High-matching-degree multi-knife-type integrated hardware mold used for die cutting

A matching and die-cutting technology, which is applied in metal processing and other directions, can solve problems such as low work efficiency, difficult operation, and time-consuming work, and achieve the effects of improving product qualification rate, improving production efficiency, and accurate mold closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

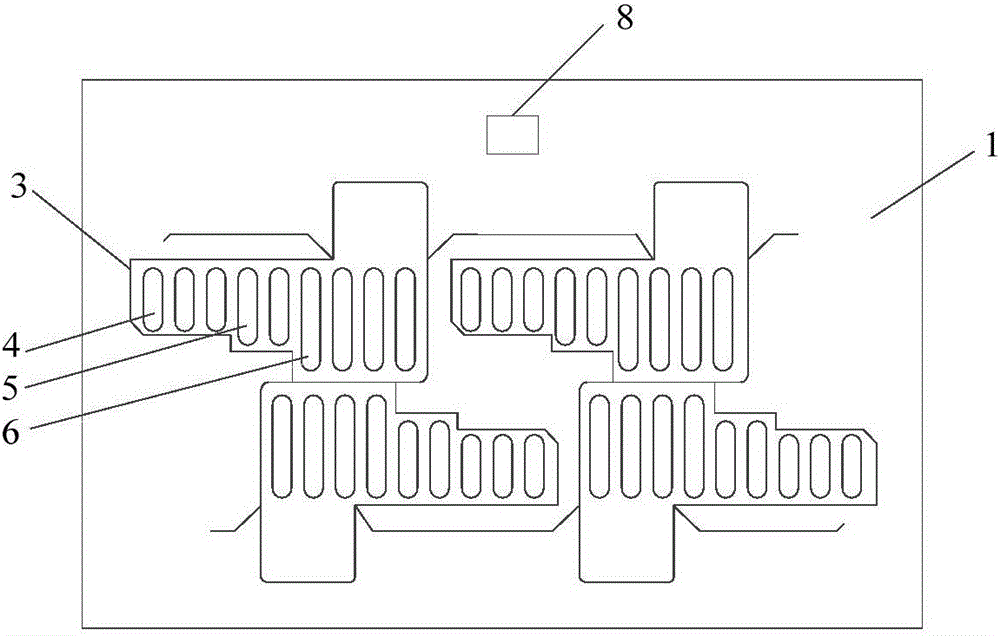

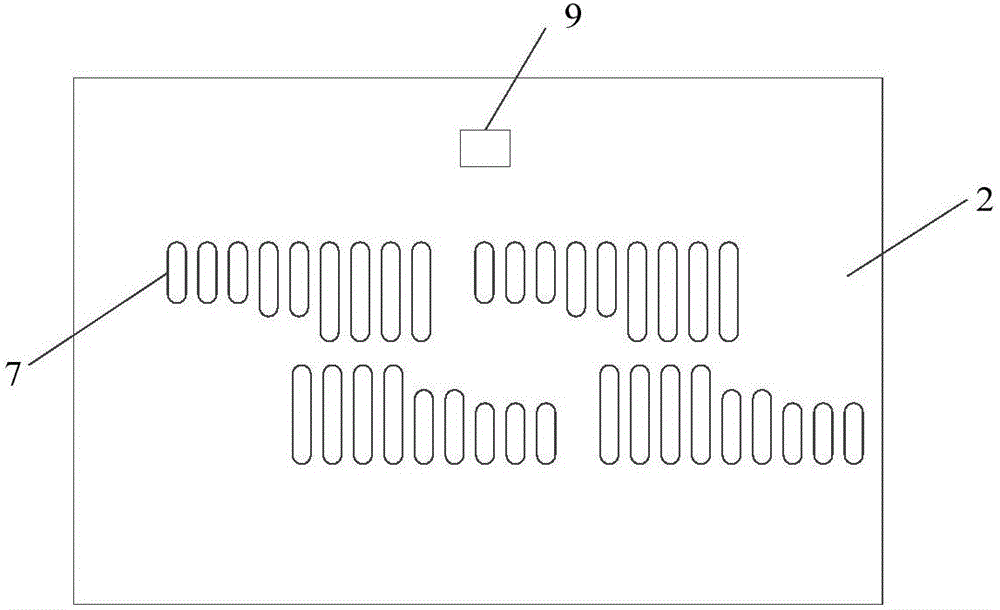

[0022] Such as figure 1 , figure 2 As shown, a high-matching multi-knife integrated metal mold for die-cutting includes an upper mold 1 and a lower mold 2. The surface of the upper mold 1 is provided with multiple sets of punching knives 3, and each set of punching knives 3 is At least one type of blade is provided, and the surface of the upper mold 1 is also provided with an upper mark 8; the corresponding position on the surface of the lower mold 2 is respectively provided with a punching knife-shaped cavity 7 corresponding to the blade and a knife-shaped cavity corresponding to the blade. The upper mark 8 matches the lower mark 9; when the mold is closed, the precise matching of the upper mark 8 and the lower mark 9 is controlled, so as to realize the accurate mold clamping of the corresponding blade and the punching knife cavity 7.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com