Patents

Literature

31results about How to "Solve the difficulty of discharging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

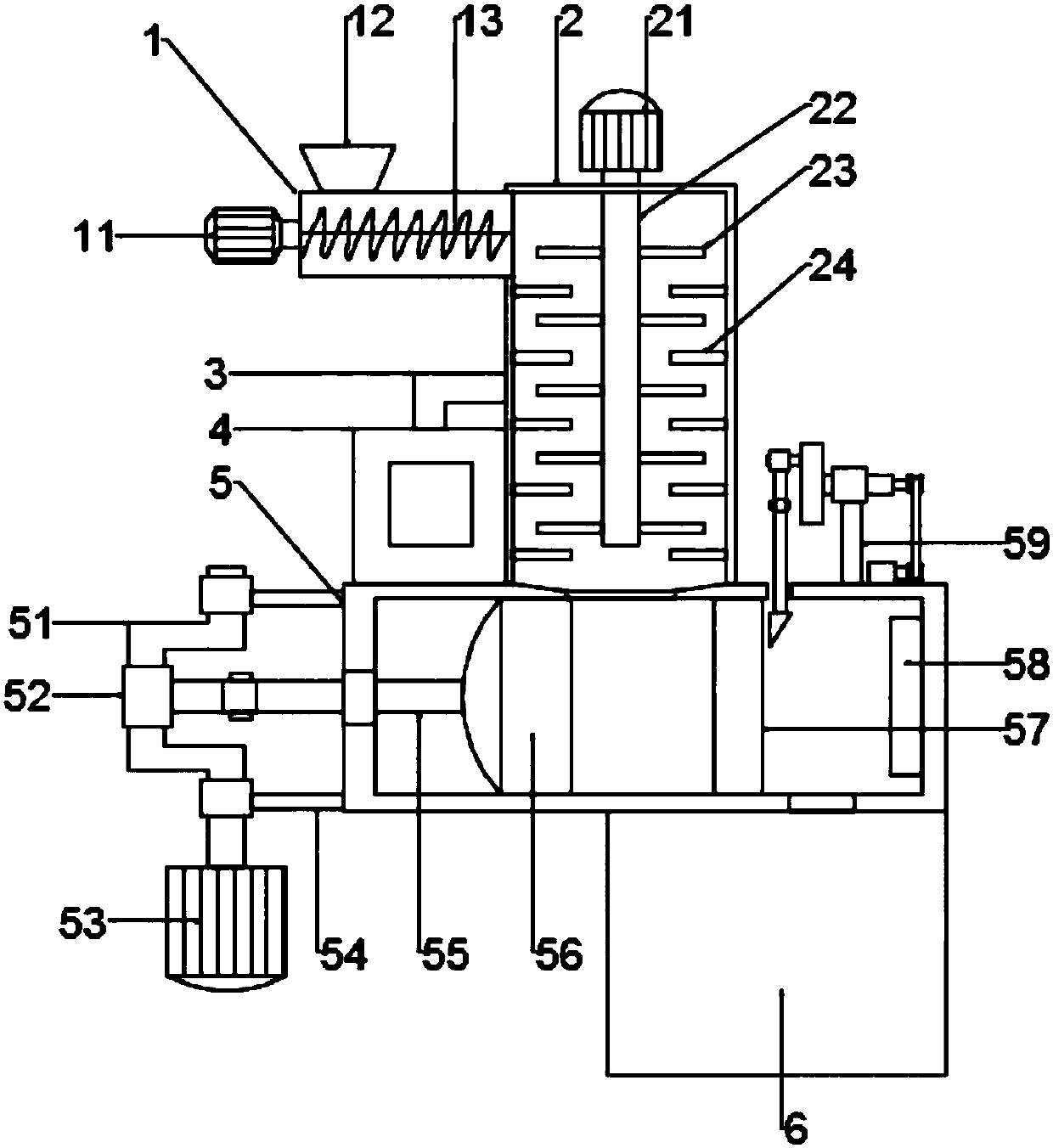

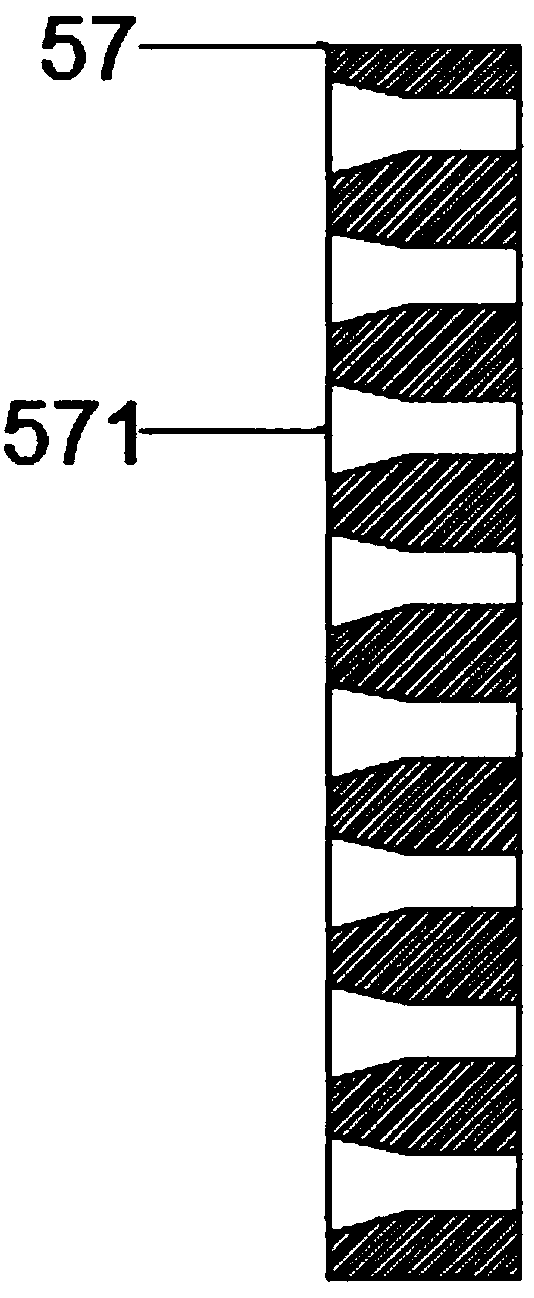

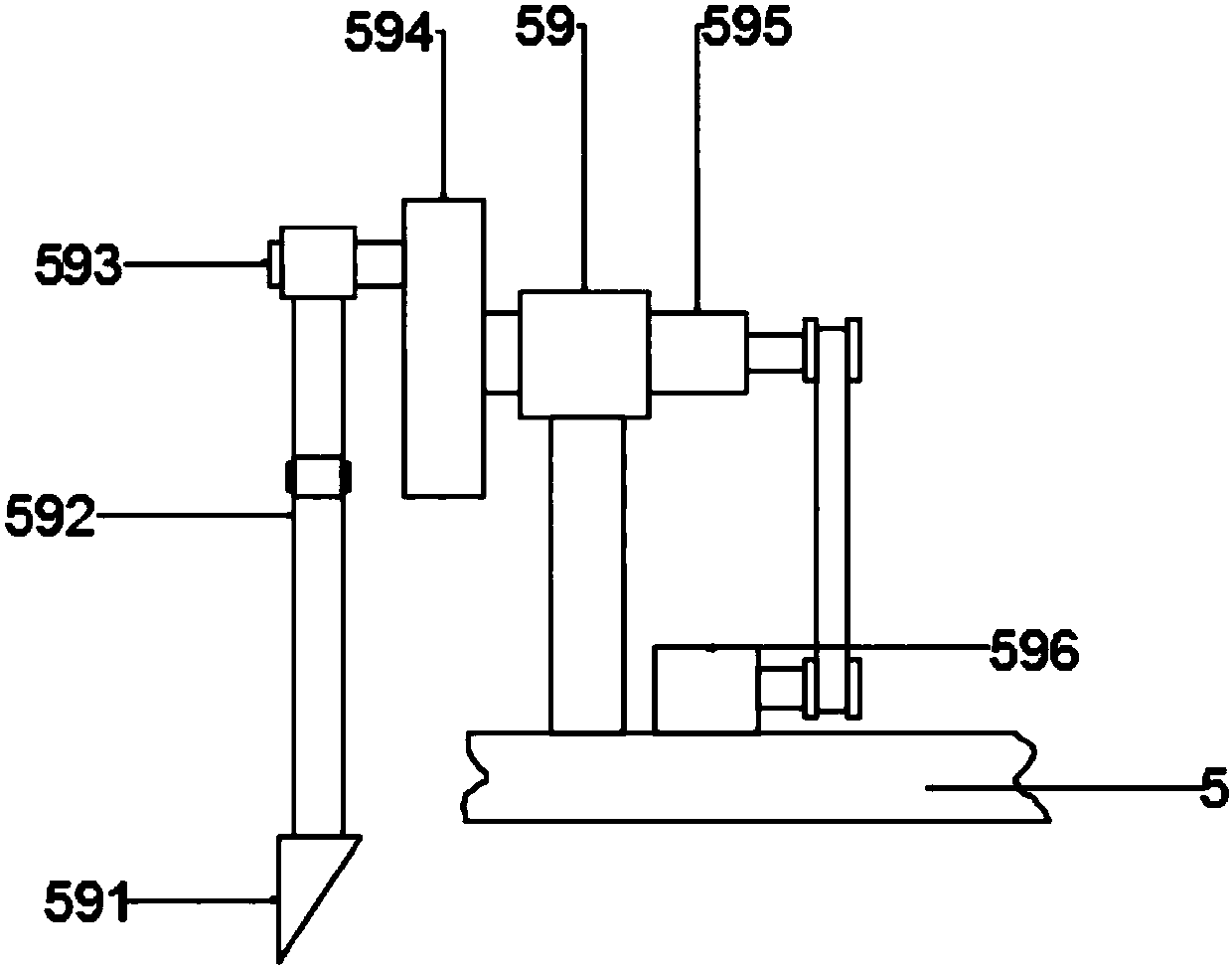

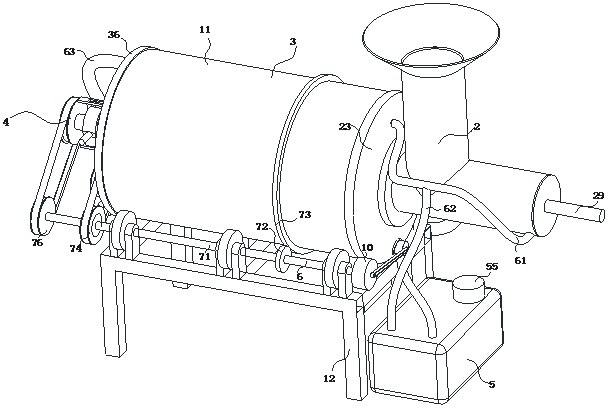

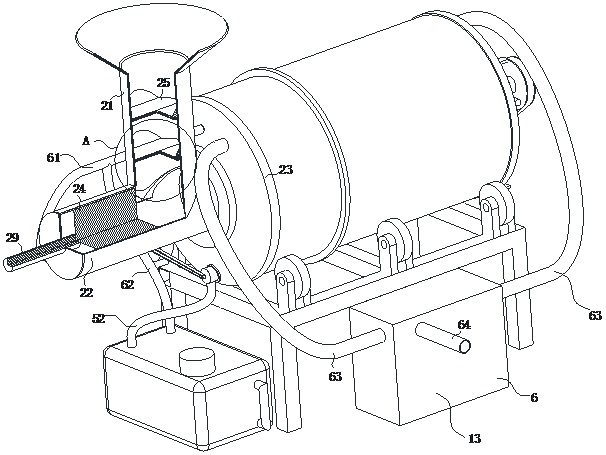

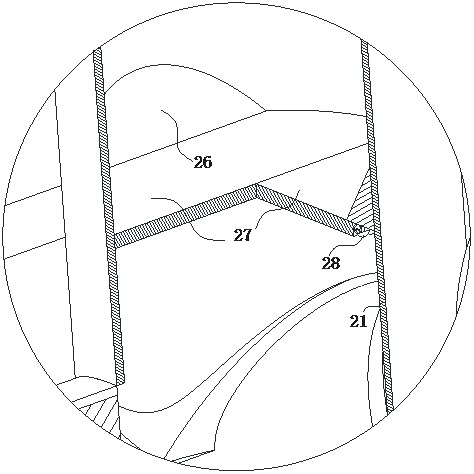

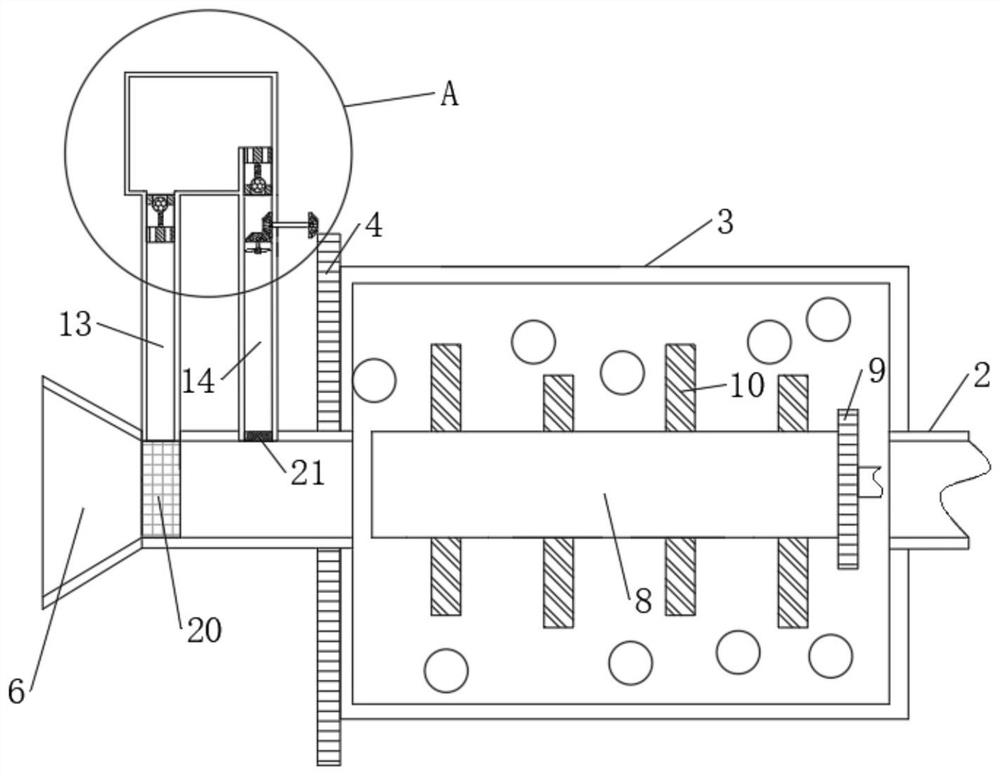

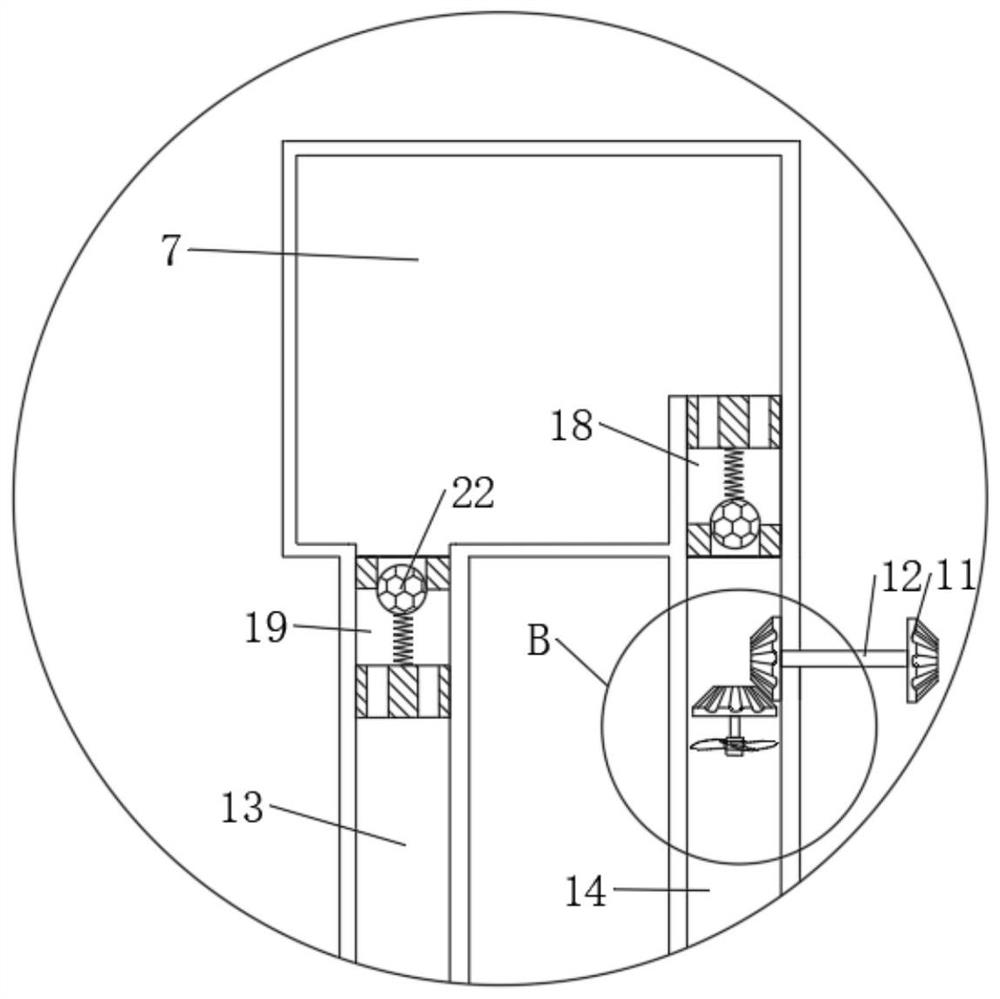

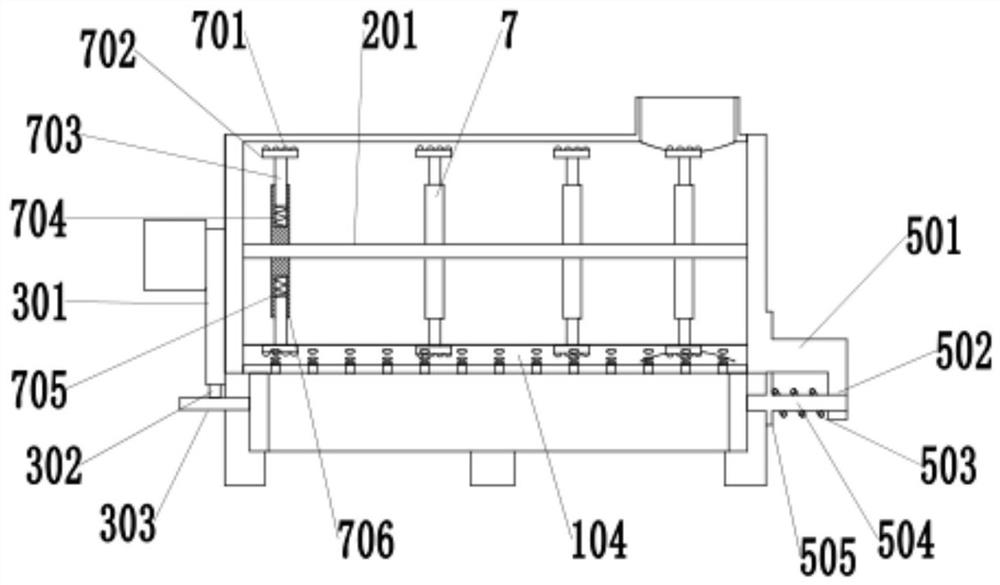

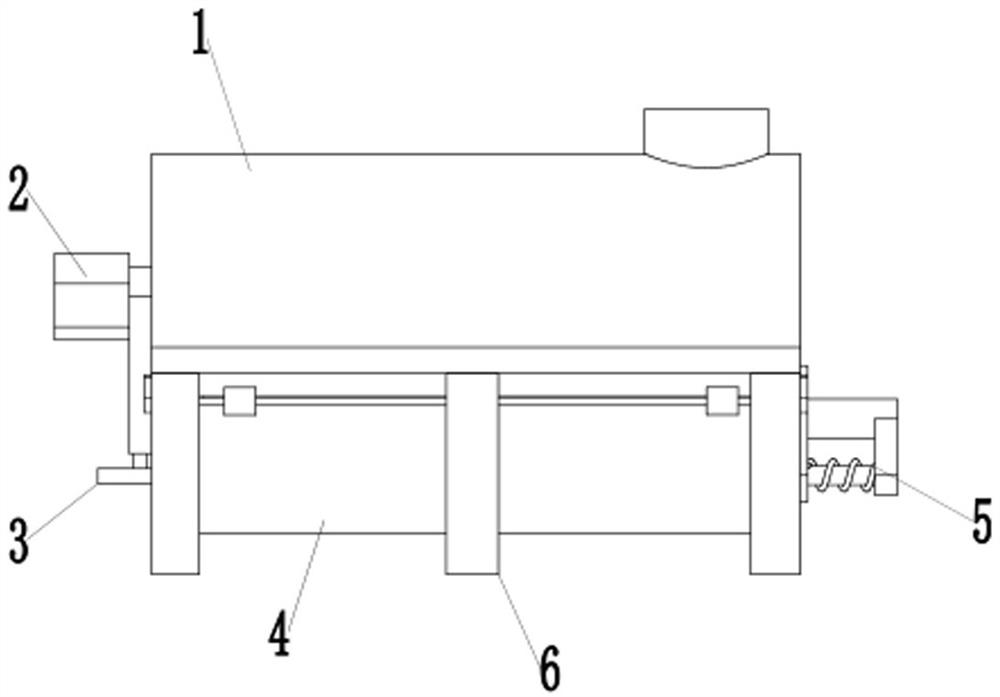

