Mold closing device of bulletproof helmet sheet paving machine

A mold clamping device and helmet laying technology, which is applied in the field of production and processing machinery for armored bulletproof products, can solve problems such as unbonded, air bubbles and wrinkles, and affect work efficiency, so as to reduce slippage, dislocation deformation, and omit pre-pressing The effect of process and performance index improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

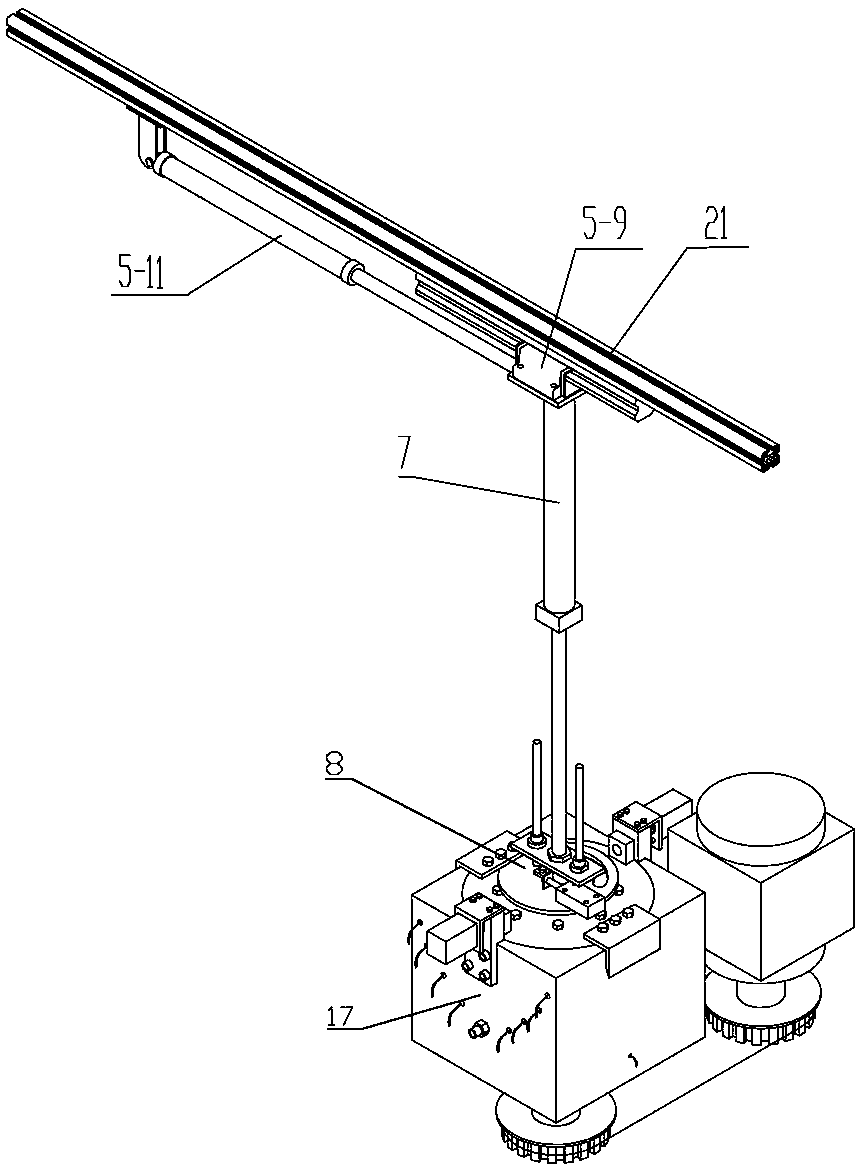

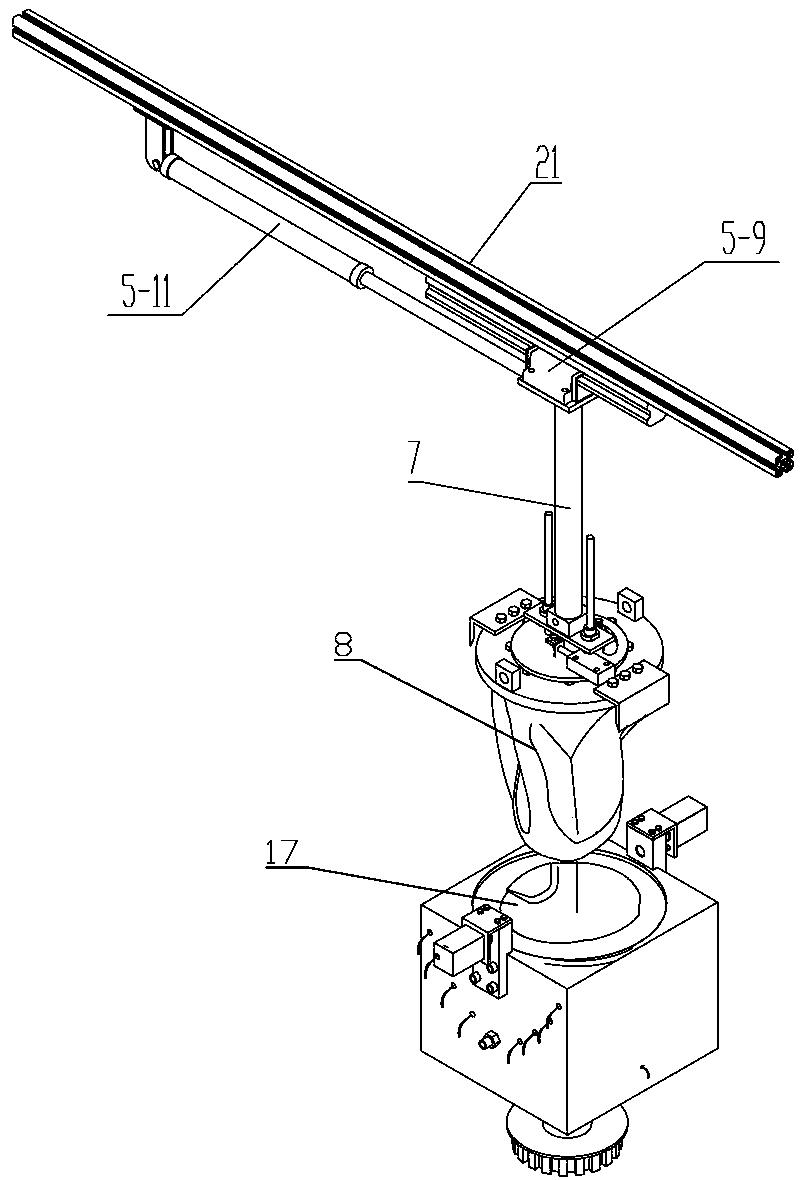

[0043] as attached figure 1 , 2 As shown, the present invention includes an upper mold 8, a lower mold 17, an upper and lower mold clamping safety locking device installed on the upper mold 8 and the lower mold 17, and an upper and lower mold clamping