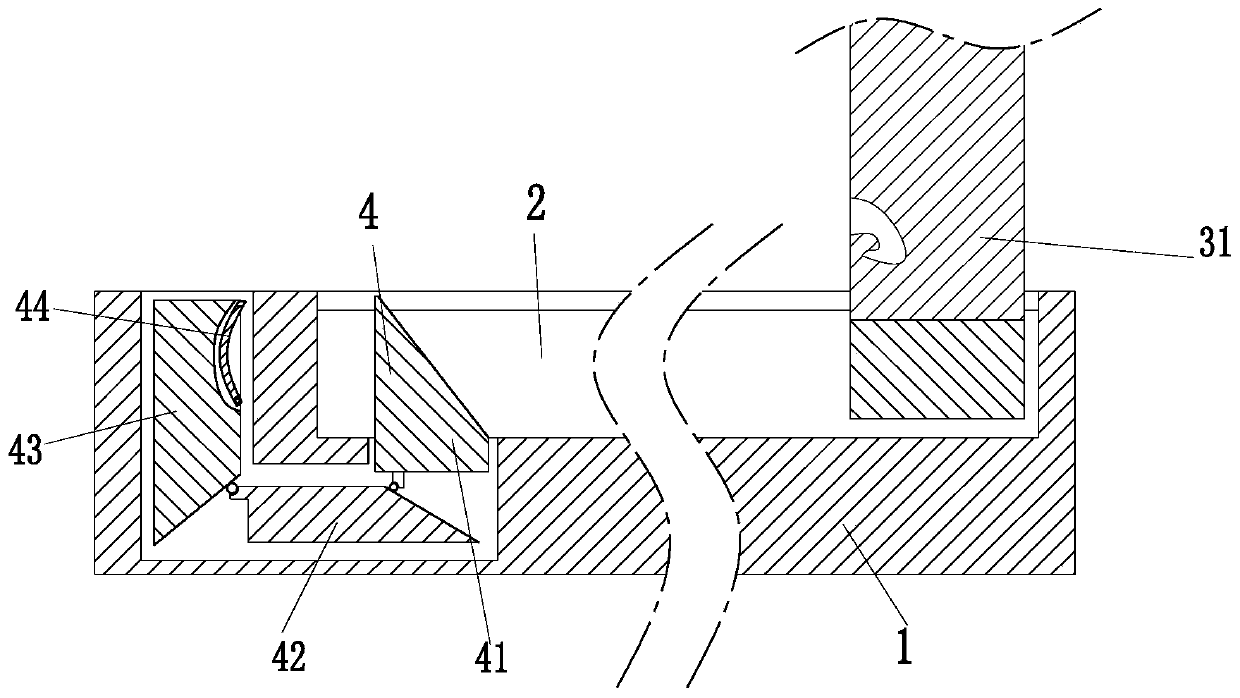

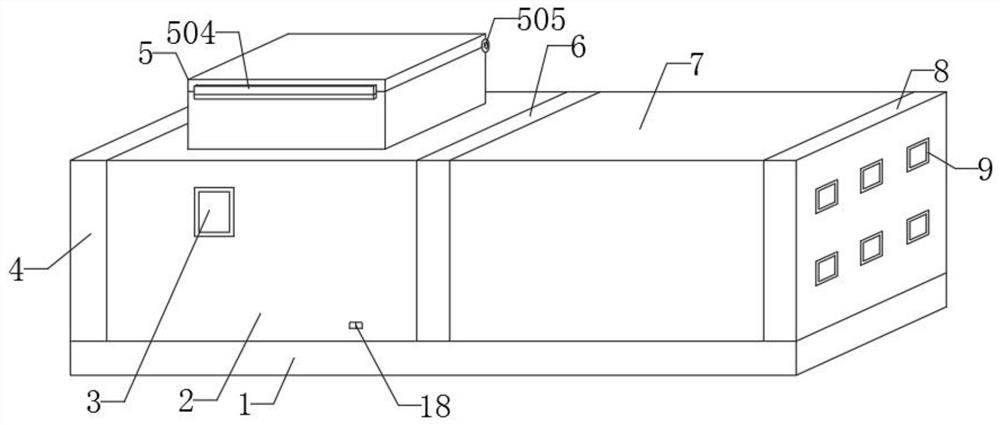

Anti-deformation treatment equipment and treatment method for wooden door frame

ActiveCN112621950BWill not affect shippingReduce moisture contentMagnetic wood treatmentWood treatment detailsMagnetic tension forceEngineering

The invention discloses a wooden door frame anti-deformation treatment device and a treatment method, which belong to the technical field of wooden door frame treatment, and comprise a first box body, one end of the first box body is provided with a first sealing material passing plate, and the other side of the first box body One end is provided with a second box body, a second sealing plate is provided between the first box body and the second box body, the other end of the second box is provided with a third sealing plate, and the first sealing plate 1. Both the second sealing material passing plate and the third sealing material passing plate are provided with material passing devices. The invention can increase the sealing performance of the device when transporting the wooden door frame by setting the feeding device, and at the same time, it will not affect the transportation of the wooden door frame. By setting the electric heating block and the magnetic fluid, the wooden door frame can be baked by the electric heating block Dry, by injecting magnetic fluid, under the action of magnetic force, the performance of the magnetic fluid can be increased, the water content of the wooden door frame can be reduced, and the anti-deformation ability of the wooden door frame can be increased through the magnetic fluid.

