Processing method for packing tape

A processing method and technology of tape, applied in the direction of adhesive, film/sheet-like adhesive, etc., can solve the problems of sticky tape roll end face, inconvenient to take, easy to stick, etc., to achieve good user experience, Ease of access and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings.

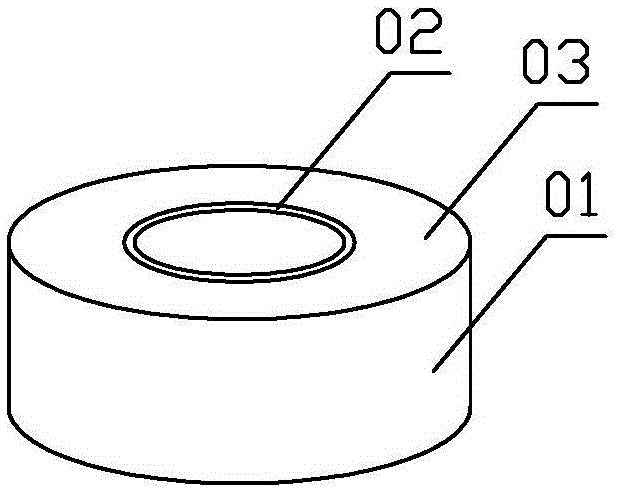

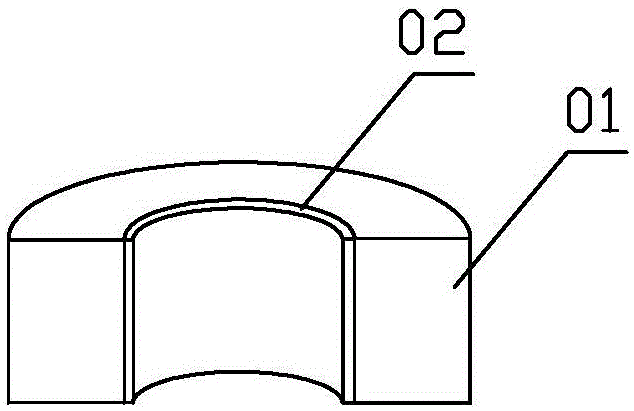

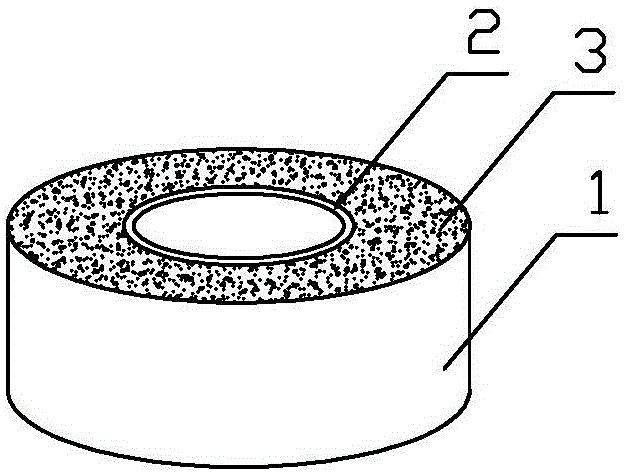

[0043] combined with image 3 to attach Figure 6 , a processing method of sealing tape, it comprises the steps:

[0044] The first step is to add the tape raw material acrylic acid to the emulsification tank for emulsification;

[0045] In the second step, put the emulsified tape raw material acrylic acid into the reaction pot for heating to make glue;

[0046] In the third step, the glue made in the second step is added to the coating machine;

[0047] The fourth step is to install the plastic film roll on the coating machine, and automatically apply the glue to the plastic film through the coating machine to make a parent roll;

[0048] The fifth step is to cut the parent roll obtained in the fourth step through a pipe cutting machine;

[0049] The sixth step is to use a slitting machine to divide the tape after the successful pipe cutting to obtain rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com