Belt-line-body cleaning mechanism

A cleaning mechanism and belt technology, which is applied to cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of not being able to clean at the same time, labor-intensive efficiency, troublesome use, etc., to achieve easy reuse, thorough cleaning, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

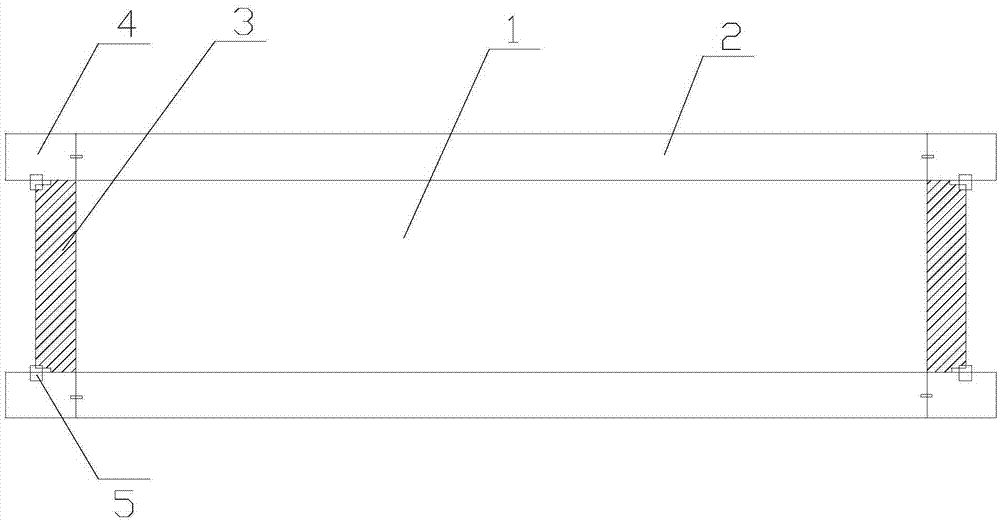

[0015] Example 1 : A belt line body cleaning mechanism, including a belt 1, a support plate 2, a cleaning brush 3 made of non-woven fabric material and a fixed plate 4, such as figure 1 As shown, the cleaning brush 3 is fixed on the support plates 2 at both ends of the belt line body through the fixing plate 4, and the cleaning brush 3 is pressed tightly on the surface of the belt 1, and the cleaning brush 3 and the The fixing plate 4 is connected by a buckle 5, and the length of the cleaning brush 3 is consistent with the width of the belt 1. During the operation of the belt line body, the cleaning part of the cleaning brush is pressed against the surface of the belt line body. Automatic cleaning of debris on the surface of the belt line body, a further optimized solution, a glove box is also fixed at the bottom of the cleaning brush, and the debris, dust, etc. cleaned by the cleaning brush fall into the glove box, making cleaning more convenient.

[0016] In addition, as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com