Patents

Literature

54results about How to "Precision mold clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mold and method for injection molding of high-compression resistance and long-life notebook computer baseboard shell

PendingCN108819113ACompact structureReasonable designDomestic articlesCoatingsBaseboardEconomic benefits

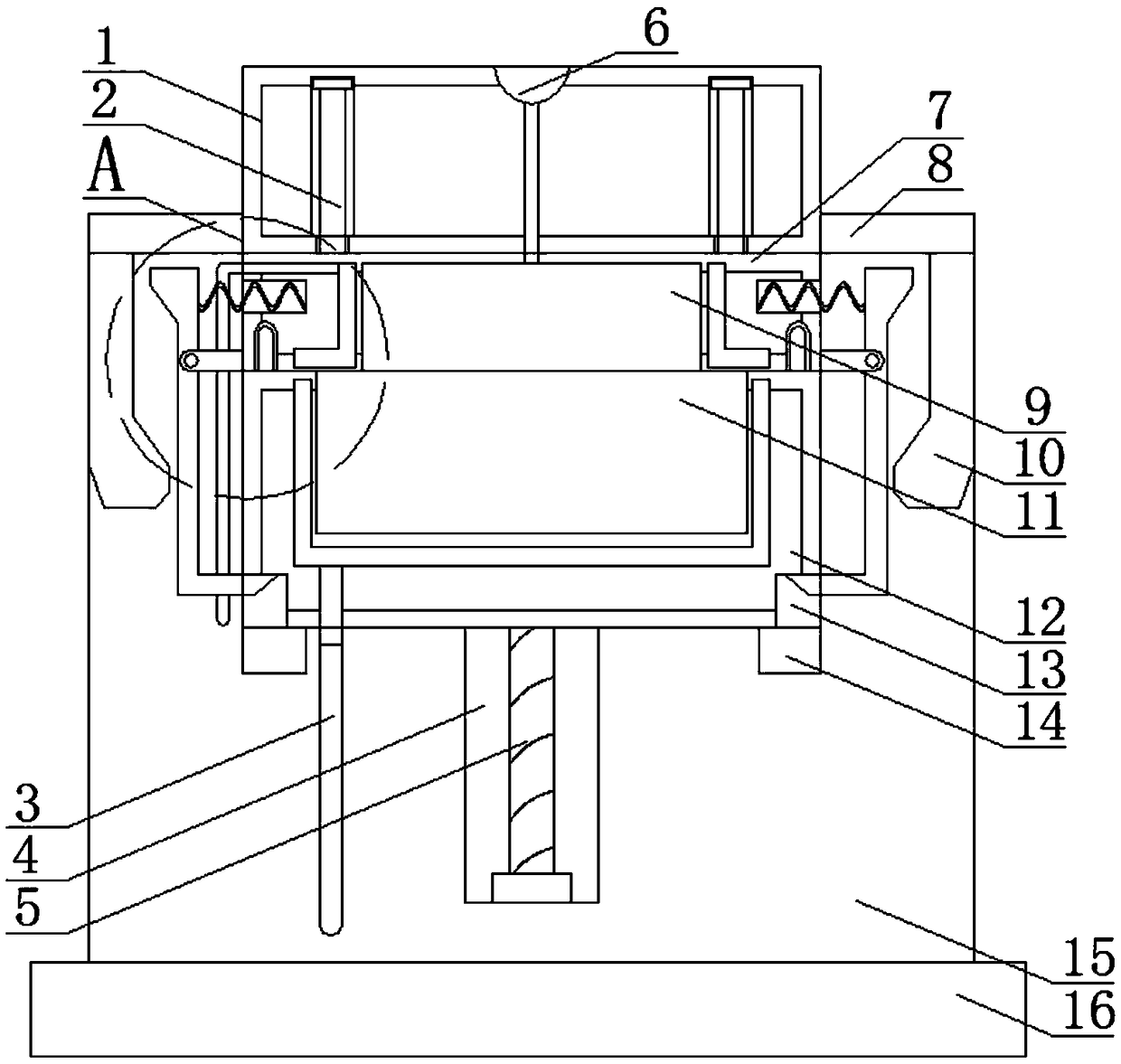

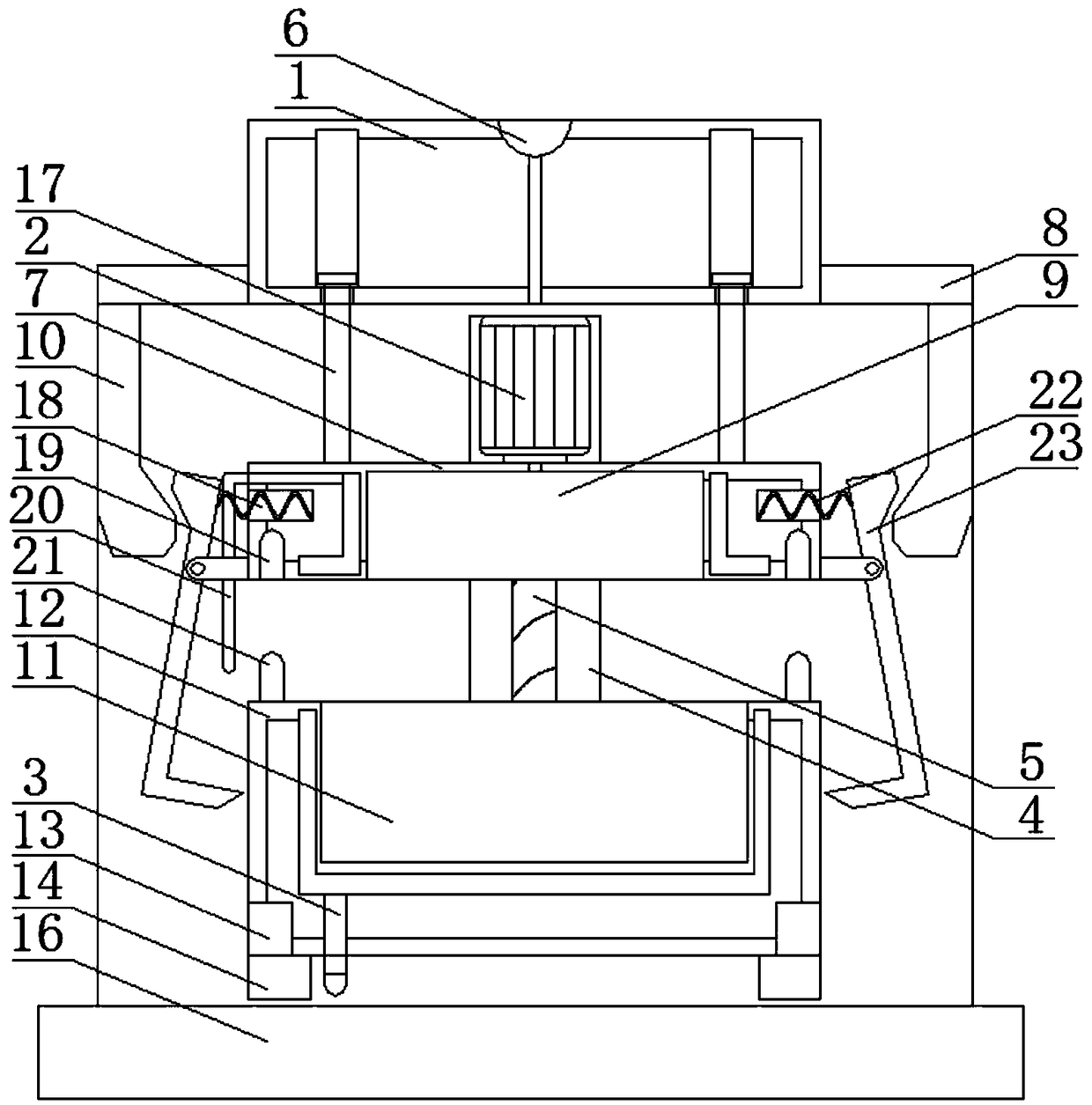

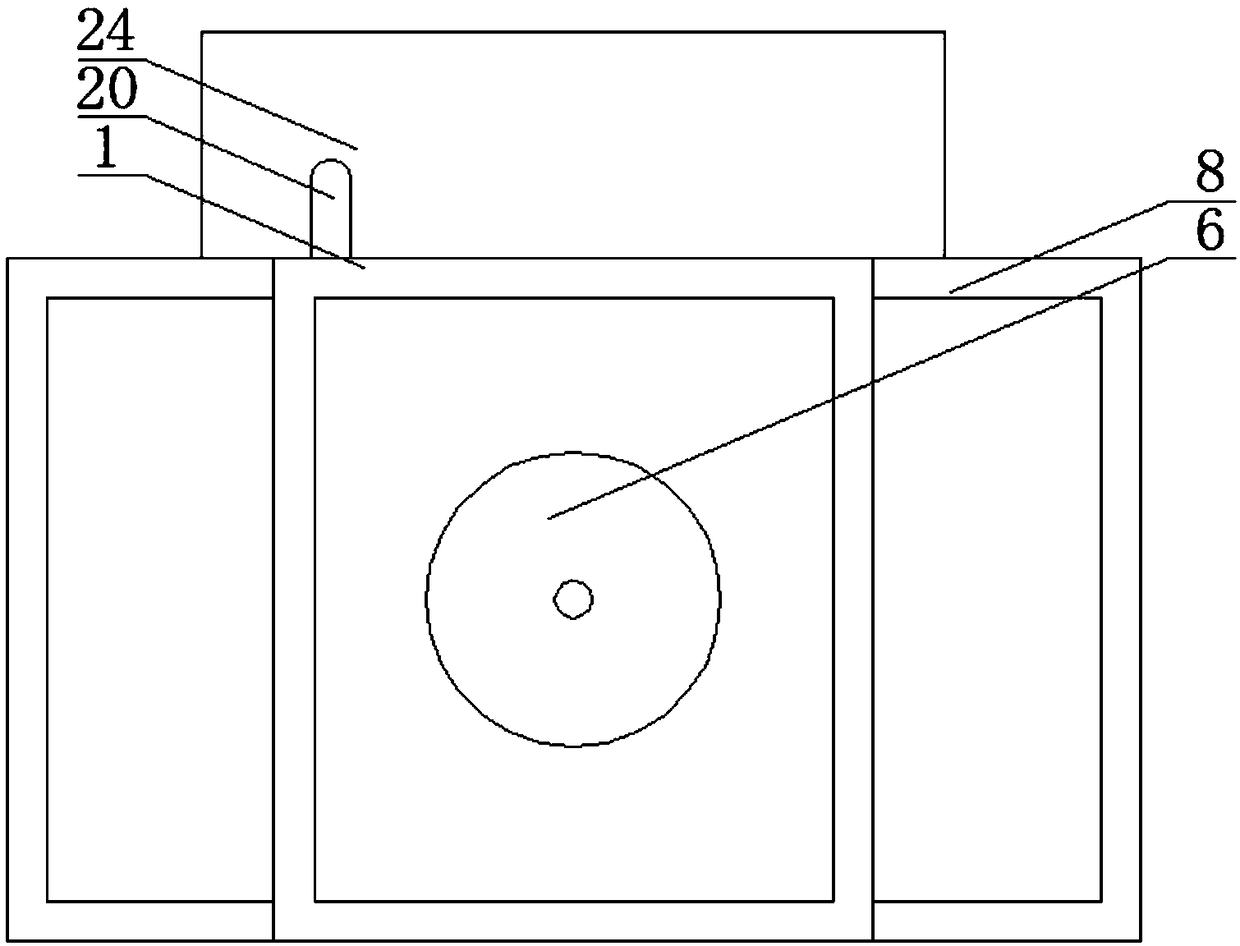

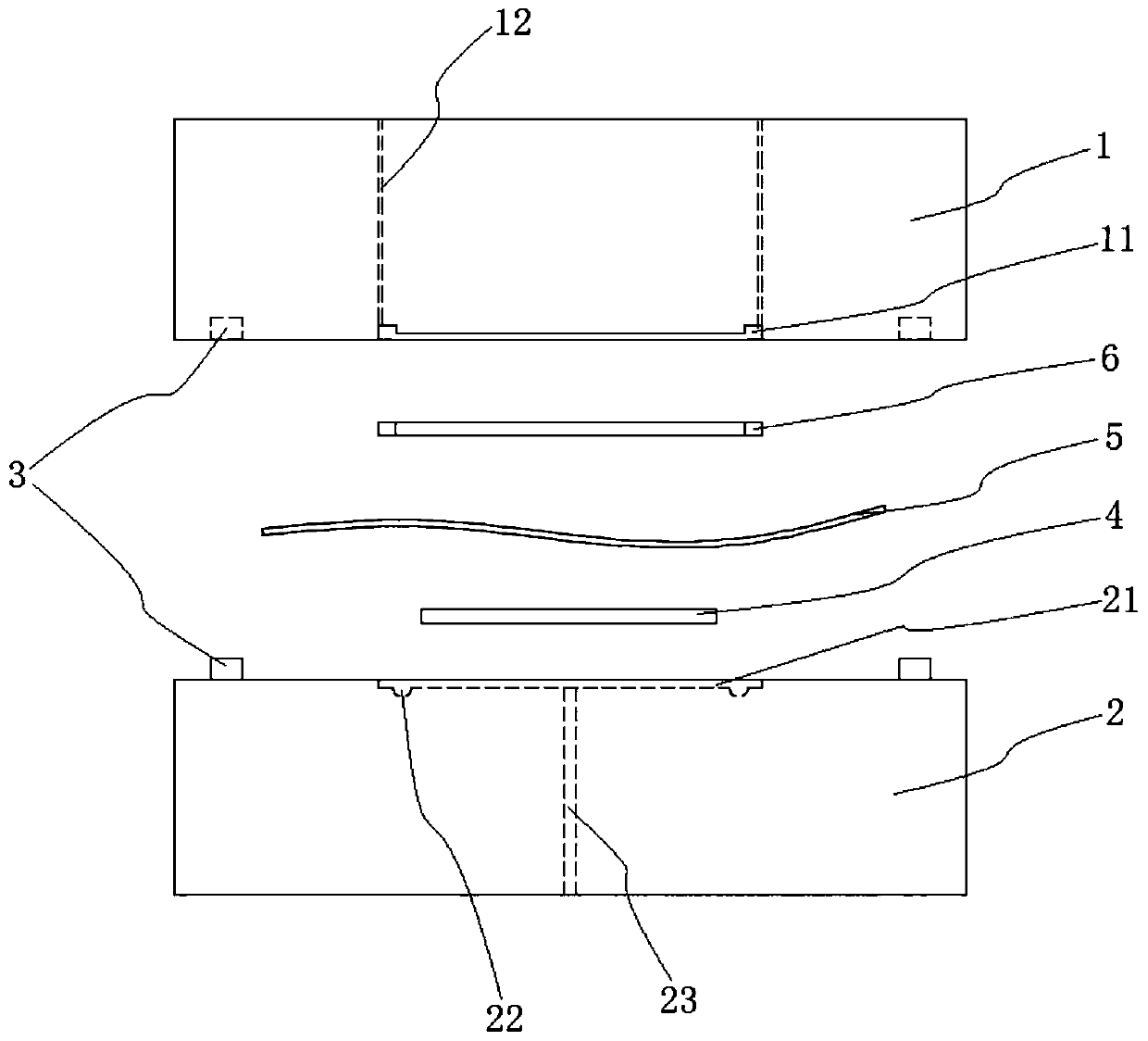

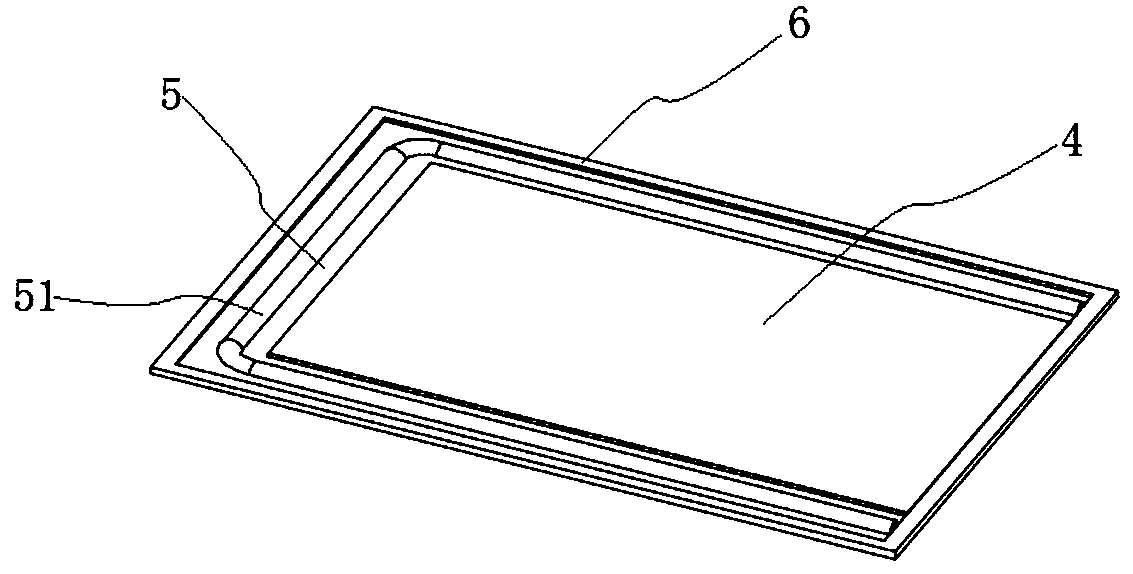

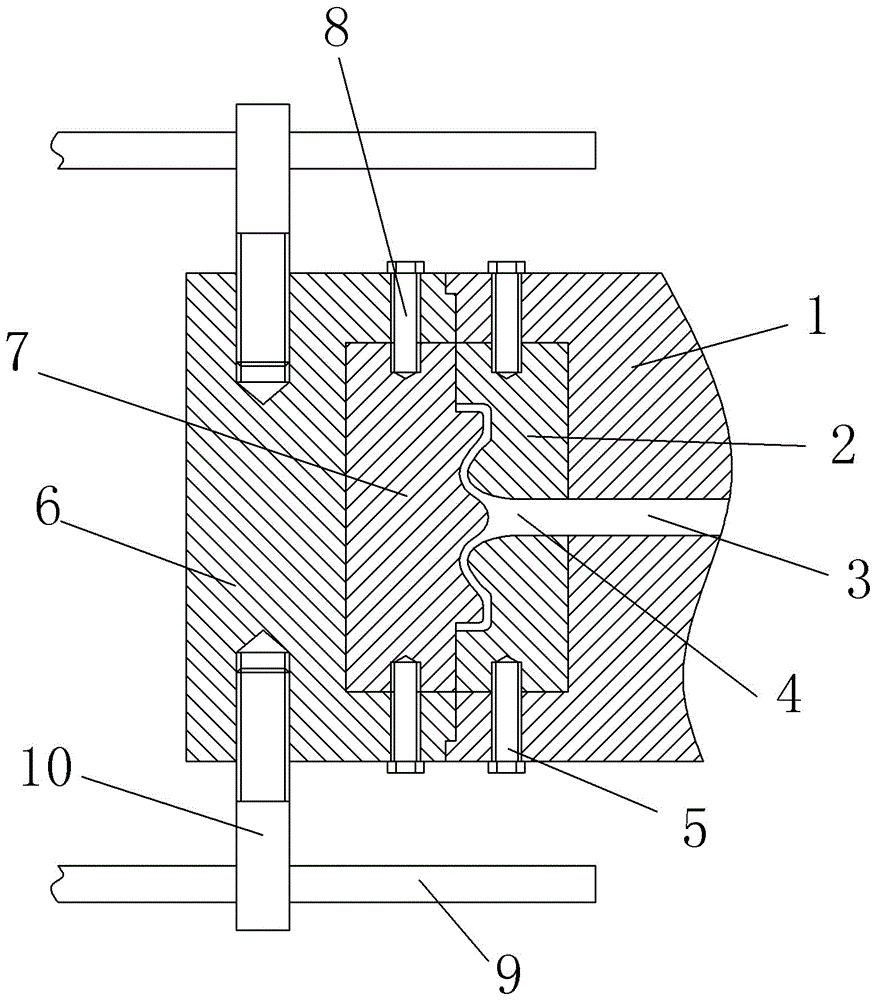

The invention provides a mold and a method for injection molding of a high-compression resistance and long-life notebook computer baseboard shell. The mold comprises: a fixed mold plate; a fixed moldblock arranged on the fixed mold plate and provided with a fixed mold groove; two support rods arranged outside two ends of the fixed mold plate, wherein slide blocks respectively sleeve the two support rods; a mobile mold block respectively connected with the slide blocks through connecting rods, wherein the lower surface of the mobile mold block is provided with a mobile mold groove, and the upper surface of the mobile mold block is provided with an injection through hole; two driving motors arranged at the outside ends of the two support rods and being in transmission connection with the slide blocks; an injection unit; and a PLC in communication connection with the driving motors, an extrusion motor and a heat source respectively in order to control the driving motors, the extrusion motor and the heat source. The mold has the advantages of compact structure, reasonable design, effectiveness and quickness in completing an injection molding process, accuracy in mold clamping, high in-place rate, high automation degree, low producing and manufacturing cost, and good economic benefit.