Owner:安徽龙鼎家居工贸有限公司

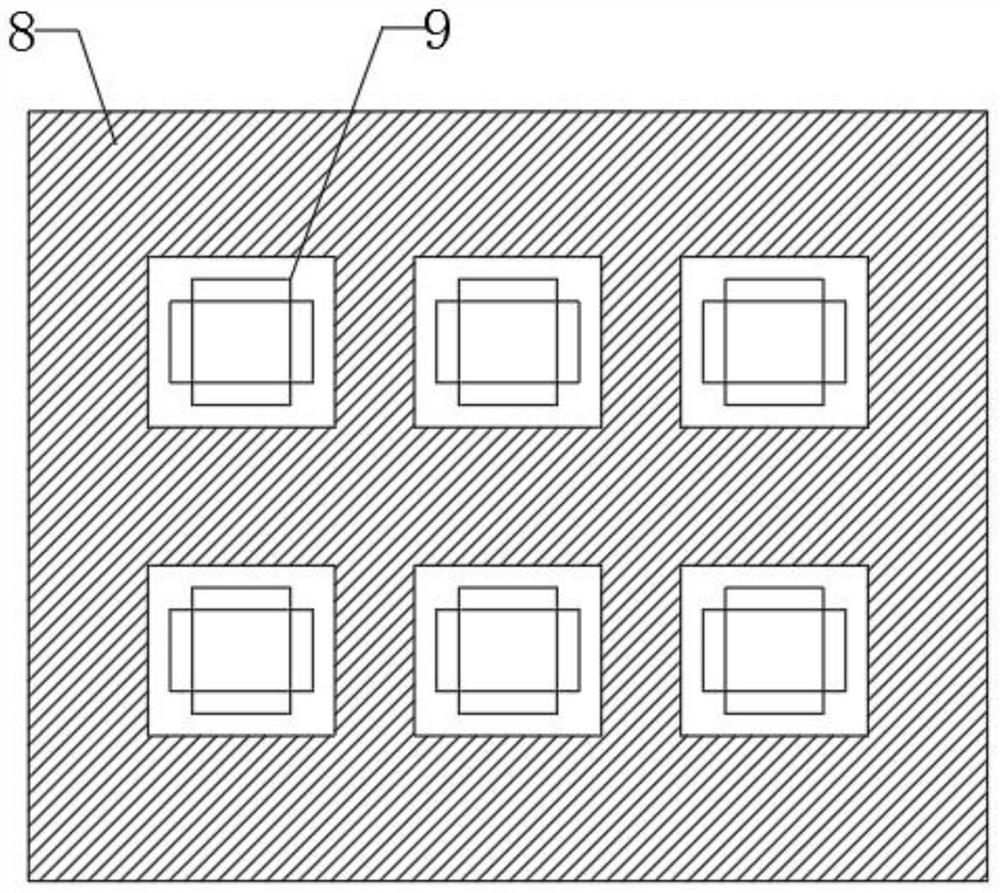

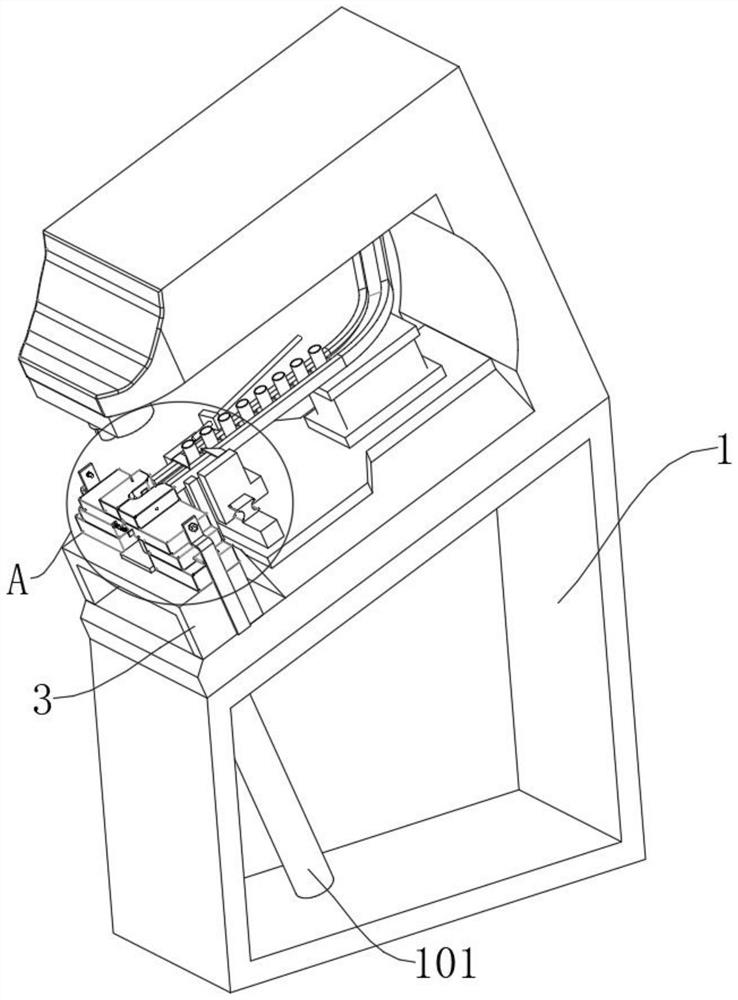

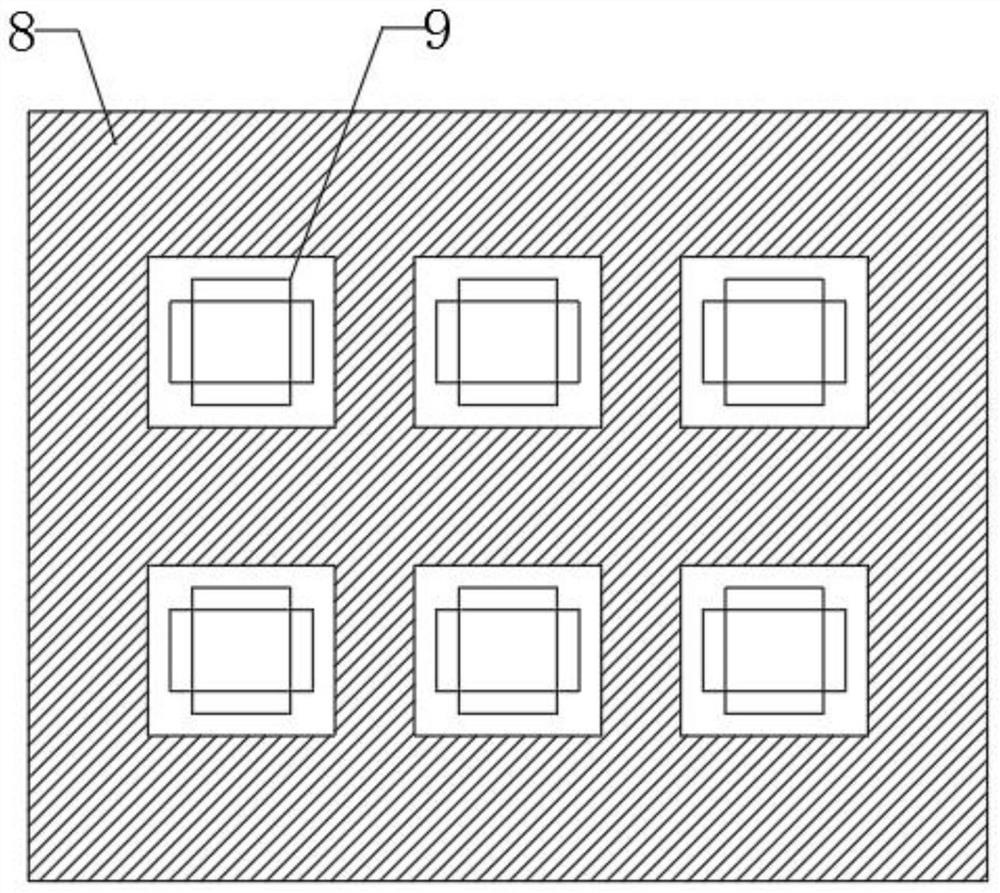

Environment-friendly full-automatic punching and riveting efficient workstation for plates

The invention discloses an environment-friendly full-automatic punching and riveting efficient workstation for plates, and belongs to the technical field of plate processing and production. An environment-friendly full-automatic efficient punching and riveting workstation for plates comprises a punching robot used for punching the plates, a conveying robot used for conveying the plates and a riveting robot used for fixing rivet parts to the plates. According to the conveying robot, through the arranged gas-liquid pressure cylinder, plate conveying of the conveying robot cannot be affected, the automation degree is improved, the fixing pressure on rivet pieces is large, the fixing effect is better, in the conveying process of the rivet pieces, through the arranged gas pipe, the rivet pieces are conveniently blown, and the conveying efficiency is improved. The rivet feeding guide rail is arranged, the situation that the rivet does not move due to too large friction force between the rivet and the rivet feeding guide rail is prevented, fixing of the rivet is facilitated, opening and closing of the air pipe can be automatically controlled when the plate is placed, the air pipe blows the rivet next time conveniently, the moving effect on the rivet is better, the automation degree is high, and more labor is saved.

