A diaphragm manufacturing process for a moving iron unit

A technology of diaphragm production and moving iron, which is applied in the direction of electrical components, sensors, etc., can solve the problems that the acoustic performance of the moving iron unit cannot be fully exerted, easy to shrink and deform, and the product quality is unstable, so as to achieve stable and reliable product quality. The effect of high production efficiency and improved acoustic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

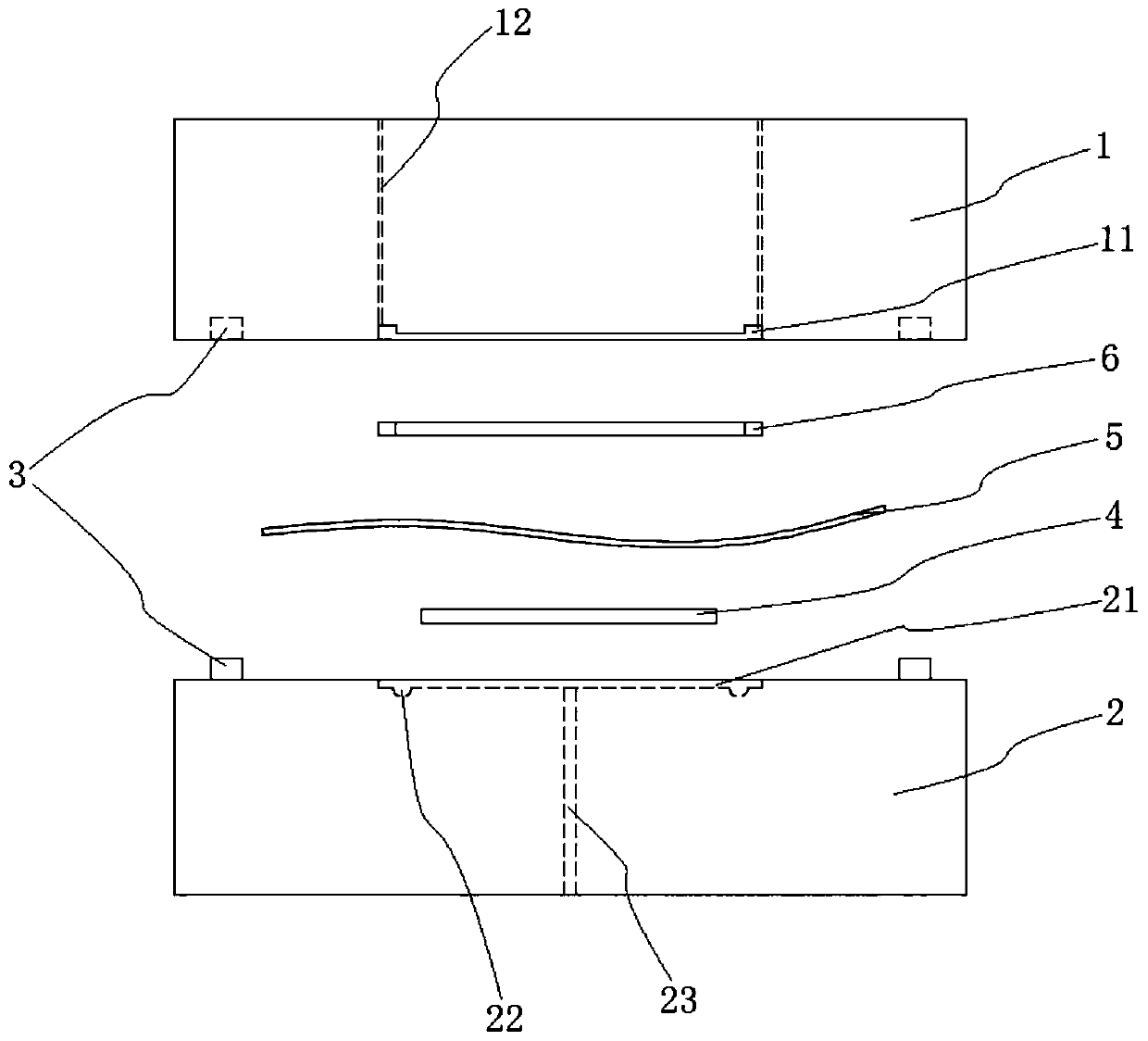

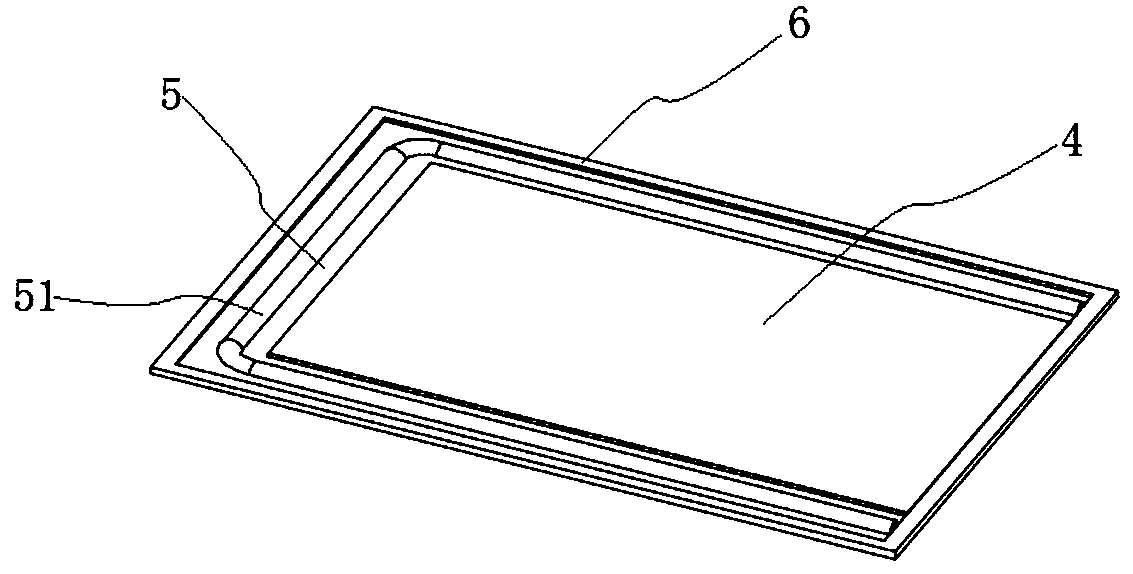

[0031] to combine figure 1 As shown, the diaphragm manufacturing process of a moving iron unit in this embodiment uses a hot pressing process to connect the diaphragm main body 4, the film 5 and the diaphragm support 6 together. The difference from the prior art is that in the mold In the upper mold 1 and the lower mold 2, there is no concave-convex structure for forming the diaphragm track 51, but in the hot pressing process, the film 5 is stretched into the track cavity 22 provided in the mold by blowing the film 5 with gas. runway 51. Using the diaphragm manufacturing process of this embodiment, the runway 51 on the film 5 is formed by gas pressure, which avoids the extrusion and deformation of the film material, thereby affecting the strength uniformity of each part of the runway 51, and avoids stretching. Runway 51 shrinkage problem. In this embodiment, the raceway structure is skillfully formed by using gas pressure in the hot pressing process of the diaphragm, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com