Excessive pressure collecting device for aluminum extruder

A collection device and aluminum extrusion technology, which is applied in the field of auxiliary devices of aluminum extrusion machines, can solve the problems of easy jamming of excess pressure, large impact of excess pressure collection device, etc., and achieve the effect of accurate signal transmission and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

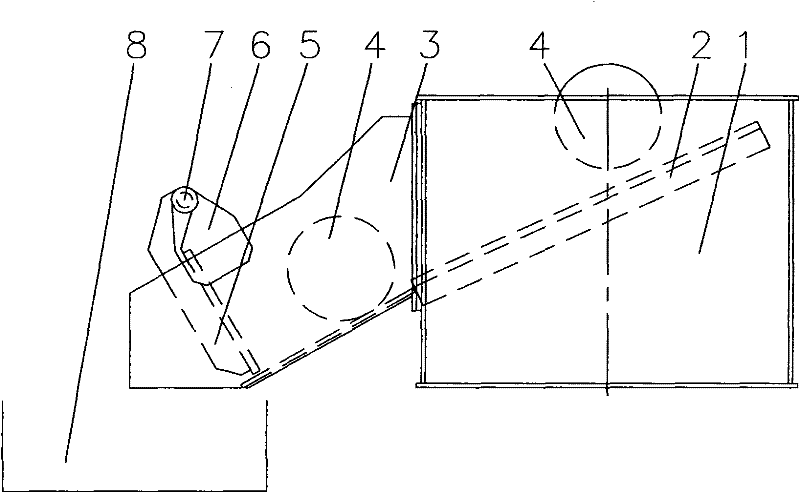

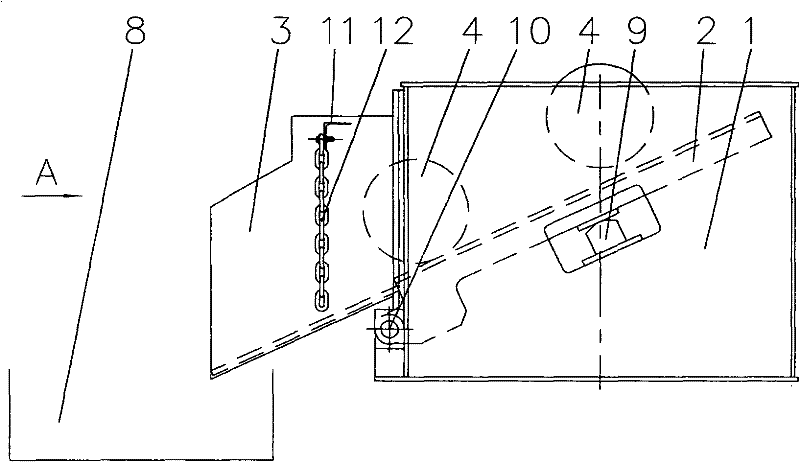

[0020] Such as figure 2 , 3 , 4, and 5, an aluminum extruder pressure residual collection device is provided with an independent inclined plate 2, one end of which is hinged on the frame 1 through a rotating shaft 10, and the frame 1 is equipped with two buffers 9, the buffer 9 Support the ramp 2. When the overpressure 4 falls on the swash plate 2 in the frame 1, since the bottom of the swash plate 2 has a buffer 9, the impact of the overpressure 4 on the swash plate 2 is reduced and the equipment is protected.

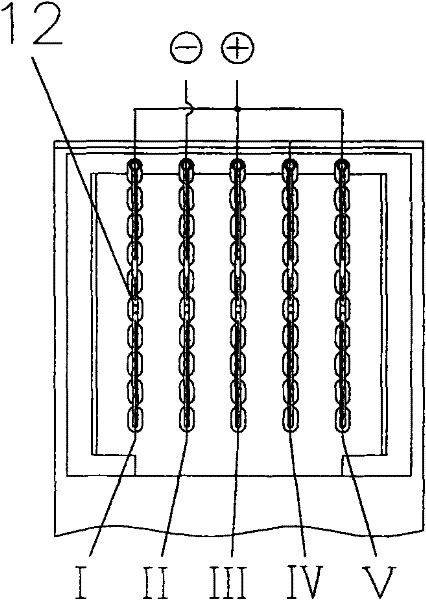

[0021] Chute 3 is fixed on one side of frame 1, and angle steel 11 is welded on the chute 3, and five chains 12 are housed on the angle steel 11. No. I, No. III, and No. V chains 12 are fixed on the angle steel 11 by bolts 13 and nuts 14. No. I, No. III, and No. V chains 12 are fixed by insulating washers 15 and insulating bushings 16 to play the role of insulation. No. I, No. III, and No. V chains 12 are connected to the "+" pole of the cable. No. II chain 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com