Owner:常州纳弘智能科技有限公司

A car of a temporary freight elevator in a high-rise building

ActiveCN110921464BWill not affect shippingAvoid hard-to-remove situationsBuilding liftsStructural engineeringControl theory

Owner:马双斌

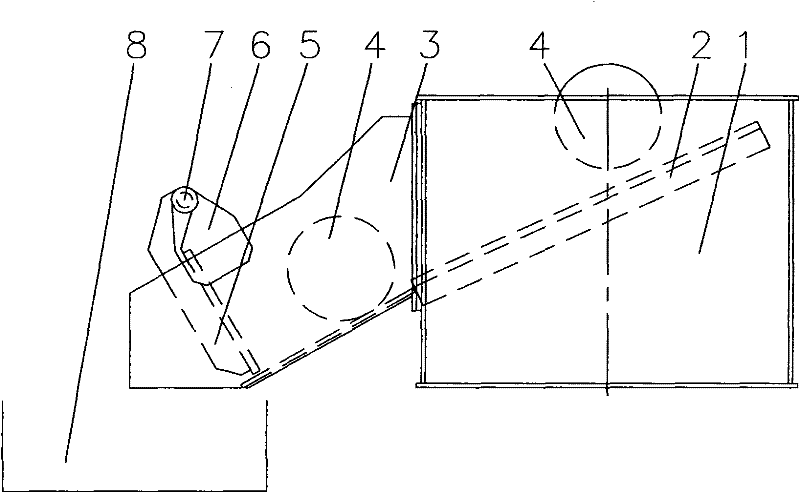

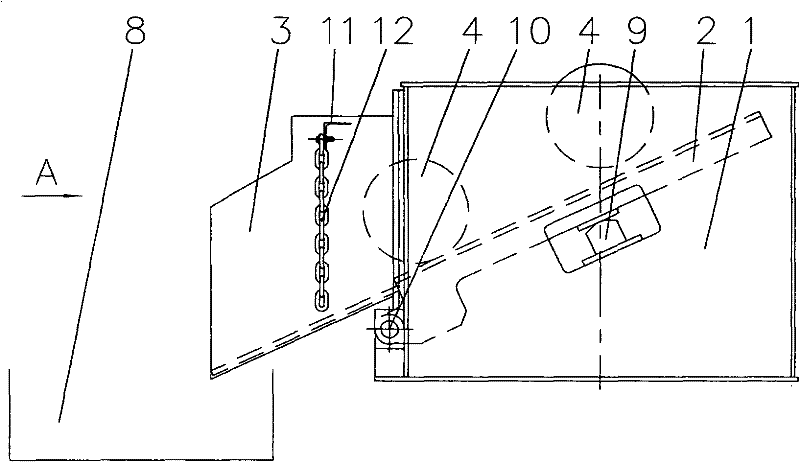

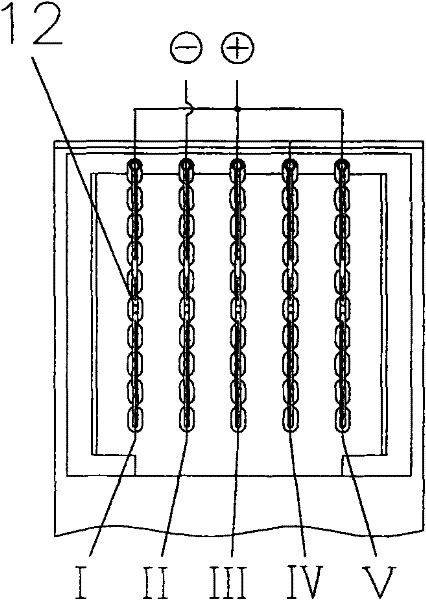

Excessive pressure collecting device for aluminum extruder

The invention discloses an excessive pressure collecting device for an aluminum extruder, and relates to an auxiliary device for the aluminum extruder. The device solves the problems that the excessive pressure collecting device of the prior art has high impact and easily blocks excessive pressure. The device is characterized in that: the lower end of an oblique plate is hinged on a framework through a rotating shaft, and two buffers are arranged in the framework and positioned at the bottom of the oblique plate; and the signaling mechanism is a chain signaling mechanism. The device is used for collecting the excessive pressure of the aluminum extruder, can effectively buffer the impact of the excessive pressure on the oblique plate, does not affect the delivery of the excessive pressure through the chain signaling mechanism, and is more accurate for signaling.

Owner:TAIYUAN HEAVY IND

Wooden door framework anti-deformation treatment equipment and treatment method

ActiveCN112621950AWill not affect shippingReduce moisture contentMagnetic wood treatmentWood treatment detailsMagnetic tension forceStructural engineering

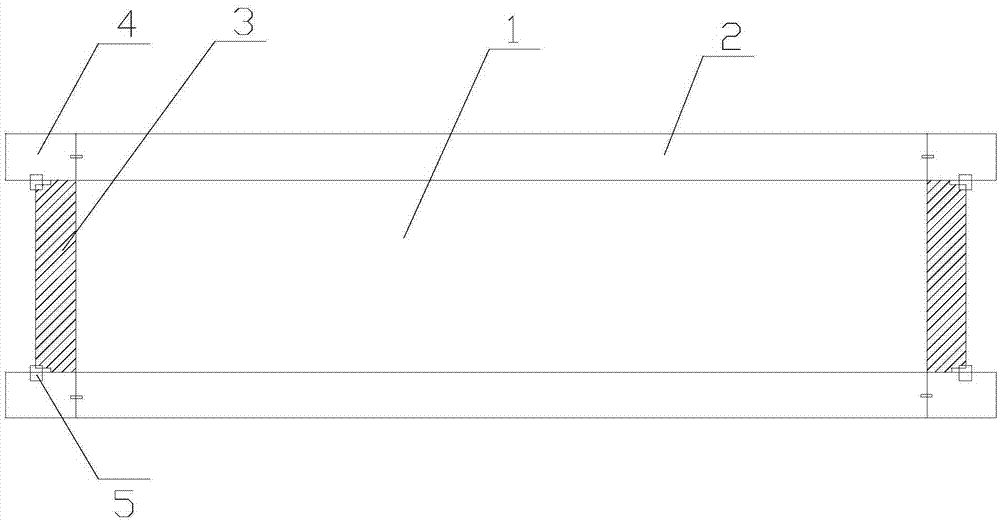

The invention discloses wooden door framework anti-deformation treatment equipment and a treatment method, and belongs to the technical field of wooden door framework treatment. The wooden door framework anti-deformation treatment equipment comprises a first box body, a first sealing material passing plate is arranged at one end of the first box body, a second box body is arranged at the other end of the first box body, and a second sealing material passing plate is arranged between the first box body and the second box body; and a third sealing material passing plate is arranged at the other end of the second box body, and material passing devices are arranged on the first sealing material passing plate, the second sealing material passing plate and the third sealing material passing plate. By arranging the material passing devices, the sealing performance of the device can be improved when wooden door framework is conveyed, meanwhile, transportation of the wooden door framework cannot be affected, by arranging an electric heating block and a magnetic fluid, the wooden door framework can be dried through the electric heating block, and by injecting the magnetic fluid, the performance of the magnetic fluid can be improved under the action of magnetic force; and the water content of the wooden door framework is reduced, and meanwhile the anti-deformation capacity of the wooden door framework is improved through the magnetic fluid.