Owner:太仓市众翔精密五金有限公司

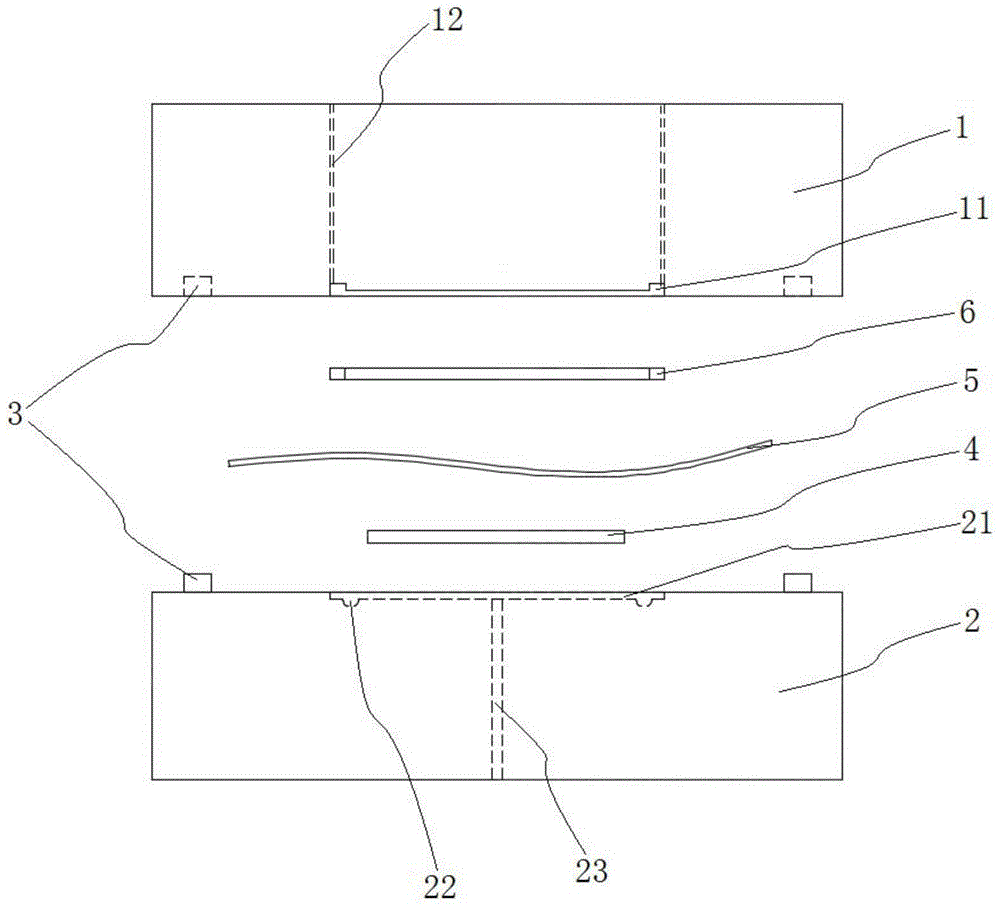

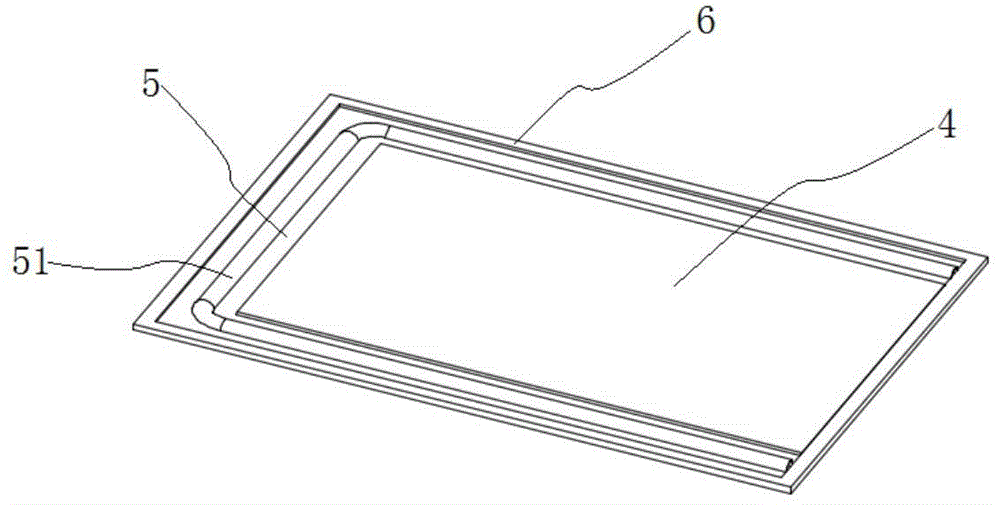

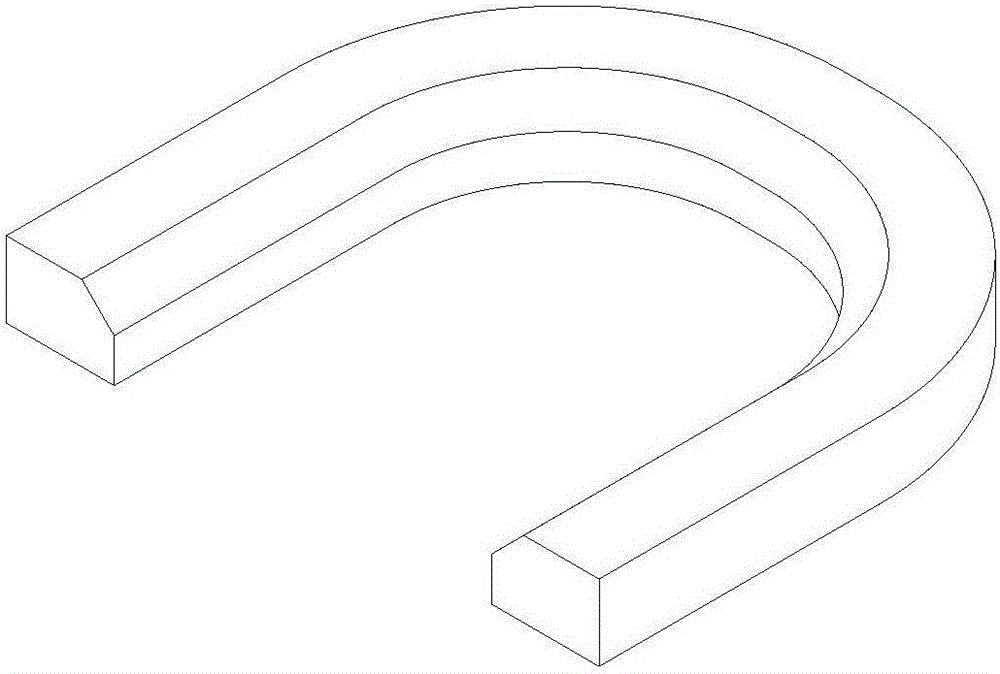

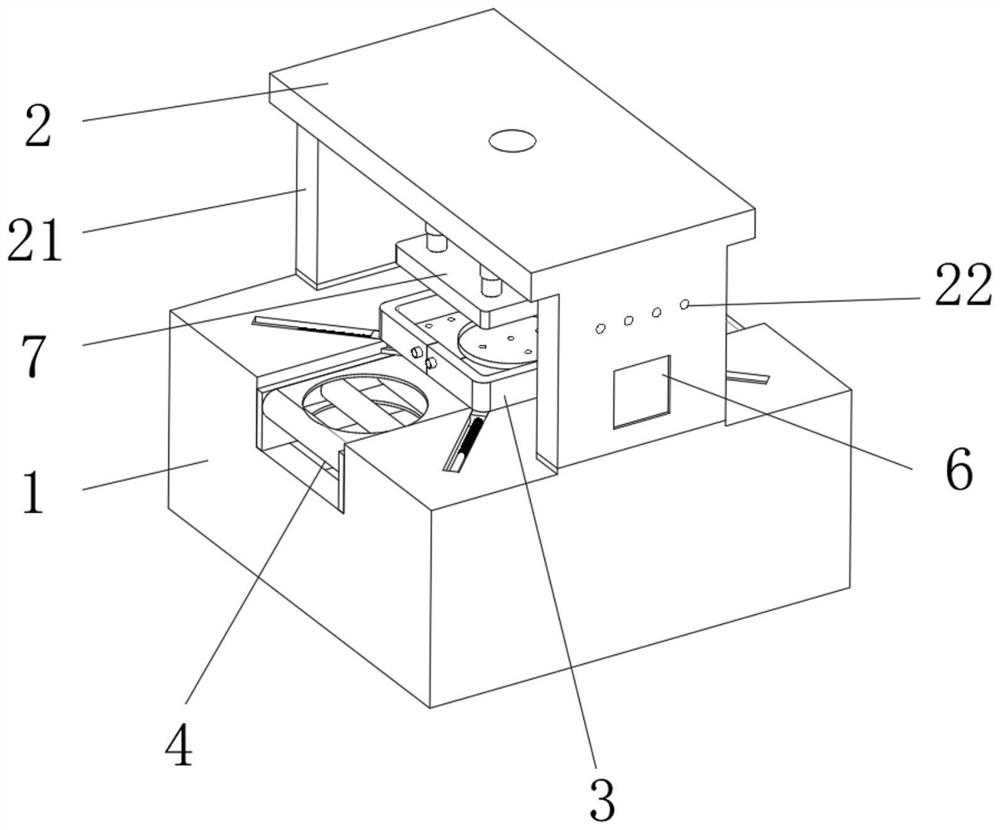

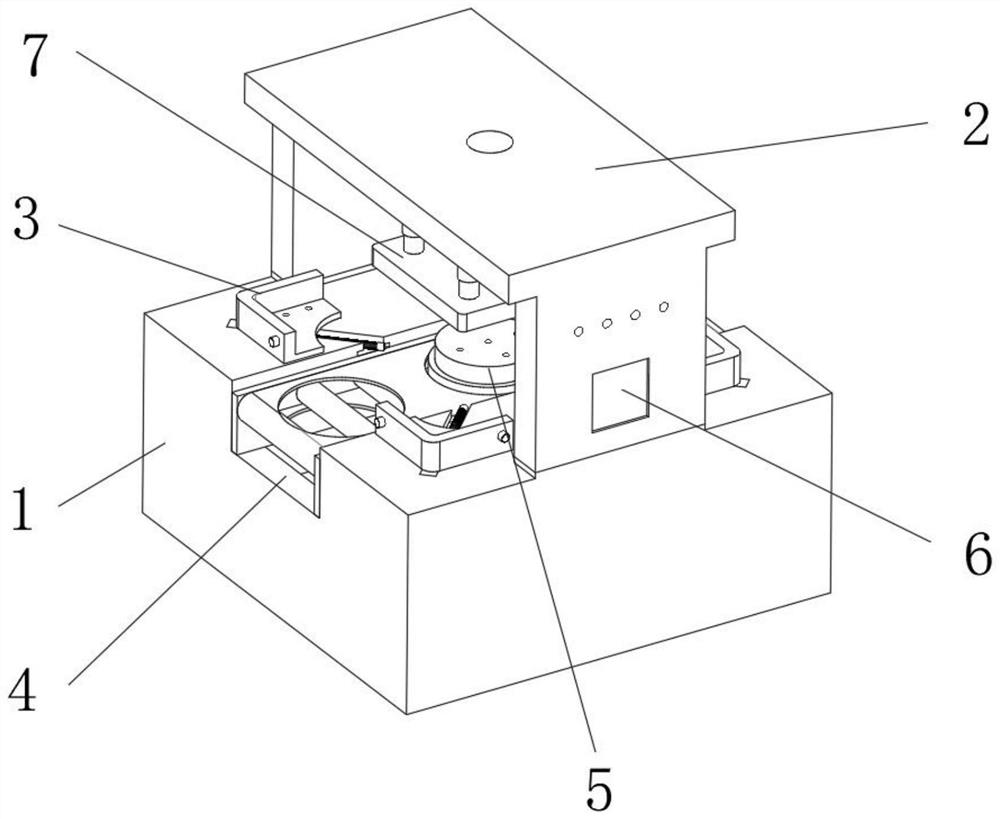

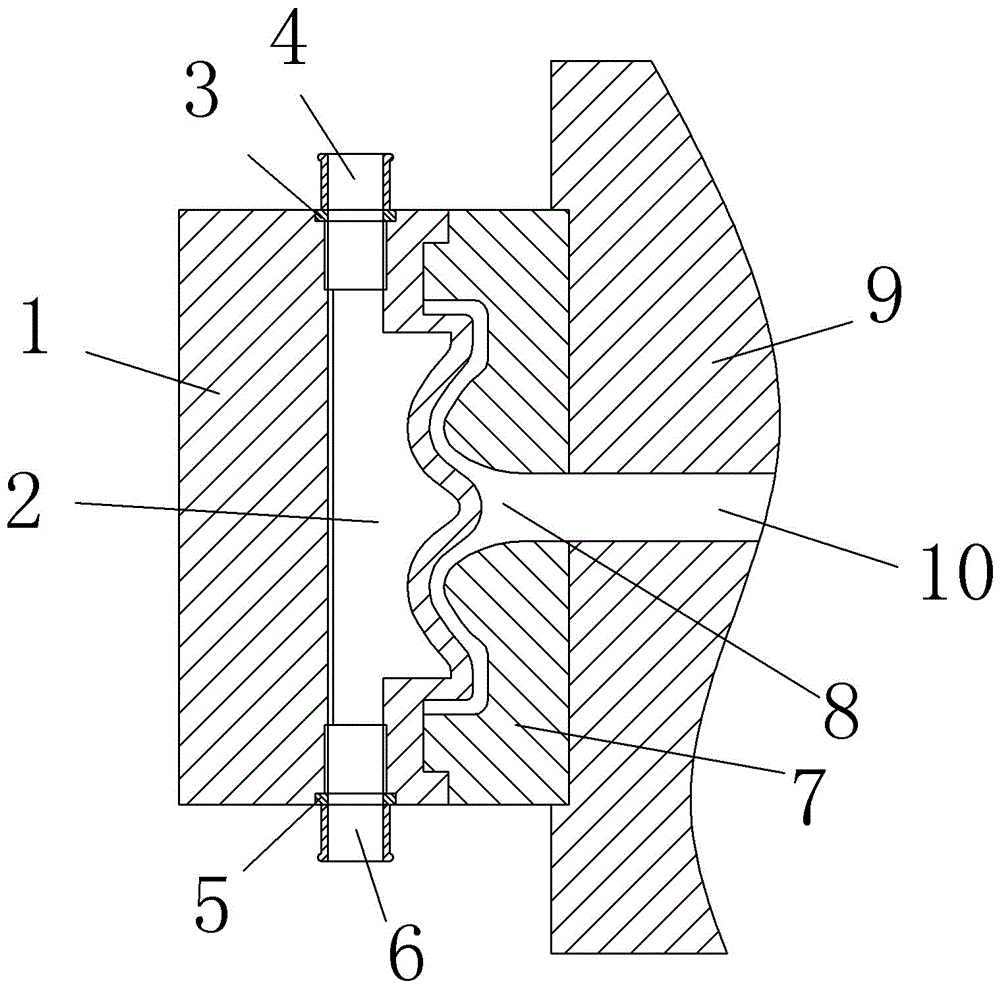

Vibration film production technology of moving iron unit

ActiveCN105681998AImprove acoustic performanceAvoid damageElectrical transducersConvex structureEngineering

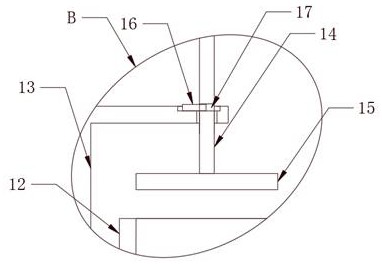

The invention discloses a vibration film production technology of a moving iron unit, and belongs to the technical field of a loudspeaker. According to the vibration film production technology of the moving iron unit provided by the invention, a vibration film body, a thin film and a vibration film bracket are connected together by utilizing a hot-pressing technology; in a hot-pressing process, the thin film is blown and sucked by a gas; and therefore, the thin film extends to a runway cavity in a die to form a runway. According to the technology provided by the invention, in the hot-pressing technology of the vibration film, a runway structure is formed by skillfully utilizing gas pressure; compared with the existing technical solution of forming the runway by adopting a concave-convex structure, the thin film is not stretched and extruded by the die; the runway structure on the thin film is not damaged; the processed vibration film is high in precision; the product quality is stable and reliable; and therefore, the acoustic performance of the moving iron unit is improved.

Owner:CHANGZHOU AMT

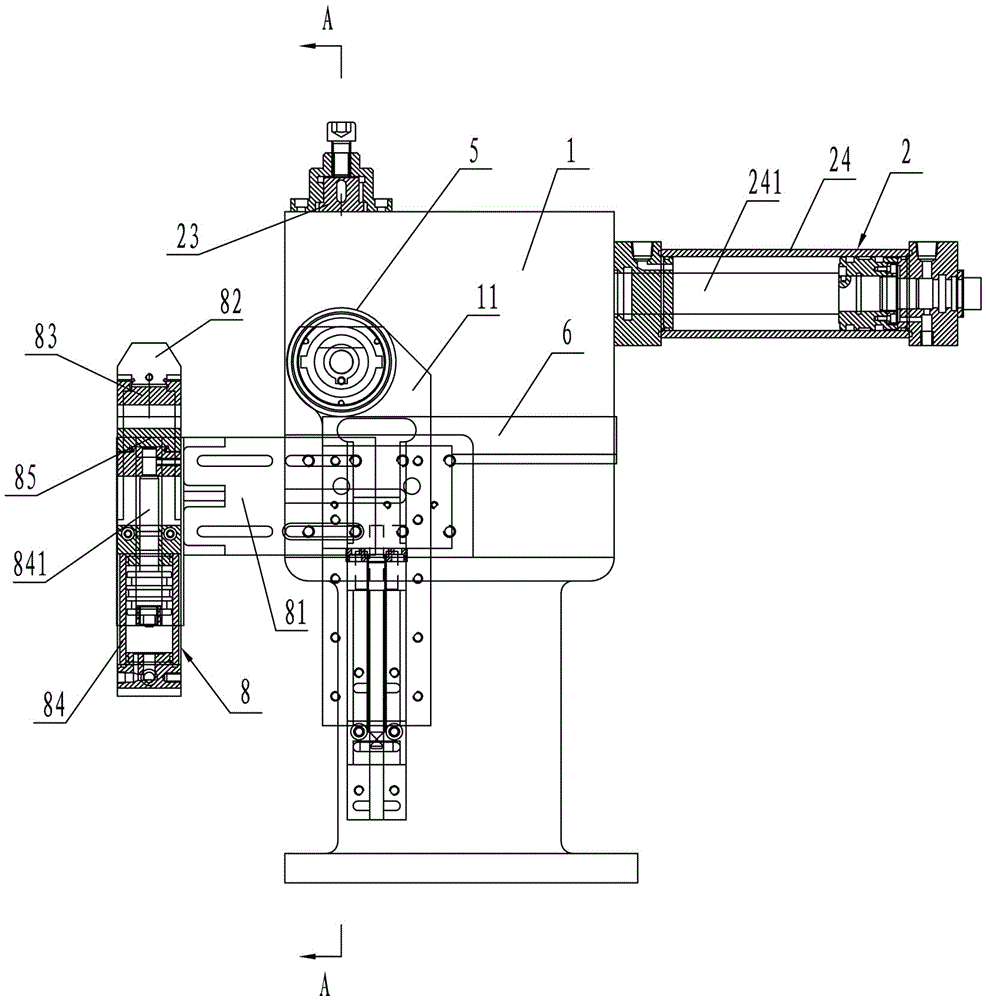

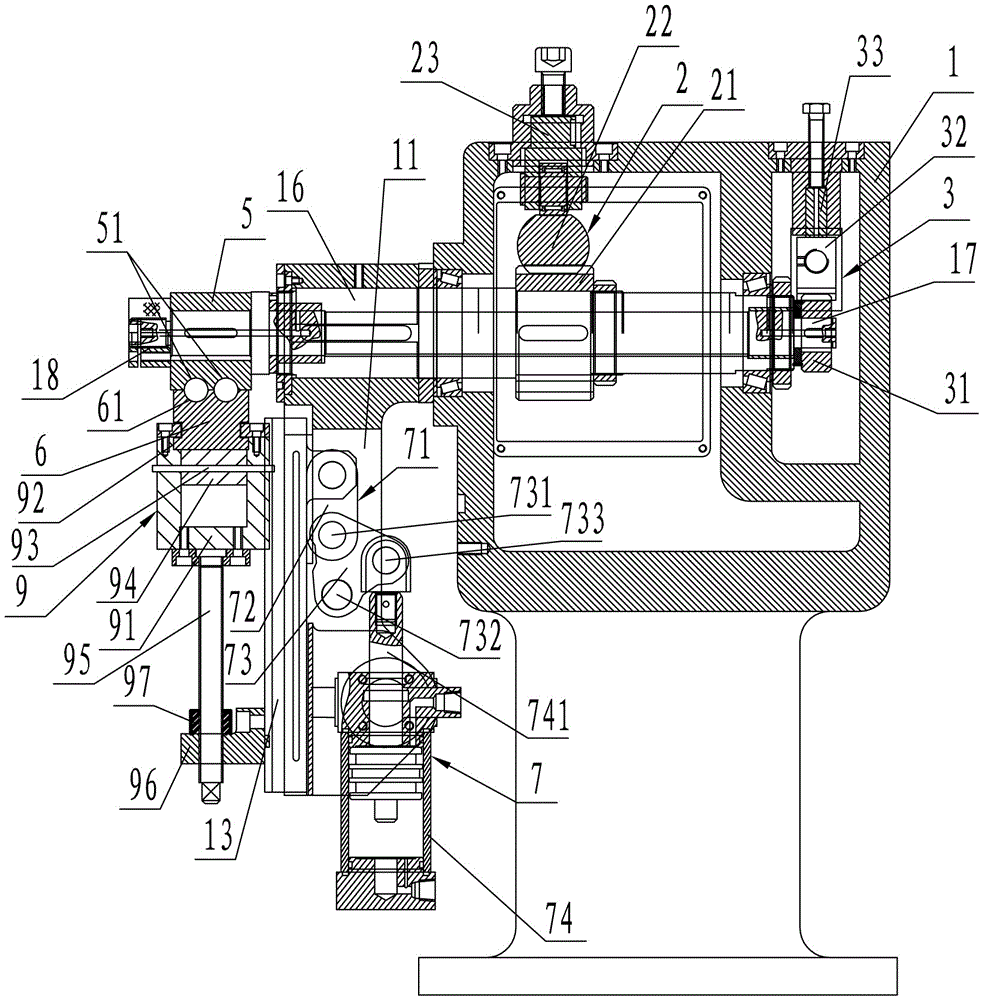

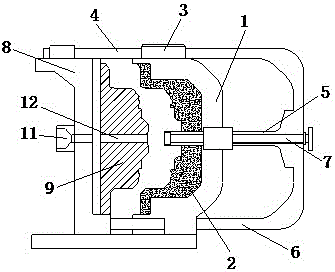

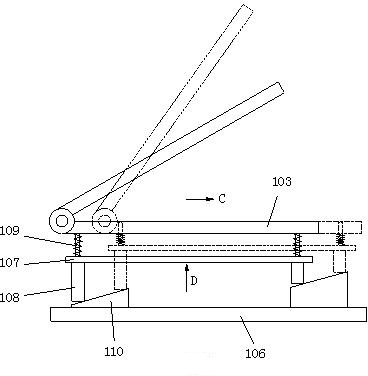

Pipe-bending forming mechanism in pipe bending machine

InactiveCN105522025APrevent movementGuarantee molding qualityMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

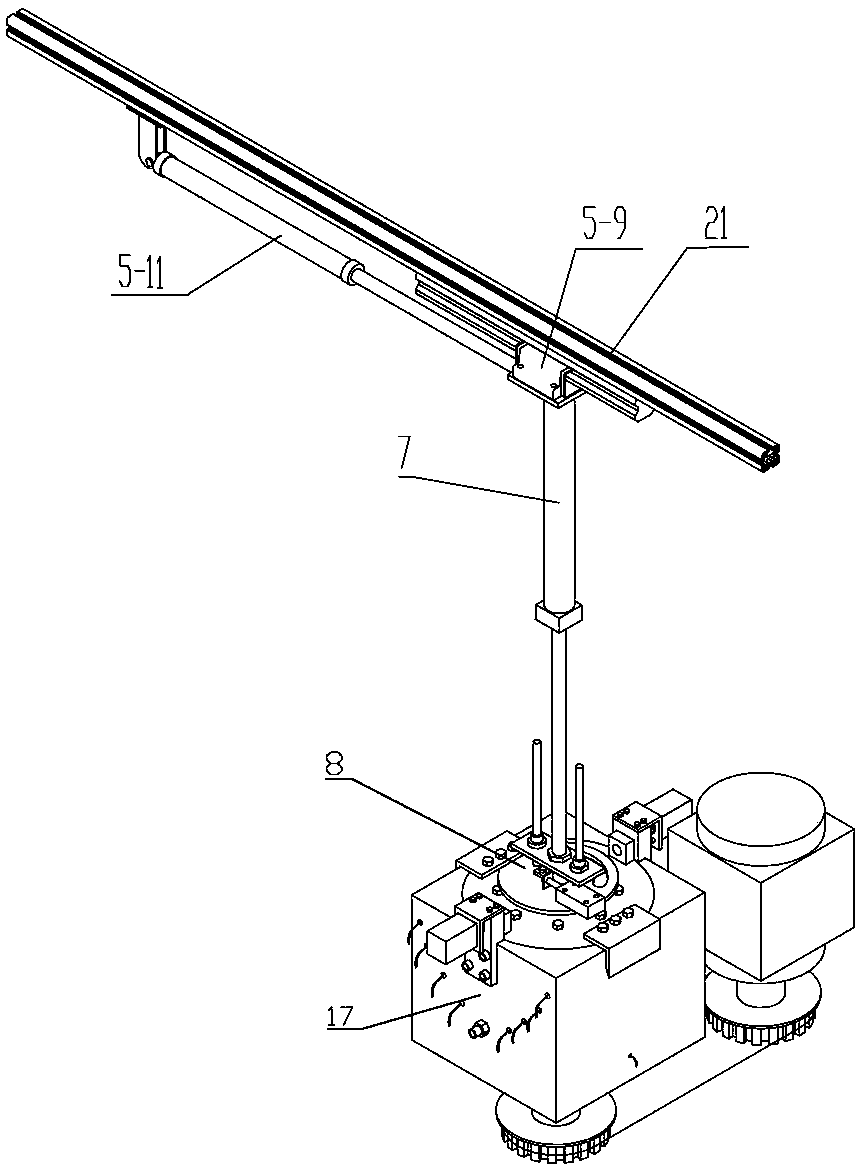

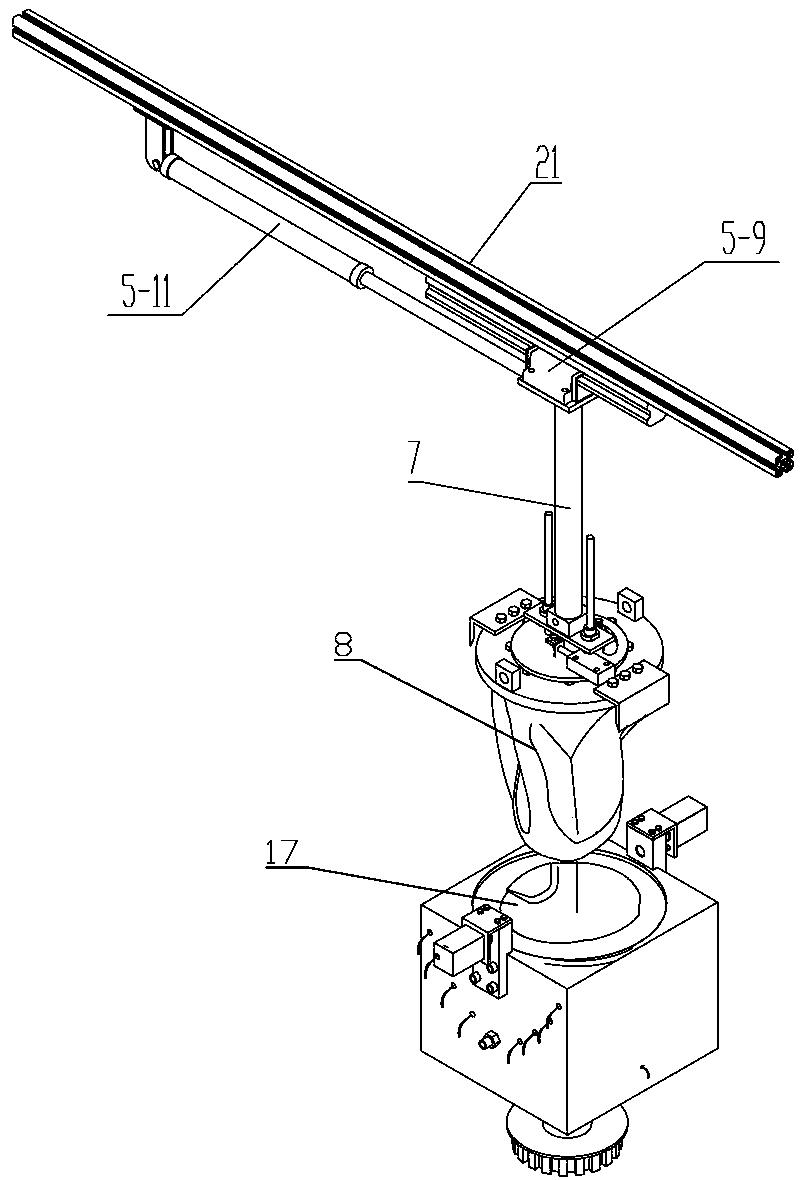

The invention discloses a pipe-bending forming mechanism in a pipe bending machine and belongs to the field of pipe bending machines. The pipe-bending forming mechanism in the pipe bending machine comprises a machine shell. A main shaft is movably supported in the machine shell and arranged in the horizontal direction. A main driving mechanism is arranged on the main shaft. A pipe bending arm is arranged at the front end of the main shaft. A die rotating shaft is movably arranged in the main shaft. Both the front end and the rear end of the die rotating shaft stretch out of the main shaft. A bending die is arranged at the front end of the die rotating shaft. A clamping die is arranged below the bending die. A die stripping driving mechanism is arranged at the rear end of the die rotating shaft. A die assembly driving mechanism and a sliding rail are arranged on the pipe bending arm. A sliding block is arranged in the sliding rail. The two sides of the sliding block are connected with the die assembly driving mechanism and a die assembly adjustment component respectively, and the die assembly adjustment component is used for adjusting the distance between the clamping die and the bending die. The die assembly adjustment component is connected with the clamping die. The clamping die and the bending die can be driven by the die assembly driving mechanism to be assembled or separated. The pipe-bending forming mechanism in the pipe bending machine has the advantages that a pipe to be bent does not need to be held manually when clamped, displacement distance errors, generated when the volume of hydraulic oil changes, of the clamping die can be eliminated, and the maintenance cost can be reduced.

