Pesticide bottle capable of resisting oil agent permeation and preparation method of pesticide bottle

An oil repellent and pesticide bottle technology, which is applied to the pesticide bottle permeated by the oil repellant and the field of its preparation, can solve the problems of unfavorable pesticide stability, poor oily solvent blocking ability, etc., and achieves improved oil blocking performance and ultraviolet protection performance. , the effect of inhibiting penetration and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

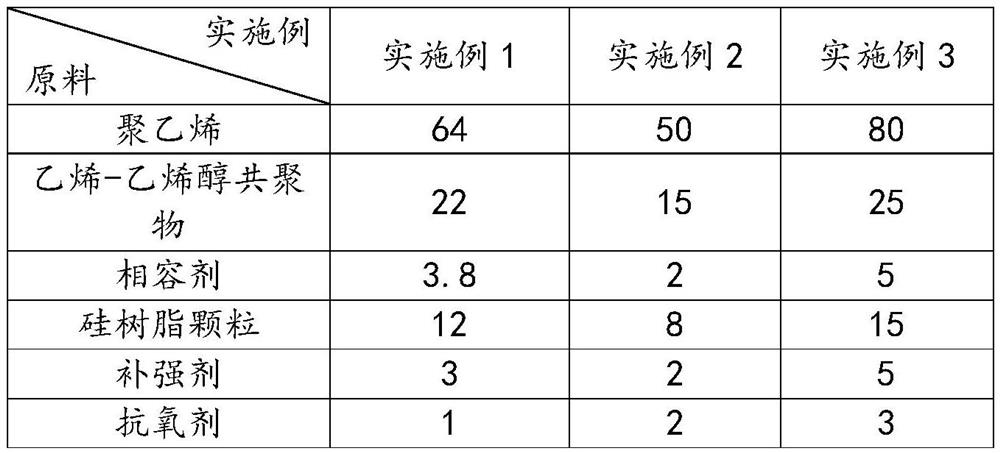

Examples

preparation example 1a

[0051] Preparation example 1a, a silicone resin particle, its raw material ratio is shown in Table 1, and it is prepared according to the following steps:

[0052] S1-1: Stir vinyl silicone oil, hydrogen-containing silicone oil, anti-ultraviolet particles, silane coupling agent and hydroxyl silicone oil in a disperser for 30 minutes according to the proportion, and disperse evenly to obtain component A; mix vinyl silicone oil and platinum catalyst according to the proportion Stir with the inhibitor in a disperser for 20 minutes, disperse evenly, and obtain component B;

[0053] S1-2: Mix component A and component B according to the mass ratio of 1:1, stir and react for 20 minutes to obtain silicone resin;

[0054] S1-3: Pulverize the silicone resin with a pulverizer to obtain particles with a particle size in the range of 1-5 cm, which are transferred to a ball mill for ball milling to obtain silicone resin particles with an average particle size of 3-8 μm.

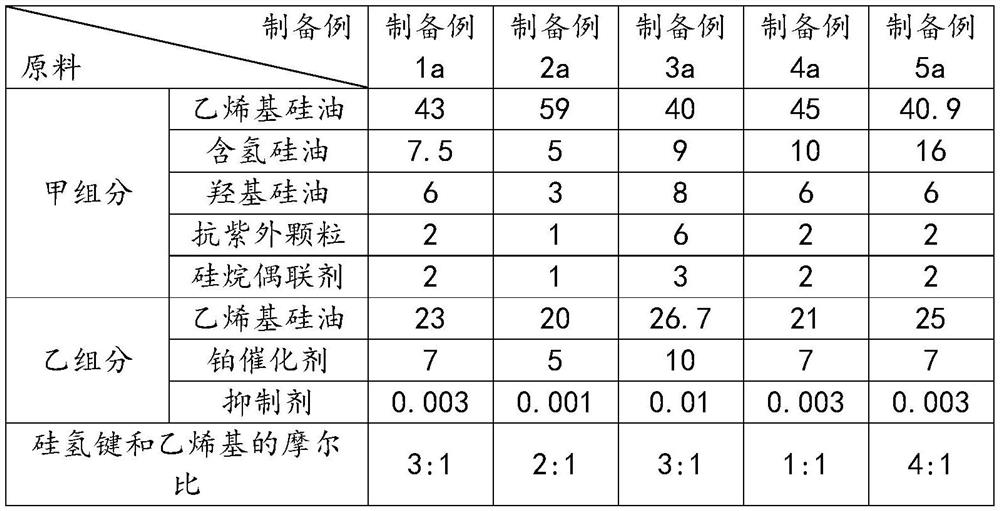

preparation example 2a~5a

[0055] Preparation examples 2a-5a, a kind of silicone resin particles, differ from preparation example 1a in that the ratio of raw materials is different, as shown in Table 1.

[0056] Table 1, the raw material ratio (kg) of preparation examples 1a~5a

[0057]

[0058]In Table 1, the vinyl silicone oil of Preparation Examples 1a-2a has a vinyl mass fraction of 1.06%; the hydrogen content of the hydrogen-containing silicone oil (side hydrogen-containing silicone oil) is 1.0%; in Preparation Example 3a, the vinyl silicone oil vinyl The mass fraction is 0.7%; the hydrogen content of the hydrogen-containing silicone oil (side hydrogen-containing silicone oil) is 0.25%; the vinyl mass fraction of the vinyl silicone oil of Preparation Example 4a is 1.06%; the hydrogen content of the hydrogen-containing silicone oil is 0.25%; The vinyl mass fraction of the vinyl silicone oil in Example 5a is 1.7%; the hydrogen content of the hydrogen-containing silicone oil is 1%.

[0059] The pl...

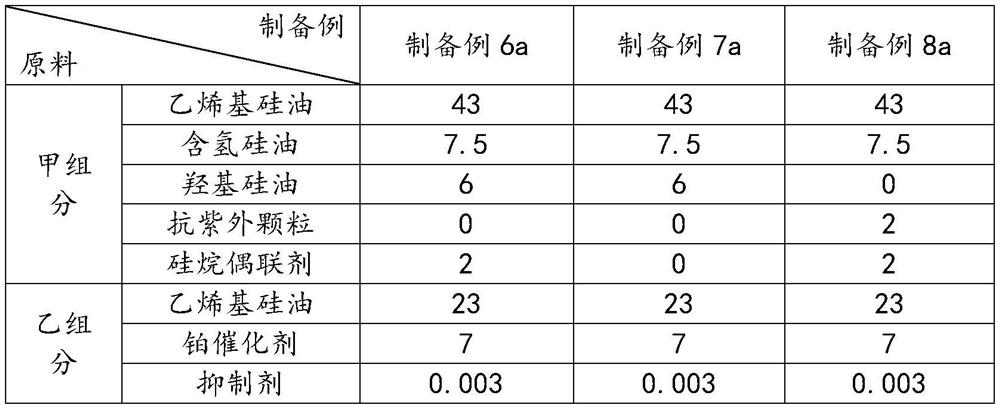

preparation example 6a~8a

[0060] Preparation examples 6a-8a, a kind of silicone resin particles, are different from preparation example 1a in that the ratio of raw materials is different, as shown in Table 2.

[0061] Table 2, the raw material ratio (kg) of preparation examples 6a~8a

[0062]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com