Owner:安徽龙鼎家居工贸有限公司

A kind of processing method of sealing tape

ActiveCN105017981BWill not affect normal useWill not affect shippingFilm/foil adhesivesSanderSand-paper

The invention provides a kind of adhesive tape that has no right-angled corners at the upper and lower ends, will not cut the user, and has no stickiness on the end surface of the tape roll, which is more convenient to take and use, and has a better user experience. The processing method of box tape. It includes the following main steps: adding acrylic acid, the raw material of the tape, to the emulsification tank for emulsification; then putting it into the reaction pot for heating to make glue; then adding it to the coating machine; installing the plastic film roll on the coating machine, through The machine applies glue to the plastic film to make a master roll; the master roll is cut through the pipe cutting machine; the tape after the successful pipe cutting is slit by a slitting machine to obtain a roll of tape; the tape after slitting Use a grinder to grind the upper and lower inner corners of the paper core of the tape; grind the right-angled corners of the inner corners into a bevel or arc surface; evenly stick the paper core powder left over from the grinding of the right-angled corners to the tape roll of the tape Finished sealing tape is made on the end face.

Owner:广东宝兰山新材料科技有限公司

A connection device for detecting transformer winding deformation

ActiveCN108511166BReal-time detection of winding deformationFirmly connectedTransformers/inductances coils/windings/connectionsUsing electrical meansStructural engineeringElectric cables

The invention relates to a connecting apparatus used for transformer winding deformation detection. The connecting apparatus comprises a ceramic sleeve pressing ring plate with an open hole and a fixed hole, a conveying cover plate with an open hole and a welding threaded rod, an insulating ceramic sleeve, a detection copper bar and a detection lead cable; the insulating ceramic sleeve passes through the open hole in the conveying cover plate; a welding bolt on the conveying cover plate passes through the fixed hole in the ceramic sleeve pressing ring plate to be fastened by a nut; the detection copper bar passes through the open hole and the insulating ceramic sleeve on the ceramic sleeve pressing ring plate and extends for one parts from the lower end of the insulating ceramic sleeve andthe upper end of the ceramic sleeve pressing ring plate respectively; and one end of the detection lead cable is connected with a copper head or a wiring copper bar led from each phase of a transformer while the other end is connected with the lower end part of the detection copper bar. By virtue of the connecting apparatus, the transformer and detection equipment can be connected conveniently, and the deformation condition of the transformer winding in the conveying process can be detected in real time; and the connecting apparatus is simple in structure, small in size, convenient to detach,simple in operation, reusable, and economical and practical.

Owner:SHANDONG POWER EQUIP

Combined one-piece gluing and trimming device and control method

ActiveCN105835141BPrevent deviationHigh degree of automationProfiling/shaping machinesAdhesive application devicesEngineeringAutomation

The invention provides a combined integrated type glue coating and edge cutting device and a control method and relates to the field of plate processing equipment. The combined integrated type glue coating and edge cutting device comprises a glue coating device and an edge cutting device and further comprises two segments of feeding mechanisms, namely, a first feeding mechanism and a second feeding mechanism; the first feeding mechanism is located on the left side of a glue coating mechanism; the second feeding mechanism is located between the glue coating device and the edge cutting device; each feeding mechanism comprises a material frame, a sliding rail and a sliding groove; each sliding groove is installed at the bottom of the corresponding material frame; the sliding rails are laid on the ground and connected with the sliding grooves in a matched manner; each material frame is provided with a plurality of supporting rollers; air cylinder push rods are further arranged; the air cylinder push rod at the front end is located on the left side of the first feeding mechanism; and a material frame supporting roller on the second feeding mechanism is further connected with a transmission device. The combined integrated type glue coating and edge cutting device is reasonable in structural design, the glue coating device and an edge cutting mechanism are connected through the corresponding feeding mechanism, the automation degree of the device is improved, and the production efficiency is improved.

