Stone crushing device for mining machinery

A mechanical and stone crushing technology, which is applied in the field of stone crushing devices, can solve the problems of manpower consumption, material resources, and capital occupation, and achieve the effects of small water flow and improved operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

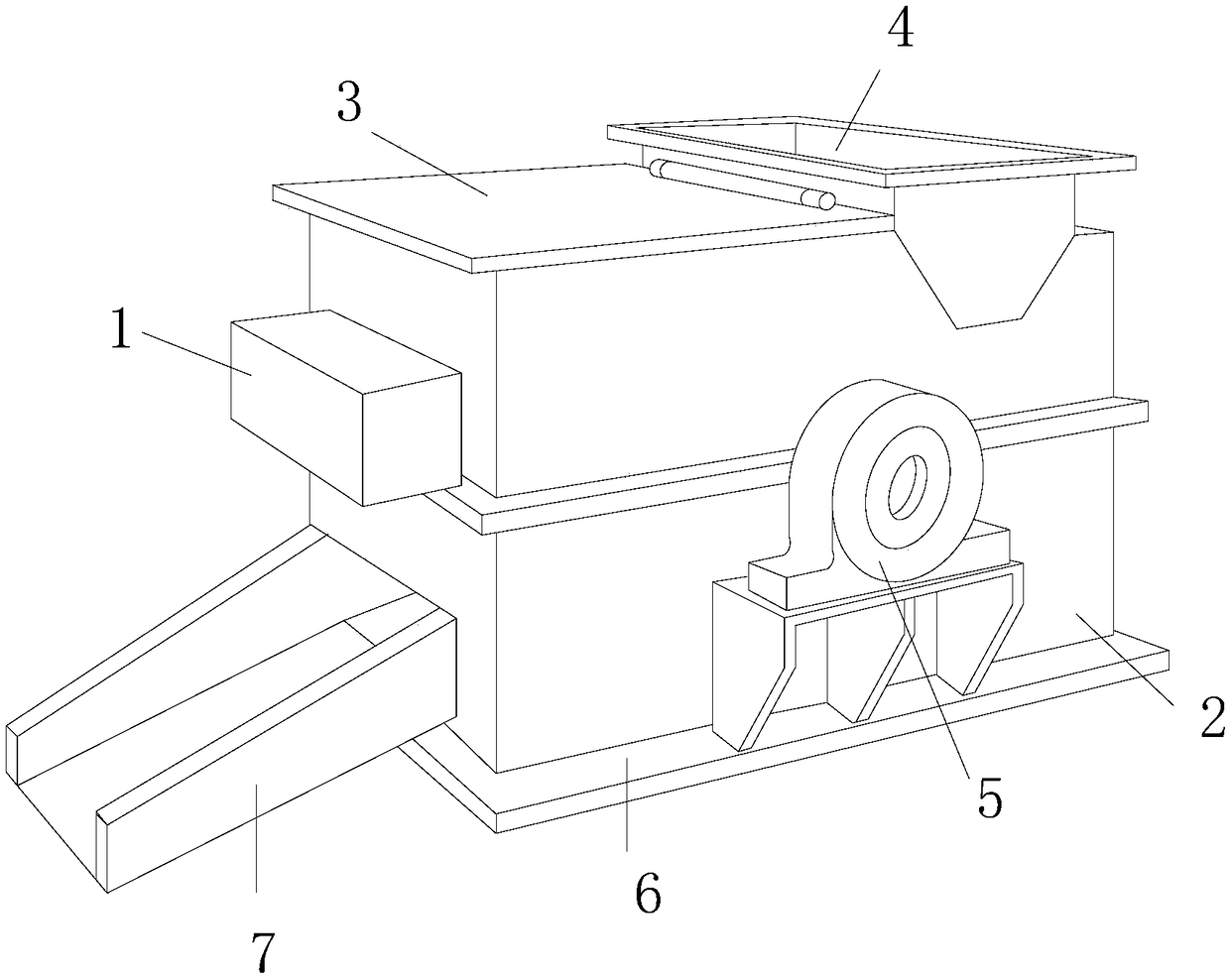

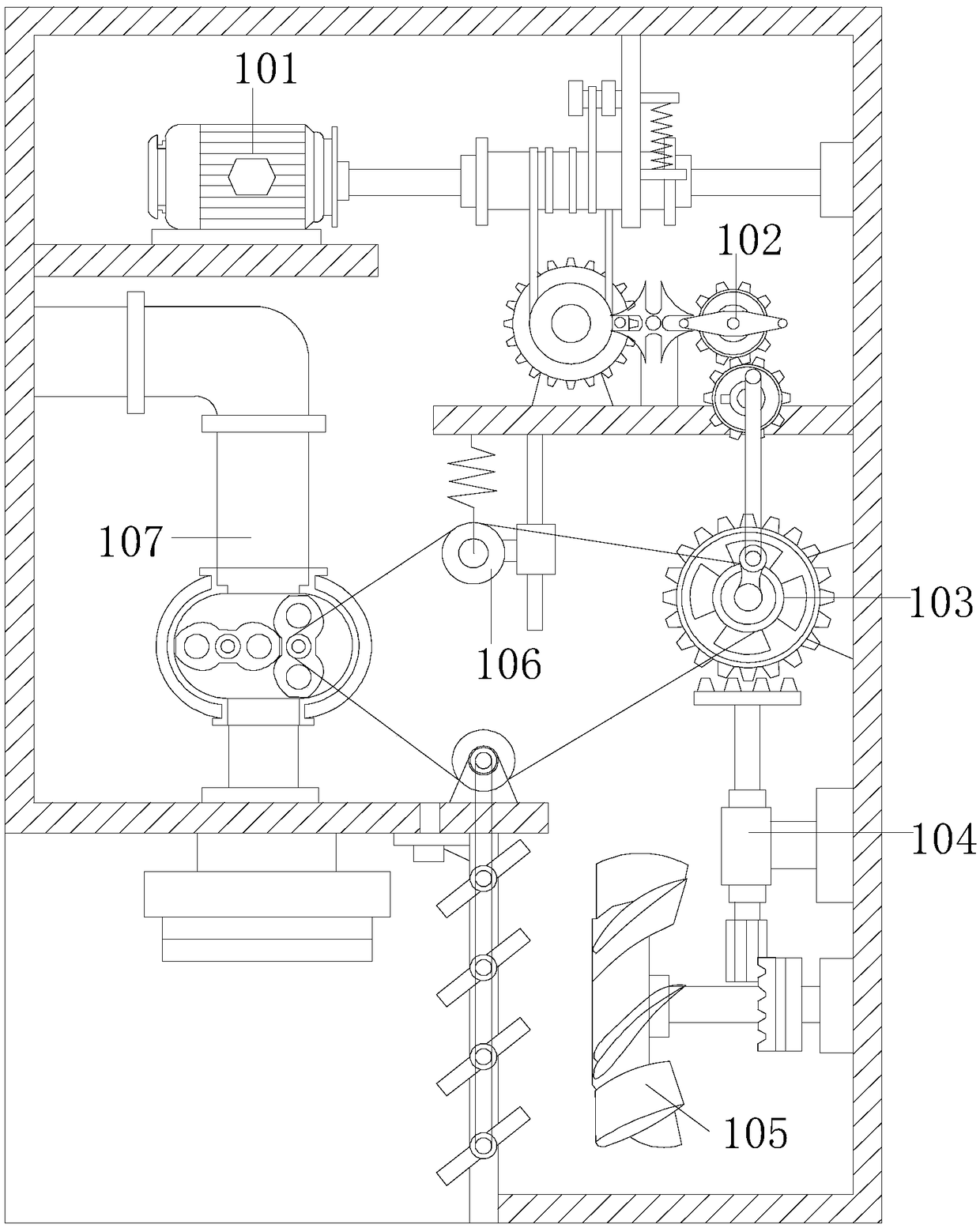

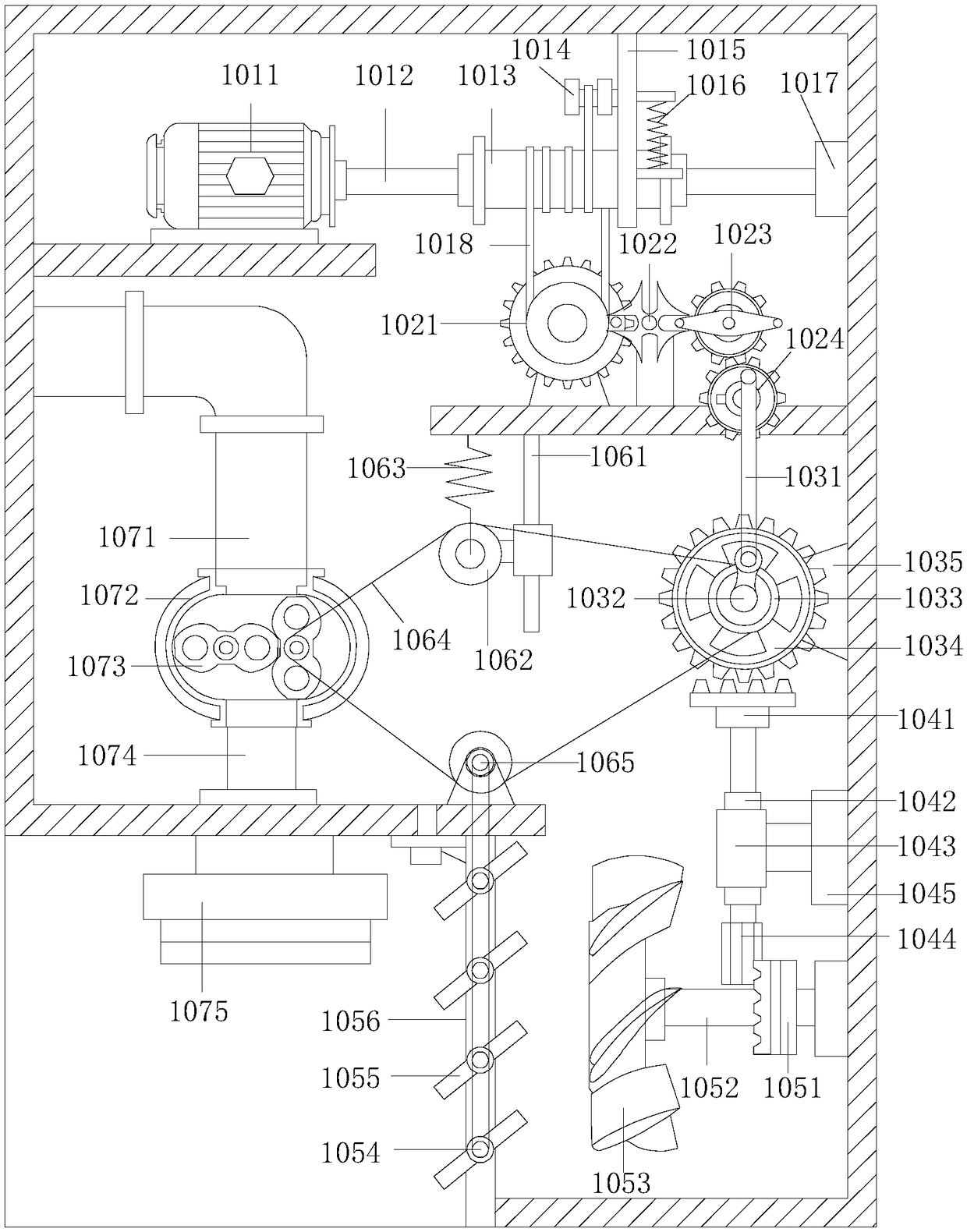

[0021] Such as Figure 1-Figure 4As shown, the present invention provides a stone crushing device for mining machinery, the structure of which includes a dust suppression mechanism 1, a stone crushing cabinet 2, a cabinet cover 3, a feed hopper 4, a power coupling 5, a base 6, and a discharge hopper 7, The housing of the dust suppression mechanism 1 is fixed on the top of the middle rim of the crushing machine case 2 by bolts, the top of the case 2 is movably connected with the case cover 3, and is interference fit with the bottom of the feeding hopper 4, the power The coupling 5 is vertically welded and fixed on the front end of the crushing box 2, the bottom of the crushing box 2 is closely attached to the top of the base 6, and the discharge hopper 7 is installed on the top of the crushing box 2 and is connected to the left side. The inside of the feed hopper 4 is connected, and the dust suppression mechanism 1 is provided with a driving device 101, a transmission gear 102,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com