Granulating and screening machine for feed production

InactiveCN107581643AMalleableImprove granulation qualityFeeding-stuffAgricultural engineeringWater pipe

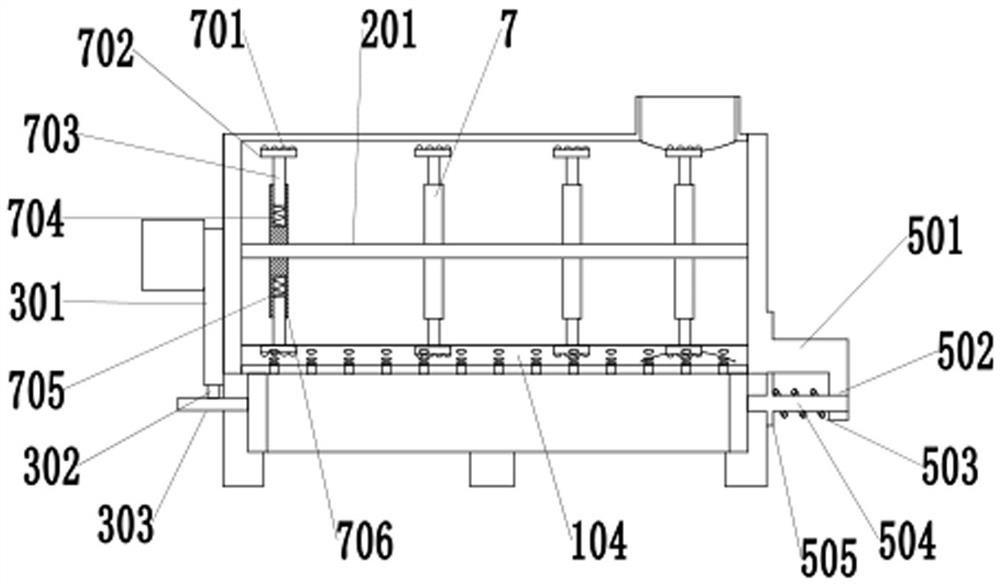

The invention discloses a granulating and screening machine for feed production. The granulating and screening machine comprises a charging device, a conditioning mechanism, a granulating box and a screening box, wherein a charging opening is formed in the upper end of the charging device, a first rotating shaft is arranged in the conditioning mechanism, stirring paddles distributed in arrays arearranged on the first rotating shaft, water filling pipes distributed in arrays are arranged on the conditioning mechanism on the left and right sides of the stirring paddles, a squeezing plate is arranged in the granulating box, a granulating plate is arranged in the granulating box on the right side of the squeezing plate, a cutting device is arranged on the granulating box on the right side ofthe granulating plate, a charging pipe is arranged on the upper end of the screening box, a screening plate is arranged in the screening box on the lower side of the charging pipe, and a discharging pipe is arranged on the screening box on the right side of the screening plate. According to the granulating and screening machine for feed production disclosed by the invention, the contact area between water and feed is large, the conditioning effect is good, the conditioning mechanism is provided with vertical conditioning for solving the problems of insufficient stirring and water addition anddifficulty in discharging of a transverse conditioning mechanism, the granulating efficiency is high, and the feed granulating quality is high.

