An integral casting mold for an aero-engine diffuser

An aero-engine and integral casting technology, which is applied in the field of aero-engines, can solve problems such as error-prone, large mold bottom plate size, and low part qualification rate, so as to strengthen the anti-deformation effect, avoid deformation, and improve casting precision and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

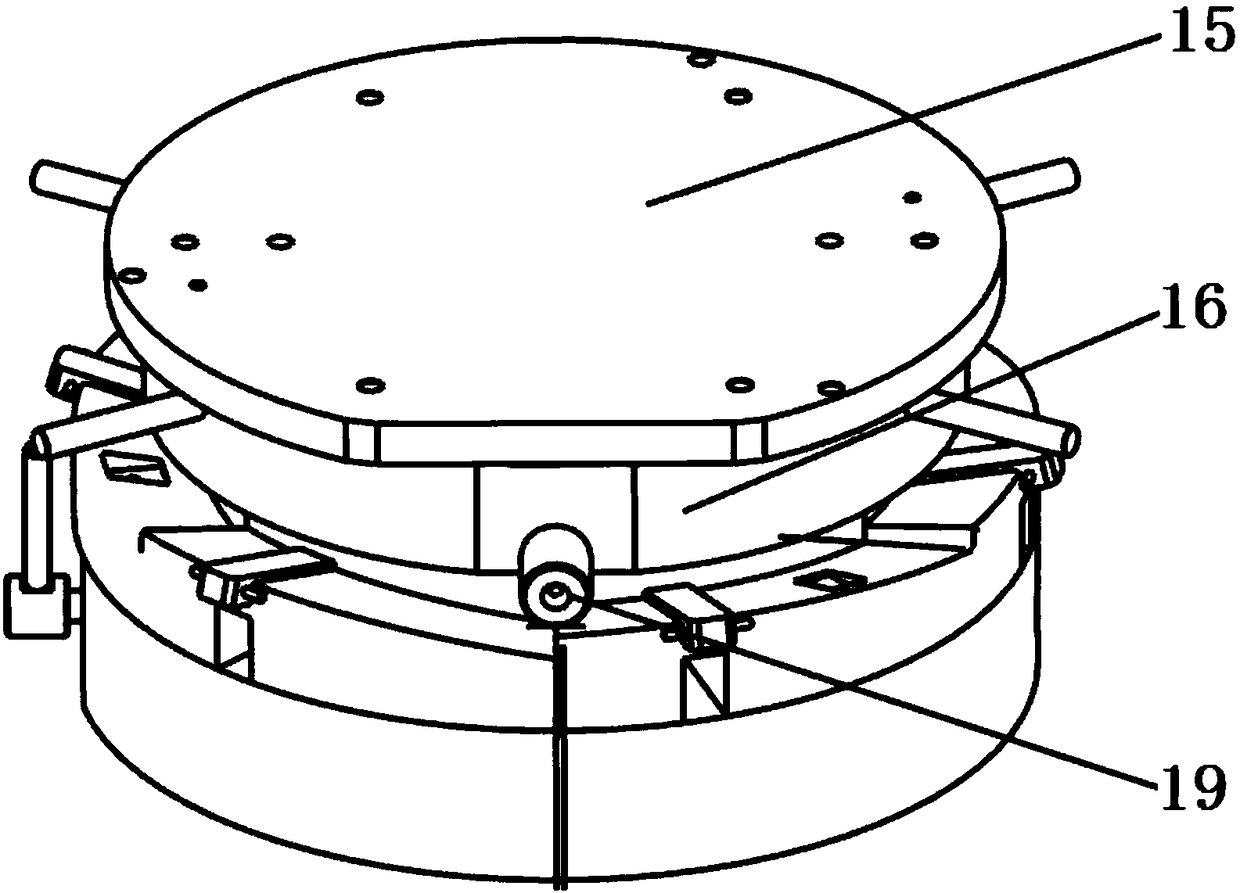

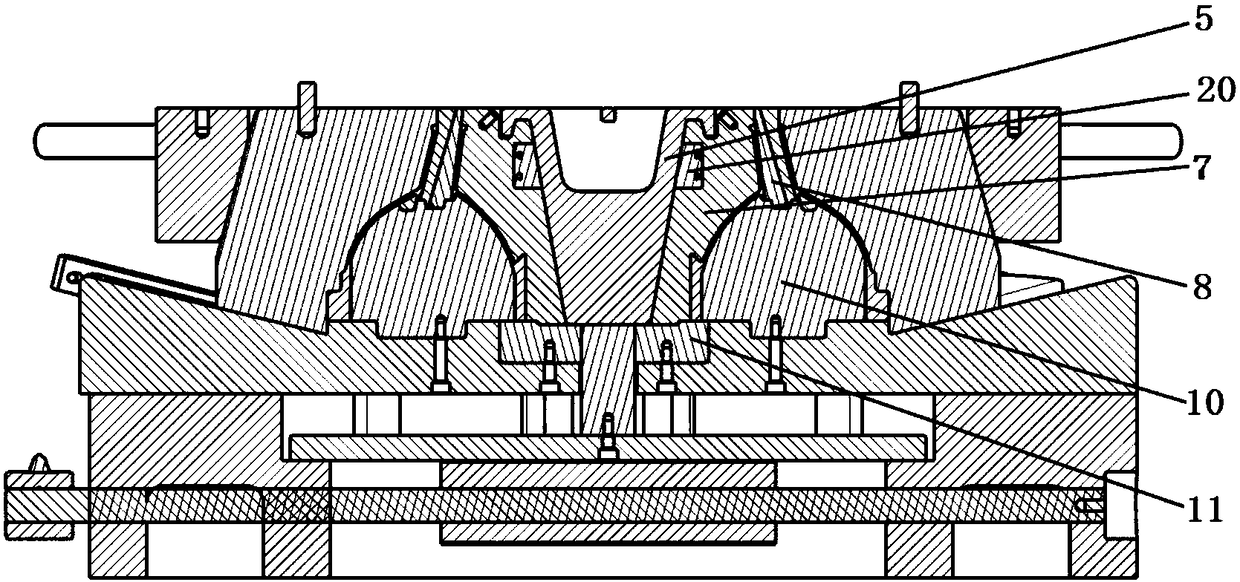

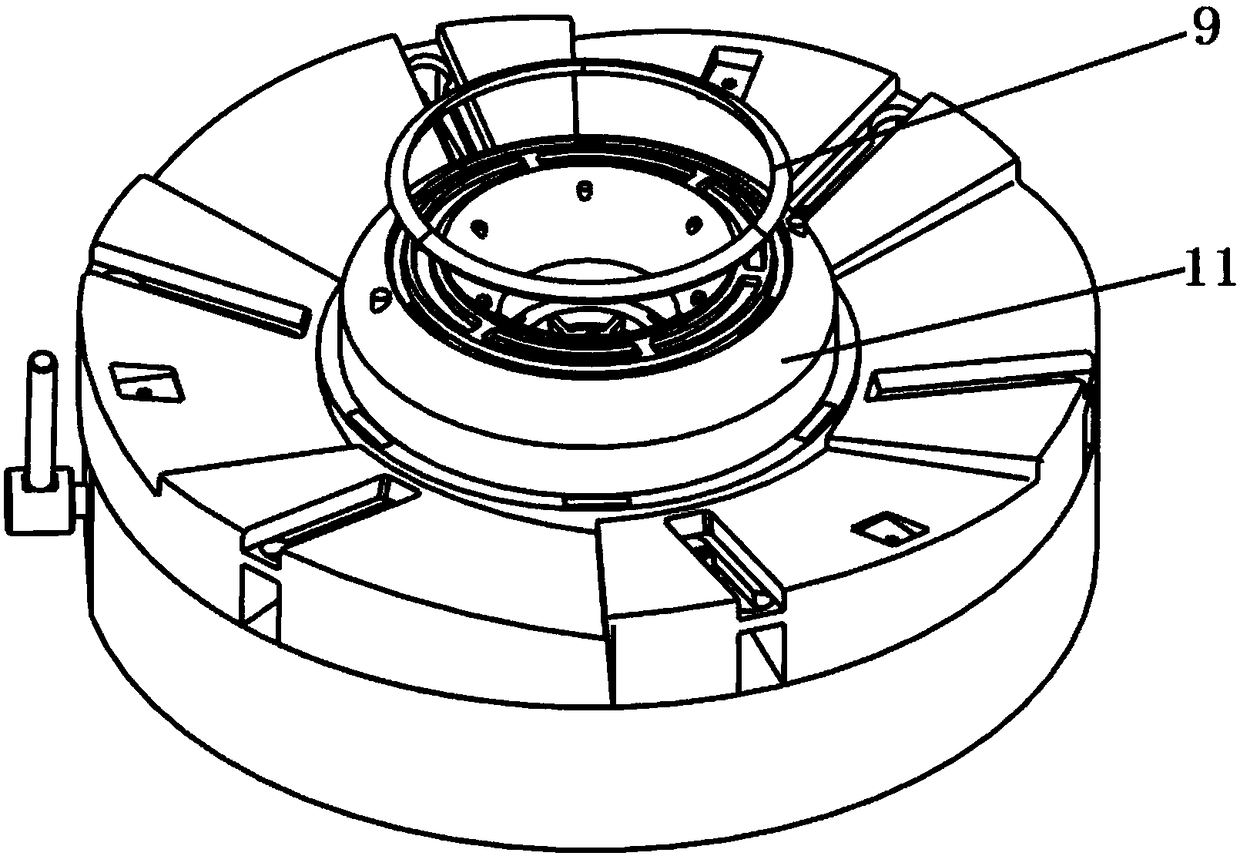

[0036] The invention provides an integral casting mold for an aero-engine diffuser, such as Figure 1-6 As shown, including the base 1, an inner annular cavity structure is provided between the base 1 and the upper cover plate 15, and the inner annular cavity structure communicates with the wax injection nozzle 19, and the wax injection nozzle 19 is used for Wax injection is performed in the annular inner cavity; the inner ring cavity structure is composed of several cavity parts, the cavity parts include the inner ring fixing block 10, the bottom of the inner ring fixing block 10 is provided with an outer ring fixing block 11 for fixing its position, The outer side of the inner ring fixed block 10 is provided with a movable block 7, and the top of the inner ring fixed block 10 is provided with a blade body movable block group 8; as image 3 As shown, a follow-up mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com