Full-automatic powder pressing machine for powder cake production

A fully automatic, powder press technology, applied in material forming presses, presses, manufacturing tools, etc., can solve the problems of high production cost and maintenance cost, failing to improve production efficiency, and extremely difficult to popularize in a large area. Achieve the effect of facilitating long-term maintenance, reducing manual workload and work intensity, and reducing the amount of computational data

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

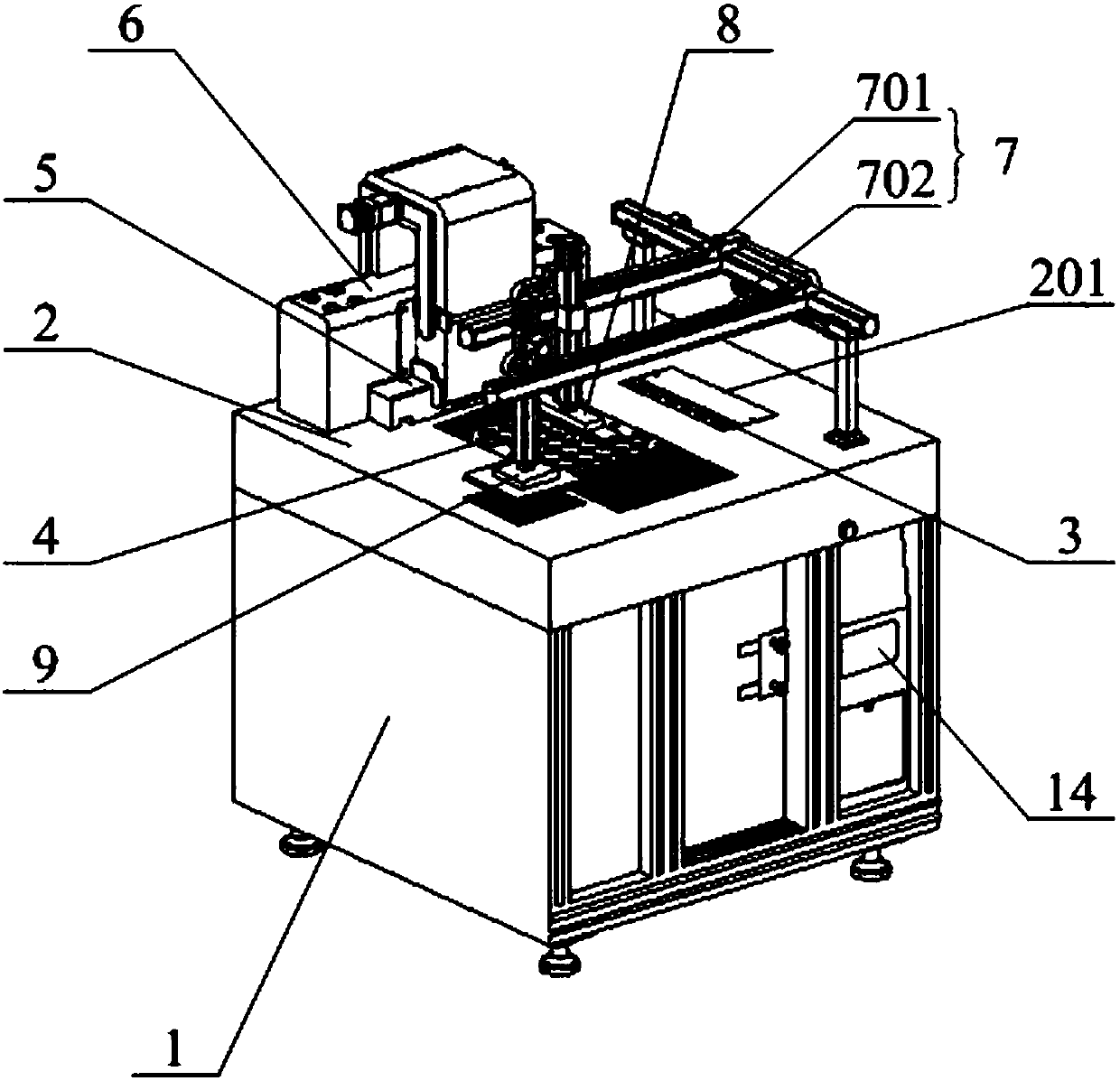

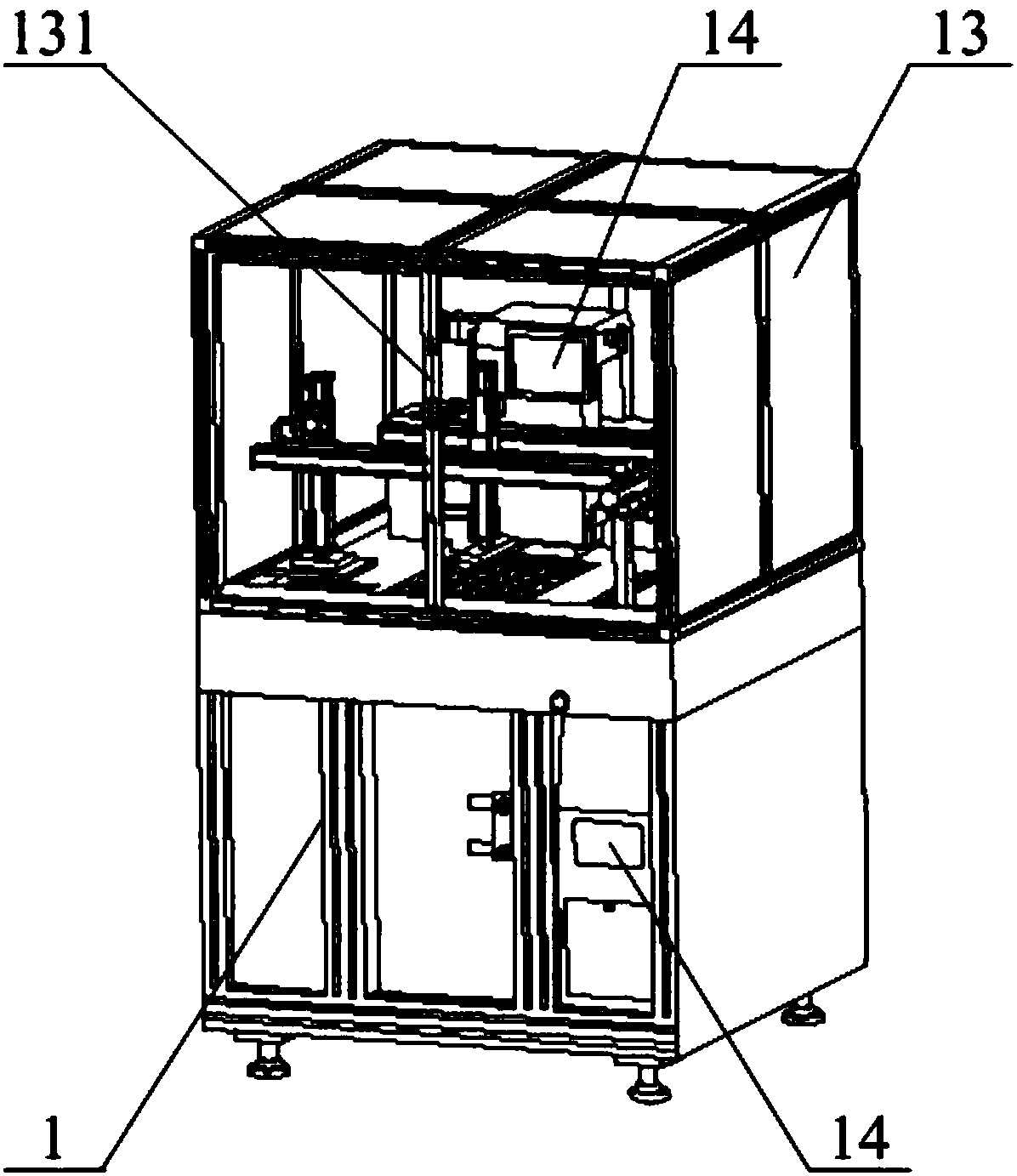

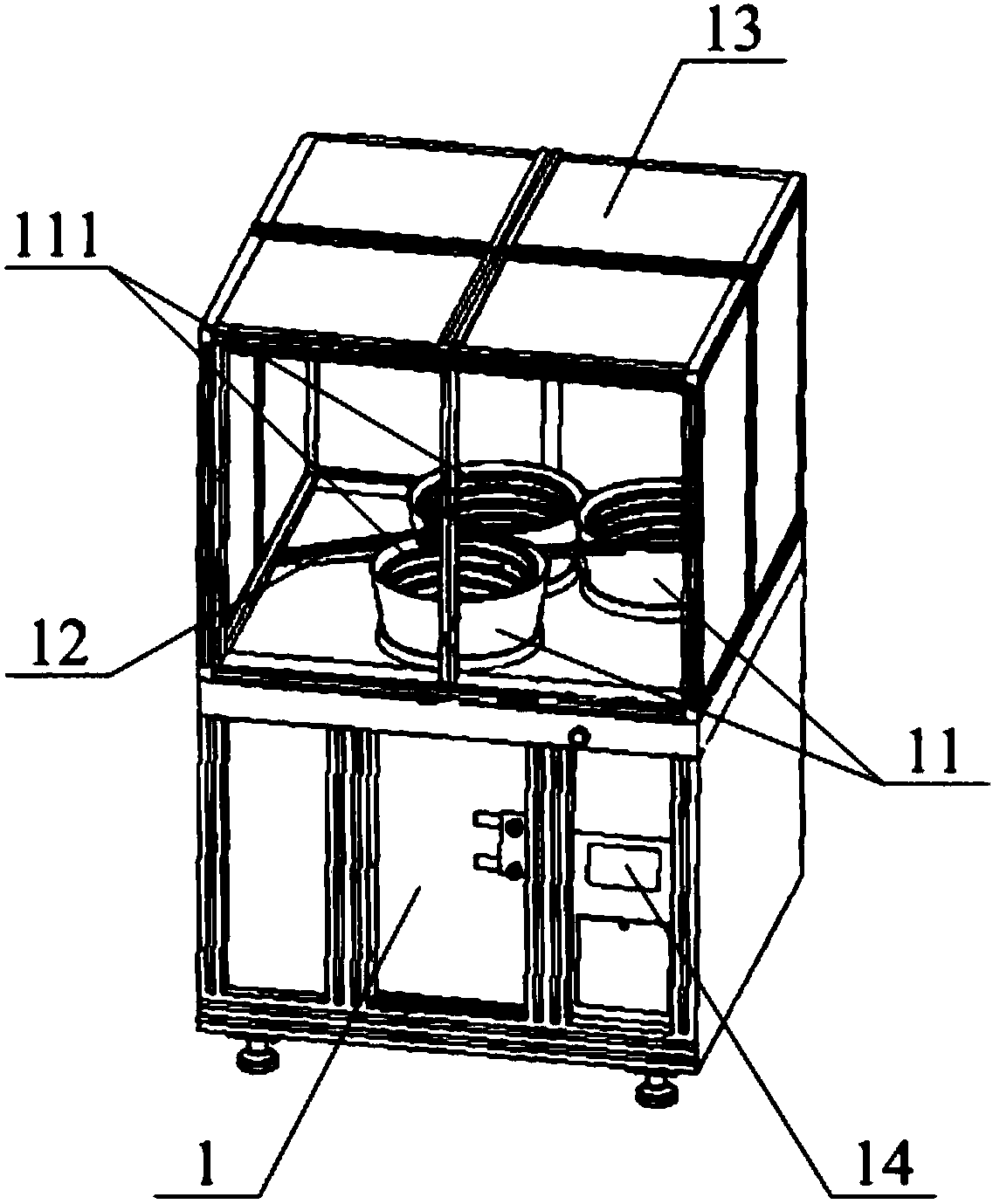

[0021] figure 1 A schematic diagram of the three-dimensional structure of the fully automatic powder pressing machine provided by the present invention is shown, figure 2 A schematic diagram showing the structure of the fully automatic powder compactor provided by the present invention with a cover, image 3 It shows a schematic diagram of the inside of the automatic powder compactor provided by the present invention with a cover.

[0022] The full-automatic powder pressing machine for powder cake production provided in this embodiment includes a frame 1, a work surface 2, a prefabricated mold for a packaging tray station 3, a moving female mold for a packaging tray 4, a powder filling mechanism 5, and a male mold Loading beam 6, manipulator moving guide rail mechanism 7 left and right, packaging tray loading manipulator 8, finished product pick-up manipulator 9 and electric control module, wherein, the said packaging tray moving master mold 4 can move back and forth on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com