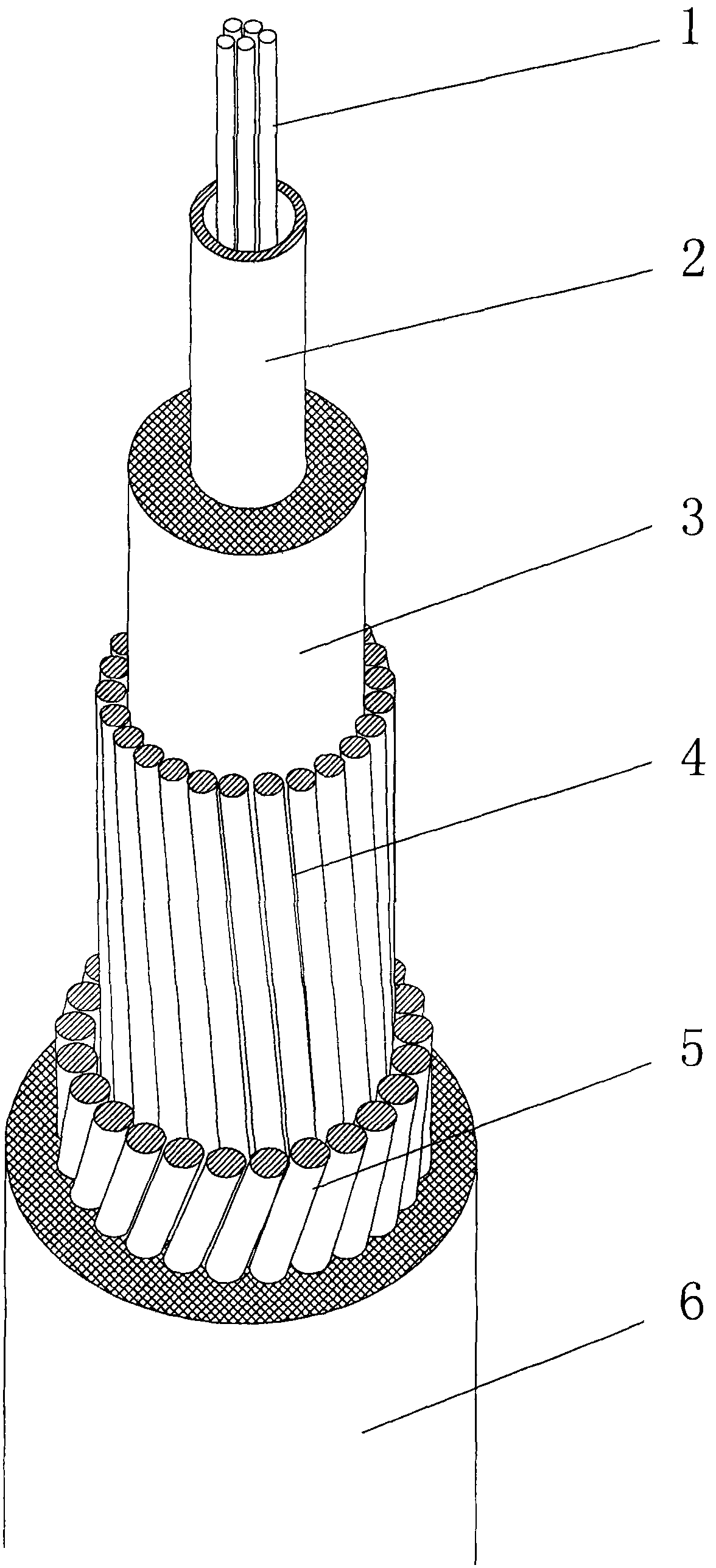

High-strength metal sleeve for optical cables

A metal sheath, high-strength technology, applied in the direction of fiber mechanical structure, etc., can solve the problems of poor compressive performance, heavy weight, large diameter of optical cable, etc., to achieve enhanced compressive performance, reduced thickness, and reduced overall diameter Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