Owner:ANHUI DONGPING WOOD GRP

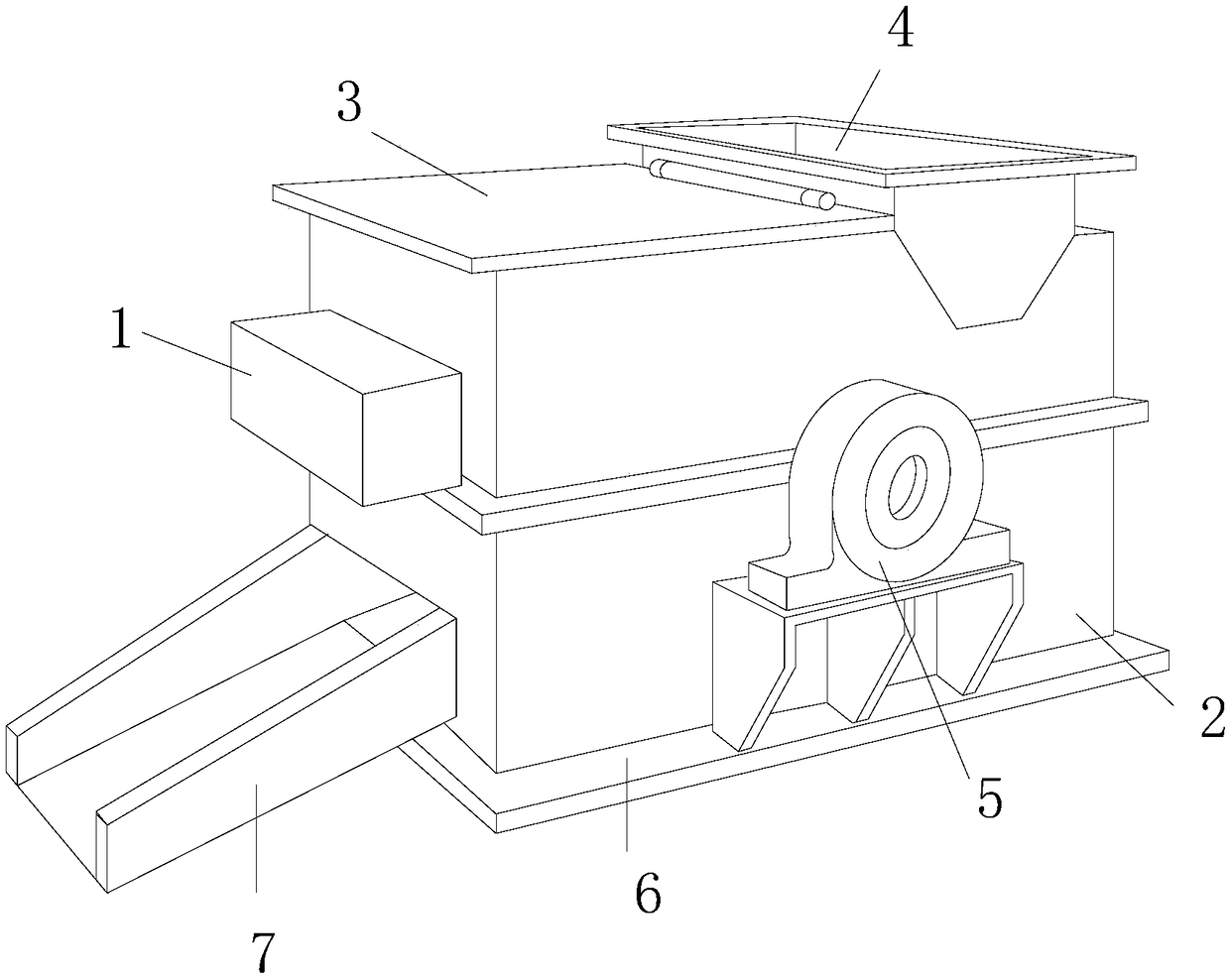

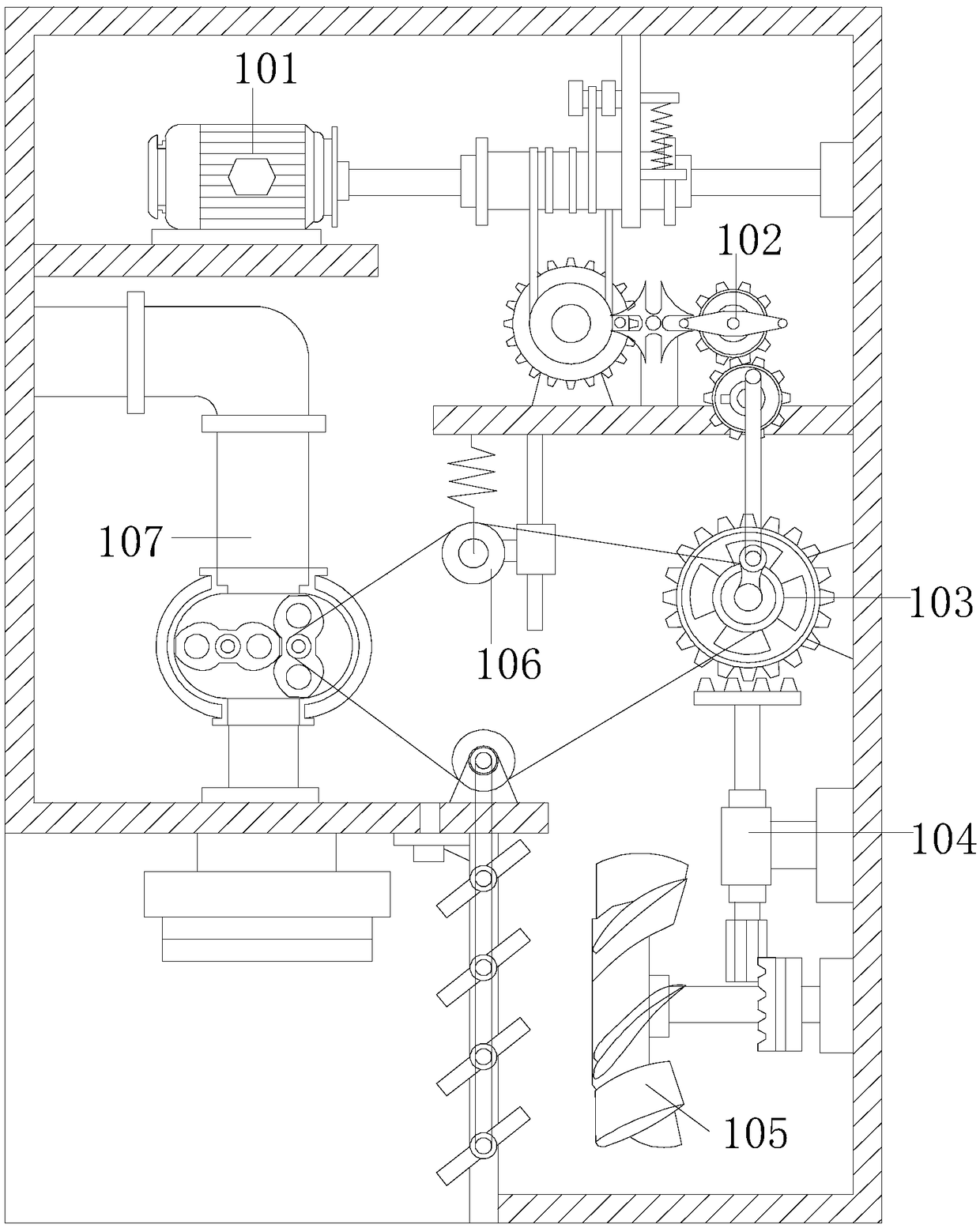

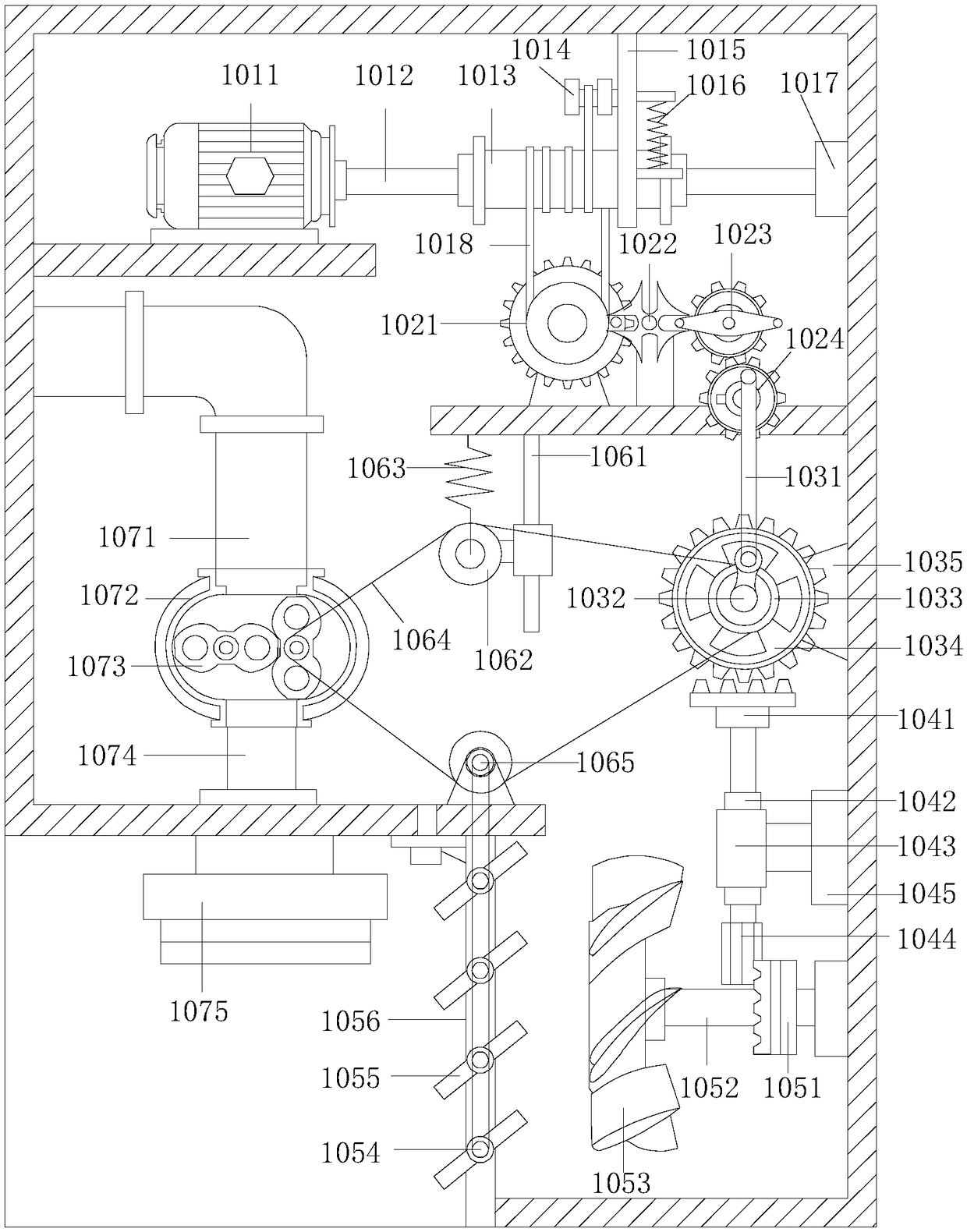

Rotator workpiece machining device

InactiveCN108214020AFast processingWill not affect shippingMeasurement/indication equipmentsOther manufacturing equipments/toolsHydraulic cylinderGear wheel