Owner:ZHANGJIAGANG XINGYU MACHINERY MFG

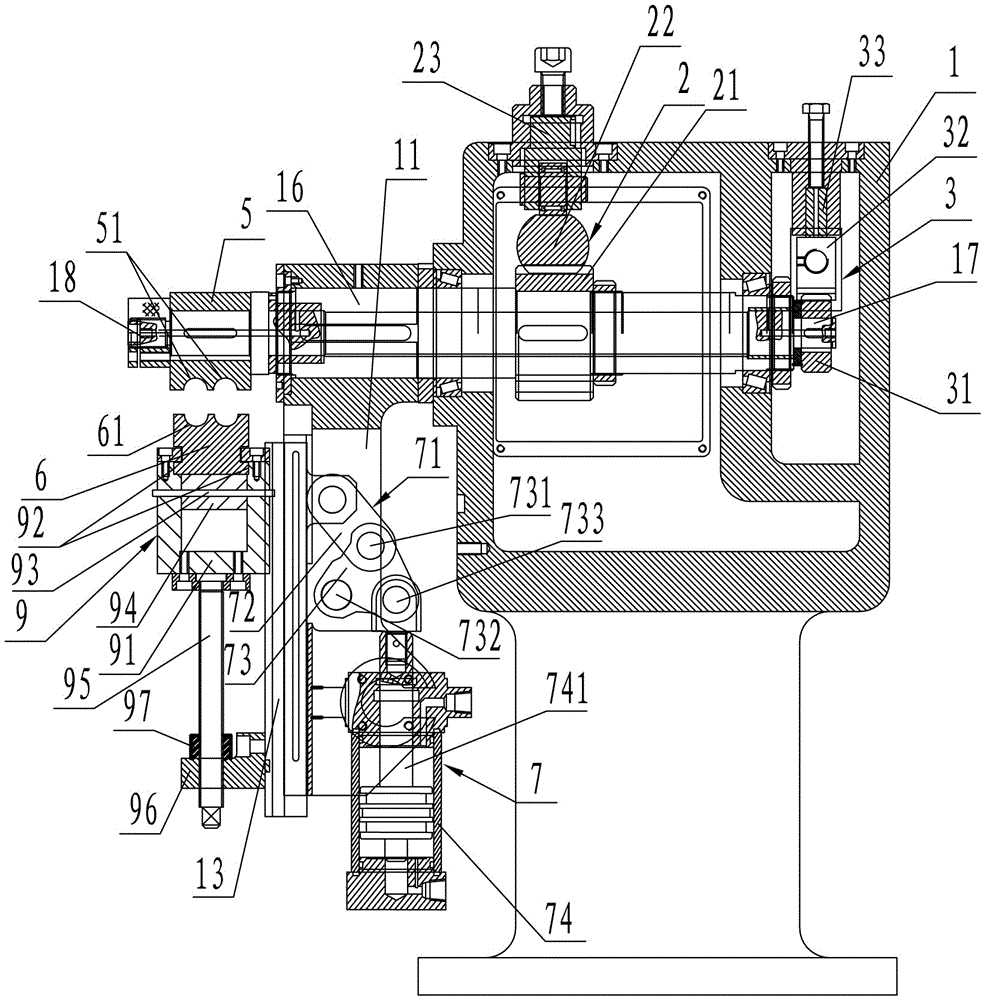

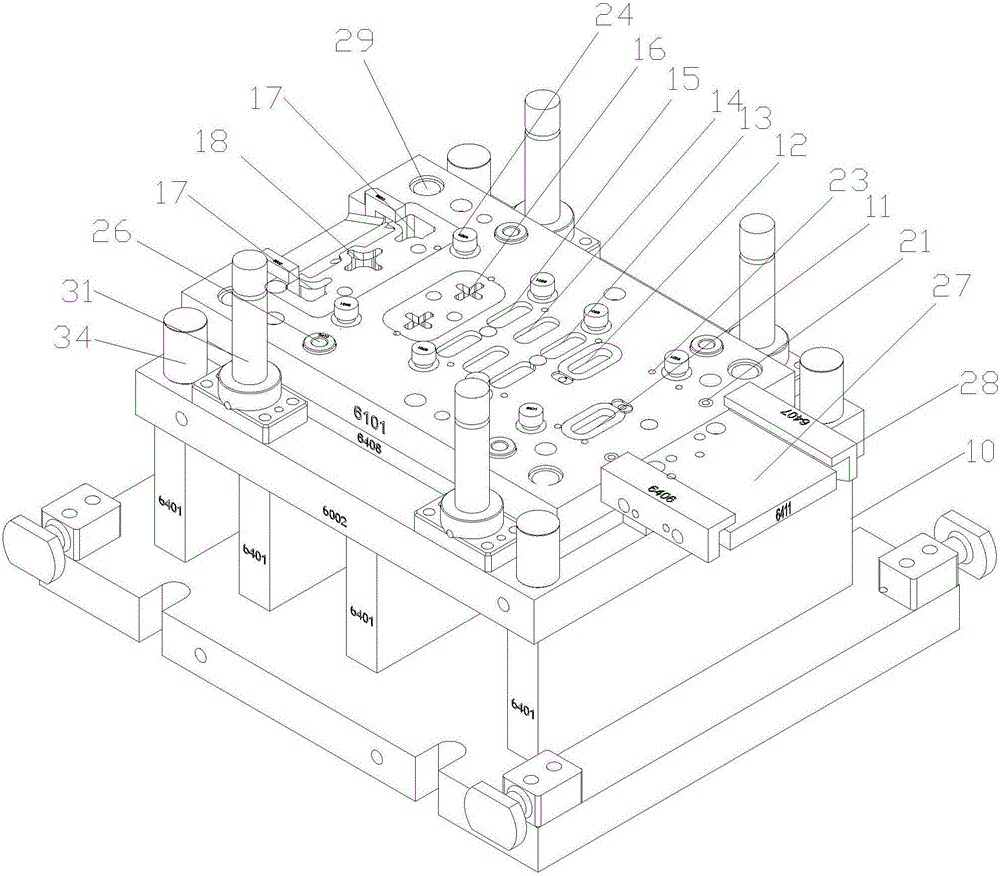

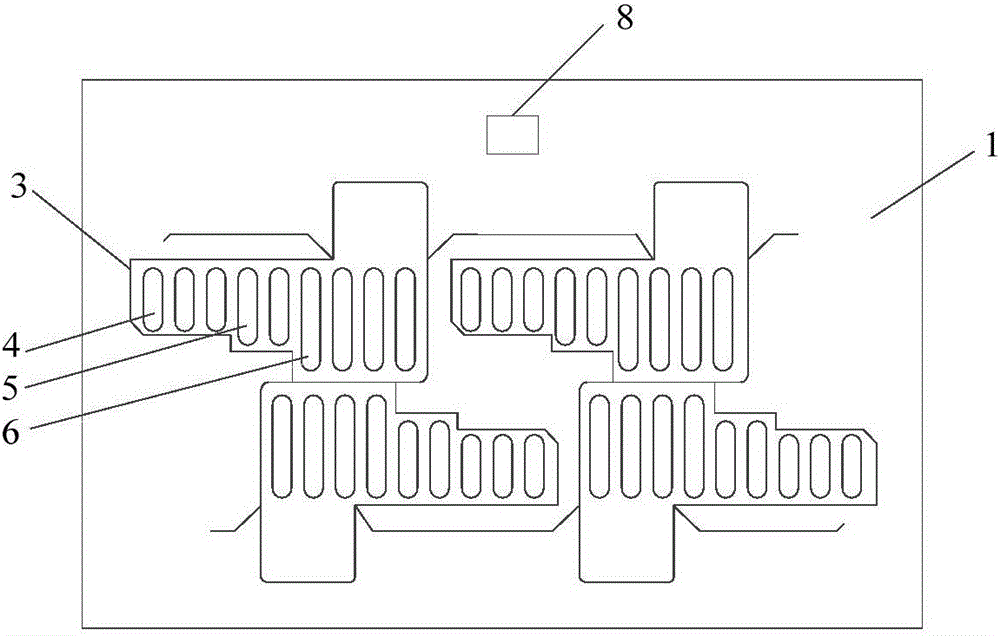

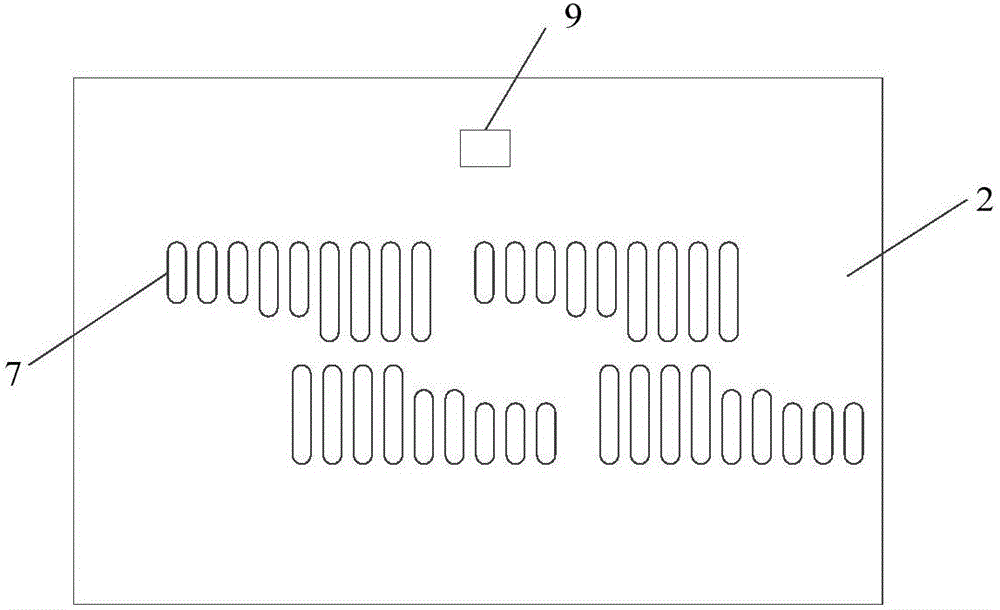

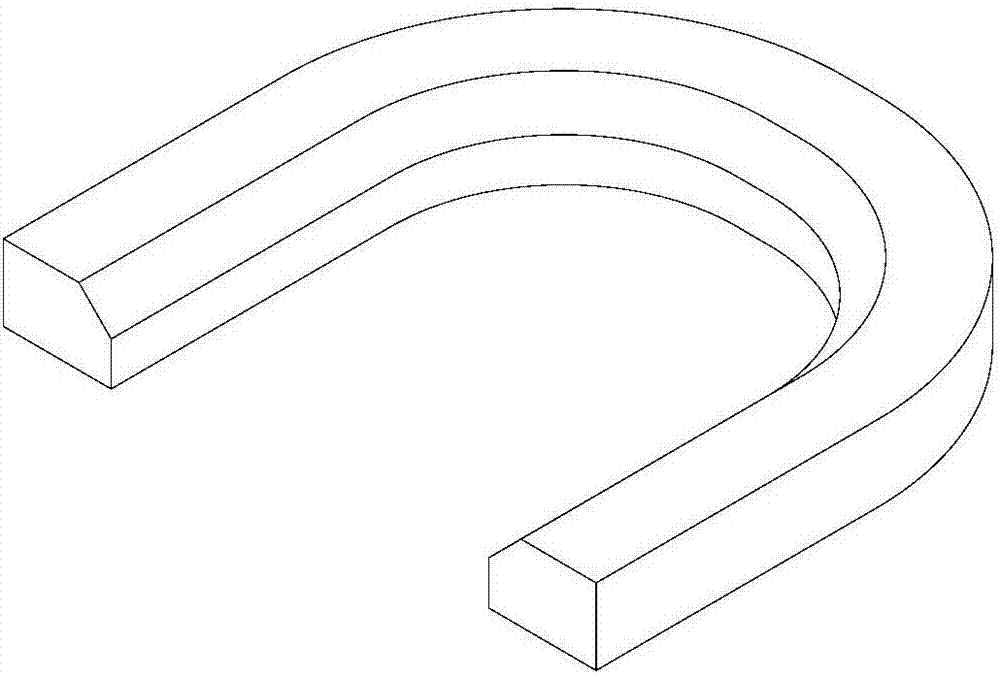

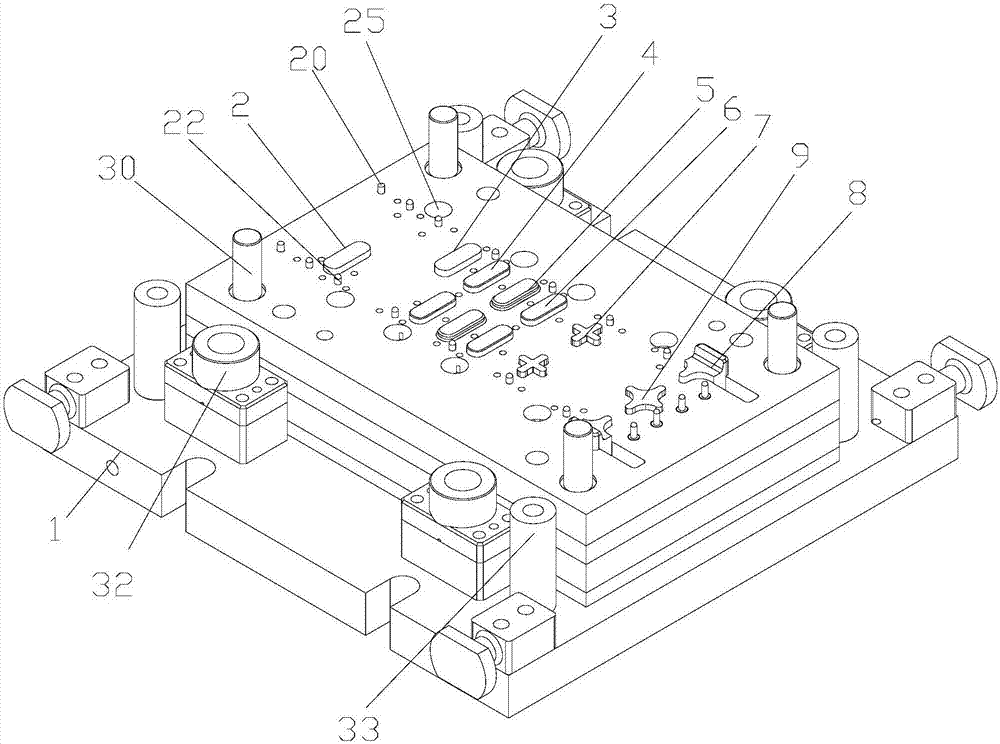

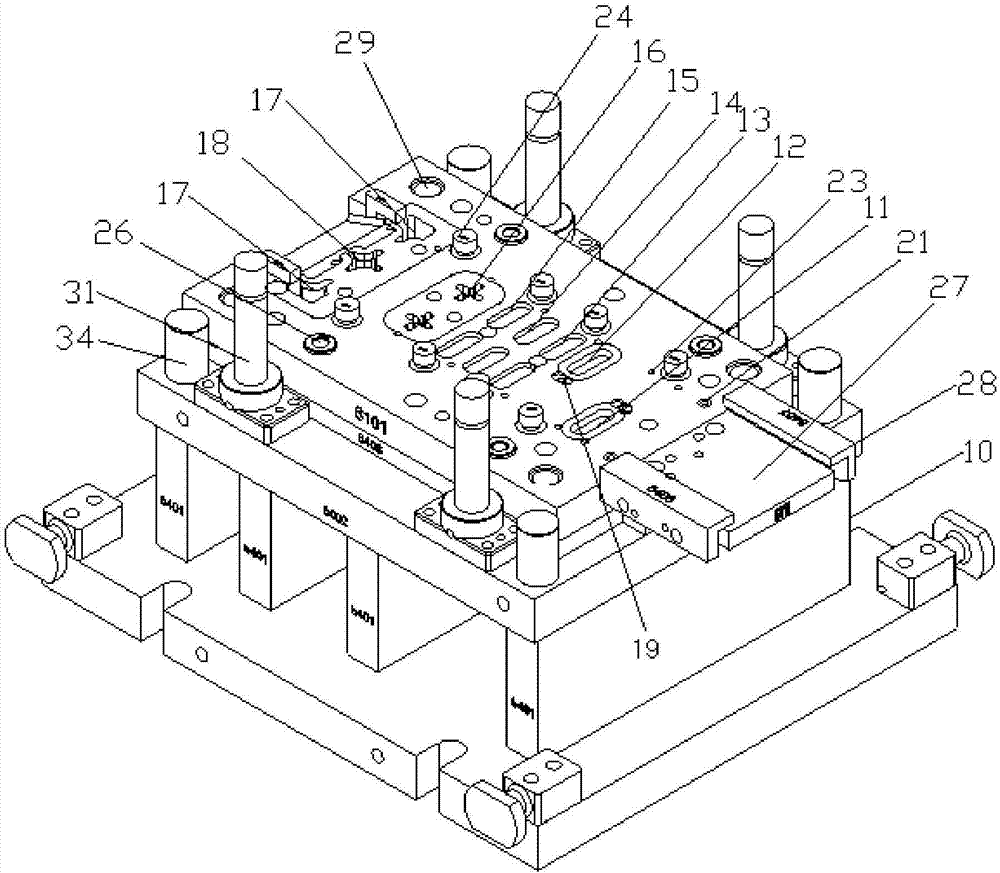

U-shaped piece grading punch forming die

The invention discloses a U-shaped piece grading punch forming die with high production efficiency. The U-shaped piece grading punch forming die comprises an upper die and a lower die, wherein the upper die comprises an upper die holder; a kidney-shaped hole shaped left piercing punch, a right piercing punch, a pair of a first positioning blocks, a pair of kidney-shaped hole shaped forming punches, a pair of a second positioning blocks, a pair of cross-shaped punches and a material dividing punch group are sequentially arranged on the upper die holder starting from the feeding end; the left piercing punch has the same shape as the right piercing punch, the first positioning blocks and the second positioning blocks; the material dividing punch group comprises two T-shaped punches and a large cross-shaped punch; the two T-shaped punches are perpendicular to the feeding direction and are in a straight line; the large cross-shaped punch is arranged between the two T-shaped punches; the lower die comprises a lower die holder; corresponding left piercing groove, a right piercing groove, a pair of first positioning grooves, a pair of forming grooves, a pair of second positioning grooves, a pair of small cross-shaped grooves and a material dividing groove group are sequentially formed in the lower die holder starting from the feeding end; the material dividing groove group comprises two T-shaped grooves and a large cross-shaped groove.

