Floating pressing plate head with adjustable clamping force

A technology of floating platen and clamping force, which is applied in the direction of clamping, supporting, positioning devices, etc., can solve the problems of difficult control of clamping force, lower product quality, looseness, etc., and achieve reduced operation difficulty, continuous and effective clamping, and improved The effect of compression deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

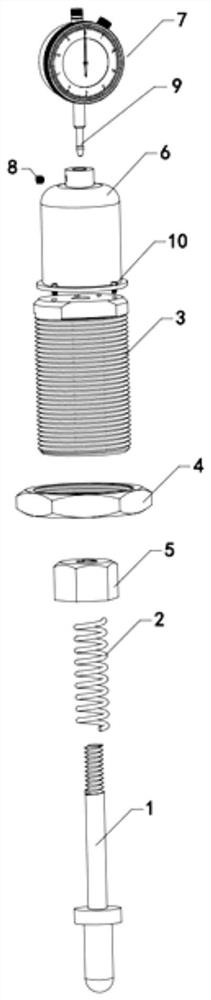

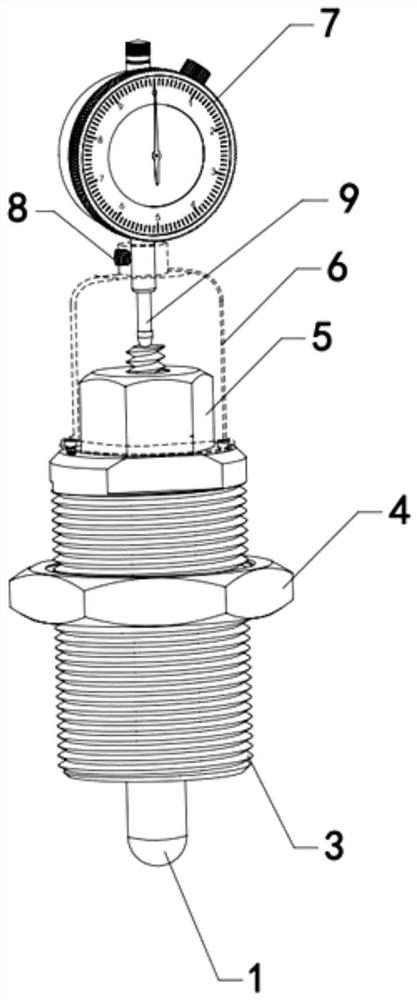

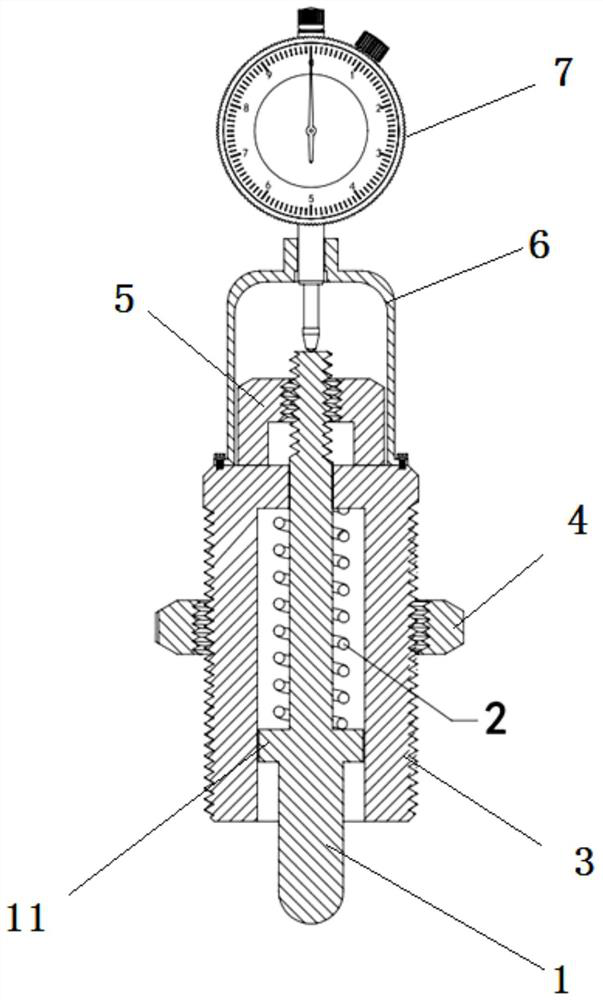

[0028] A floating platen head with adjustable clamping force, its structure see Figure 1-3 As shown, it includes a connecting body 3 that can be fixedly connected with the external pressure plate and specifically penetrates up and down through the hollow cavity, and the two ends respectively protrude from the upper and lower ends of the hollow cavity. The elastic part at the top of the cavity, the pre-adjustment part fixedly connected to the top of the movable pressure head 1 and against the top of the coupling body 3, and the pressure gauge 7 fixed above the coupling body 3, the probe 9 of the pressure gauge 7 is also against the movable The top of the indenter 1.

[0029] see you again Figure 1-Figure 3 As shown, the top of the coupling body 3 is also fixedly provided with a casing 6 covering the top of the presetter and the movable pressure head 1 , and a pressure gauge 7 is installed on the casing 6 . In this embodiment, the pressure gauge 7 is preferably fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com