The invention discloses a rotator workpiece machining device which comprises a loading and unloading platform, a conveying mechanism, a machining mechanism, a spraying mechanism, a baking mechanism and a control box. The upper surface of the loading and unloading platform is divided into a loading zone and an unloading zone by a partition plate which is fixedly arranged, the conveying mechanism comprises a mounting frame, transmission gears, a toothed chain and a conveying motor, rotary shafts are mounted at two ends of the mounting frame via bearings, the transmission gears are mounted at theupper ends and the lower ends of the rotary shafts, the toothed chain is mounted on the outer sides of the transmission gears, a first fixture and a second fixture are mounted on the inner side of the toothed chain, an output end of the conveying motor is connected with the upper end of the rotary shaft at an end of the mounting frame, the machining mechanism comprises a support frame, a first hydraulic cylinder, a machining motor and a cutter, and the support frame is fixedly arranged at the end, which is close to the loading zone, of the mounting frame. The rotator workpiece machining device has the advantages that integral machining procedures can be completely carried out on workpieces which are clamped at one step, accordingly, the production efficiency can be improved, and the rotator workpiece machining device is high in automation degree.

Owner:张洁如

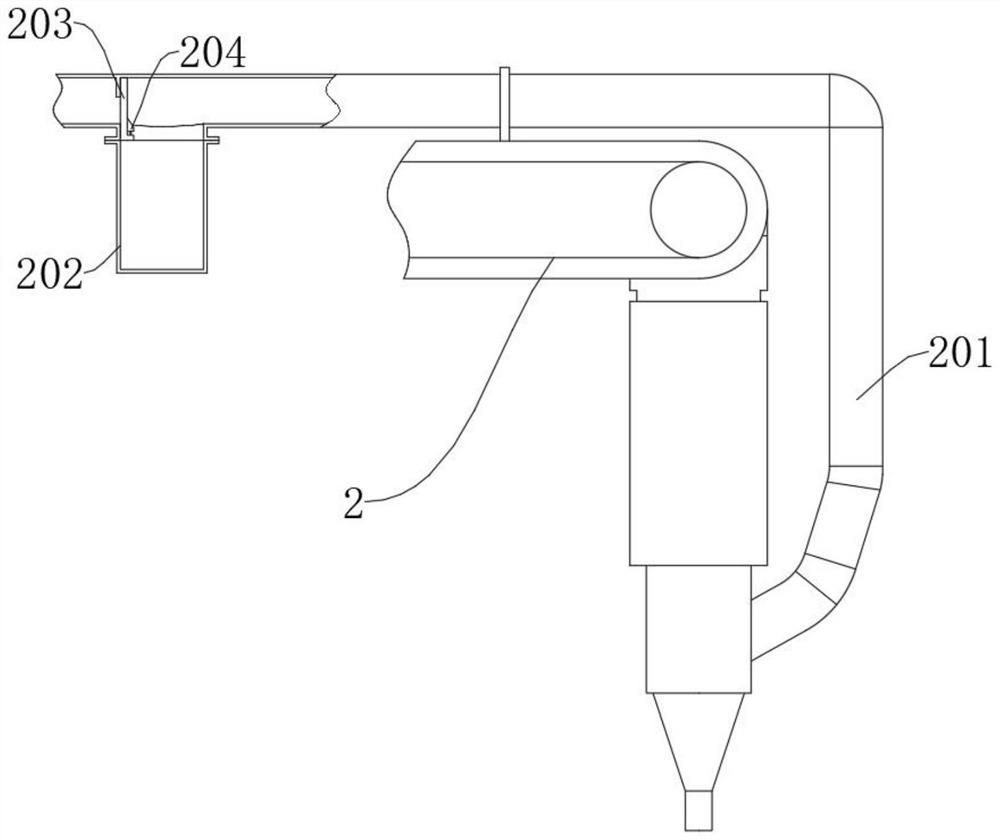

A device and method for engraving on egg shells

ActiveCN104209868BWill not affect shippingHigh speedDecorative surface effectsAbrasive blasting machinesEggshellSolenoid valve

A device for carving an eggshell comprises a sand blasting seal box. Two ends of the sand blasting seal box are provided with an access respectively. A conveyer belt is arranged within the sand blasting seal box. Two ends of the conveyer belt respectively pass through the accesses on the sand blasting seal box. Egg holders are uniformly arranged on the conveyer belt. A locating block is arranged beside each egg holder. The lower part of the conveyer belt is provided with a motor relay. The upper end face of the sand blasting seal box is welded with a supporting beam. A spray gun is mounted on the supporting beam. The upper end of the spray gun is connected to an air compressor, and the lower end passes through a viewing window to the interior of the sand blasting seal box to connect the spray gun. An iron hollow pattern is formed below spray nozzle of the spray gun close to the eggshell. The spray gun is located above the conveyer belt and is connected to a sand suction port via a sand suction pipe. A proximity switch is mounted at the nozzle of the spray gun. The spray gun is connected with a time solenoid valve. The time solenoid valve, the proximity switch and the motor relay are respectively connected to a PLC programming controller. The device of the invention has fast speed and low cost and is suitable for batch production. The success rate can be adjusted to be above 99 %.