Owner:苏州金鸿顺汽车部件股份有限公司

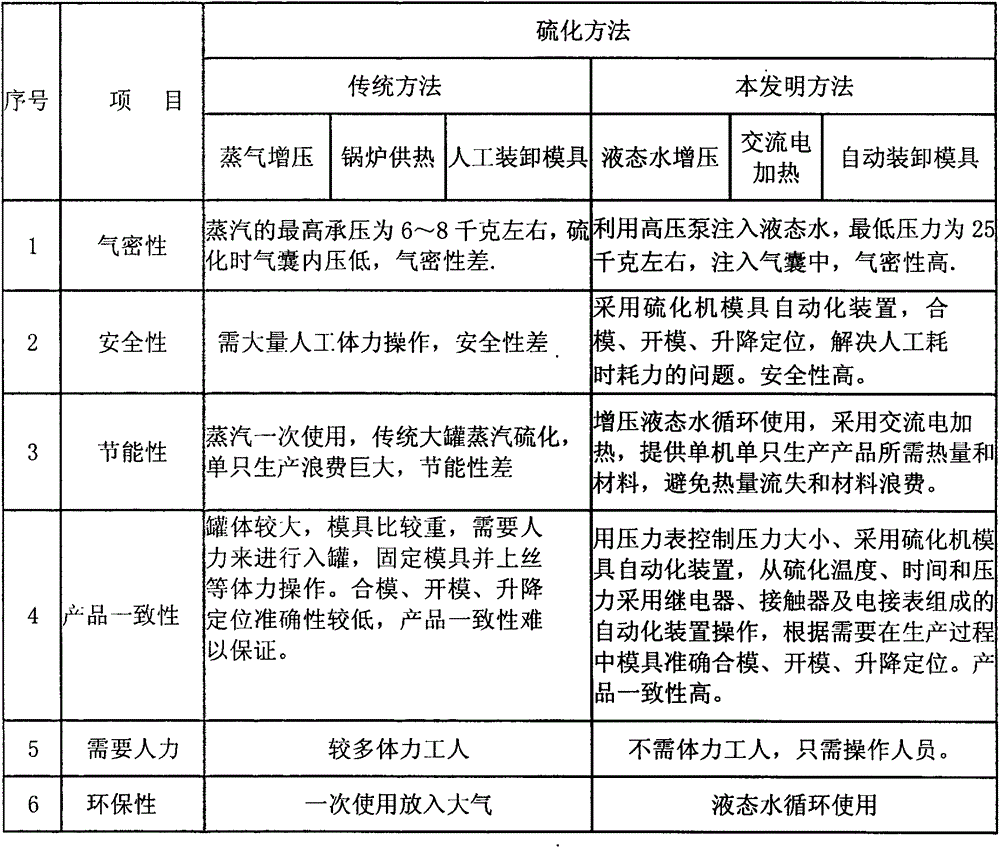

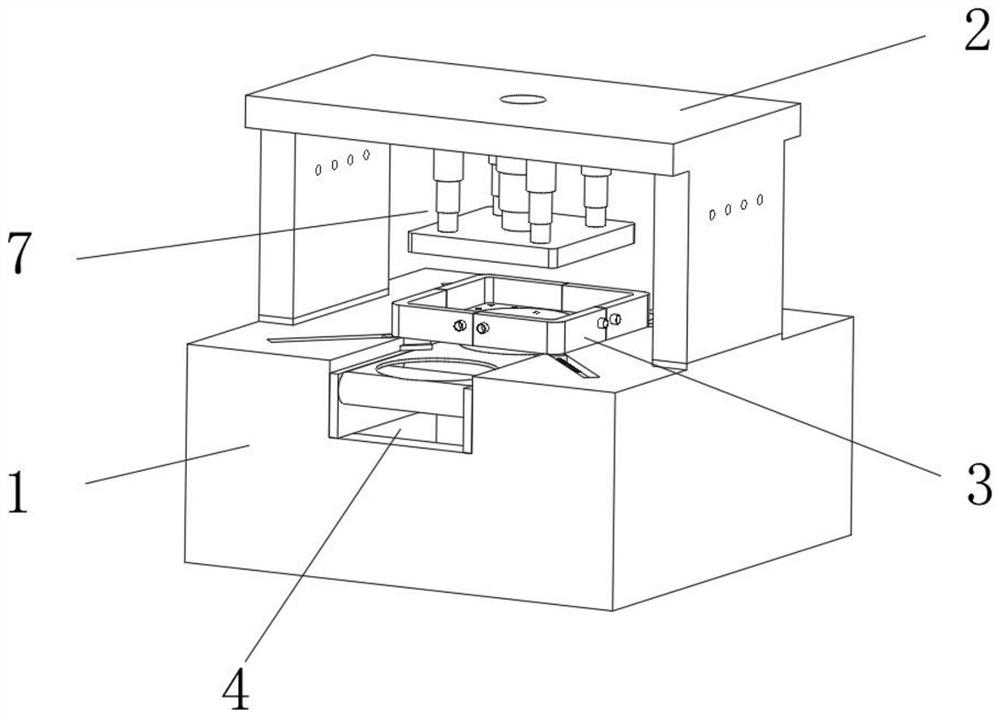

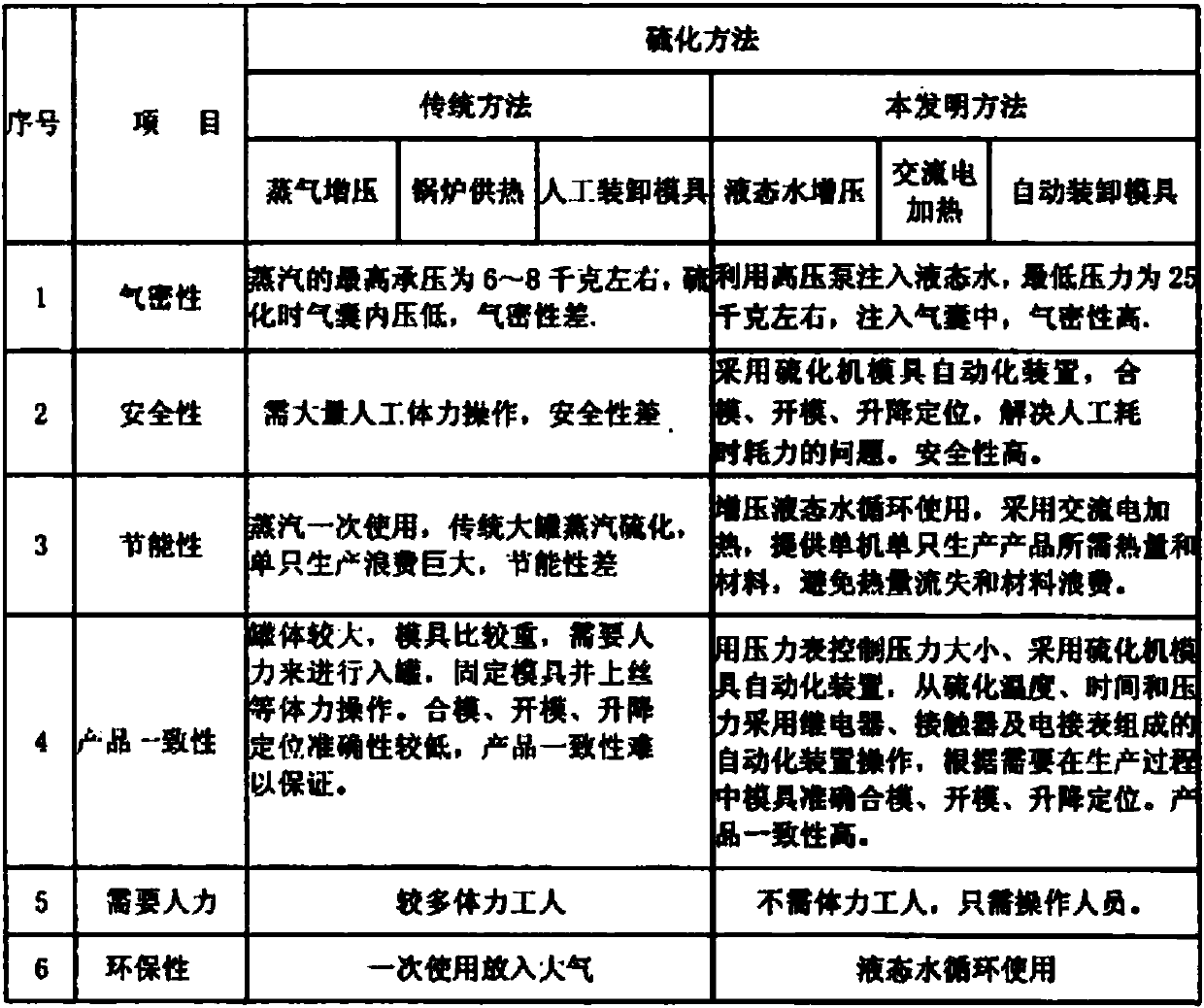

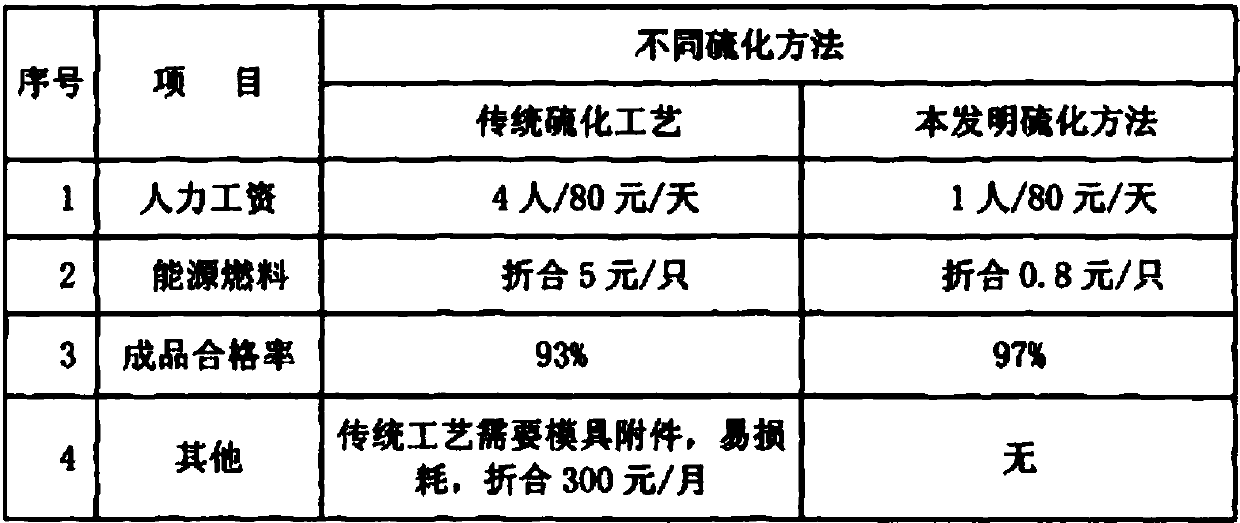

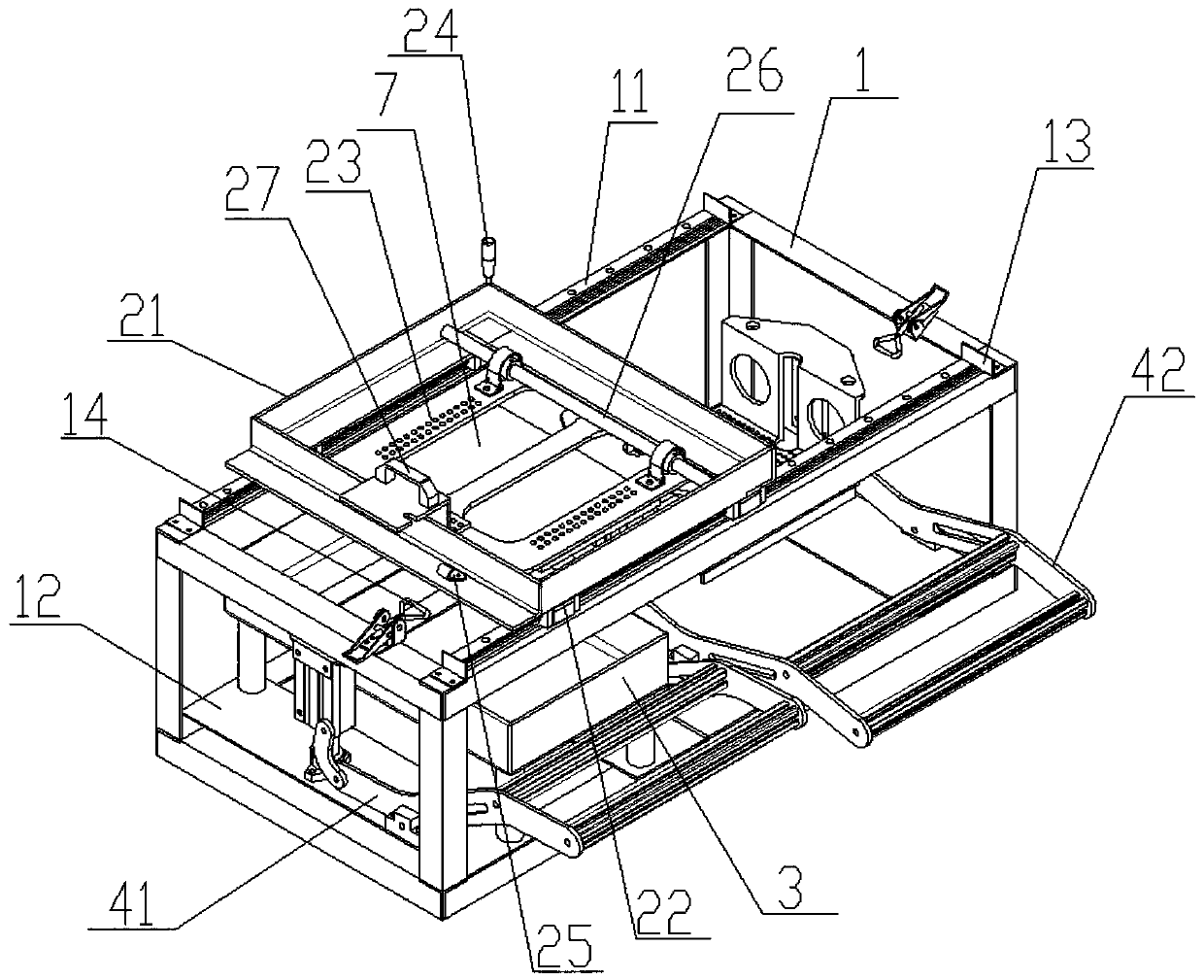

Processing method of pneumatic rubber capsule special for petroleum drilling machine

The invention discloses a processing method of a pneumatic rubber capsule special for petroleum drilling machine. The method consists of six technical steps: rubber mixing, calendaring cutting, extrusion, molding, vulcanization, and packaging, etc. In the vulcanization step, liquid water is injected into a pneumatic rubber capsule by a high-pressure pump, the pressure is controlled by a pressure gauge, thus replacing the steam pressurization used by traditional vulcanization, increasing the internal pressure of the pneumatic rubber capsule during vulcanization, increasing the density of the pneumatic rubber capsule, and optimizing the product quality of the processed pneumatic rubber capsule. Also a pneumatic rubber capsule automated die on a vulcanization machine is adopted during vulcanization production, the vulcanization temperature, time and pressure are adjusted, so that in the production process, the die can achieve accurate die closing, die opening and lifting positioning, thus fundamentally solving the time consuming and labor consuming problems. In addition, liquid water is low in cost and can be recycled, so that the production cost of enterprises can be significantly reduced.

