Mold structure for manufacturing precise optical lens cone

A technology of precision optics and lens barrel, which is applied in the field of mold structure for making precision optical lens barrels. It can solve problems such as appearance or performance that cannot meet market demand, achieve high coaxiality, avoid top damage, and improve stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

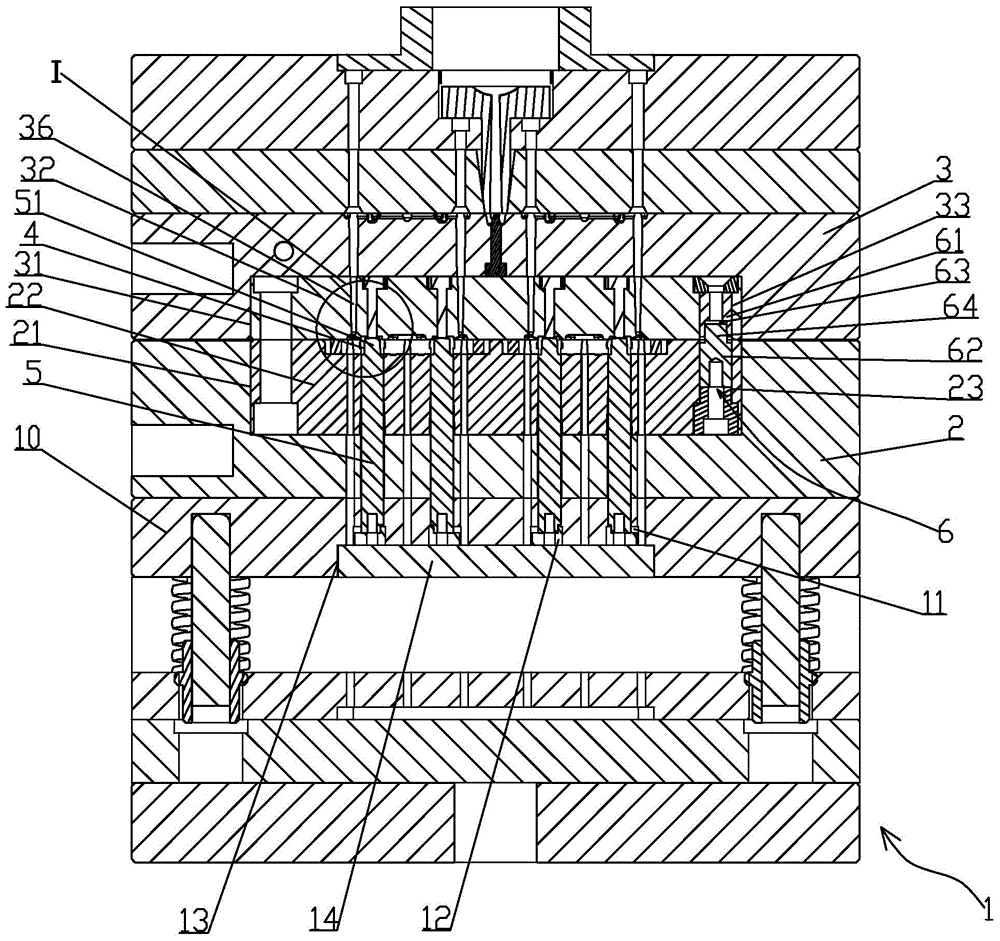

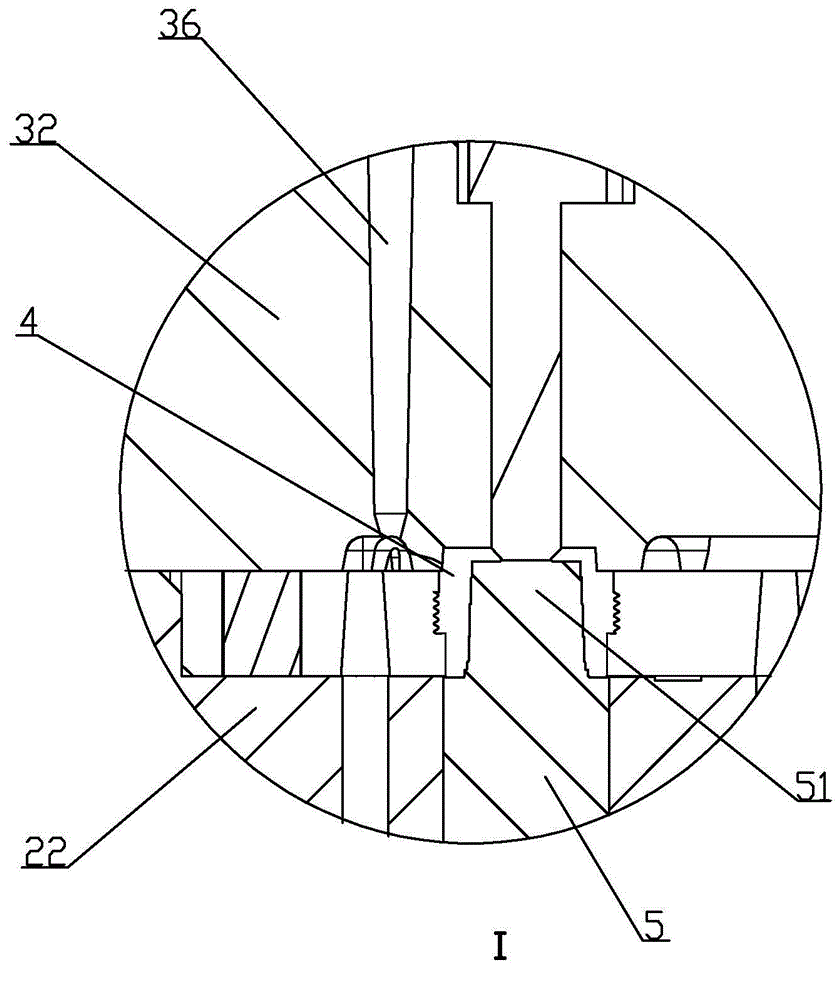

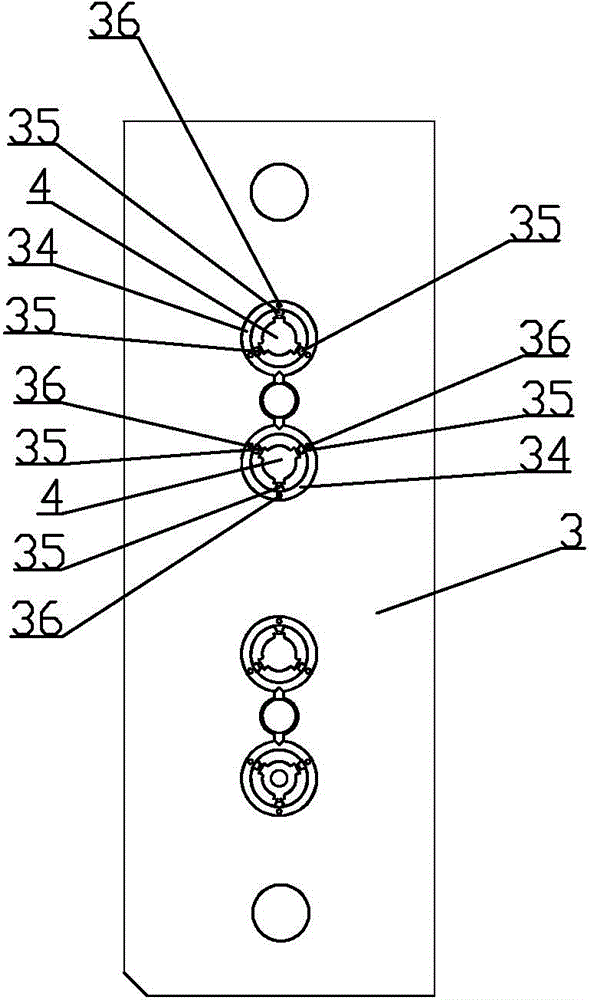

[0019] Such as Figure 1 to Figure 5 As shown, a mold structure for making a precision optical lens barrel includes a base body 1, a punch fixing plate 10, a lower mold base 2, and an upper mold base 3 are sequentially arranged on the base body 1, and a lower mold base 2 is provided with a lower mold base. Die cavity 21, the upper mold base 3 is provided with the upper mold cavity 31 that covers with the upper mold cavity 21, the lower mold cavity 21 is provided with a lower mold core 22, and the upper mold cavity 31 is provided with an upper mold core 32, convex The die fixing plate 10 is provided with a punch rod 5 that passes through the lower mold base 2 and is inserted into the lower mold core 22. The lower mold core 22, the upper mold core 32 and the punch rod 5 are surrounded by a molding cavity 4, and the lower mold core 22 A lower posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com