Hydraulic flexible sheet spreading device adopting concave mould for bulletproof helmet

A bulletproof helmet and concave mold technology, which is applied in the field of a bulletproof helmet concave mold thermo-hydraulic flexible sheet-laying device, can solve problems such as affecting work efficiency, non-sticking, and reduction in anti-performance and strength, and achieves guaranteeing the quality and precision of sheet-laying, The effect of reducing slip dislocation deformation and preventing material displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

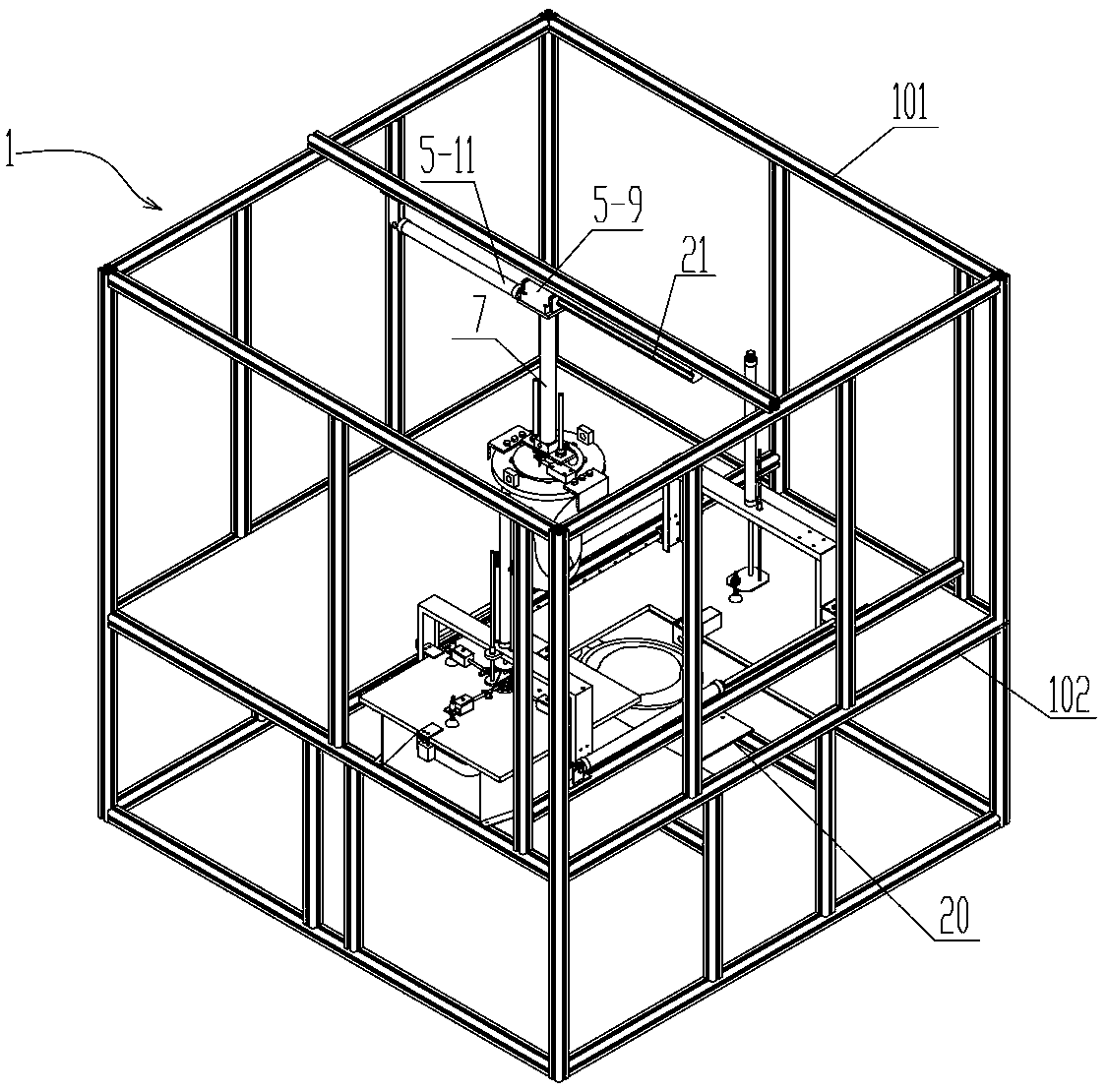

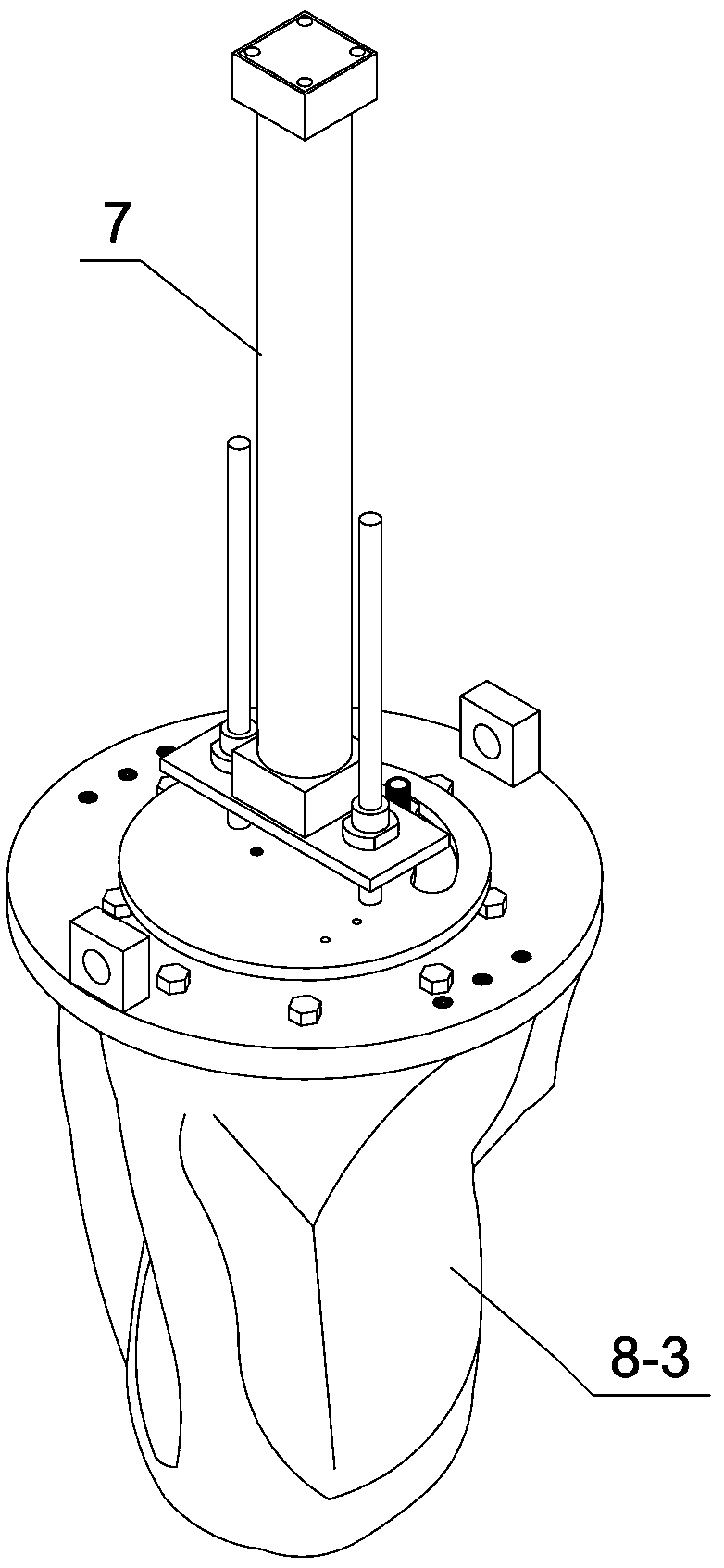

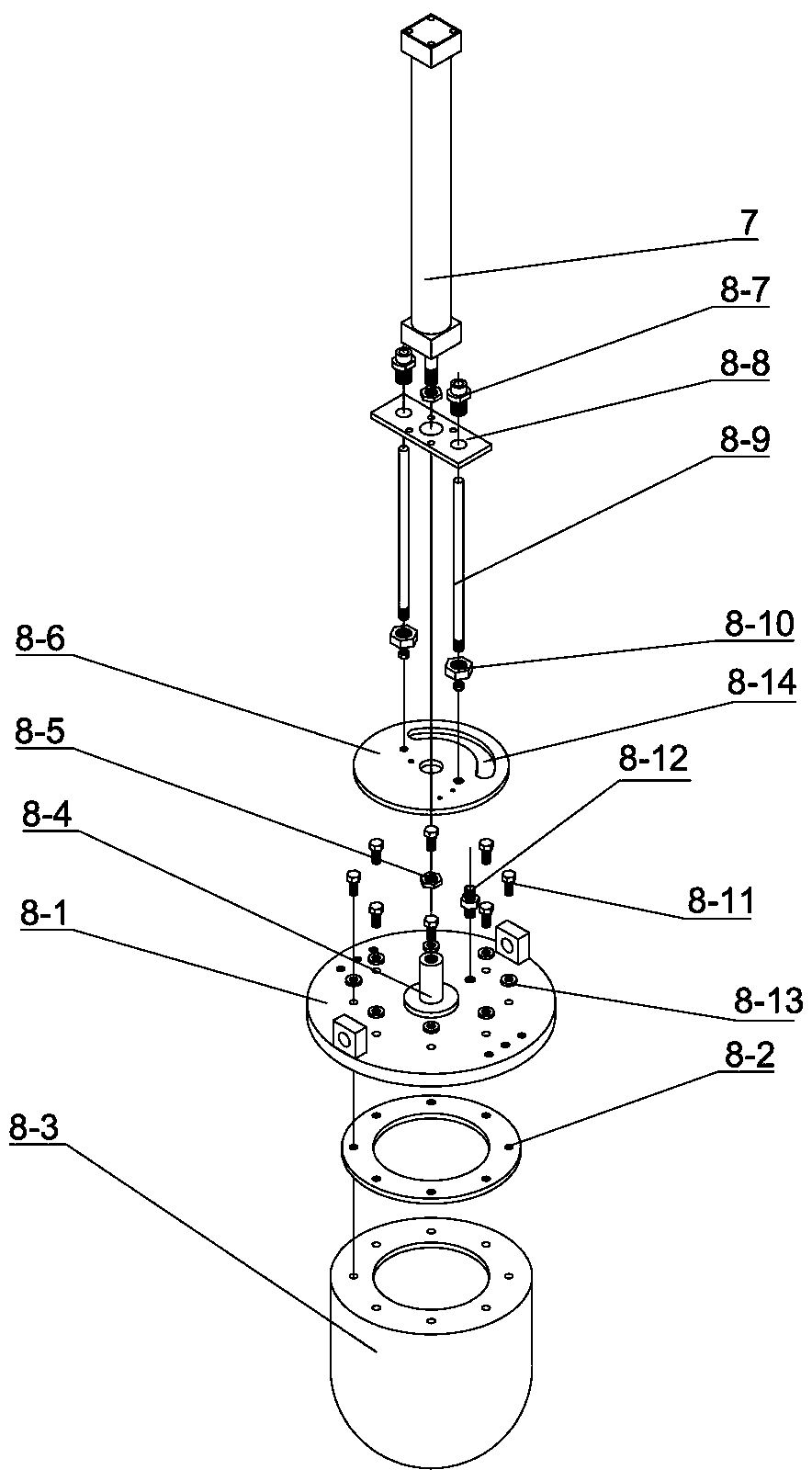

[0043] as attached figure 1 , 2 As shown, the present invention includes frame, upper mold 8 and lower mold 17 installed in the frame; The middle frame 102 is provided with an operating platform 20 on the middle frame 102; a linear slide rail 21 is installed on the upper frame 101, and an upper mold drive cylinder 5-11 is installed on the linear slide rail 21 through a slider 5-9 , the cylinder end of the upper mold driving cylinder 5-11 is installed on the beam of the upper frame 101, and the upper mold lifting cylinder 7 is installed at the bottom of the slider 5-9, and the upper mold 8 is installed on the piston rod end of the upper mold lifting cylinder 7 , the lower mold 17 is installed on the operating platform 20; the upper and lower molds are installed on the upper mold 8 to guide the deviation correction device, the upper mold rotates with the lower mold and the holding device, and the thermal hydraulic system connected with the upper mold 8; The mold clamping safet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com