Owner:HENAN DALIN RUBBER & TELECOMM APP

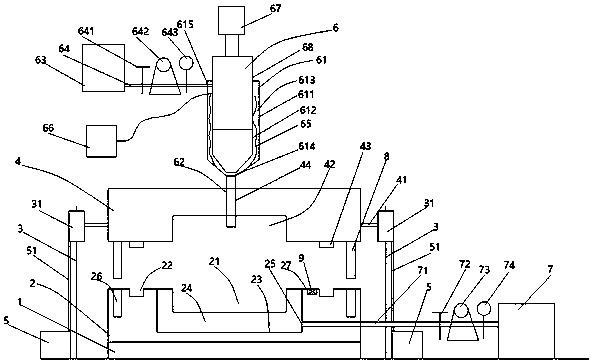

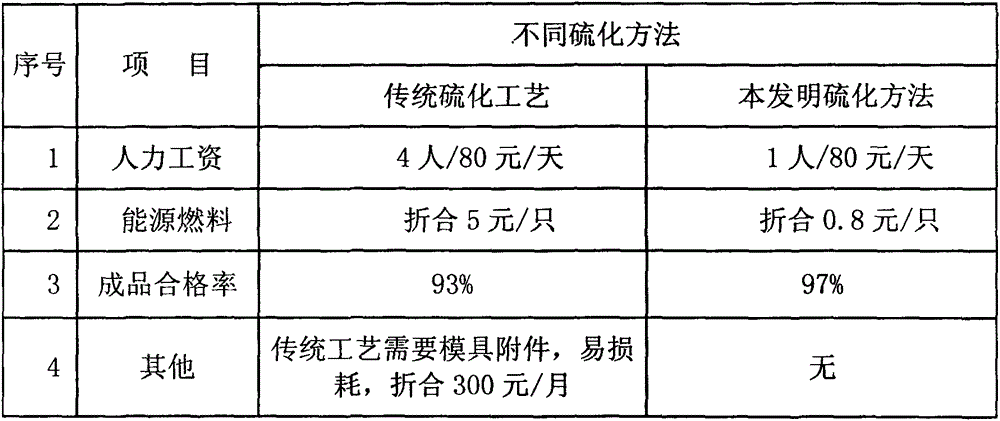

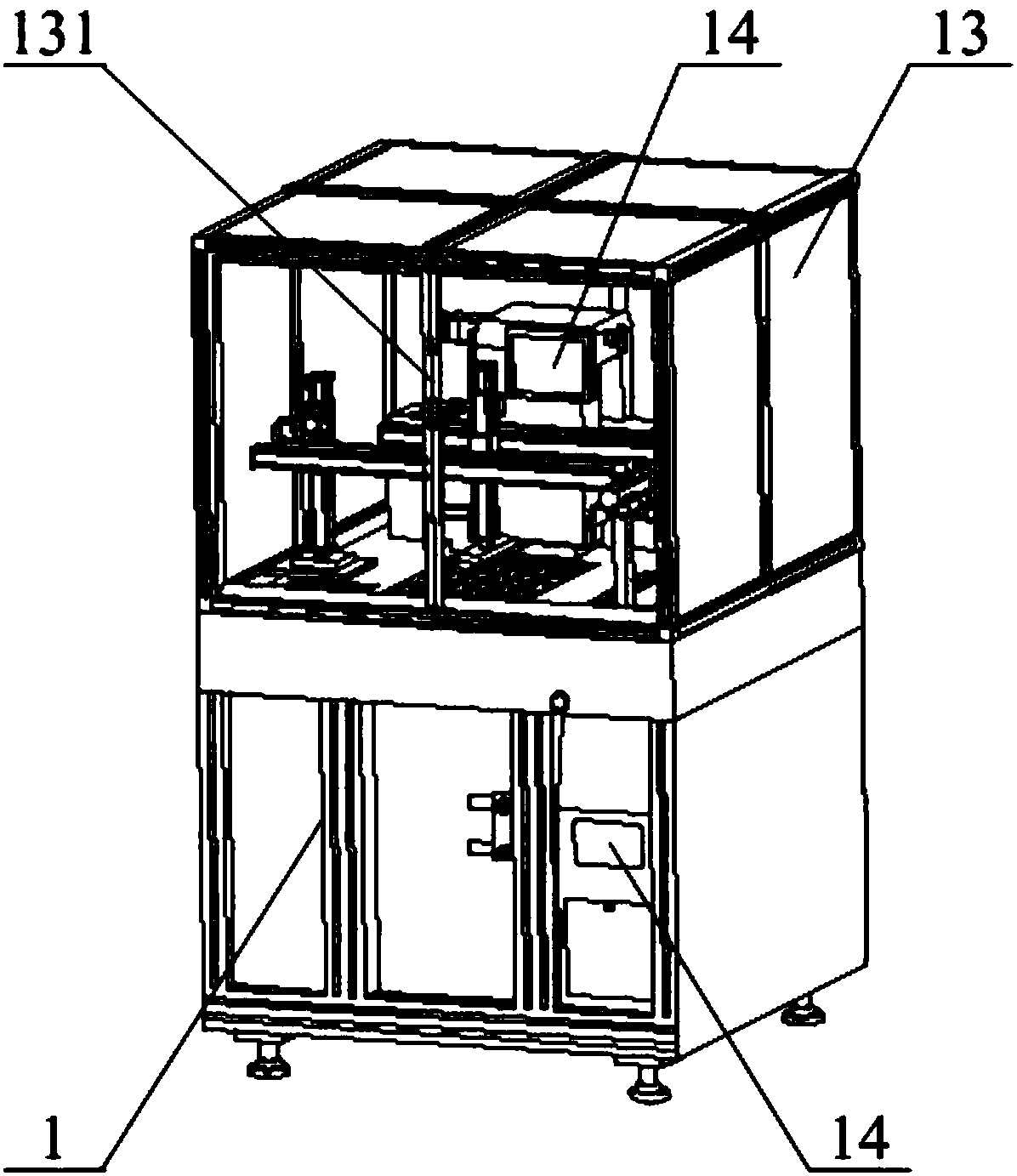

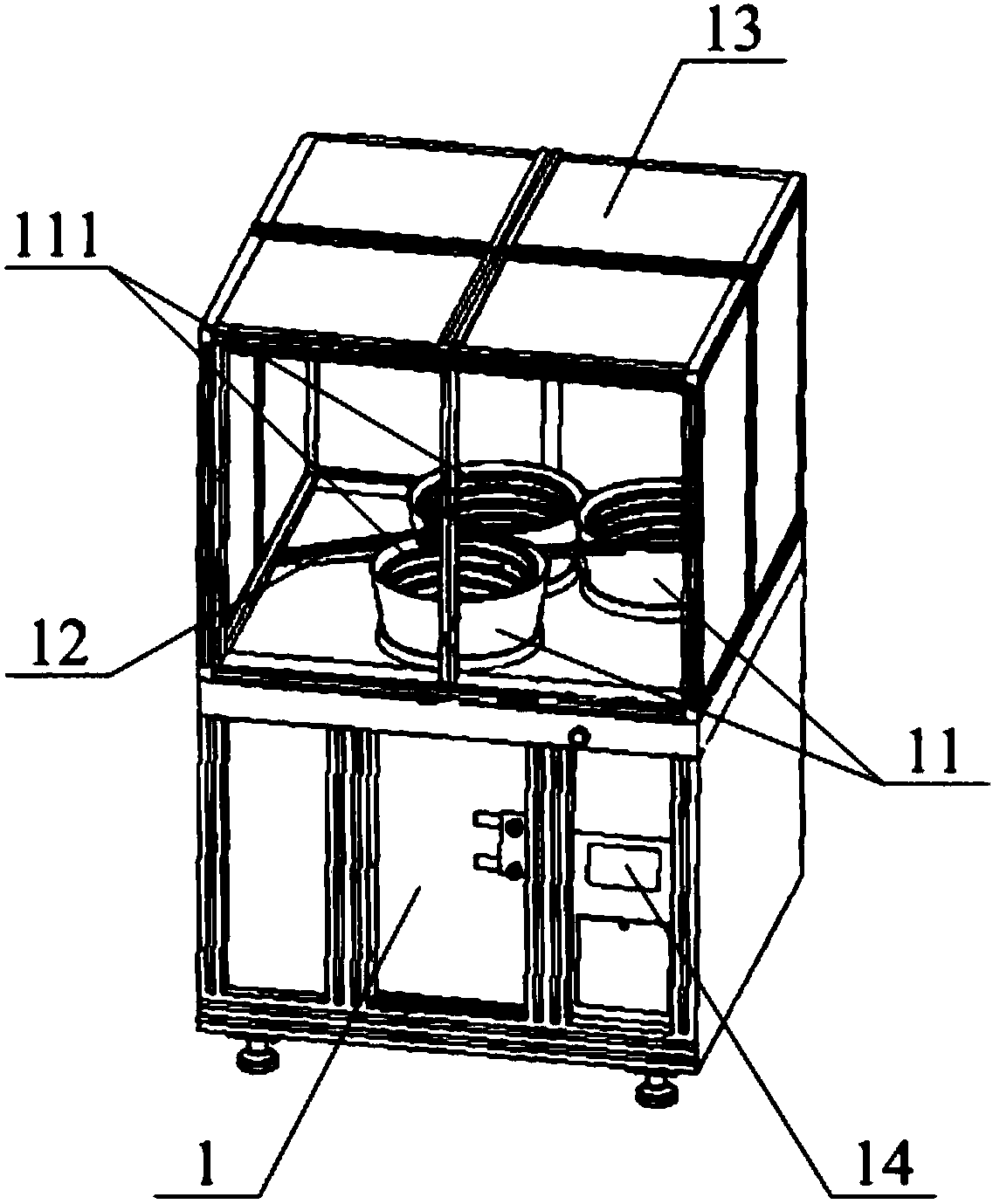

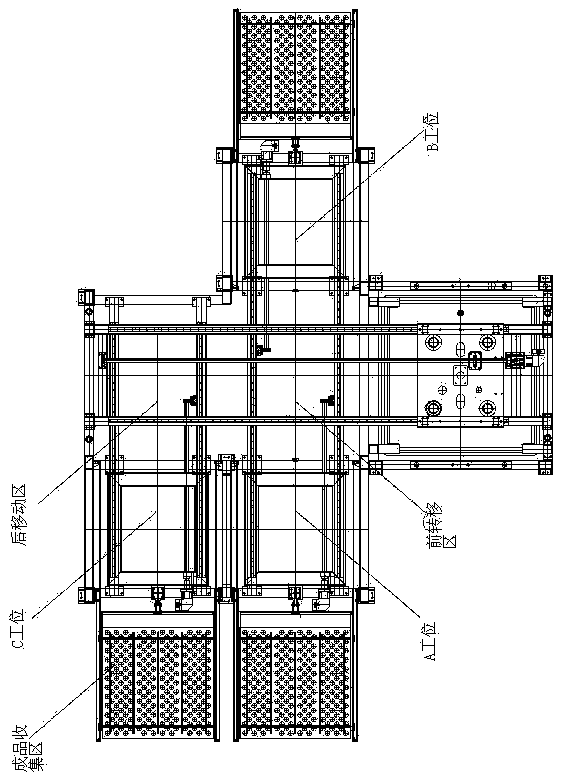

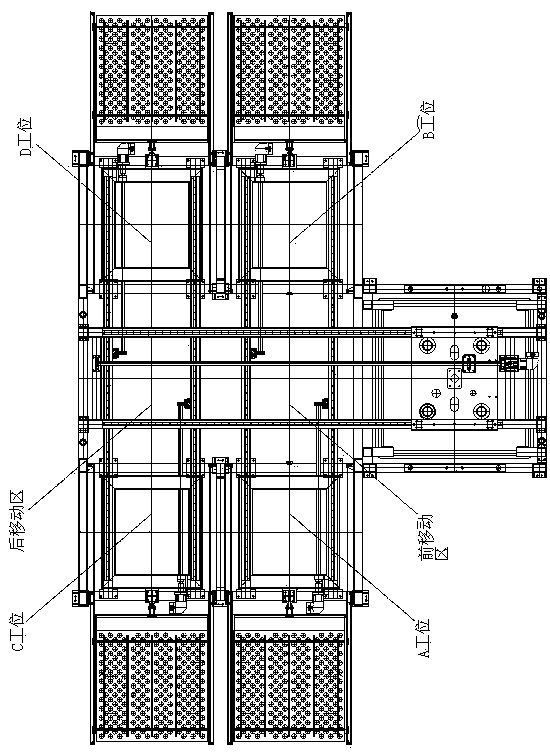

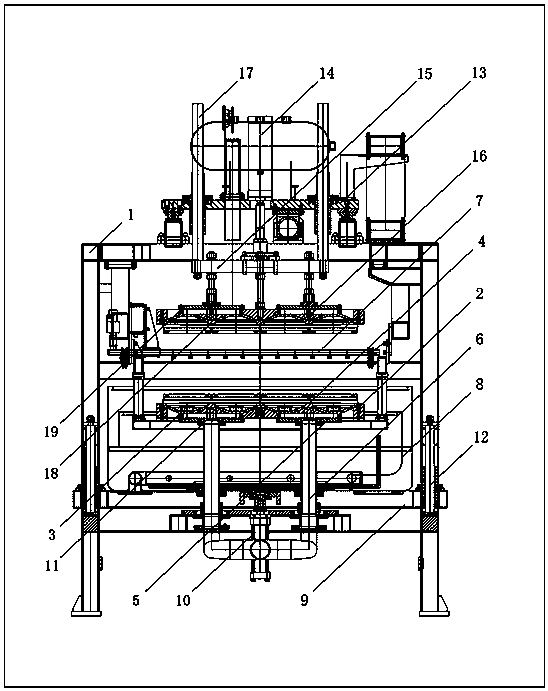

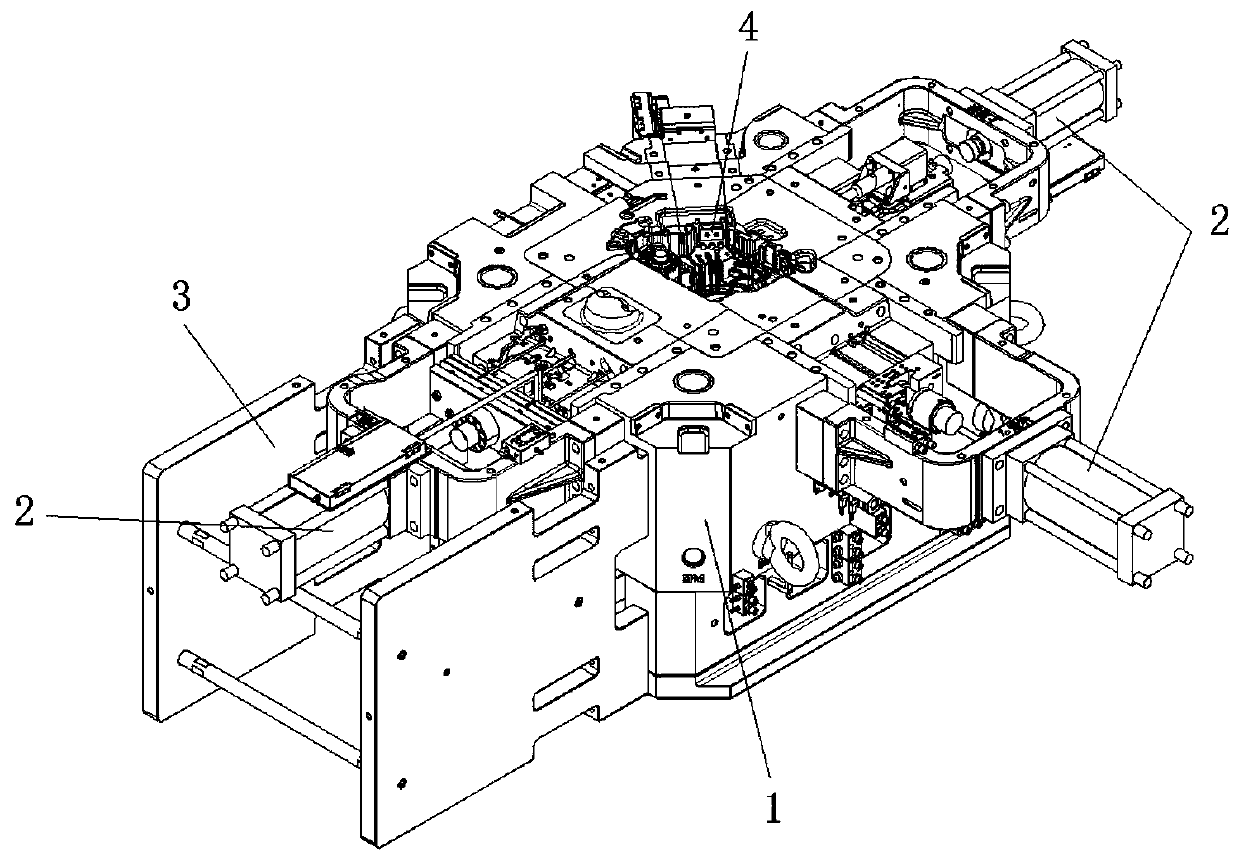

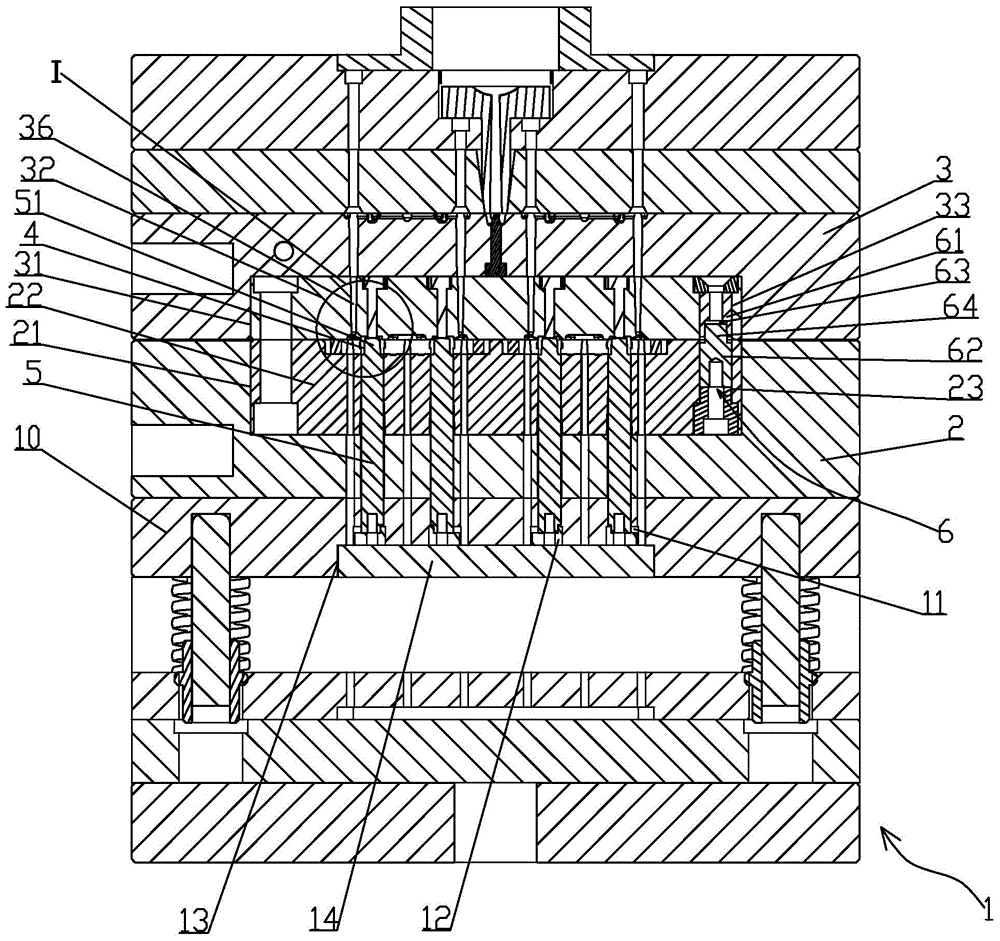

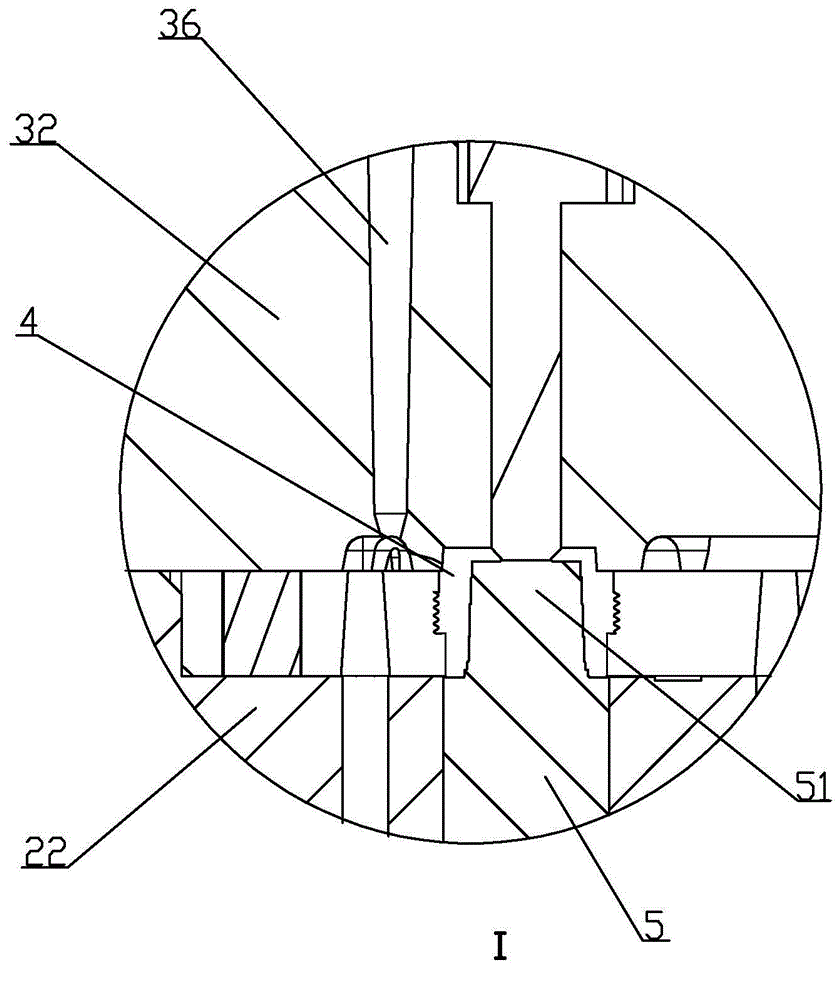

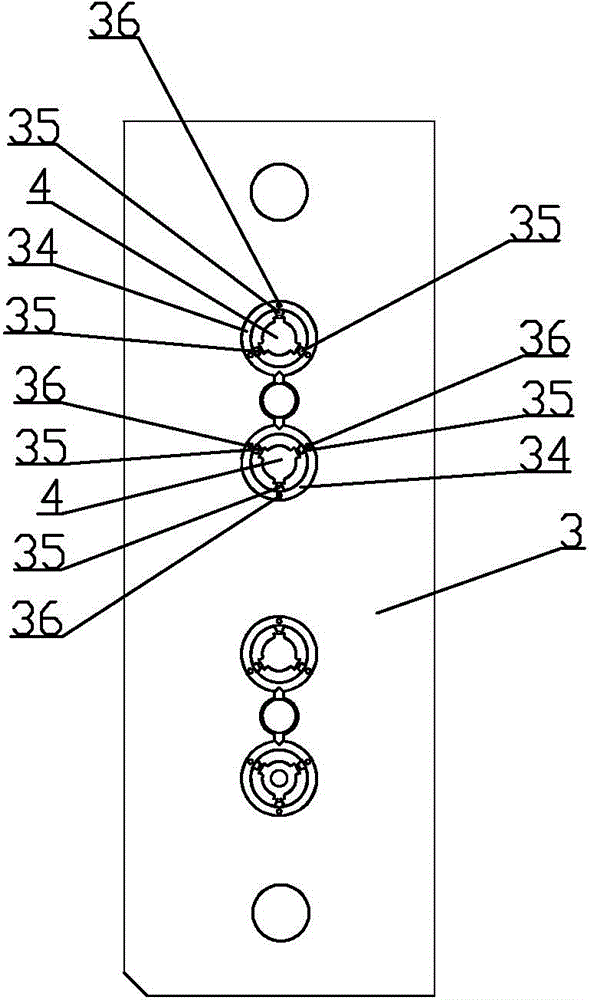

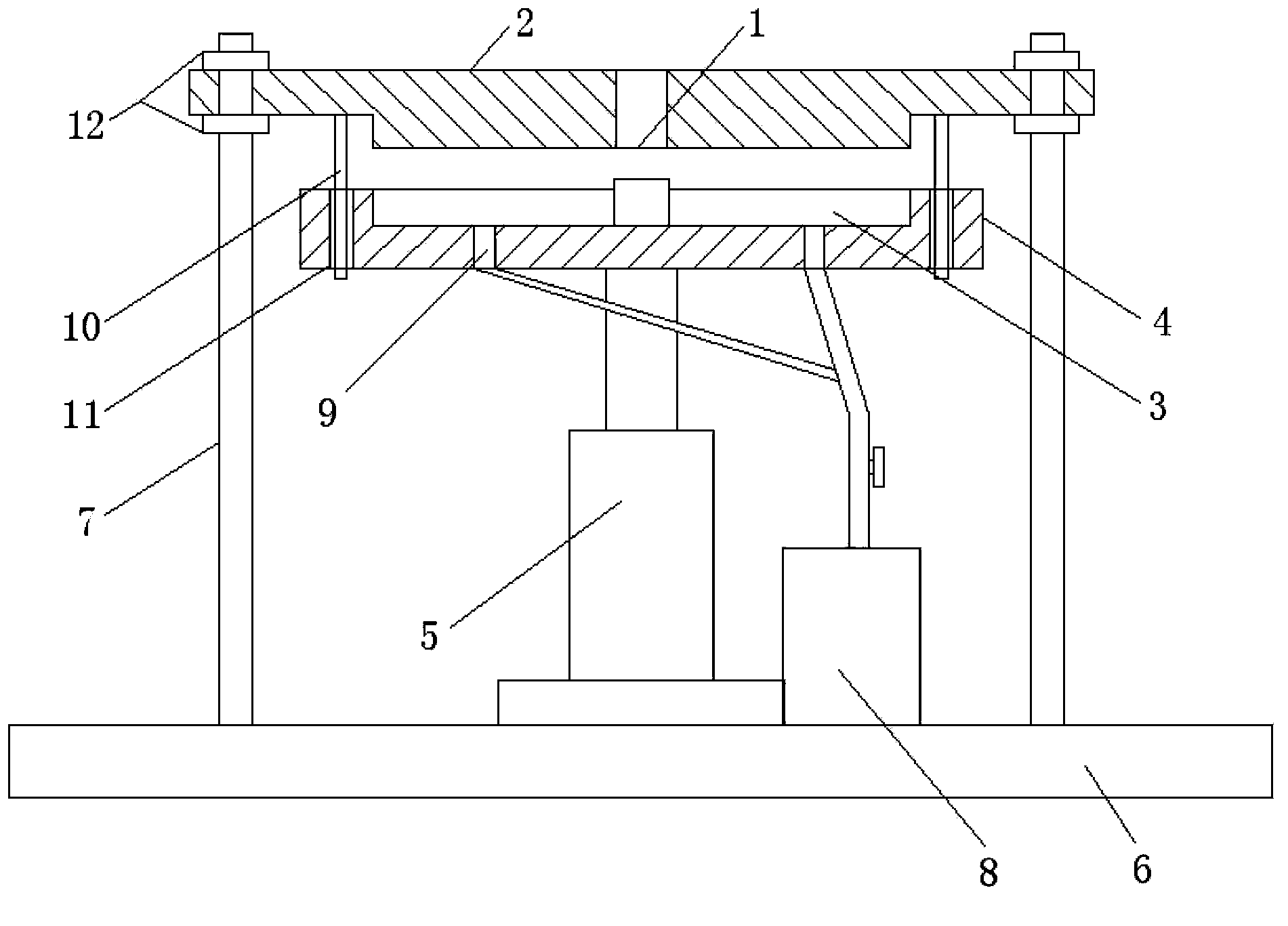

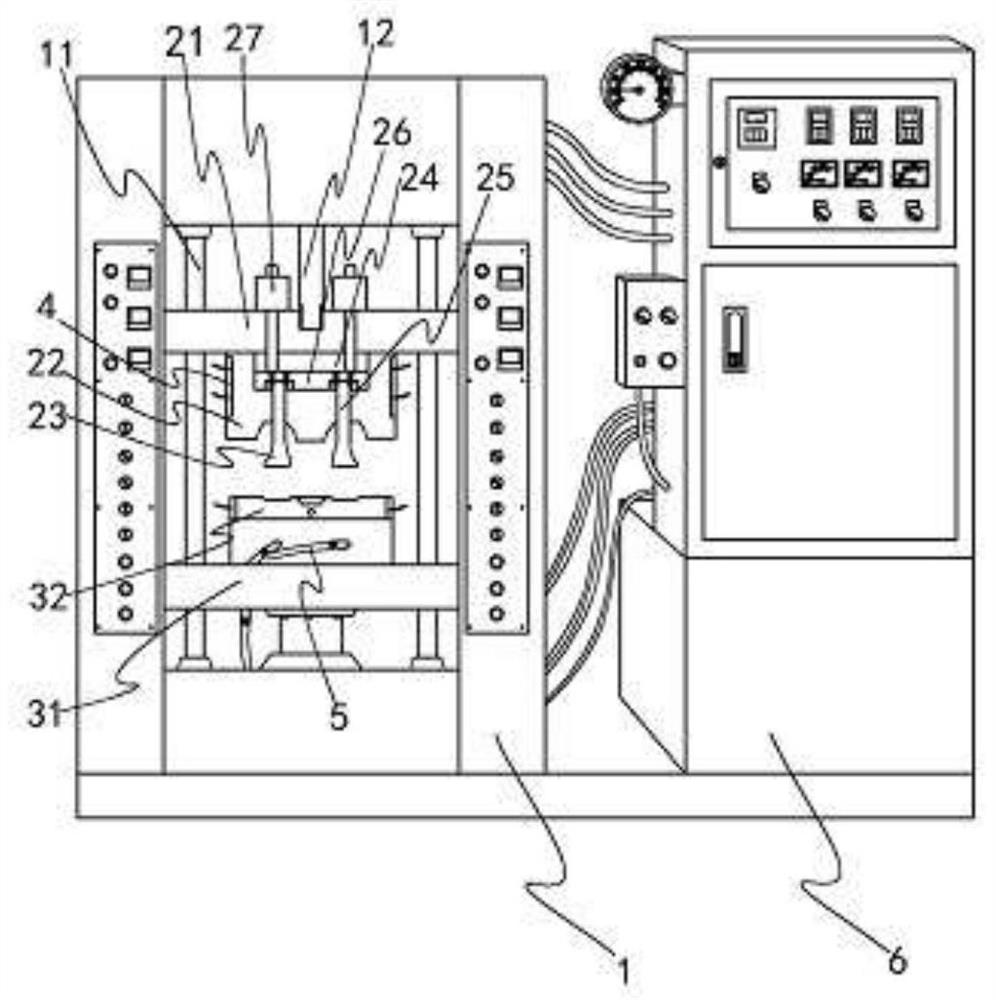

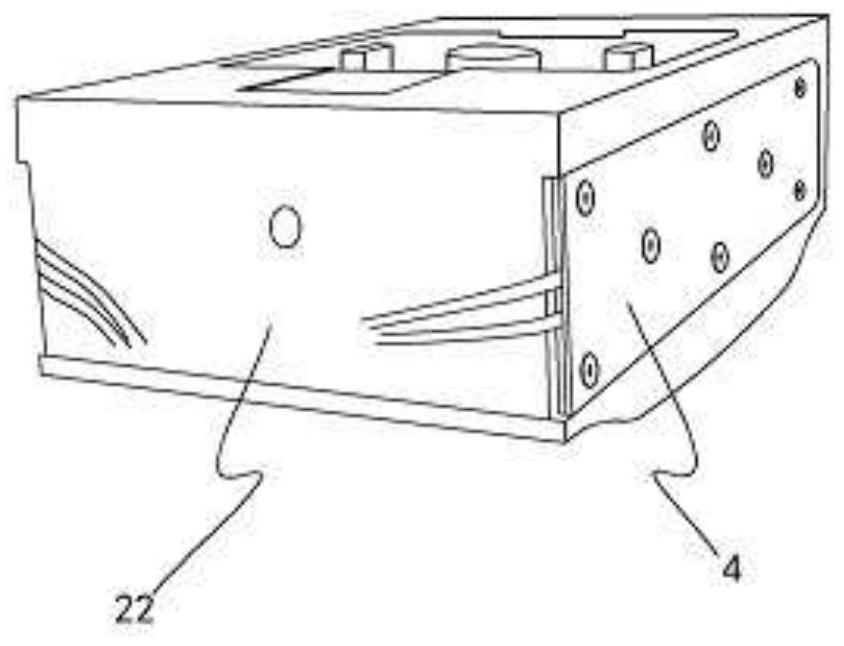

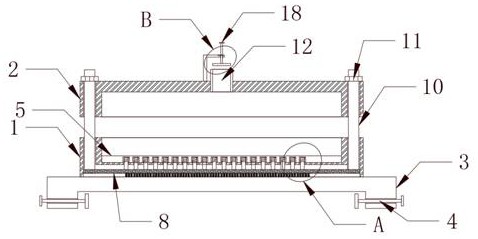

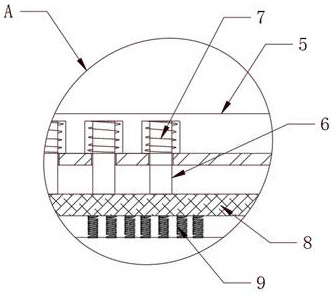

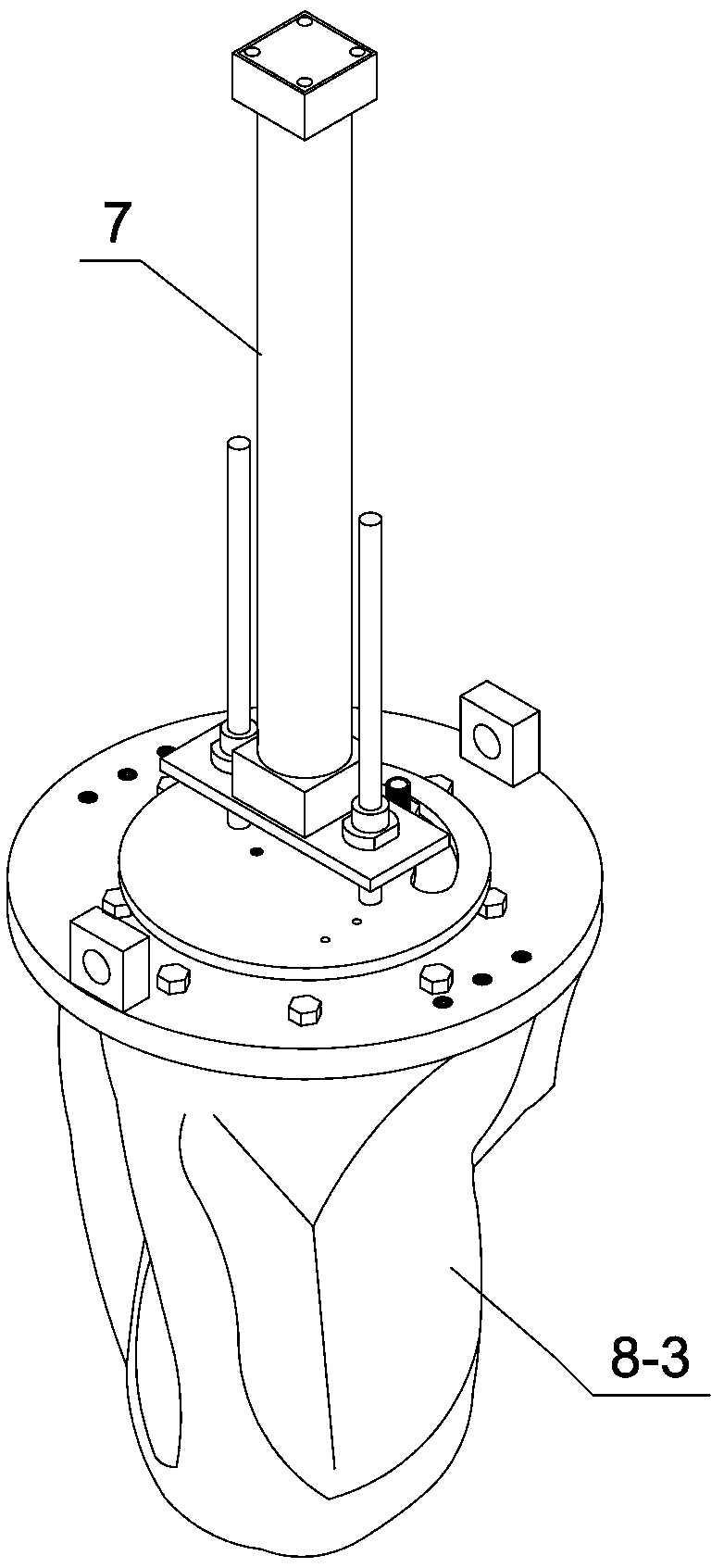

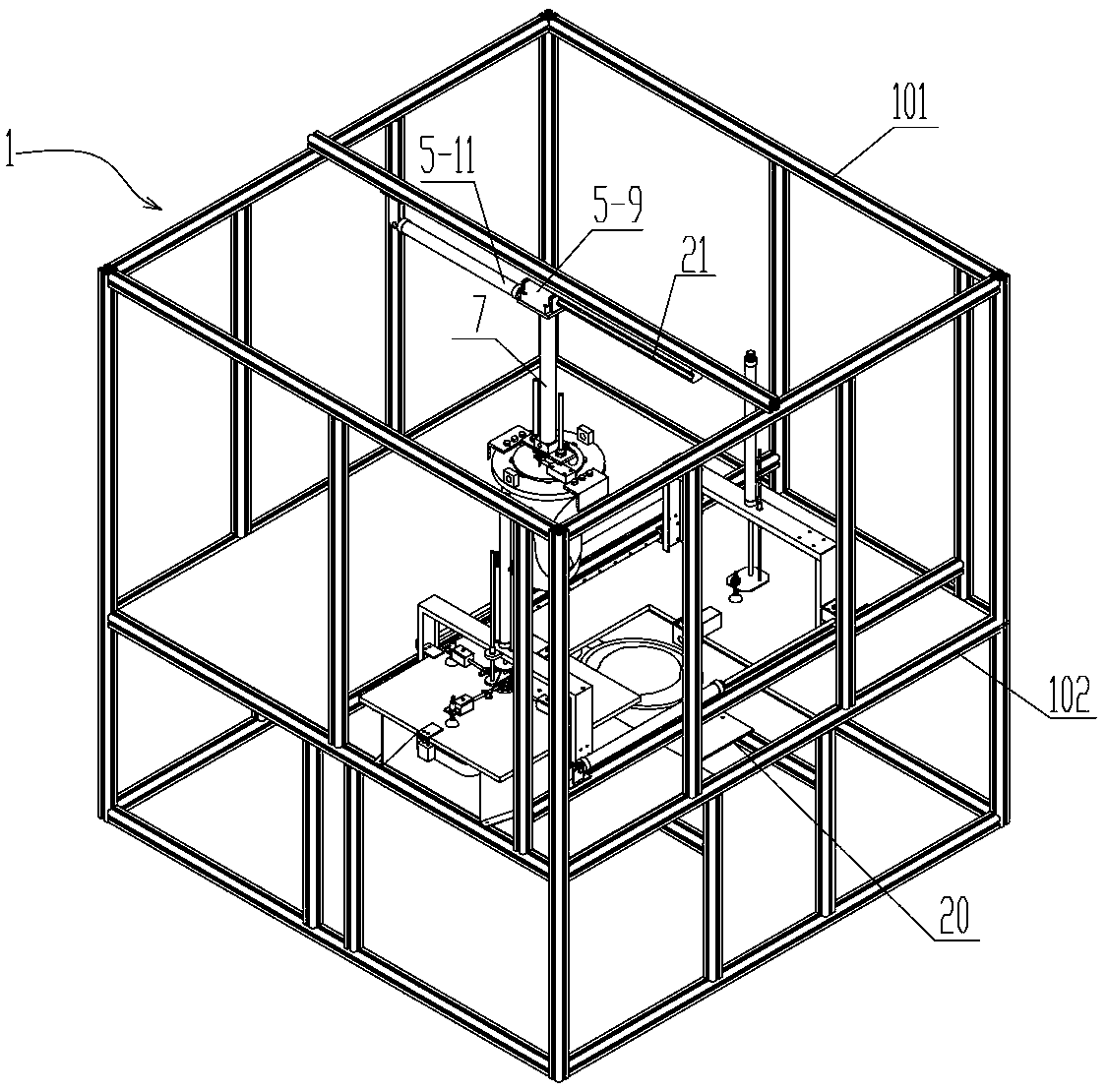

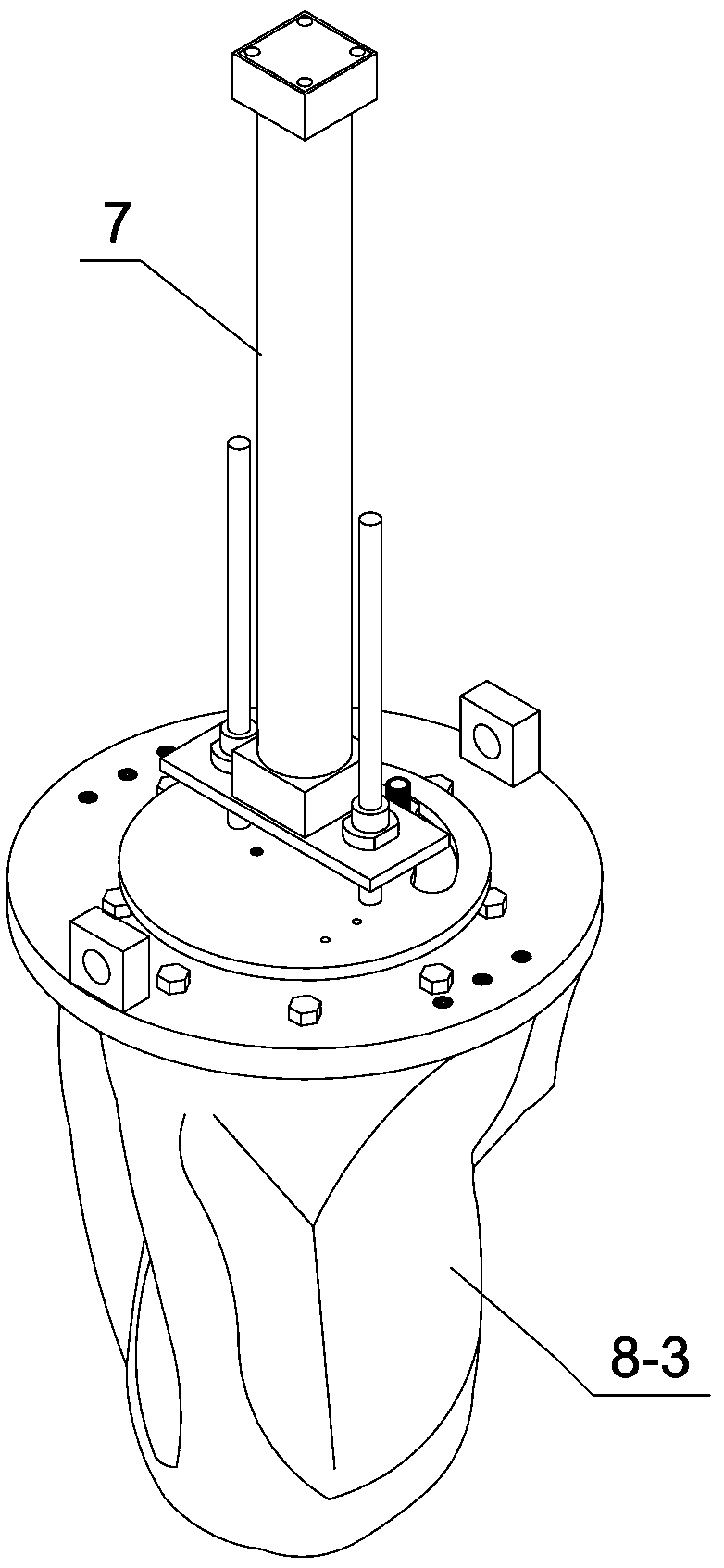

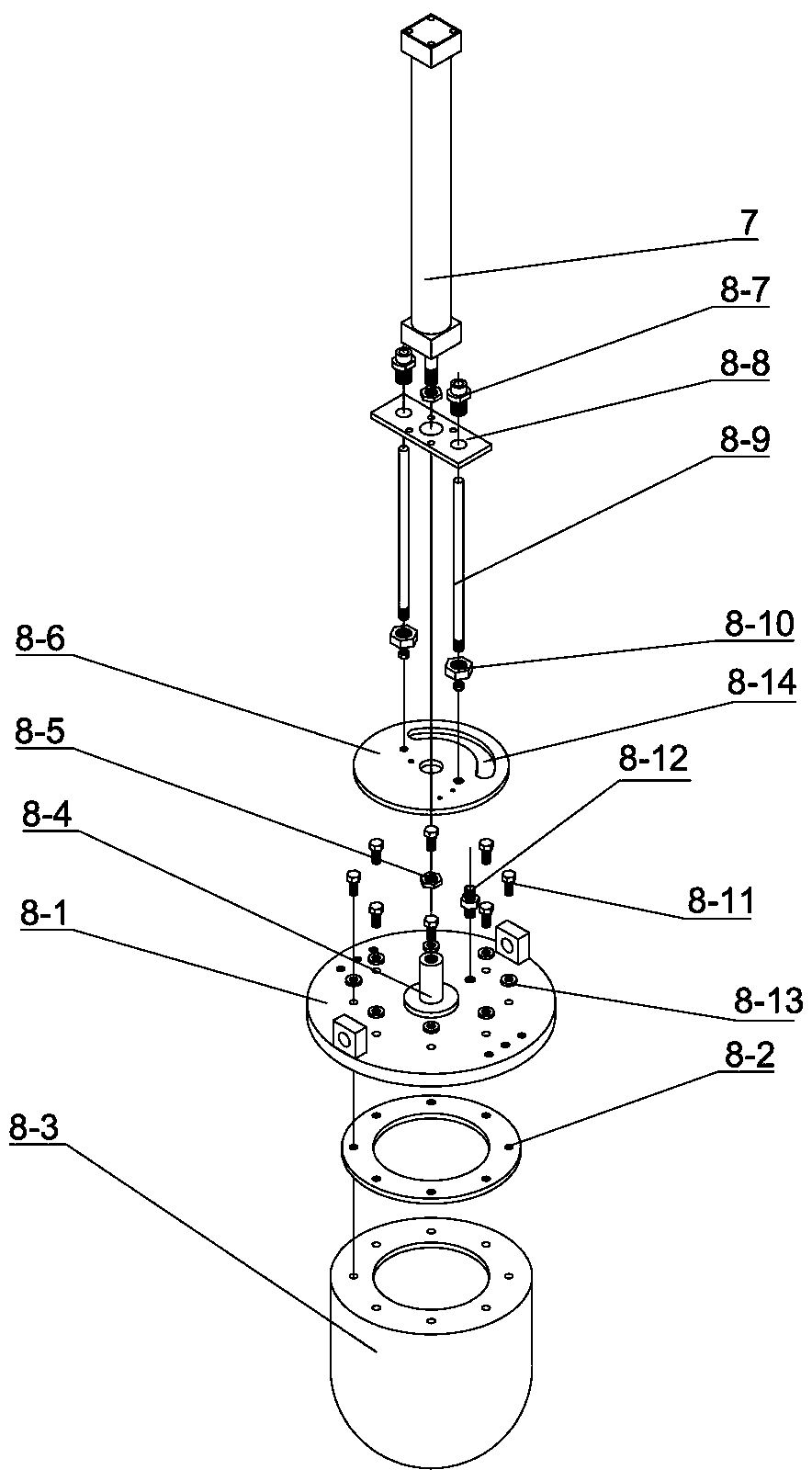

Full-automatic powder pressing machine for powder cake production

ActiveCN108044983APrecision mold clampingImprove efficiencyShaping pressPhysical healthImaging processing

The invention relates to the field of powder cake production equipment, and discloses a full-automatic powder pressing machine for powder cake production. According to the full-automatic powder pressing machine for powder cake production, on one hand, a full-cycle powder cake automatic production process can be realized, wherein the full-cycle powder cake automatic production process comprises automatic filling of packing trays, automatic movement of powder pressing molds, automatic mold closing and pressing of powder cakes and automatic demolding, and therefore, manual workload and working intensity can be greatly reduced, and the adverse influence of dust on physical health of workers can be avoided; on the other hand, a visual system and an image processing technology do not need to beintroduced, and therefore, not only can the operation data amount be greatly reduced, but also the automatic speed can be accelerated, furthermore, mechanical faults caused by the dust can be avoided, long-term maintenance is facilitated, and the service life of a machine is prolonged; and meanwhile, separation of a female mold and a male mold in the powder pressing molds can be realized, and through the backward move of the female mold and the upward move of the female mold when mold closing and pressing are in place, the powder feeding action, the mold closing and pressing action and the demolding action can be automatically realized, and compactness and completeness are achieved.

Owner:黄峰

High-precision splicing type mold for injection molding machine

The invention relates to the technical field of plastic molds, and discloses a high-precision splicing type mold for an injection molding machine. The mold comprises a protective shell, a top end supporting platform, an outer side mold, a conveying mechanism and a central mold, wherein a controller is arranged on the side face of a supporting column on one side of the top end supporting platform, and a top end mold is arranged at the bottom end of the center of the top end supporting platform. A conveying belt with multiple circular holes is arranged, and therefore a central mold head can exactly pass through the circular holes in the ascending and descending process under the accurate control of the controller, and then the conveying belt cannot affect the process that the plastic mold is subjected to the mold assembling and splitting operation. Due to the fact that the controller accurately controls driving motors, a central pushing motor, hydraulic telescopic rods and conveying motors, the plastic part production process of the whole splicing type plastic mold can be accurately and efficiently operated, the whole production process can be orderly carried out, the utilization efficiency of the plastic mold can be effectively improved, the yield of plastic parts is improved, and the production efficiency is improved.