Owner:遂昌县宏创技术开发有限公司

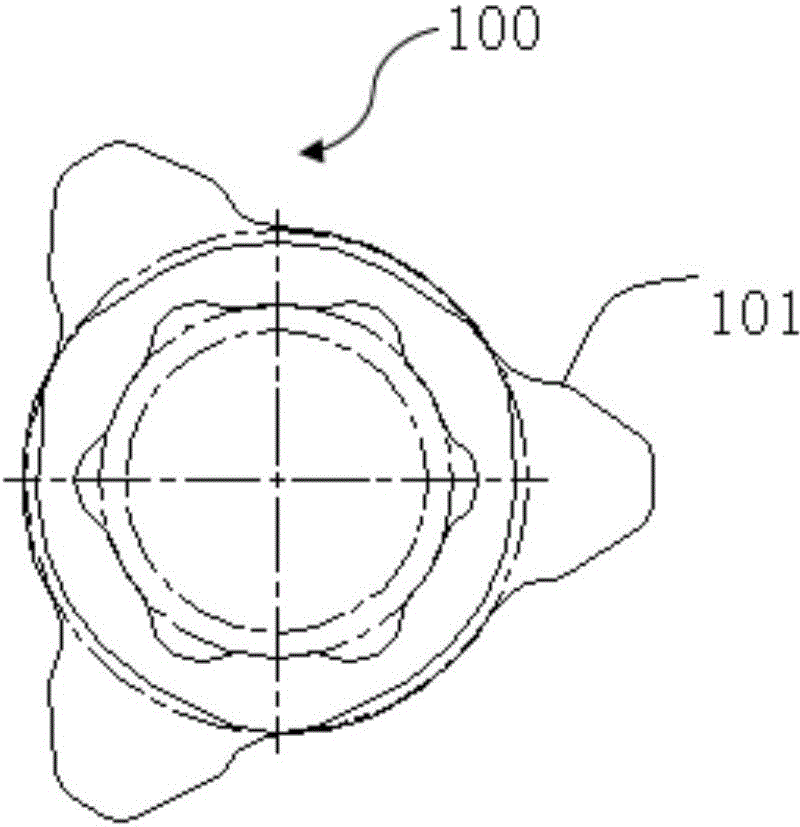

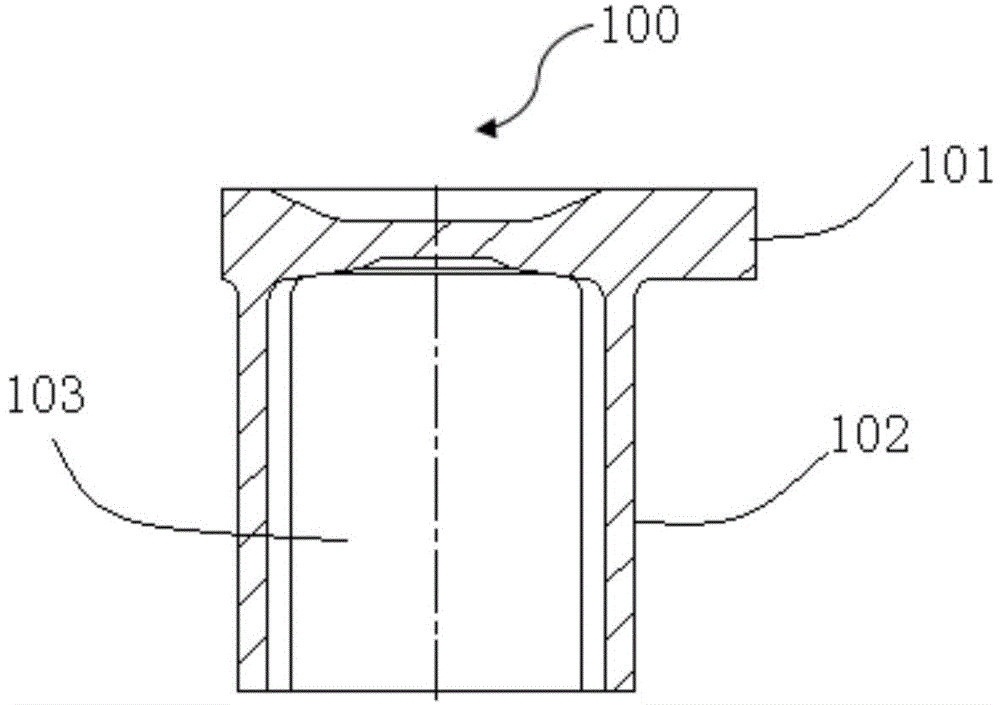

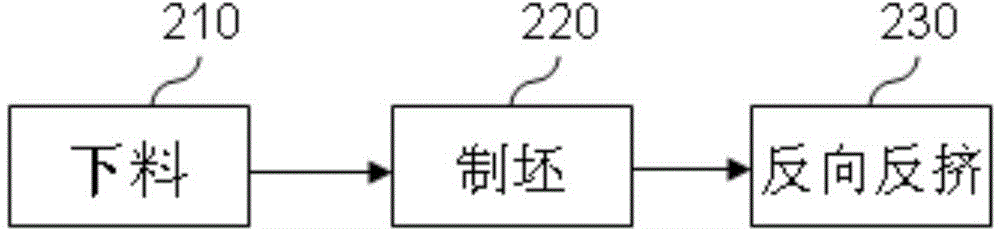

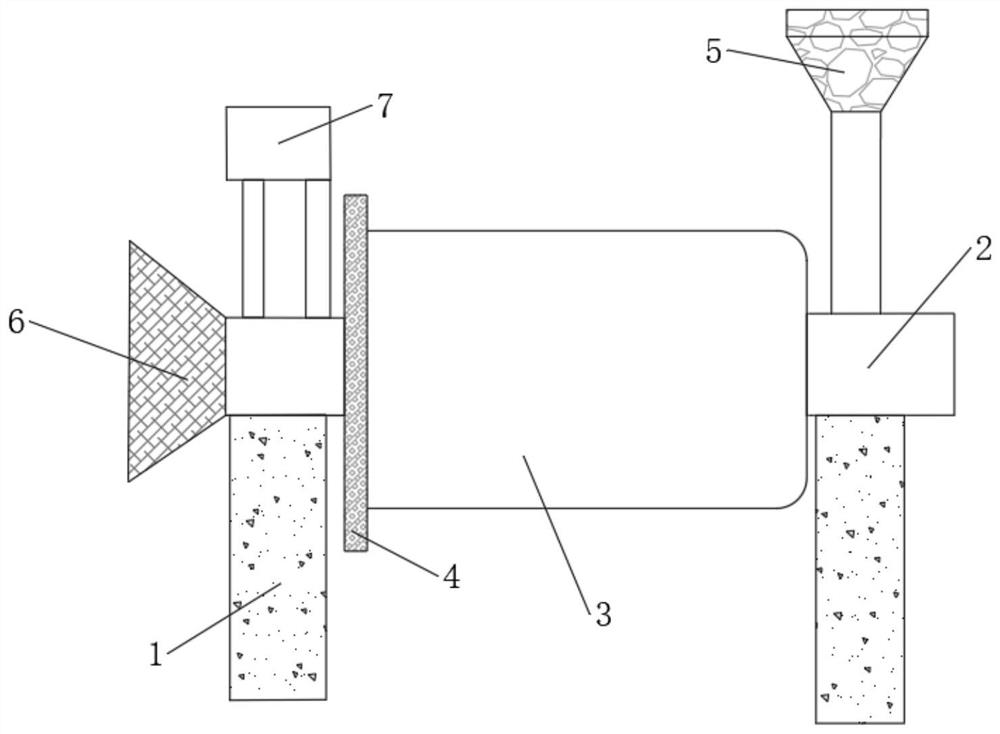

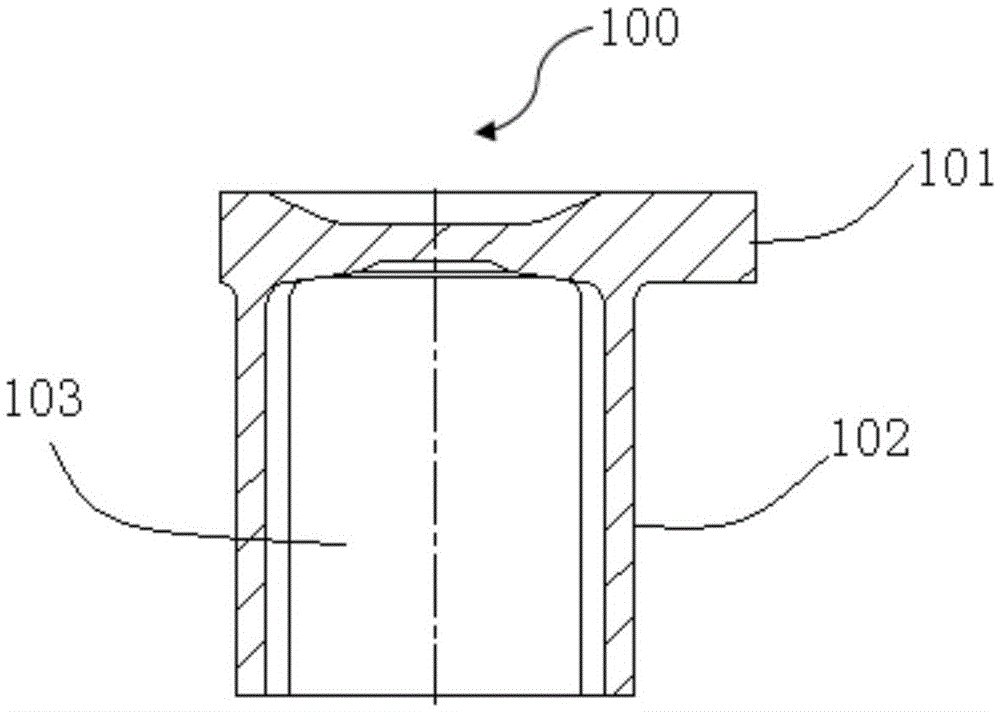

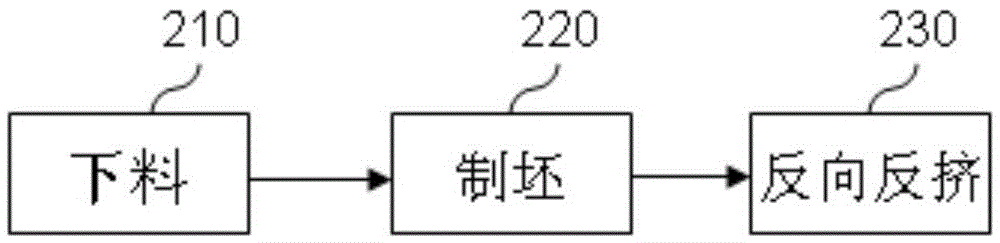

Equilateral three-jaw flange sliding sleeve inversion reverse extrusion technology and inversion reverse extrusion mould

The invention provides an equilateral three-jaw flange sliding sleeve inversion reverse extrusion technology. The equilateral three-jaw flange sliding sleeve inversion reverse extrusion technology comprises inversion reverse extrusion, wherein the inversion reverse extrusion comprises the steps of placing a rod material after sheet stamping into a mould cavity of an inversion reverse extrusion mould, simultaneously carrying out upsetting and extrusion on the rod material to form a blank, wherein one end of the blank is provided with an equilateral three-jaw flange disc, and the other end of the blank is in a barrel-type shape. The equilateral three-jaw flange sliding sleeve inversion reverse extrusion technology provided by the invention has the advantages that the relative movement of a reverse extrusion concave module and a reverse extrusion punch is utilized to carry out backward extrusion, an upsetting flange and reverse extrusion equal-wall-thickness sliding sleeve process are simultaneously performed, the technology is reduced, the efficiency is improved, the technology solves the problem that a material is hard to discharge, a thick gap is formed between the reverse extrusion punch and an inner wall of a reverse extrusion module cavity, the contacting area of the reverse extrusion punch and the rod material is small, the friction force is reduced when the material returns, the service life of the mould is prolonged, the technology is simple and practicable, the material is saved, the efficiency is improved, an inversion reverse extrusion mould is simple to manufacture, the assembly is easy, the service life is long, and the cost of the mould is saved.