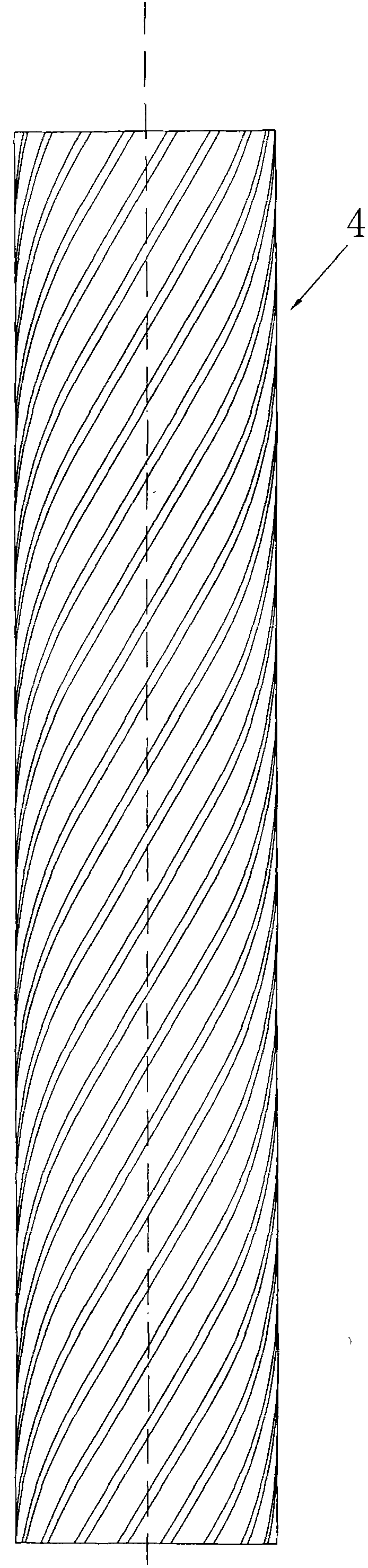

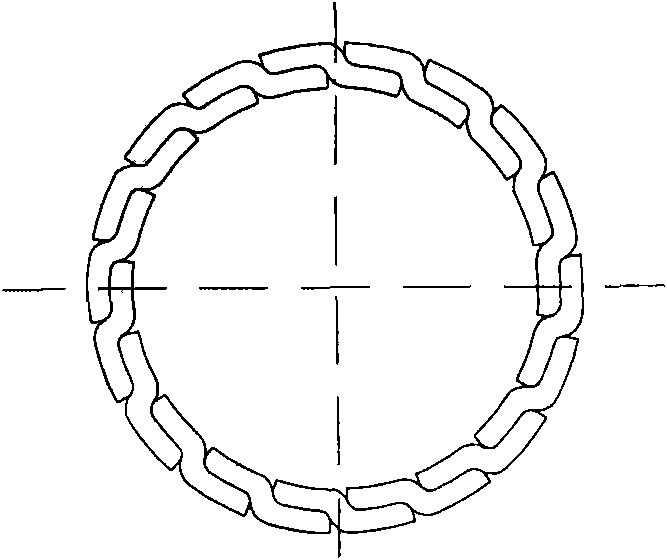

Embodiment Construction

[0016] A single strip metal sheet 41 is shaped as Figure 5 , as shown in Figure 6, the embodiment is made of stainless steel, of course it can also be made of other rust-resistant or rust-resistant metal materials. The production process is as follows: first cut the stainless steel sheet or draw it into a narrow strip with steel wire, and then roll it to form a circular arc surface in the transverse direction. The curvature of the arc surface is determined by the required cable specifications; Pressed into a basic "Z" shape by a mold, the height of the formed step matches the thickness of the stainless steel strip 41, and the upper and lower step surfaces 41a and 41b formed are all arc surfaces, so that the horizontal overlap is as close as possible Paste; the formed step bend can play the role of reinforcing ribs, which is beneficial to enhance the compressive strength of the sheath; finally twist it into a spiral shape, and the direction of twist can be left-handed or right...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com