Owner:武汉联镇科技有限公司

Processing method of rubber gasbag special for petroleum drilling machine

The invention discloses a processing method of a rubber gasbag special for a petroleum drilling machine. The processing method comprises six process steps of refining rubber, rolling and cutting, pressing, forming, vulcanizing and packaging, wherein in the vulcanizing process step, liquid water is injected into the rubber gasbag by a high-pressure pump and the pressure is controlled by a pressuregauge, so that steam pressurizing for the traditional vulcanization is replaced, the internal pressure of the rubber gasbag during vulcanization is increased, the density of the rubber gasbag is increased, the product quality of the processed rubber gasbag is optimized; furthermore, a rubber gasbag automatic mold on a vulcanization machine is adopted during vulcanization production, and vulcanization temperature, time and pressure are adjusted, so that the mold in the production process can perform mold closing, mold opening and lifting positioning accurately, and the problem that time and power are consumed by manual operation is solved; in addition, the liquid water is low in cost and can be recycled, so that the production cost of enterprises can be obviously reduced.

Owner:南通通江橡胶制品有限公司

Novel hot glue applying device special for lost foam casting white die

ActiveCN109590158AControl ascentAvoid deformationLiquid surface applicatorsMaterial gluingEngineeringLost-foam casting

The invention discloses a novel hot glue applying device special for a lost foam casting white die. The novel hot glue applying device special for the lost foam casting white die comprises a rack, a white die moving mechanism, a glue applying mechanism, a glue pool, a lifting structure and a white die bracket; two symmetrical sliding rails are fixedly connected to the upper surface of the rack; the white die moving mechanism is arranged on the sliding rails and can move along the sliding rails; the glue pool and the lifting structure are both fixed to the interior of the rack; the glue applying mechanism is located over the glue pool and connected with the lifting structure; and the white die bracket is fixed to the lifting structure. According to the device, manual glue applying is replaced, therefore, the labor force is liberated, the manual glue applying nonuniformity is avoided, the white die adhering speed is increased, and the finished product rate of a lost foam casting technology is increased.

Owner:武汉华兴同创科技有限公司

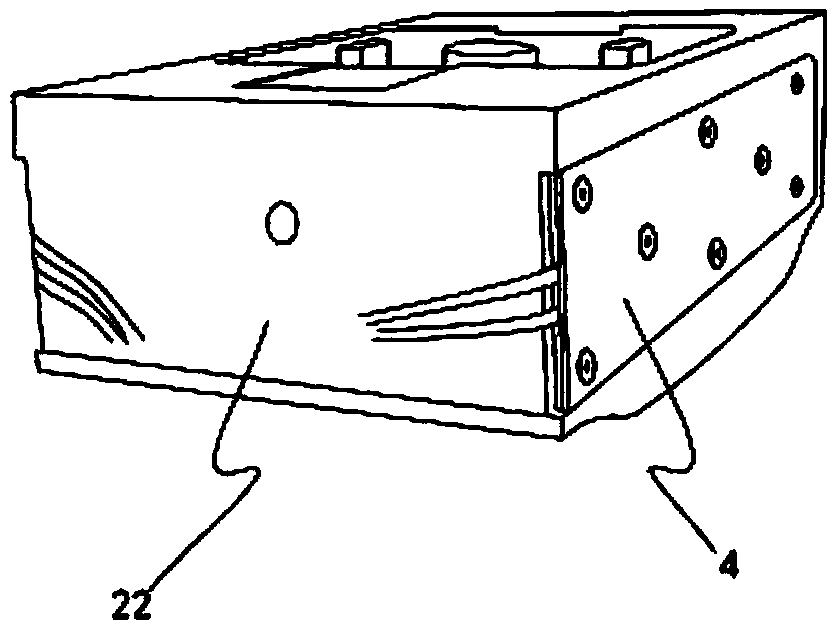

High-matching-degree multi-knife-type integrated hardware mold used for die cutting

InactiveCN106514779AIncrease productivityPrecision mold clampingMetal working apparatusPunchingMaterials science

The invention relates to a high-matching-degree multi-knife-type integrated hardware mold used for die cutting. The mold comprises an upper mold body and a lower mold body and is characterized in that a plurality of sets of punching knives are formed on the surface of the upper mold body, and at least one type of knife point is arranged on each set of punching knives; an upper identifier is arranged on the surface of the upper mold body, and a punching knife form cavity and a lower identifier matched with the upper identifier are arranged at the corresponding position of the surface of the lower mold body; during mold assembly, precise matching of the upper identifier and the lower identifier is controlled, and therefore accurate mold assembly of the corresponding knife points and the punching form cavities is achieved; compared with the prior art, the high-matching-degree multi-knife-type integrated hardware mold has the beneficial effects of being simple in structure, high in production efficiency, high in product yield and the like.