Owner:CHUZHOU XINLONG SANJIANG MACHINERY EQUIP

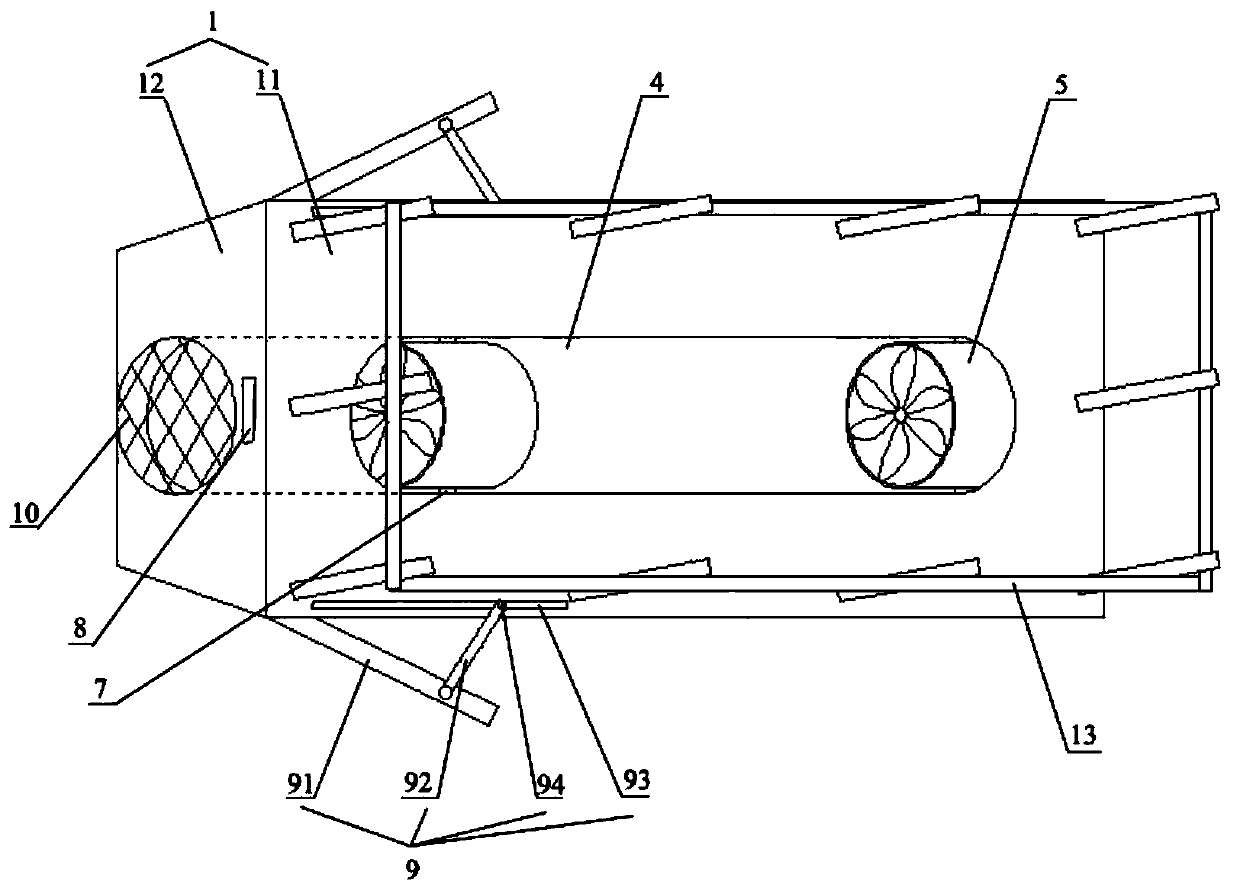

Boat loaded horizontal type hydraulic power generation equipment

ActiveCN110332071AGuaranteed power generation efficiencyWill not affect shippingHydro energy generationMachines/enginesElectricityWater flow

The invention relates to the field of hydraulic power generation, in particular to boat loaded horizontal type hydraulic power generation equipment which comprises a bottomless pontoon, a cabin body,a telescopic device, a water flow pipeline, a plurality of horizontal type hydroelectric generating sets and a lifting device, wherein the bottomless pontoon comprises a coaming and a top plate sealing the upper end of the coaming; a water inlet and a water outlet matched with the water flow pipeline are formed in the front and back parts of the coaming; the horizontal type hydroelectric generating sets are arranged in the water flow pipeline and can adopt the water flow in the water flow pipeline to generate electricity; the cabin body is arranged on the top plate; the lifting device is connected with the cabin body; the telescopic device comprises a plurality of fixed sleeves and a plurality of telescopic pistons; the fixed sleeves are symmetrically arranged on the two sides of the waterflow pipeline and are fixed on the top plate; communicating holes are formed in the bottoms of the fixed sleeves; and the telescopic pistons are arranged in the fixed sleeves and are connected with the lifting device. The boat loaded horizontal type hydraulic power generation equipment does not need to dam a river or relocate residents, does not occupy the land, and does not need to build a hydroelectric generation facility. A plurality of the boat loaded horizontal type hydraulic power generation equipment are connected in series to generate more clean energy.

Owner:何志荣

Stone crushing device for mining machinery

The invention discloses a stone crushing device for mining machinery. The device structurally comprises a dust inhibiting mechanism, a stone crushing case, a case cover, a feeding hopper, a power coupler, a base and a discharging hopper, wherein a housing of the dust inhibiting mechanism is fixed to the top part of an annular edge of the middle part of the stone crushing case through a bolt; the top part of the case is movably connected to the case cover and is in interference fit with the bottom part of the feeding hopper; the power coupler is vertically fixedly welded to the front end of thestone crushing case; the bottom part of the stone crushing case clings to the top part of the base; and the discharging hopper is mounted on the top part of the stone crushing case and communicates with the inner part of the feeding hopper at the left side. According to the stone crushing device for the mining machinery, the improved stone crushing device is capable of removing dust, and the operating environment of workers in work can be improved; and the service life is prolonged while the dust is decreased.

Owner:湖州振锋贸易有限公司

A paper bag packaging production line equipment

ActiveCN106564214BAvoid overlapping entryPrevent deviationBag making operationsPaper-makingProduction linePulp and paper industry

Owner:烟台中科恩吉科创新产业园管理有限公司

Hot stamping mold capable of efficiently heating product

InactiveCN107983848AIncrease profitImprove stamping effectShaping toolsHot stampingMaterials science

The invention discloses a hot stamping mold capable of efficiently heating a product. The mold comprises an upper mold holder, a lower mold holder, a stamping assembly connected to the upper mold holder, a stamping plate which is arranged on the lower mold holder and is arranged below the stamping assembly, a first heating plate which is arranged on the lower mold holder and located beside the stamping plate, a telescopic part arranged at the upper end of the heating plate and a second heating plate connected to the lower portion of the telescopic part. After the product is heated through theheating plates on the upper and the lower, heating can be rapidly and efficiently finished, the product is conveyed to the stamping plate immediately to be stamped through a limiting roller assembly,the energy utilization rate can be improved, and the stamping effect is improved.

Owner:KUNSHAN YIBANGTAI AUTO PART MFG CO LTD

Belt-line-body cleaning mechanism

The invention discloses a belt-line-body cleaning mechanism. The belt-line-body cleaning mechanism comprises a belt, supporting plates, cleaning brushes and fixing plates. The cleaning brushes are fixed on the supporting plates at the two ends of a belt line body through the fixing plates and slightly pressed on the surface of the belt, and the length of the cleaning brush is coincident with the width of the belt. The belt-line-body cleaning mechanism is simple in structure and low in cost, cleaning can be synchronously cleaned while the belt line body works, and time and labor are saved.

Owner:JIANGSU TENGEN ELECTRIC

Connecting apparatus used for transformer winding deformation detection

ActiveCN108511166AReal-time detection of winding deformationFirmly connectedTransformers/inductances coils/windings/connectionsUsing electrical meansEngineeringCopper

The invention relates to a connecting apparatus used for transformer winding deformation detection. The connecting apparatus comprises a ceramic sleeve pressing ring plate with an open hole and a fixed hole, a conveying cover plate with an open hole and a welding threaded rod, an insulating ceramic sleeve, a detection copper bar and a detection lead cable; the insulating ceramic sleeve passes through the open hole in the conveying cover plate; a welding bolt on the conveying cover plate passes through the fixed hole in the ceramic sleeve pressing ring plate to be fastened by a nut; the detection copper bar passes through the open hole and the insulating ceramic sleeve on the ceramic sleeve pressing ring plate and extends for one parts from the lower end of the insulating ceramic sleeve andthe upper end of the ceramic sleeve pressing ring plate respectively; and one end of the detection lead cable is connected with a copper head or a wiring copper bar led from each phase of a transformer while the other end is connected with the lower end part of the detection copper bar. By virtue of the connecting apparatus, the transformer and detection equipment can be connected conveniently, and the deformation condition of the transformer winding in the conveying process can be detected in real time; and the connecting apparatus is simple in structure, small in size, convenient to detach,simple in operation, reusable, and economical and practical.