Owner:江苏理研科技股份有限公司

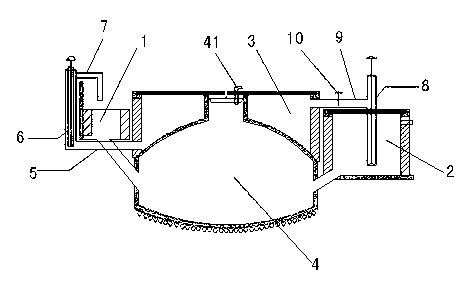

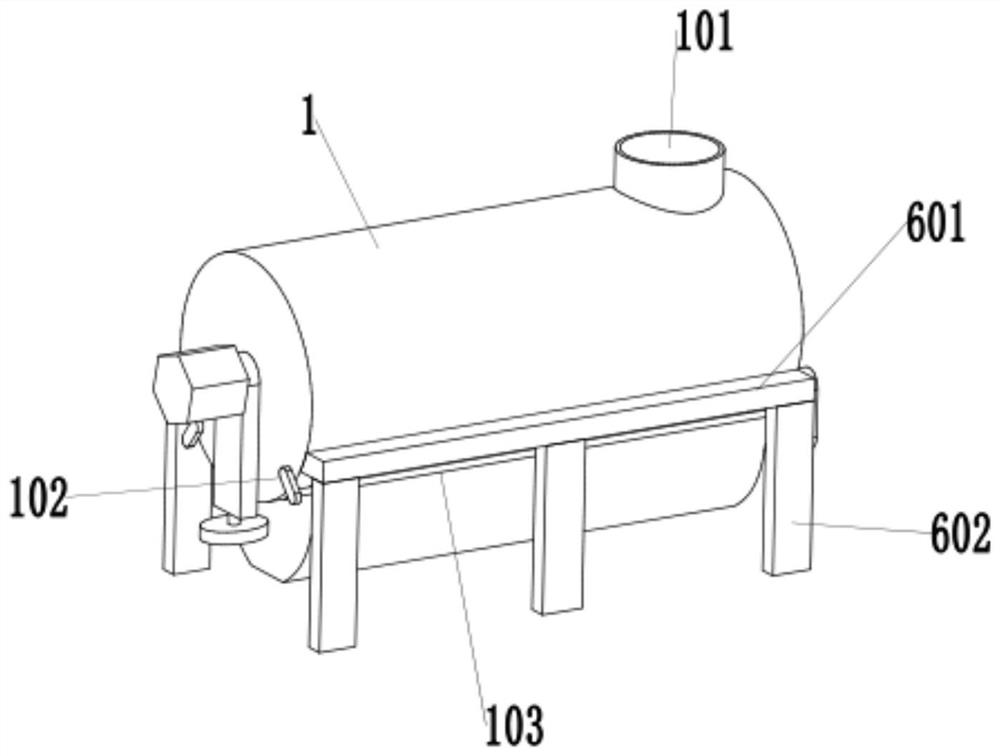

