Composite with low density, high resilience and high slip resistance and preparation method thereof

A technology of resilience and low density, which is applied in the field of compositions with low density, high resilience and high anti-skid property and its preparation, to achieve the effect of improving competitiveness, easy acquisition and promoting international competition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

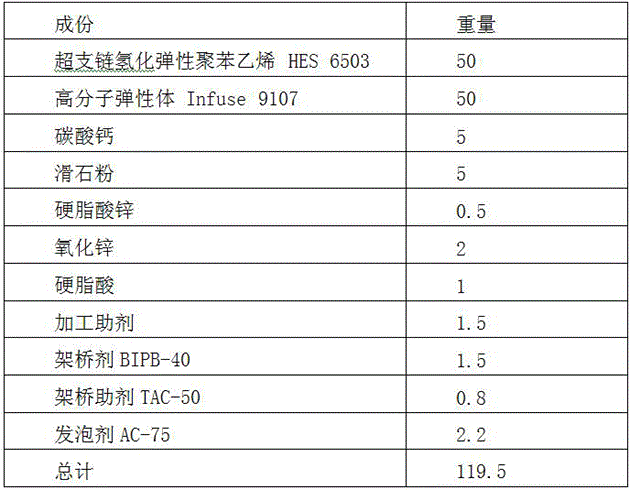

[0019] Example 1: The expansion ratio is about 136%; the hardness is about 67.

[0020] Such as figure 1 As shown, weigh and take the composition in Table 1 to prepare and mix uniformly, then mold and foam, and the foamed test piece is tested for related physical properties.

[0021] Table 1 Composition table of high anti-slip application composition

[0022]

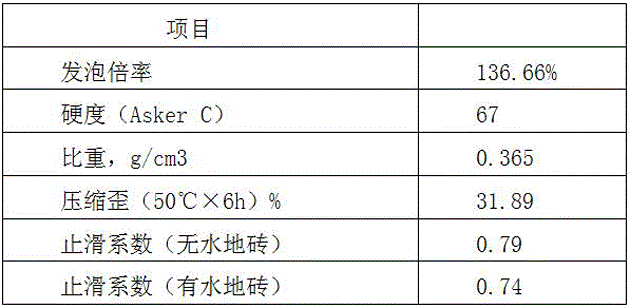

[0023] Table 2 Application test results (foaming condition 175℃×380sec)

[0024]

Embodiment 2

[0025] The application formula of Example 2, the expansion ratio is about 150% and the hardness is about 38:

[0026] Such as figure 1 As shown, weighed according to the combination formula in Table 3, prepared and mixed uniformly, then molded and foamed, and the foamed test pieces were tested for related physical properties.

[0027] Table 3 High elastic application composition composition table

[0028]

[0029] Table 4 Application Test Results (Foaming Condition 175℃×380sec)

[0030]

[0031] Conclusion: The hyperbranched hydrogenated elastic polystyrene application composition was uniformly mixed and foamed to prepare a test piece, and then the relevant physical properties of the test piece were tested. Tests have shown that the composition of hyperbranched hydrogenated elastic polystyrene has a density of less than 0.5 g / cm 3 , the compression deformation is less than 35%, and the anti-slip coefficients are all greater than 0.7, which can have the characteristics...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com