Environment-friendly full-automatic punching and riveting efficient workstation for plates

A fully automatic, workstation technology, which is applied in the field of plate processing and production, can solve the problems of insufficient rivet impact pressure, poor rivet fixing effect, and low degree of automation, and achieve the effect of high fixing pressure, good fixing effect, and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

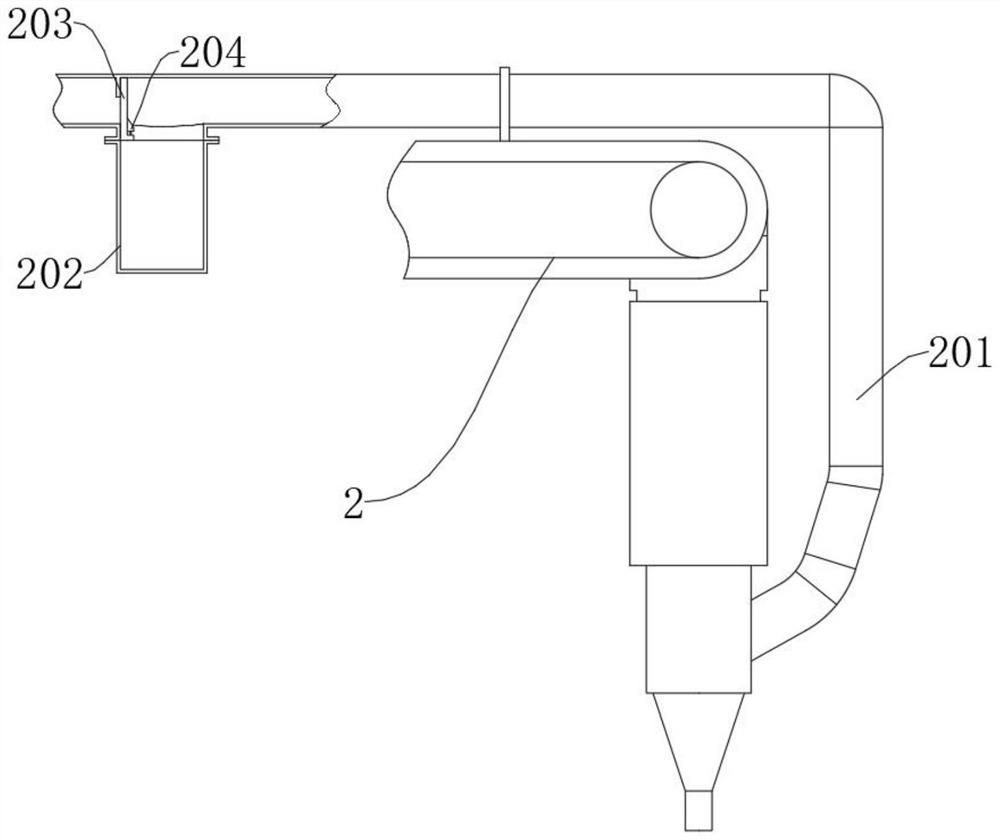

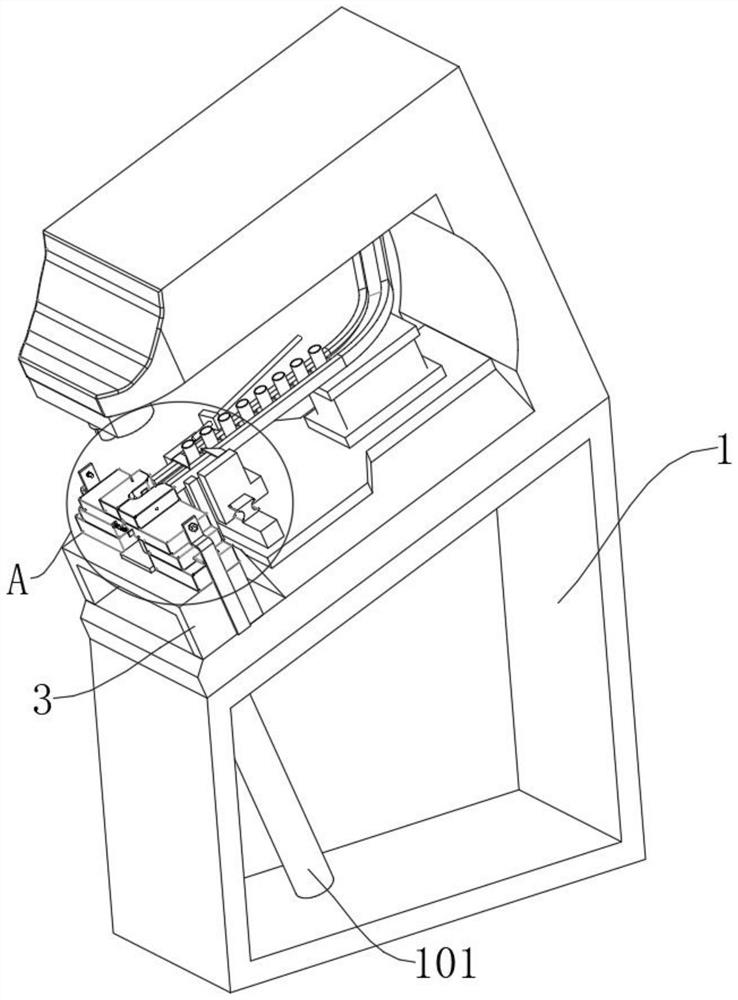

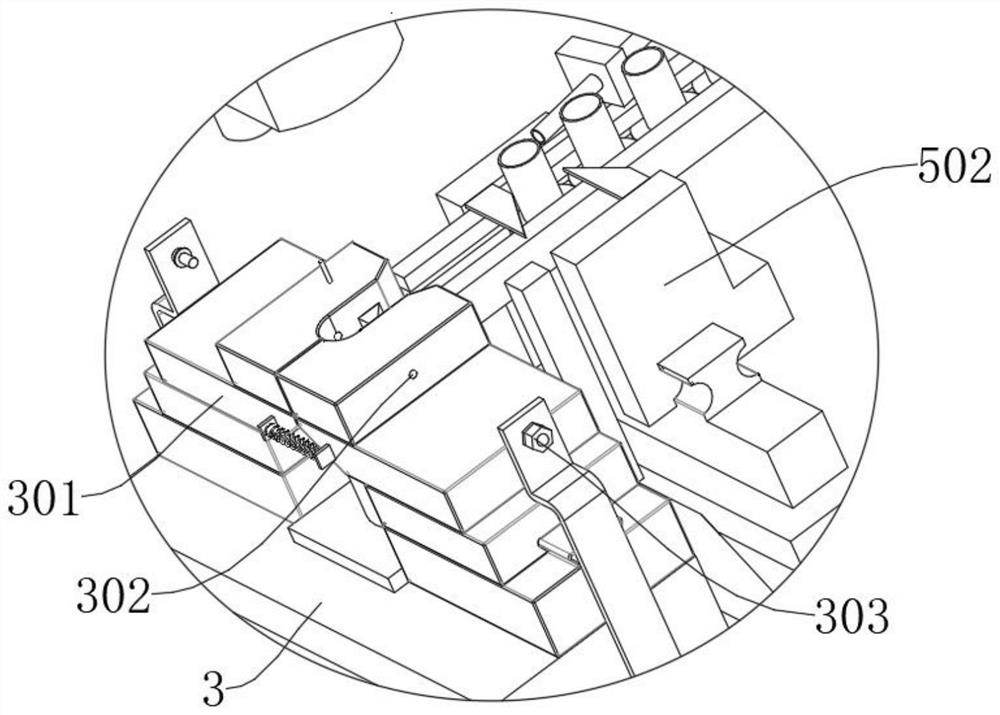

[0035] refer to Figure 1-11, an environmentally friendly automatic punching rivet high-efficiency workstation, including a punching robot 2 for punching a plate. It should be noted that when the punching robot 2 punches a plate, the temperature of the plate will be affected by friction. The trachea 201 is set up to suck the punching end of the punching robot 2 to extract the waste debris and heat generated during the punching process. Gas extraction and storage, in this device, the extracted gas is exhausted to the rivet piece 501, the flow of the gas can blow the rivet piece 501 to slide on the inclined rivet feeding rail 5, and the heat in the gas can blow on the rivet piece 501 , the heating temperature of the rivet piece 501 increases, the molecules are active, and the hardness will decrease, which is convenient for the gas-liquid booster cylinder 101 to fix the rivet piece 501 on the plate. ℃, it can prevent the plate from reaching the ignition point, and when the plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com