Aluminum alloy diameter-expanded wire for overhead transmission line

A technology for overhead transmission lines and aluminum alloys, applied in circuits, conductors, electrical components, etc., can solve the problems of wire compression deformation, strand jumping, etc., and achieve the effect of improving compression deformation, increasing electrical conductivity, and ensuring electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

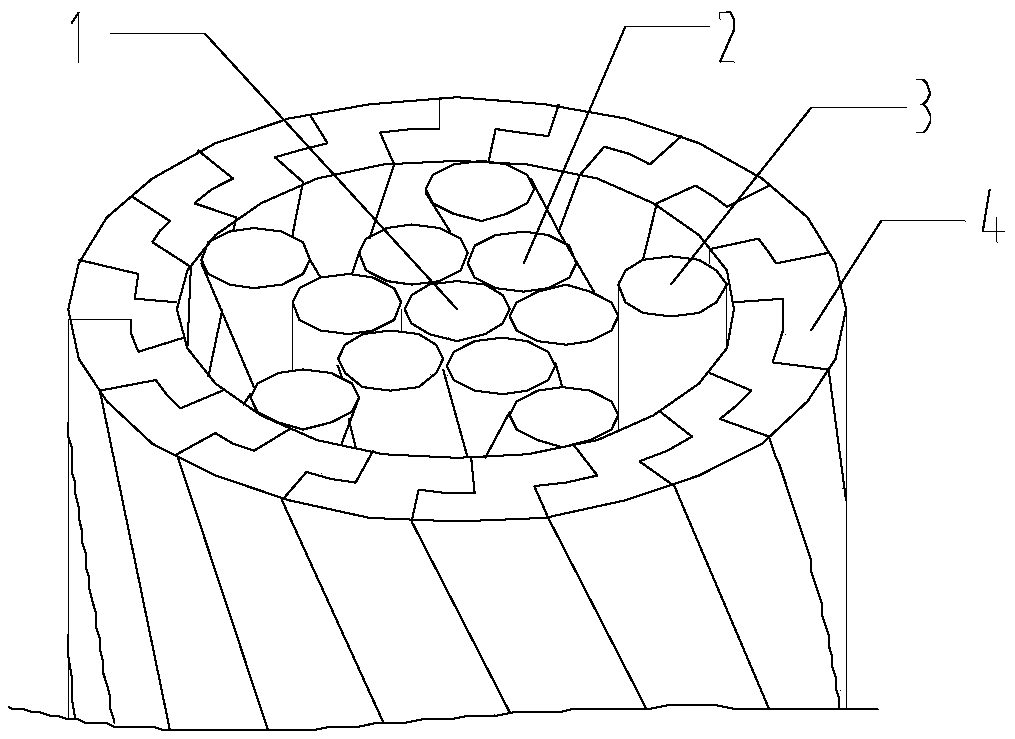

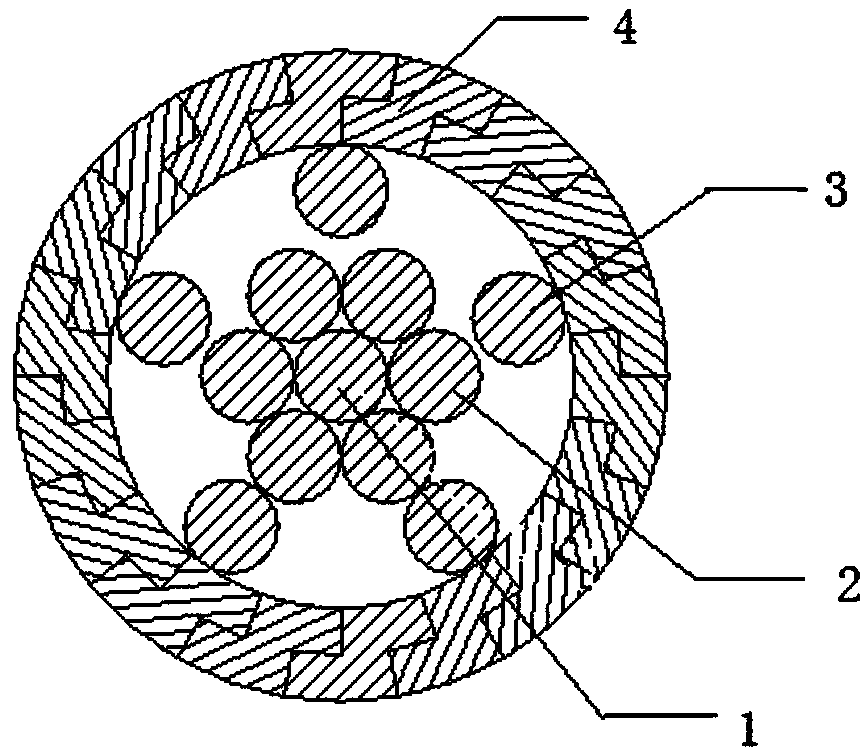

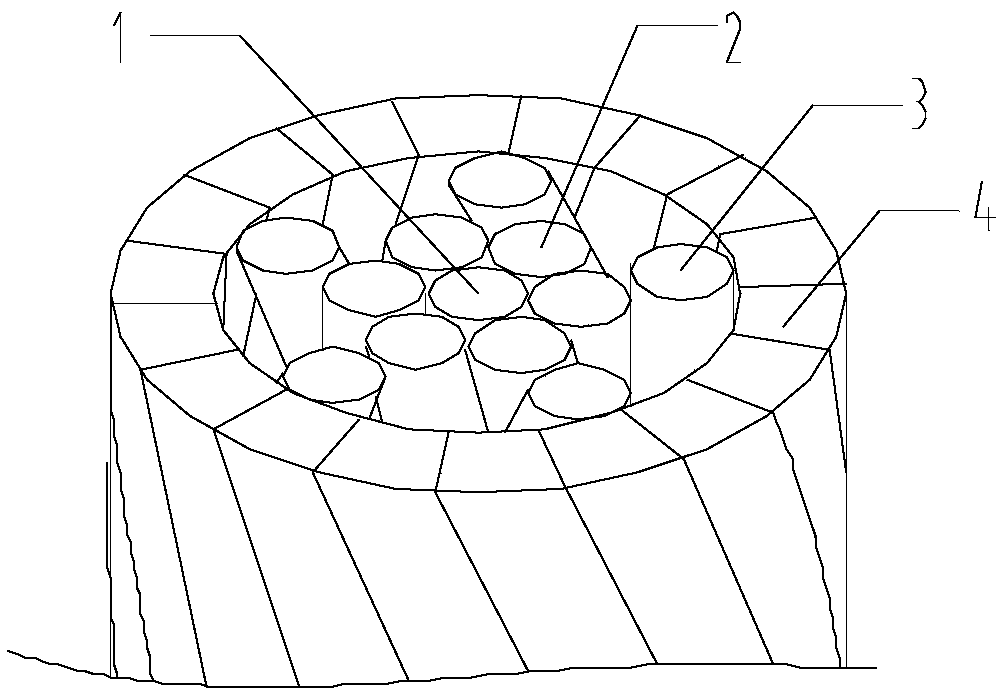

[0017] The present invention provides an aluminum alloy diameter-expanding wire used for overhead transmission lines. The entire aluminum alloy diameter-expanding wire type is a comb-twisted type, including multiple layers of twisted wires arranged in turn from the inside to the outside. It is a stranded wire layer wound by LHA1, LHA2 high-strength or LHA3 medium-strength aluminum alloy S, Z or T-shaped monofilament, and other stranded wires within the outermost layer are all wound by LHA1 or LHA2 high-strength aluminum alloy round monofilament strand layer. The outermost layer is made of LHA1, LHA2 high-strength aluminum alloy or LHA3 medium-strength aluminum alloy stranded wire. Compared with the conventional steel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com