Conveying belt accumulated water removing device of belt conveyer

A technology for belt conveyors and clearing devices, which is applied in the direction of cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of inconvenient collection and dredging, poor implementability, high pressure, etc., and achieve the benefit of collecting and dredging Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with drawings and embodiments.

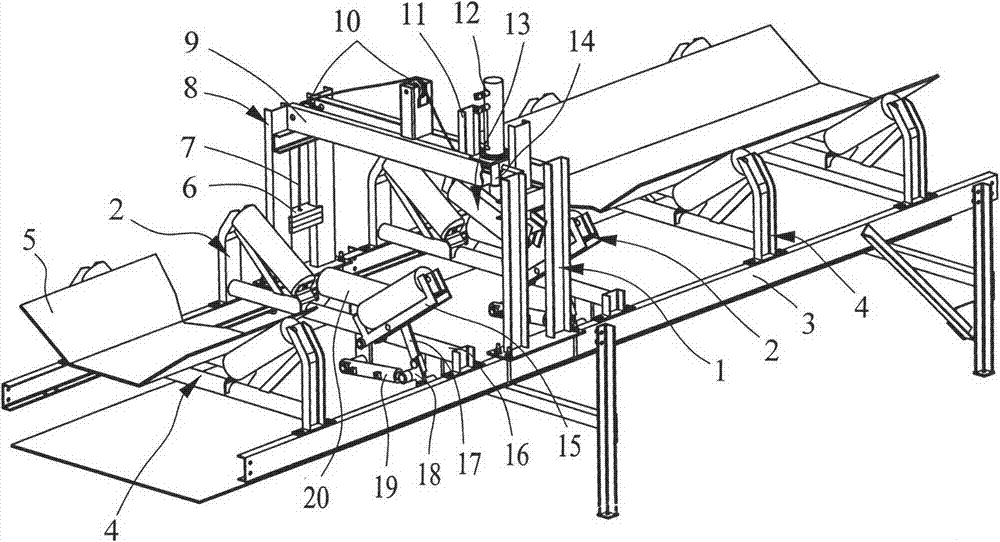

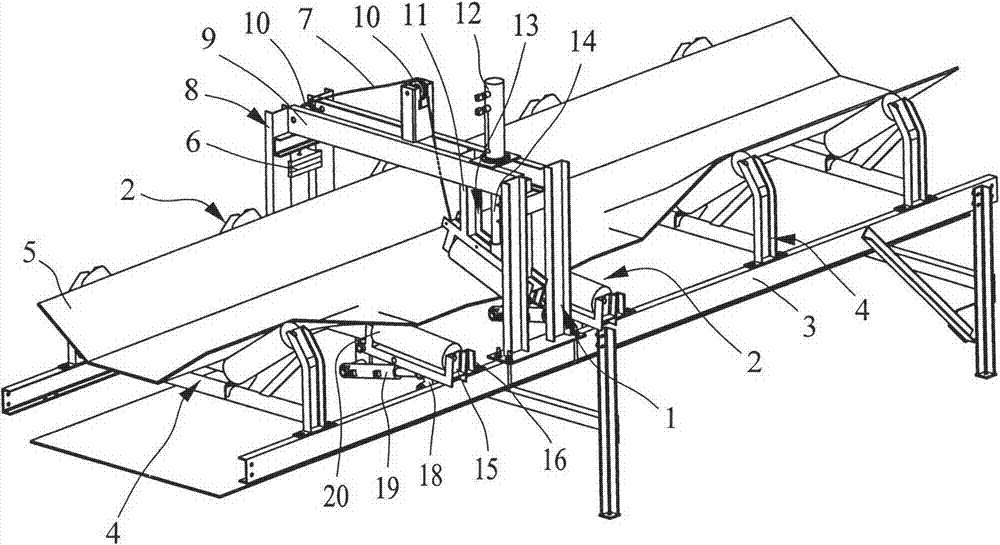

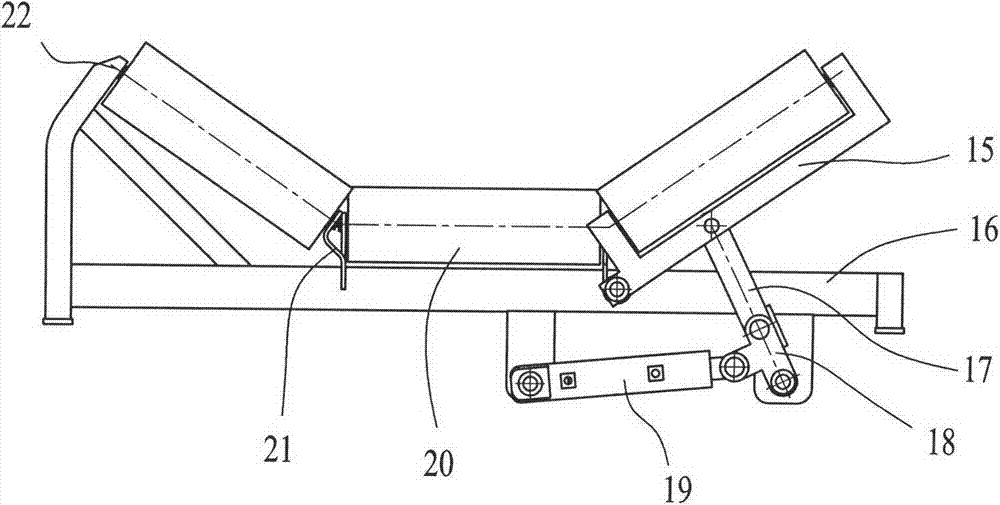

[0016] figure 1 As shown, the present invention includes a belt pressing device 1 and an adjustable groove angle idler group 2, at least two groups of the adjustable groove angle idler groups 2 are adjacently installed on the intermediate frame 3 of the belt conveyor, and support The conveyor belt 4, the belt pressing device 1 is in the middle position of the adjustable groove angle idler roller group 2, and the gantry type mounting frame 8 of the belt pressing device 1 straddles the trough conveyor belt 5 and is installed on the middle frame 3 of the conveyor;

[0017] figure 1 , 2 Among them, the belt pressing device 1 includes a gantry mounting frame 8, a linear driver 12, a belt pressing unit 13, a counterweight 6, and a steel wire rope 7, and is fixed on the gantry mounting frame 8 on the intermediate frame 3 of the belt conveyor. There is a beam 9, the beam 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com