guide deviation correction device installed on the upper mold 8 and an upper mold clamping device. The mold rotates with the lower mold and the holding device; the upper mold 8 and the lower mold 17 are correspondingly installed on the frame of the bulletproof helmet sheeting machine.

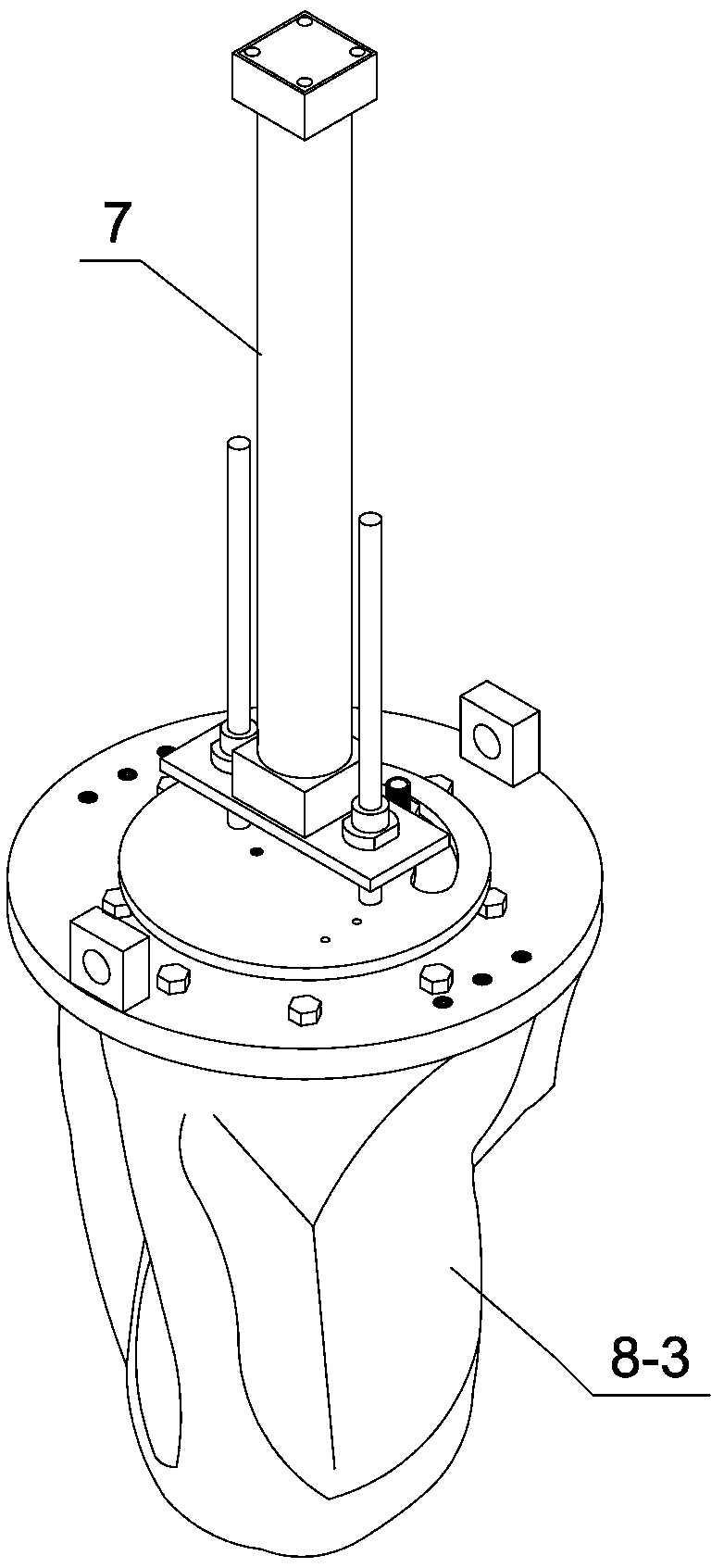

[0044] as attached image 3 , 4 As shown, the upper mold 8 of the present invention includes an upper mold circular cover plate 8-1, a guide sleeve mounting plate 8-8, a brake disc 8-6, a guide rod 8-9 and a rubber bag 8-3. The rubber bag 8-3 is a bag body with an opening on the top wall; the guide sleeve mounting plate 8-8 is installed at the lower end of the upper mold lifting cylinder 7, and the guide sleeve 8-7 is installed on both sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com