Owner:YUANRANG IND SHANGHAI

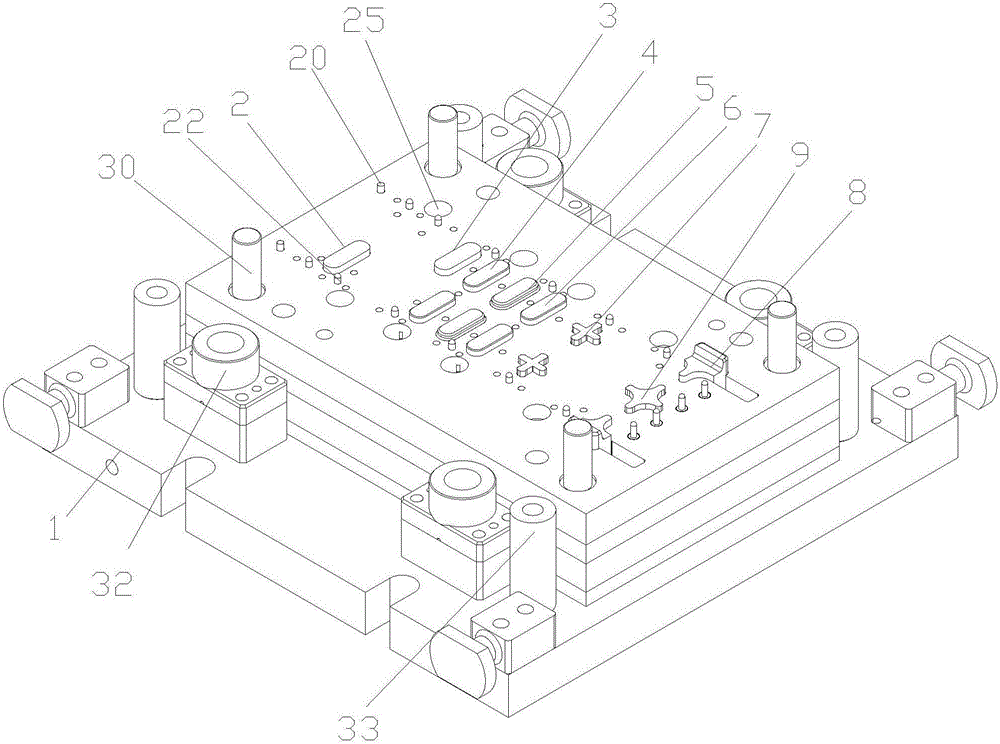

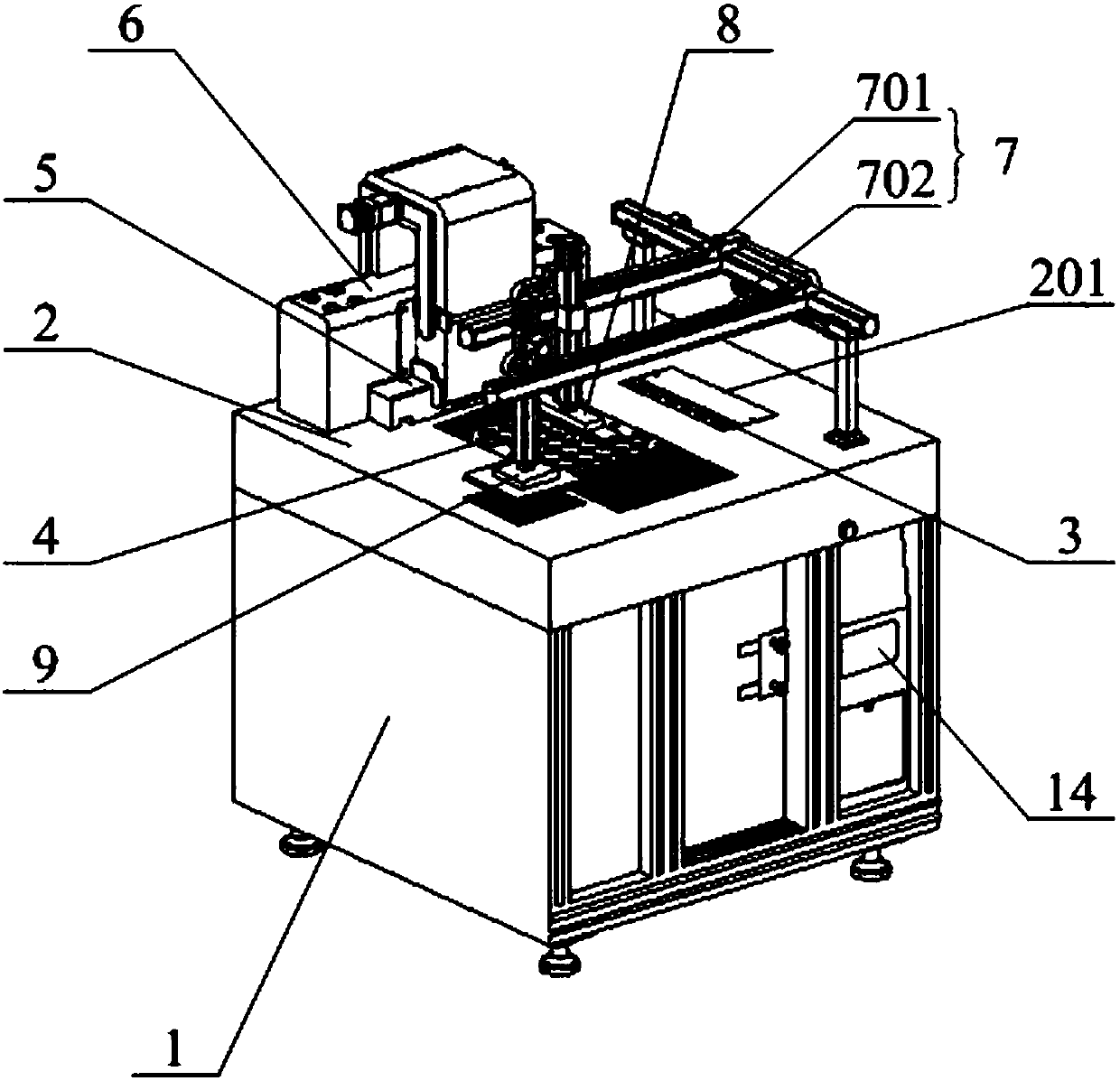

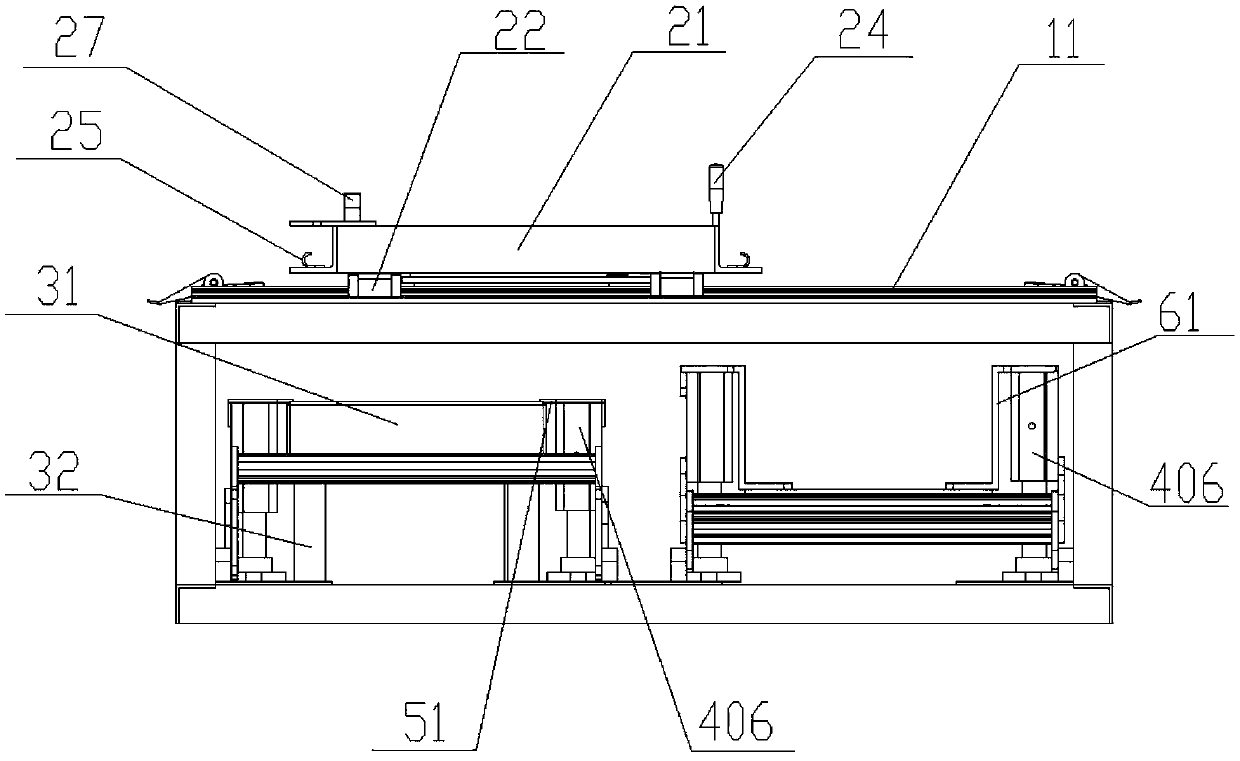

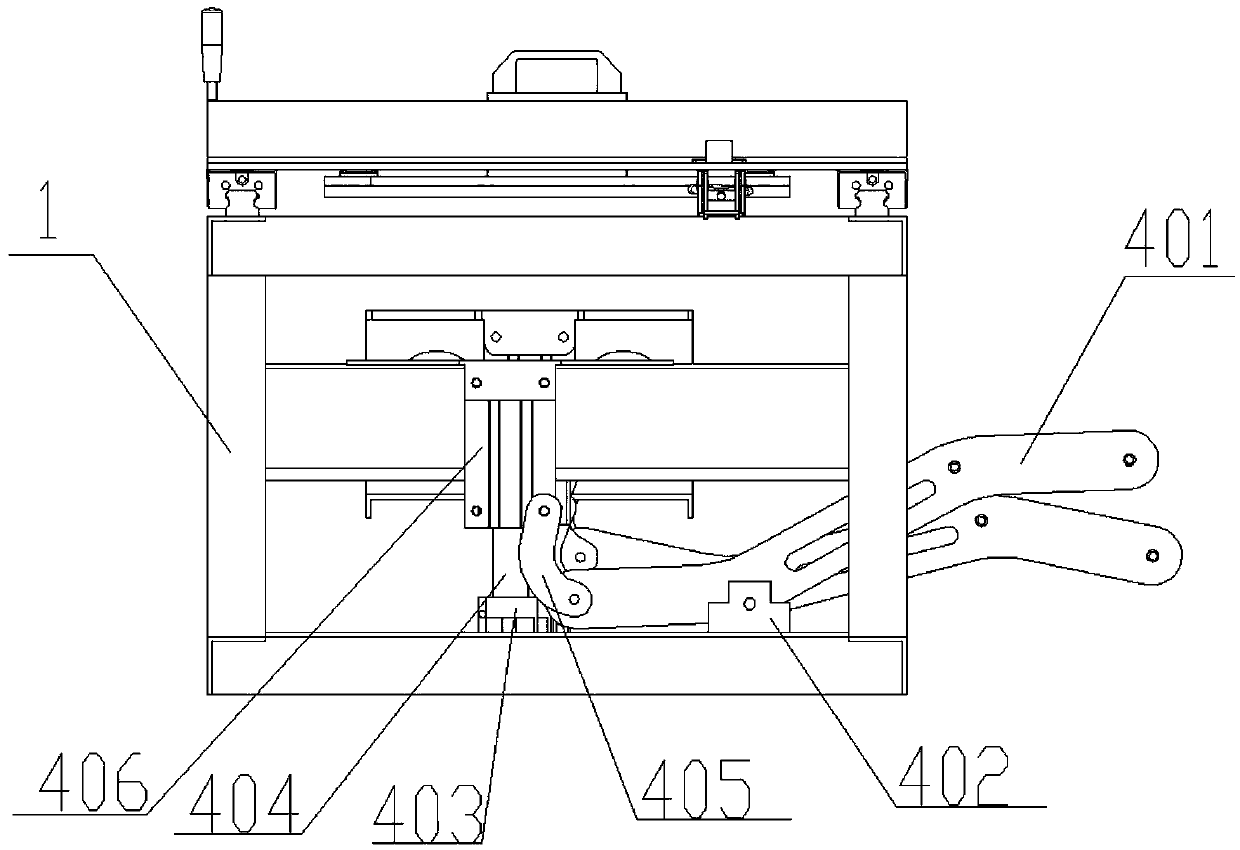

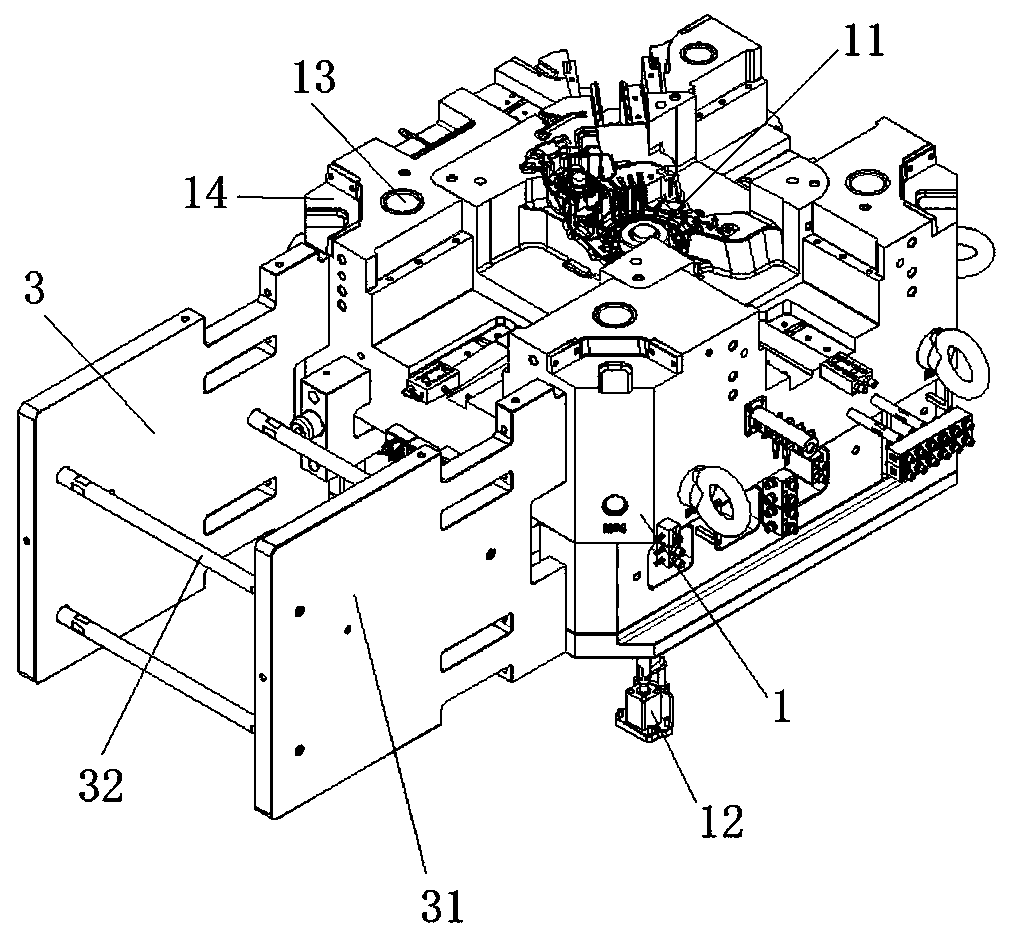

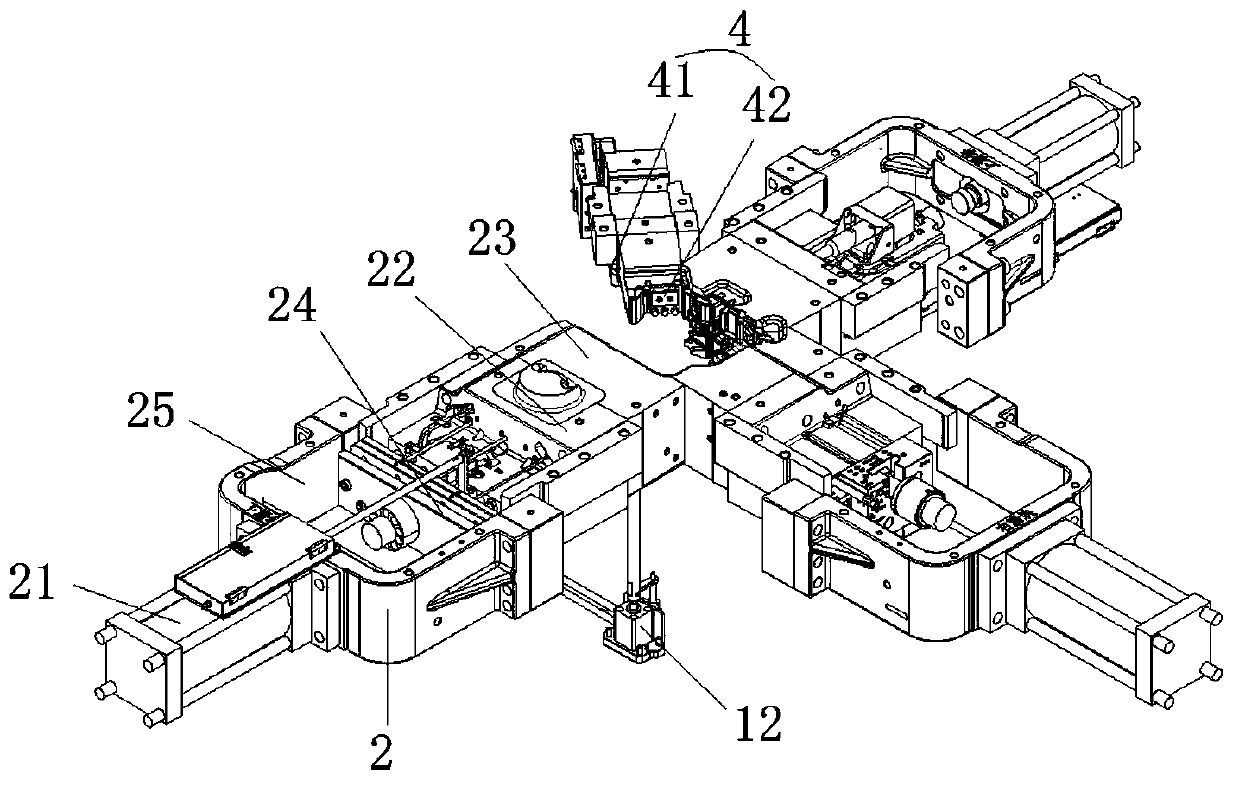

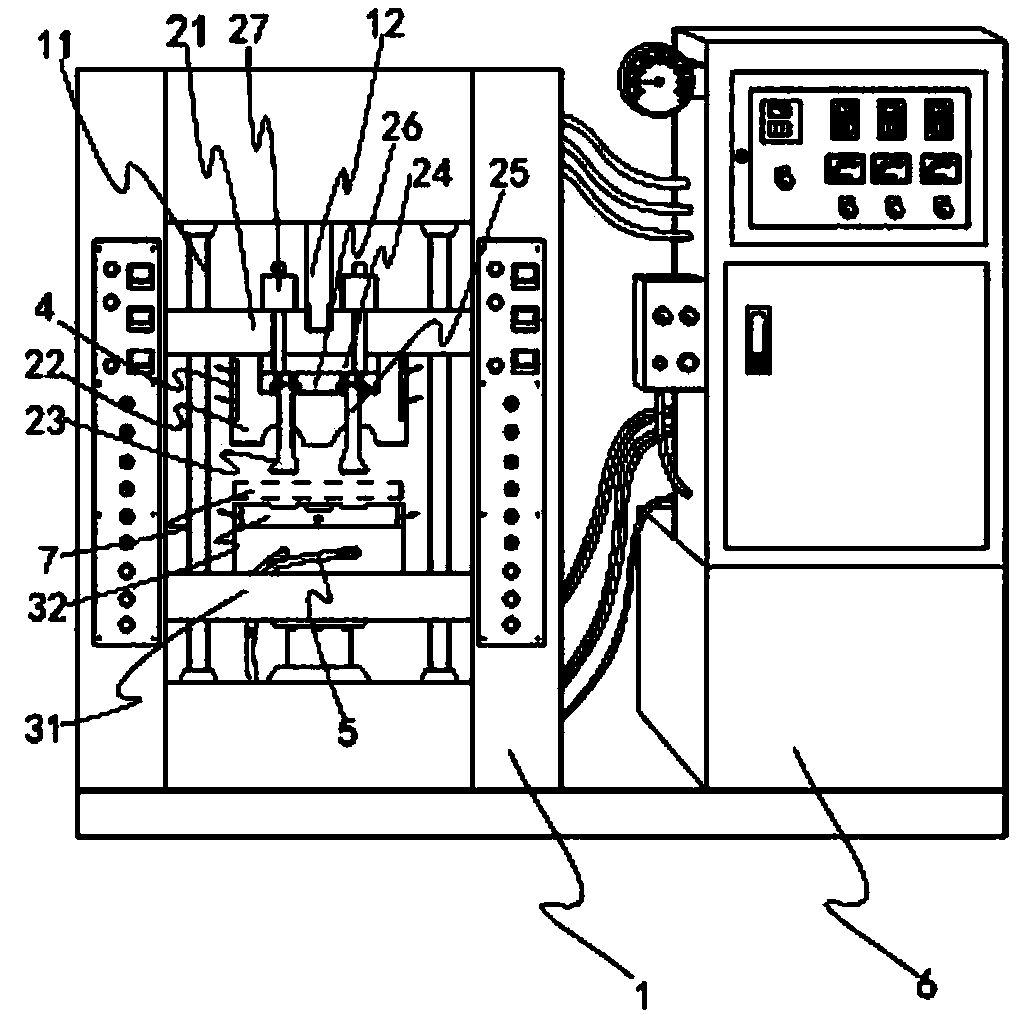

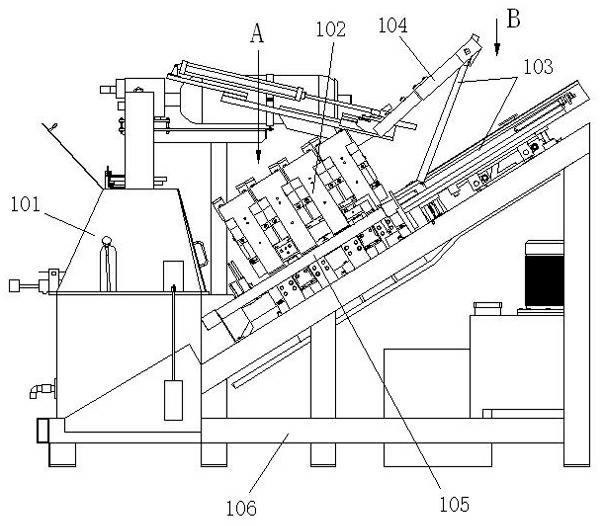

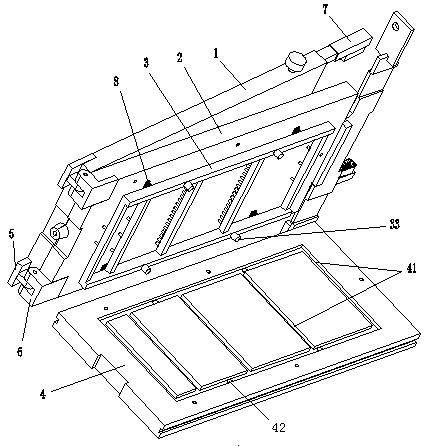

Fully automatic pulp molding multi-station equipment and production process

ActiveCN106638164BSmall weight deviationShorten the timeTextiles and paperMolded pulpThermal deformation

The invention belongs to the field of pulp molding product production equipment in a papermaking technique. Full-automatic multi-station integrated pulp molding equipment comprises an electric-heat conduction oil universal heating device, a steam heating device, a pulp chest homogenizing device, an adsorptive molding device, hot-press sizing devices, a first kind product collection device not needing stacking and a second kind product collection device capable of automatically conducting stacking; a groove is formed in a molding template of the molding device, an airflow dispersion cover plate is installed over the groove, an airflow main pipeline is vertically installed, a deckle edge spraying and template cleaning device is independently installed, heating plates of the molding devices are fixed to an upper molding template and a lower molding template through heat insulation plates, the upper molding template achieves multi-point pressurizing through a pressure stabilizing frame, the lower molding template is fixed to a transverse tackle, and heat deformation of the heating plates is effectively controlled by the molding templates. The equipment is suitable for large-scale production of pulp molding products, few molds are used, and the molds are unified and easy to replace.

Owner:许洪涛 +1

Gearbox cavity die moving die

The invention discloses a gearbox cavity die moving die. The gearbox cavity die moving die comprises a moving die base and multiple sliding mechanisms. A first die core matched with the shape of a gearbox is arranged in the middle of the moving die base. A moving die extrusion oil cylinder is arranged on one side of the moving die base. A piston rod of the moving die extrusion oil cylinder vertically faces the moving die base and can be connected with the first die core in an abutting manner. The multiple sliding mechanisms are arranged along the periphery of the moving die base. Each of the multiple sliding mechanisms comprises a sliding cylinder and a sliding die. A piston rod of each sliding cylinder is connected with a corresponding sliding die. Pistons rods of the sliding cylinders vertically face the first die core. A second die core matched with the shape of the gearbox is arranged on a side edge of each sliding die. According to the gearbox cavity die moving die, the moving dieextrusion oil cylinder is arranged on one side of the moving die base, and the multiple sliding mechanisms are arranged; and when a gearbox is cast, accurate location can be conducted on the first die core and the second die cores so that die closing is accurate, and thus the casting precision and quality of the gearbox are improved.

Owner:GUANGZHOU DIE & MOLD MFG

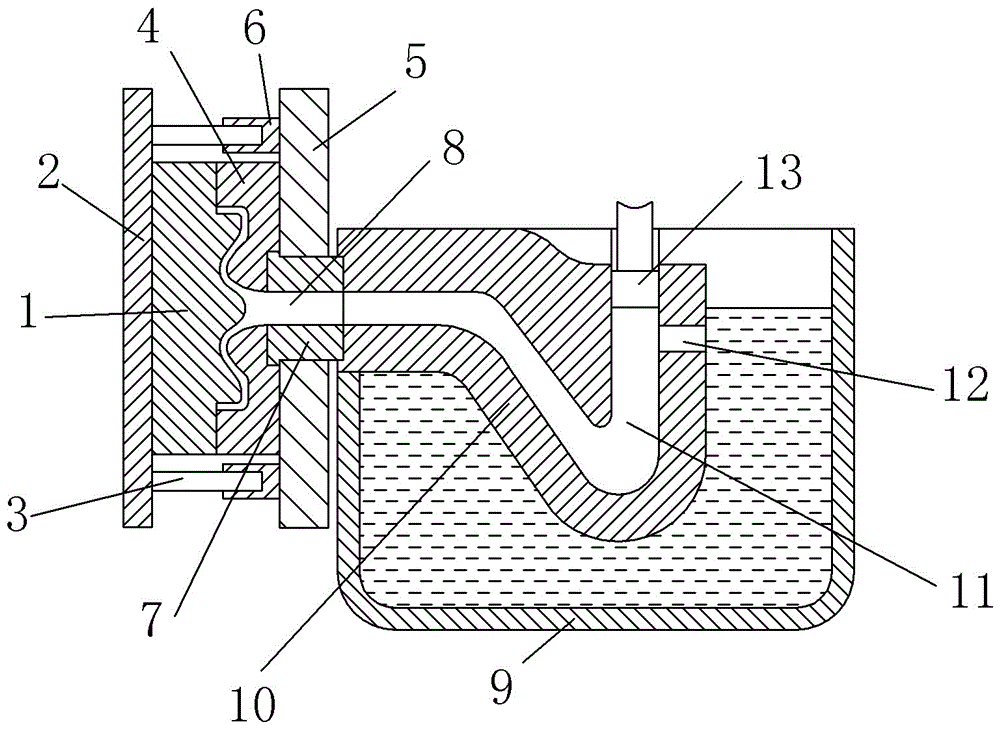

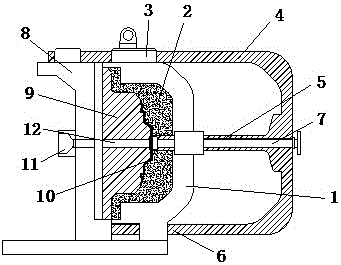

Hot chamber die casting machine with guiding structure

The invention discloses a hot chamber die casting machine with a guiding structure. The hot chamber die casting machine comprises a movable die, a fixed die and a crucible. A fixed die installing plate is arranged at the position of the fixed die. A movable die installing plate is arranged at the position of the movable die. A connecting block is arranged between the fixed die and the crucible. The connecting block is provided with a connecting channel. A press chamber and molten metal are arranged in the crucible. The press chamber is provided with a gooseneck channel and a liquid inlet channel. A press injection head is arranged on one side of the gooseneck channel. The fixed die installing plate is provided with at least one guiding protrusion. Each guiding protrusion is provided with a guiding groove. The movable die installing plate is provided with guiding columns. According to the scheme, when the movable die gets close to the fixed die, the guiding columns on the movable die installing plate stretch into the guiding grooves of the fixed die installing plate, under the action of the guiding grooves, the movable die installing plate drives the movable die to move according to the specific route, accordingly, accurate die assembly between the movable die and the fixed die can be achieved, and the quality of a casting is improved.

Owner:CHONGQING YINGRUISHENG DIE CASTING

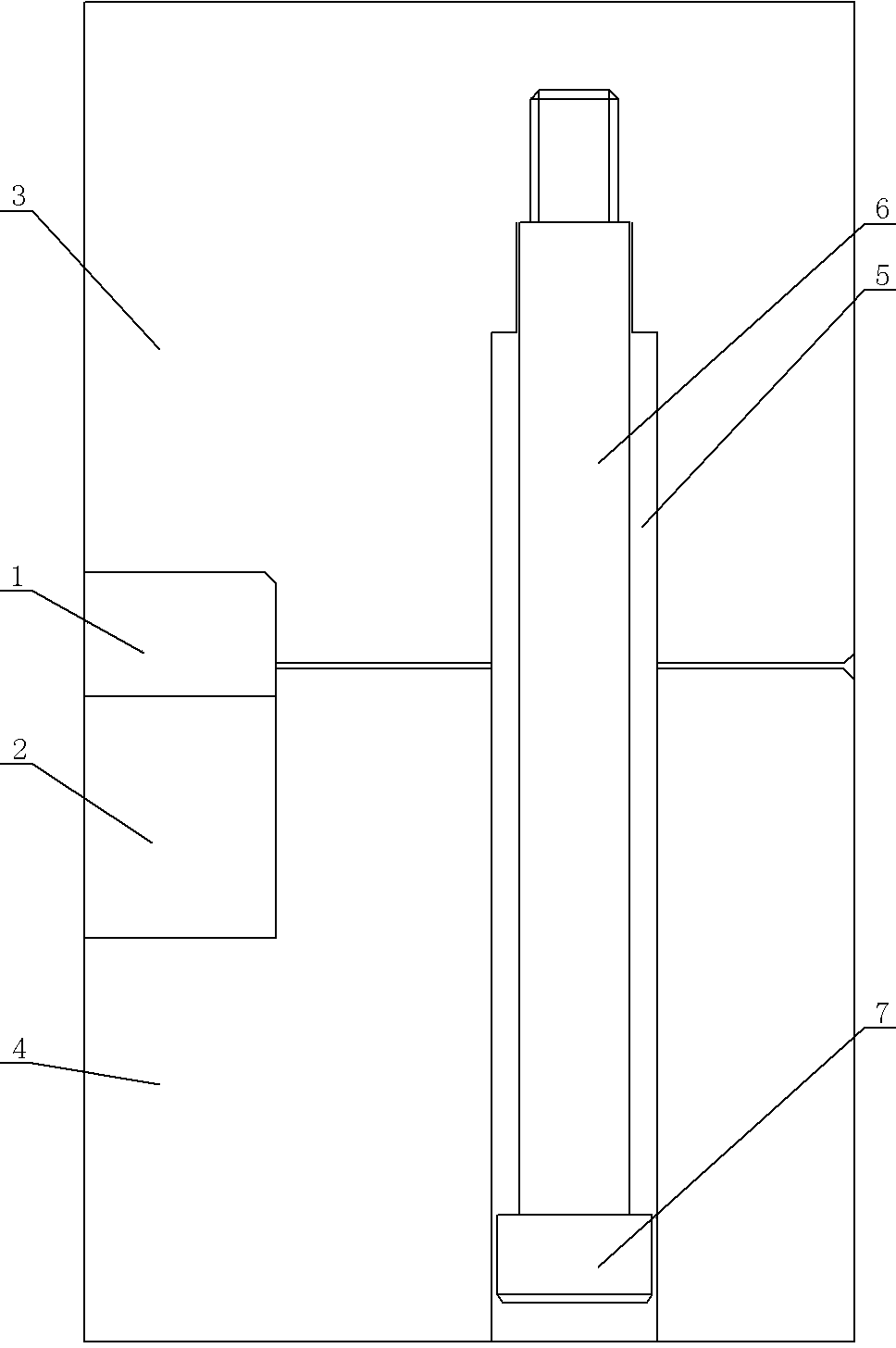

Demolding limiting structure

The invention provides a demolding limiting structure. Through the demolding limiting structure, in demolding, a front mold does not shift in the plane so that the next mold closing process can be carried out fast and accurately, and the distance of travel is less so that energy is saved. The demolding limiting structure comprises a front mold, a rear mold, an A plate and a B plate. A cavity is formed between the front mold and the rear mold. The front mold is fixedly connected to the A plate. The demolding limiting structure is characterized in that the opposite parts of the A plate and the B plate are provided with a guide groove; the guide groove is arranged vertically; a limiting bolt is arranged in the guide groove; the guide groove passes through the B plate and extends to the middle of the A plate from bottom to top; a screw thread part of the limiting bolt passes through the guide groove from bottom to top and is fixedly connected to the A plate; and the a lower part of the limiting bolt is a screw part.