Owner:SHANDONG POWER EQUIP

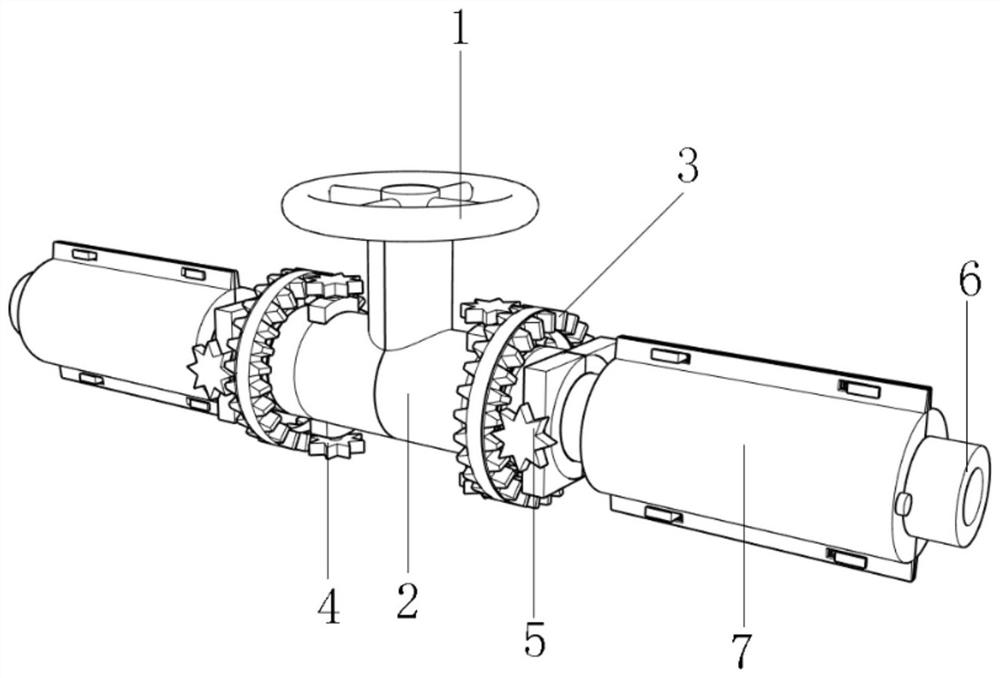

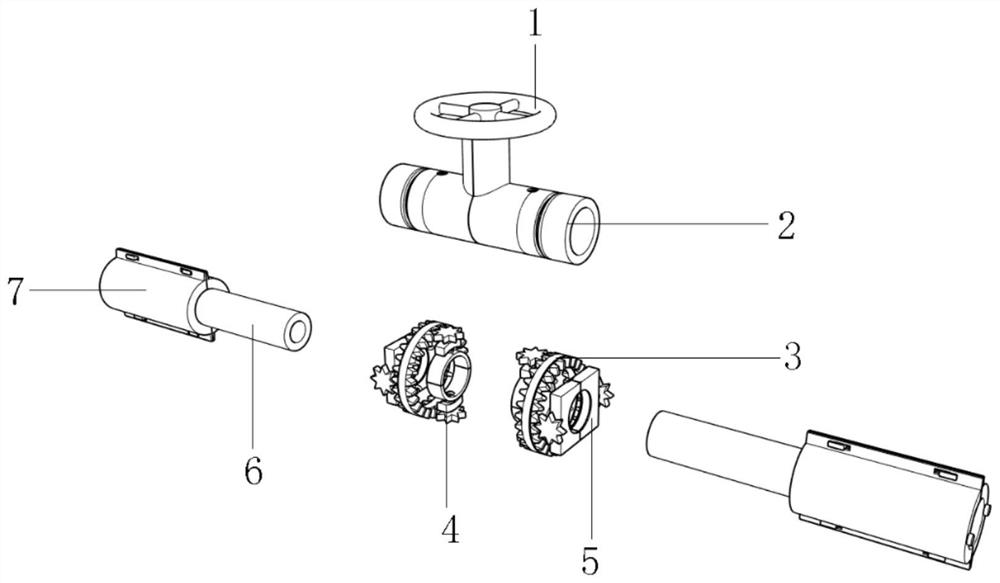

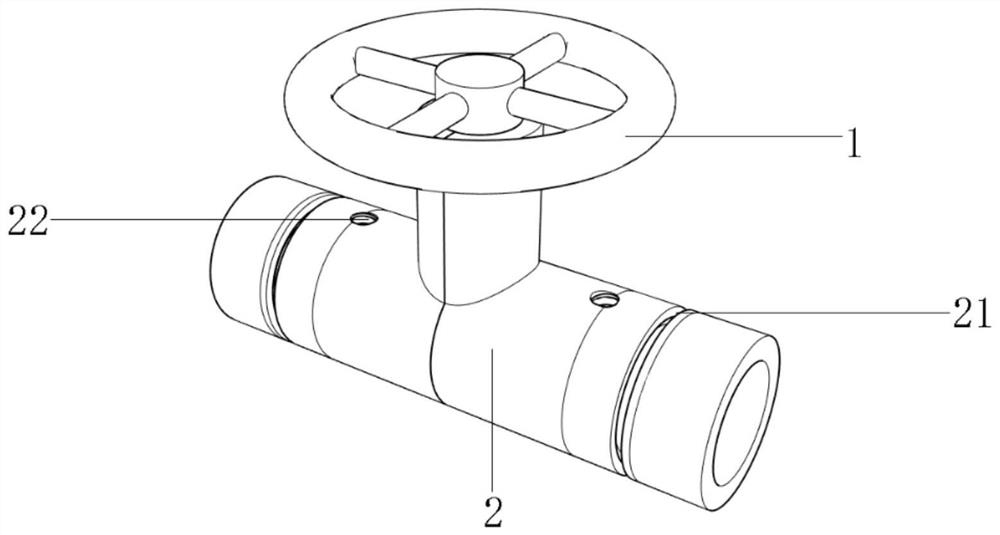

Single-pipe combination valve group wellhead flow path device easy to install

InactiveCN114109305AEasy to installEasy to operateInsulationWell/borehole valve arrangementsStructural engineeringIndustrial engineering

The invention discloses an easy-to-install single-pipe combination valve group wellhead flow device, and particularly relates to the technical field of oil well valves, the easy-to-install single-pipe combination valve group wellhead flow device comprises a knob, a two-way connecting pipe is movably installed at the bottom end of the knob, rotating assemblies are movably installed at the left end and the right end of the two-way connecting pipe, and dismounting assemblies are movably installed on the left sides of the rotating assemblies; a sealing assembly is movably installed on the right side of the rotating assembly, and conveying pipelines are detachably installed at the two ends of the two-way connecting pipe. By arranging the dismounting and mounting assembly, the pipeline and the valve can be mounted more quickly and conveniently, excessive time does not need to be spent, the structure is simple, operation of workers is facilitated, the working time of the workers is saved, meanwhile, the effect of improving the working efficiency of the workers is achieved, and therefore the effect of greatly improving the practicability of the whole device is achieved; and by arranging the sealing assembly, sealing work between the pipeline and the valve can be rapidly completed, the working steps of workers are reduced, and the effect of improving the practicability of the whole device is achieved.

Owner:徐宏洋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com