Owner:WUXI CITY NEW DISTRICT WEICHUANGLI MOLD FACTORY

Mold structure for manufacturing precise optical lens cone

Owner:UNION OPTECH

Casting mould used for metal parts

InactiveCN105935745AQuality improvementIncrease the speed of mold clampingFoundry mouldsFoundry coresMetalMaterials science

The invention discloses a casting mould used for metal parts. The casting mould comprises a fixed molding board and a movable molding board, wherein a fixed mould is mounted at the inner side of the fixed molding board; the left end of a limiting rod is fixed to the top of the movable molding board; a stripper rod is arranged on the middle part of the fixed molding board; the bottom of the fixed molding board is further provided with a positioning rod in a penetration manner; and the left end of the positioning rod is fixed with the movable molding board. According to the casting mould used for metal parts, the fixed mould and the movable mould of the casting mould are connected together by virtue of the limiting rod and the positioning rod arranged, so that errors between the fixed mould and the movable mould are avoided when the casting mould is used for mould closing, and therefore, the quality of castings is greatly improved; and meanwhile, a slide slot is formed in the bottom of the movable molding board, so that the casting mould is more labor-saving during mould closing, and therefore, the fixed mould and the movable mould can be closed and fixed by only one person, the mould closing speed of the mould is greatly increased, and the workload of a worker is also relieved.

Owner:无锡市锡山区羊尖镇锦达商业设备厂

Punching belt rubber piece device capable of realizing automatic material returning

InactiveCN104249389APrecision mold clampingSolve the difficulty of dischargingMetal working apparatusPunchingEngineering

The invention relates to a punching belt rubber piece device capable of realizing automatic material returning. The punching belt rubber piece device comprises an upper mold and a lower mold, wherein the lower end surface of the upper mold is provided with an upper die cavity, the upper end surface of the lower mold is provided with a lower die cavity, after the upper mold and the lower mold are combined, the upper die cavity and the lower die cavity are combined into a complete die cavity, an ascending and descending mechanism is arranged at the lower end surface of the lower mold, the lower end of the ascending and descending mechanism is fixedly arranged on a base, at least two support rods are arranged on the base, the upper ends of the two support rods are respectively arranged on the upper mold, an automatic material returning device is arranged on the lower mold, the automatic material returning device comprises an air supply device arranged on the base, a material jacking hole is formed in the lower mold and is communicated with the lower die cavity of the lower mold, the air supply end of the air supply device is arranged in the material jacking hole, after the punching process is completed, the air supply device is started, and the air supply end of the air supply device conveys high-pressure air into the material jacking hole, so rubber pieces in the lower die cavity are ejected out from the lower die cavity through high-pressure air, the problem of difficult manual material discharging is solved, and the work efficiency is improved.

Owner:CHANGZHOU LIWEI KNIFE

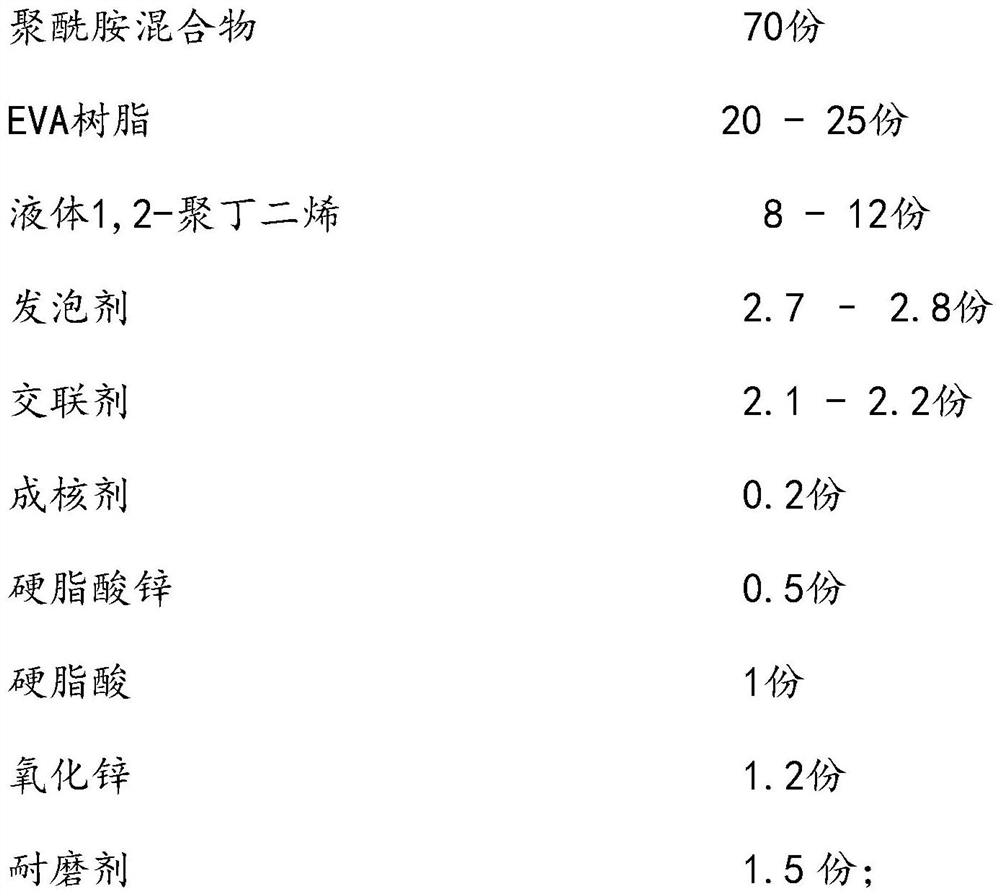

Method for preparing indoor two-color casual shoes

ActiveCN109648902AReduce crystallization rateImproved compression deformation capabilityDomestic footwearEnvironmental resistanceCross-link

The invention relates to the technical field of shoe making, and provides a method for preparing indoor two-color casual shoes. The obtained indoor two-color casual shoes are subjected to SEBS modification, thus, the material crystallization rate is decreased, the compressive deformation property of a material is improved, rubber is good in hand feeling, and comfort is high; the shoes are subjected to OBC modification, the material dimensional stability is improved; an environment-friendly cross-linking agent 17-40B, volatile organic compounds such as acetophenone are not used, and the shoes has the environmental protection characteristic; and a mold device adopted by the method for preparing the indoor two-color casual shoes is rapid in heating, quickly, the duplication precision of solelines is effectively improved, demolding is quick, the injection molding yield and production efficiency are effectively improved, and the method is suitable for mass production and use.

Owner:QUANZHOU JINKE TECH TESTING CO LTD

High-performance aluminum alloy casting and casting method thereof

InactiveCN108866403AQuality improvementImprove performanceFoundry mouldsFoundry coresComputer moduleMaterials science

The invention discloses a high-performance aluminum alloy casting. A bottom plate is included, and a back plate is fixed to one side of the upper end of the bottom plate; a moving device is arranged on one side of the back plate; a cooling device is arranged on the other side of the back plate; a fixed plate is fixed to the upper end of the back plate; a connection block is arranged on the fixed plate in a penetrating manner; a baffle is fixed to each of the two sides of the lower end of the fixed plate; the lower end of the connection block is provided with an upper module; the upper module is located between the two baffles; the lower end of the upper module is provided with an upper mold groove; and the two sides of the lower end of the upper module are each rotationally connected withan L-shaped rod. The invention further provides a casting method of the high-performance aluminum alloy casting. The high-performance aluminum alloy casting achieves accurate matching between materials, performs effective treatment on molten aluminum and improves the quality of the molten aluminum, during casting, mold closing can be accurately performed, in the casting process, close connection between modules is guaranteed, the product quality is guaranteed powerfully, and the performance of products is effectively improved.

Owner:TIANJIN QIANXIN NONFERROUS METAL PRODS

Lead-acid battery grid die-casting machine mold

The invention discloses a mold for a die casting machine of a lead-acid storage battery plate grid. The mold comprises a moving die and a fixed die, wherein the fixed die comprises a fixed die plate, a bottom plate and an ejecting device; the bottom plate is arranged on the lower surface of the fixed die plate in a covering manner; the ejecting device is fastened in a containing cavity arranged on the lower surface of the fixed die plate or the upper surface of the bottom plate; a plurality of rows of ejecting needles are fixed on the ejecting device, and are respectively inserted in ejectingneedle holes on the lower surface of the fixed die plate in a one-to-one manner; and a pushing hole is arranged on the lower surface of the bottom plate, and a pushing rod on an outer ejecting mechanism penetrates through the pushing hole and then pushes the ejecting device to move upwards, so as to lead the ejecting needles to be ejected out upwards. According to the mold, the work finished by aset of outer ejecting mechanism is changed to be finished by two sets of inner and outer ejecting mechanisms together, the completeness of the mold is guaranteed, the pollution of the ejecting needleholes, the ejecting needles and a return spring by waste lead liquid is avoided, the stressing of the ejecting needles is improved, the working reliability of the mold is guaranteed, and the condition for improving the yield of finished plate grids is created.

Owner:JIANGSU SANHUAN IND HLDG CO LTD

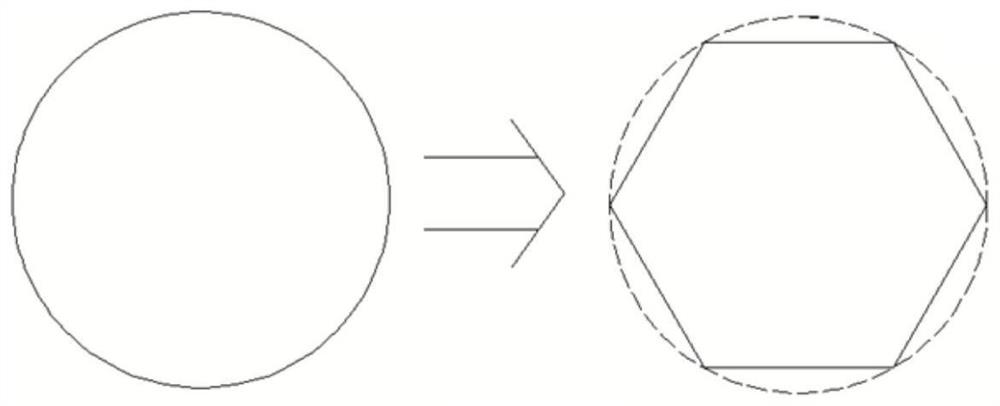

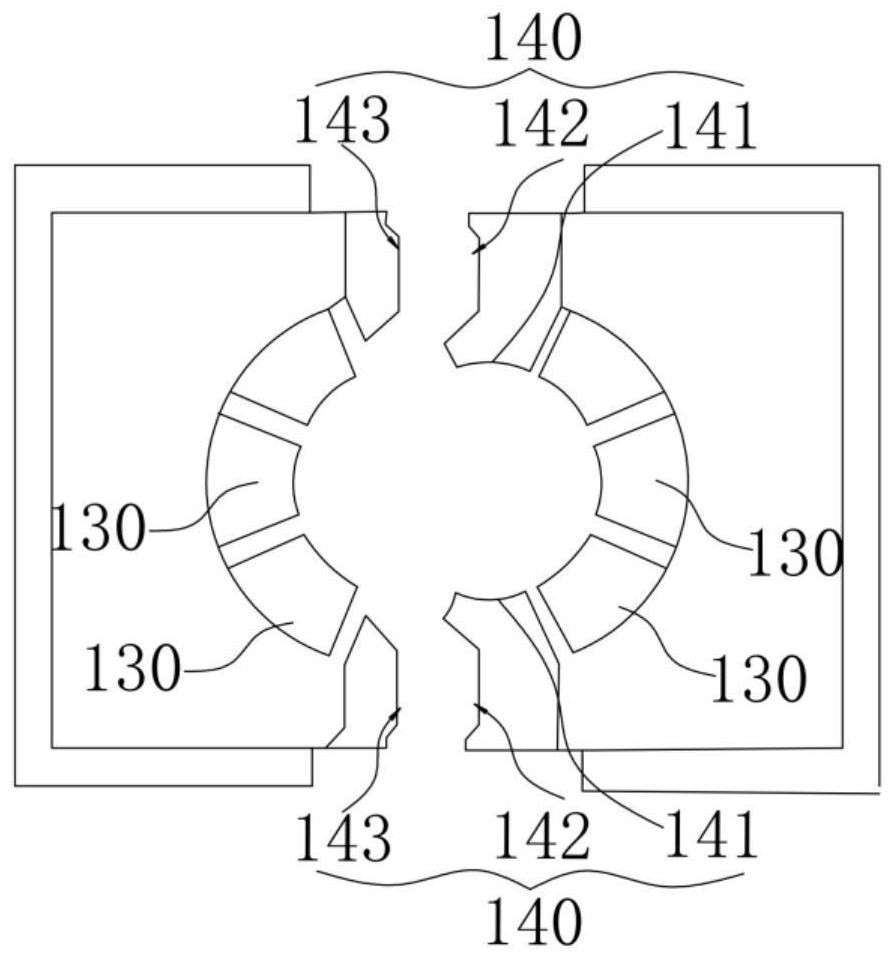

Pipeline necking and crimping machine, pipeline crimping method and crimping pipe

PendingCN113725693APrecision mold clampingPlay a guiding roleLine/current collector detailsConnections effected by permanent deformationLine tubingStructural engineering

The invention provides a pipeline necking and crimping machine, a pipeline crimping method and a crimping pipe, which relate to the technical field of crimping equipment. The pipeline necking and crimping machine comprises abuckling and pressing main machine. The buckling and pressing main machine comprises a main machine body and an opposite opening and closing module. The opposite opening and closing module comprises a fixed mold and a movable mold; each of the fixed mold and the movable mold comprises a slot petal mold and a plurality of split petal molds, the slot petal molds are arranged on the opposite side surfaces of the fixed mold and the movable mold, and the slot petal molds on the two sides are matched with each other to form a combined split petal mold; and the split petal mold and the combined split petal mold are drawn close to the circle center of the arc at the same time to form an inner circle surface for clamping a pipeline. The pipeline necking and crimping machine is used in the pipeline crimping method. The crimping pipe is obtained by using the pipeline necking and crimping machine or the pipeline crimping method. By means of the pipeline necking and crimping machine, the technical problems that crimping is not firm and mechanical performance is affected in an existing crimping mode are solved, and the technical effects that crimping is firm and the mechanical performance is improved are achieved.

Owner:YINGKOU ELECTRIC POWER SUPPLY COMPANY OF STATE GRID LIAONING ELECTRIC POWER SUPPLY +2

Ventilated round clutch rubber airbag and preparation method thereof

PendingCN109971155AHas super tear resistanceWith super wear resistanceHollow articlesVulcanizationLiquid water

The invention discloses a ventilated round clutch rubber airbag, which comprises the following raw materials in parts by weight: 15-25 parts of cis-butadiene rubber, 35-55 parts of urethane rubber, 15-25 parts of chloroprene rubber, 8-12 parts of zinc oxide, 2-3 parts of stearic acid, 3-5 parts of paraffin, 25-30 parts of carbon black N774, 1.5-2.5 parts of anti-aging agent A, 1.5-2.5 parts of anti-aging agent D, 0.5-1.5 parts of anti-aging agent 4010NA, 2.5-3.5 parts of graphene, 3-5 parts of petroleum pitch, 0.5-1.5 parts of accelerator M, 1.5-2.5 parts of accelerator TMTD, and 1.5-2.5 partsof sulfur. The preparation method comprises six process steps of rubber mixing, calender cutting, extrusion, molding, vulcanization and packaging. The vulcanization temperature, time and pressure areadjusted in the vulcanization process, thereby fundamentally solving the problem of labor consumption and time consumption. In addition, because liquid water is low in cost and can be recycled, the production cost of an enterprise can be significantly reduced.

Owner:HENAN DALIN RUBBER & TELECOMM APP

A preparation method of soft skin-friendly slippers

ActiveCN109694569BIncrease polarityImproved compression deformation capabilityDomestic footwearFootwearPolyamideProcess engineering

The invention relates to the technical field of shoe-making technology, and provides a method for preparing soft, skin-friendly slippers. The shoes prepared by the indoor two-color casual shoes are modified with low-melting polyamide, which improves the polarity of materials, reduces crystallization, and can effectively Control shrinkage, improve the compression deformation performance of the material, and the rubber has a good feel and high comfort; OBC modification improves the dimensional stability of the material; The use of environmentally friendly cross-linking agent, no volatile organic compounds such as acetophenone, has environmental protection characteristics Moreover, the mold device used in the preparation method of the soft skin-friendly slippers heats rapidly, effectively improves the reproduction accuracy of the sole pattern, and demolds quickly, effectively improves the injection molding yield and production efficiency, and is suitable for mass production.

Owner:QUANZHOU JINKE TECH TESTING CO LTD

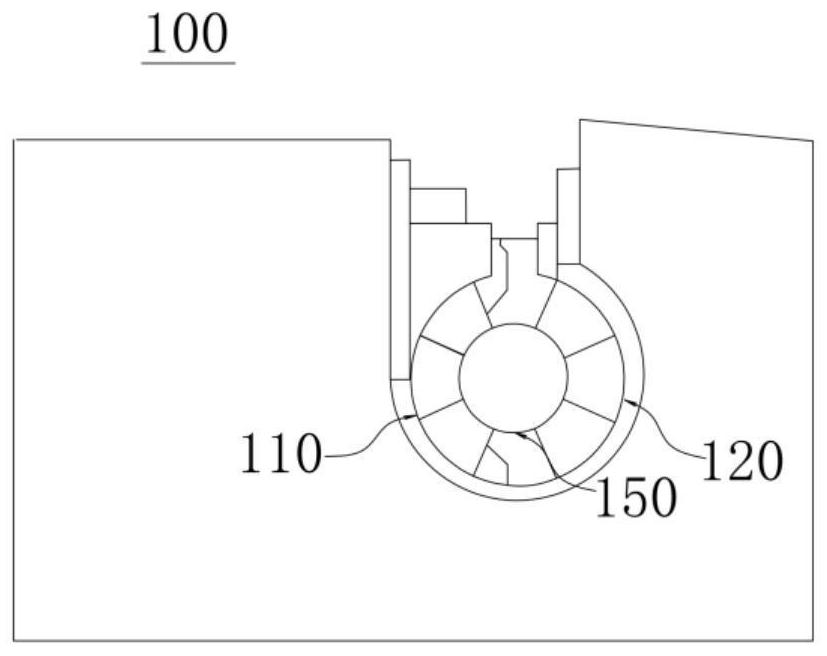

Hot chamber die-casting die

InactiveCN105935757AImprove liquiditySolve the problem of increased scrap ratePoor mobilityDie casting

The invention discloses a hot chamber die-casting die. The hot chamber die-casting die comprises a movable die body and a fixed die body. A fixed die installing plate is arranged at the position of the fixed die body. A liquid inlet runner is formed in the fixed die installing plate. A liquid runner is formed in the movable die body. The liquid runner comprises a liquid inlet section, a middle section and a liquid outlet section. The liquid inlet section of the liquid runner is in threaded connection with a liquid inlet pipe. The liquid outlet section of the liquid runner is in threaded connection with a liquid outlet pipe. The side, close to a casting runner, of the middle section of the liquid runner has the contour line the same as that that of the casting runner. According to the scheme, the liquid runner is formed in the movable die body, high-temperature liquid is injected into the liquid runner, molten metal in the casting runner always has good mobility through heat generated by the high-temperature liquid, and accordingly the problem that due to poor mobility of the molten metal, the casting runner cannot be well filled with the molten metal, and consequently the rejection rate of a die-casting fitting is increased is effectively solved.

Owner:CHONGQING YINGRUISHENG DIE CASTING

A progressive stamping die for u-shaped parts

ActiveCN105921613BReduce in quantityIncrease productivityShaping toolsMechanical engineeringEngineering

The invention discloses a U-shaped piece grading punch forming die with high production efficiency. The U-shaped piece grading punch forming die comprises an upper die and a lower die, wherein the upper die comprises an upper die holder; a kidney-shaped hole shaped left piercing punch, a right piercing punch, a pair of a first positioning blocks, a pair of kidney-shaped hole shaped forming punches, a pair of a second positioning blocks, a pair of cross-shaped punches and a material dividing punch group are sequentially arranged on the upper die holder starting from the feeding end; the left piercing punch has the same shape as the right piercing punch, the first positioning blocks and the second positioning blocks; the material dividing punch group comprises two T-shaped punches and a large cross-shaped punch; the two T-shaped punches are perpendicular to the feeding direction and are in a straight line; the large cross-shaped punch is arranged between the two T-shaped punches; the lower die comprises a lower die holder; corresponding left piercing groove, a right piercing groove, a pair of first positioning grooves, a pair of forming grooves, a pair of second positioning grooves, a pair of small cross-shaped grooves and a material dividing groove group are sequentially formed in the lower die holder starting from the feeding end; the material dividing groove group comprises two T-shaped grooves and a large cross-shaped groove.

Owner:苏州金鸿顺汽车部件股份有限公司

A diaphragm manufacturing process for a moving iron unit

ActiveCN105681998BImprove acoustic performanceAvoid damageElectrical transducersConvex structureLoudspeaker

Owner:CHANGZHOU AMT

Mould for producing grey cast iron

The invention belongs to the technical field of cast iron molds, and particularly relates to a grey cast iron production mold which comprises a lower mold body and an upper mold body, a mounting base is fixedly mounted at the bottom of the lower mold body, a groove is formed in the bottom of the mounting base, and the two sides of the groove are each in threaded connection with two first screw rods; fixing plates are fixedly connected to the ends, close to each other, of the four first screws, a rotating disc is fixedly connected to the ends, away from each other, of the four first screws, a lower mold groove is formed in the top of the lower mold, a sliding plate is slidably connected to the bottom of the lower mold groove, and a plurality of evenly-distributed spring chambers are formed in the bottom of the sliding plate; and connecting rods are slidably connected into the multiple spring chambers correspondingly, the surfaces of the connecting rods are sleeved with first springs correspondingly, a sliding cavity is formed in the bottom end of the lower mold, and a sliding block is slidably connected into the sliding cavity. The mold is convenient to mount and dismount, the mold can be accurately and rapidly closed, and meanwhile iron in the mold can be conveniently taken out.

Owner:江苏纳萨铸造有限公司

Heat chamber die-casting mold with slide block guide

The invention discloses a heat chamber die-casting mold with slide block guide. The heat chamber die-casting mold comprises a movable mold frame and a fixed mold frame; a movable mold core is arranged on the movable mold frame; a fixed mold core is arranged on the fixed mold frame; the movable mold core and the fixed mold core are closed to form a casting runner; and the fixed mold frame is provided with a liquid inlet runner communicated with the casting runner. The heat chamber die-casting mold is characterized by further comprising at least one frame; a slide block capable of performing a reciprocating motion along the frame is arranged on the frame; an external thread is arranged on the other side, matched with the frame, of the slide block; and the slide block is in threaded connection with the movable mold frame. The heat chamber die-casting mold guides motions of the movable mold core and the movable mold frame through matching between the slide block and the frame, so that the movable mold core and the fixed mold core can be precisely closed; and the heat chamber die-casting mold is high in guide precision, excellent in quality of a die-casting piece, simple in whole structure and convenient for operation.

Owner:CHONGQING YINGRUISHENG DIE CASTING

Mold closing device of bulletproof helmet sheet paving machine

The invention relates to a mold closing device of a bulletproof helmet sheet paving machine. The mold closing device comprises an upper mold, a lower mold, an upper mold and a lower mold closing safelocking device installed on the upper mold and the lower mold and an upper mold and lower mold closing guiding and deviation rectifying device and a lower mold following upper mold rotating and keeping device which are installed on the upper mold; and the upper mold and the lower mold are correspondingly installed on a rack of the bulletproof helmet sheet paving machine. According to the mold closing device of the bulletproof helmet sheet paving machine, all programming of the whole working process is controlled by a PLC and automatically runs, the shape of each layer of material sheets can keep completely consistent with the shape of the interior of a sheet paving concave mold cavity of the lower mold after thermal hydraulic flexible sheet pressing is conducted, the material sheets are bonded closely and have no wrinkles or bubbles, therefore, the pre-pressing process of a bulletproof helmet can be omitted, the production efficiency is improved, the product quality is guaranteed, andthe mold closing device of the bulletproof helmet sheet paving machine is suitable for being applied and popularized by equipment fitting enterprises.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Hydraulic flexible sheet spreading device adopting concave mould for bulletproof helmet

The invention relates to a hydraulic flexible sheet spreading device adopting a concave mould for a bulletproof helmet. The hydraulic flexible sheet spreading device comprises a rack, and an upper mould and a lower mould which are mounted in the rack, wherein an upper and lower mould closing guide deviation-rectifying device, a device for enabling the upper mould to rotate along with the lower mould and keeping, and a hot hydraulic system which is connected to the upper mould, are mounted on the upper mould; and an upper and lower mould closing safety locking device is mounted on the upper mould and the lower mould. The hydraulic flexible sheet spreading device is automatic in operation, each layer of sheets can be kept to be completely consistent to the inner part of a sheet spreading concave mould cavity of the lower mould in shape after being thermally, hydraulically and flexibly pressed, and the layers are bonded tightly without wrinkles and gas bubbles, so that a pre-pressing process of the bulletproof helmet can be cancelled, production efficiency is improved and product quality is guaranteed, and therefore, the hydraulic flexible sheet spreading device is suitable for beingpopularized and applied in the equipment fitting enterprises.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com