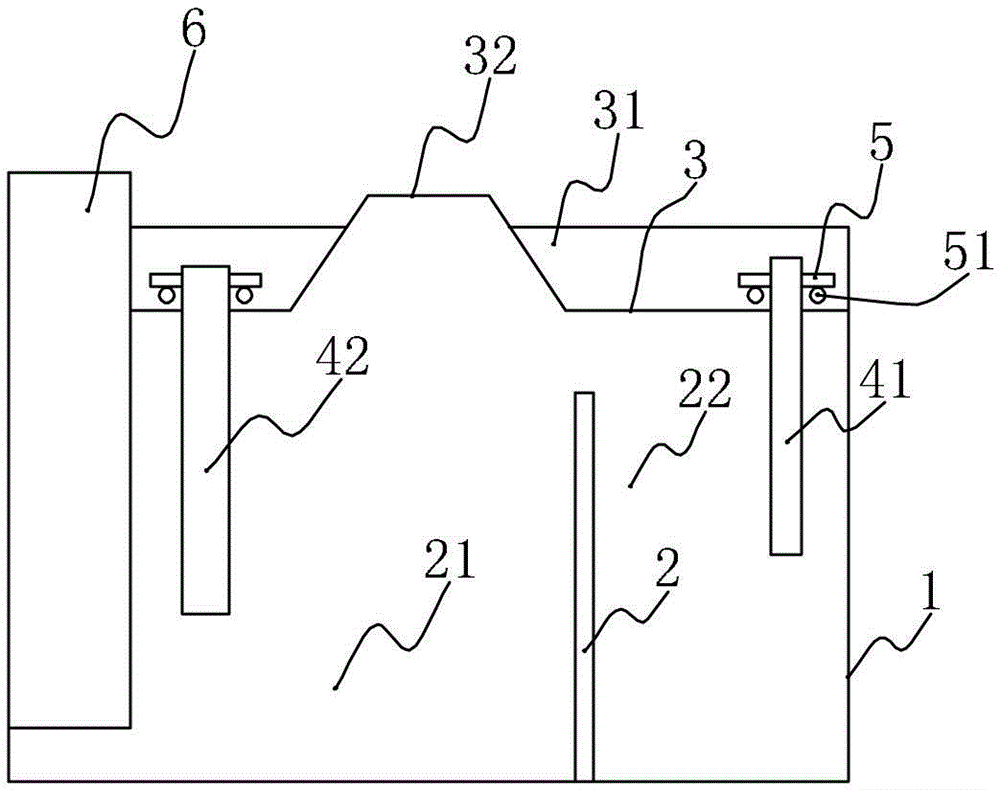

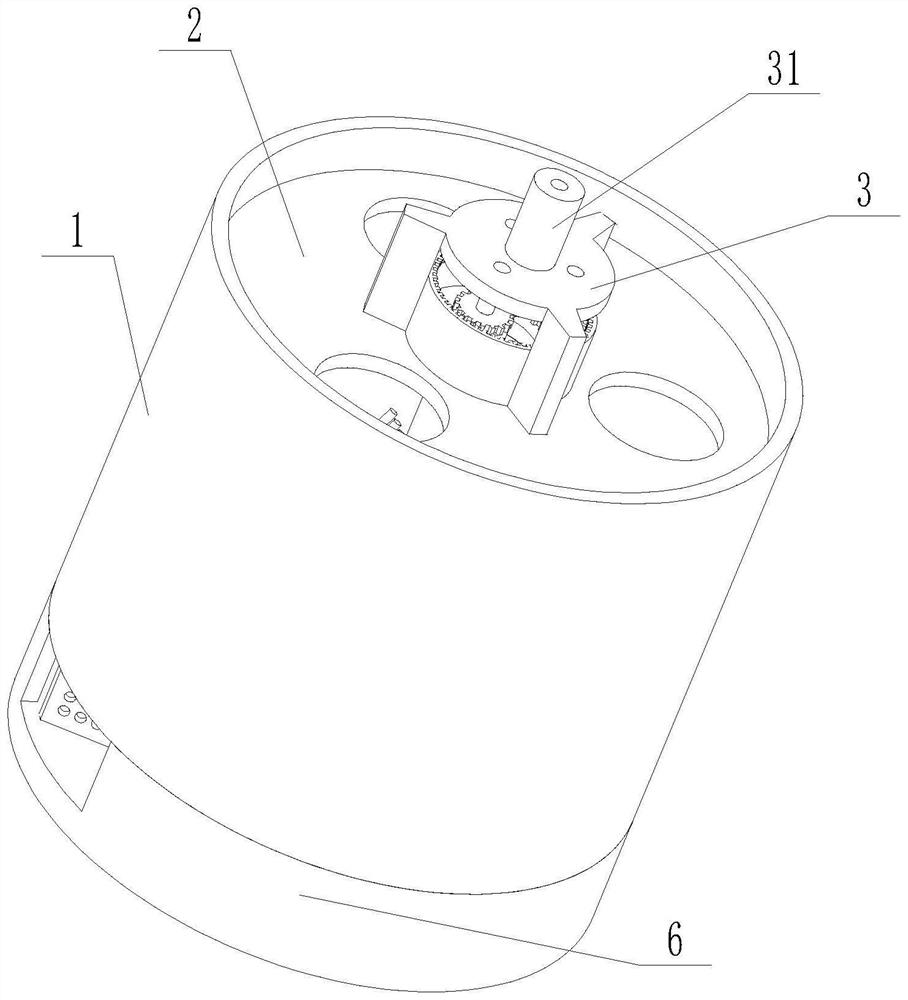

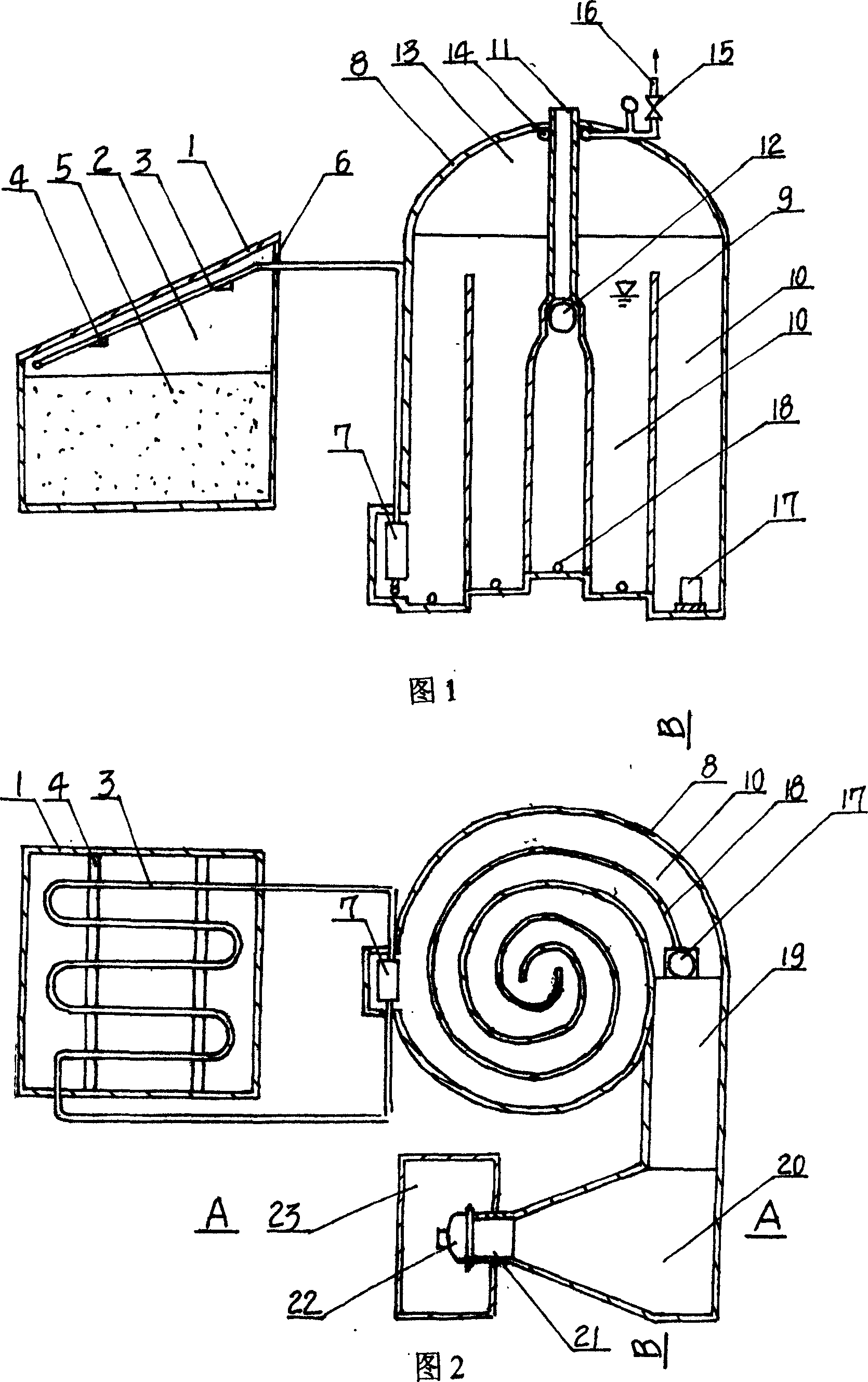

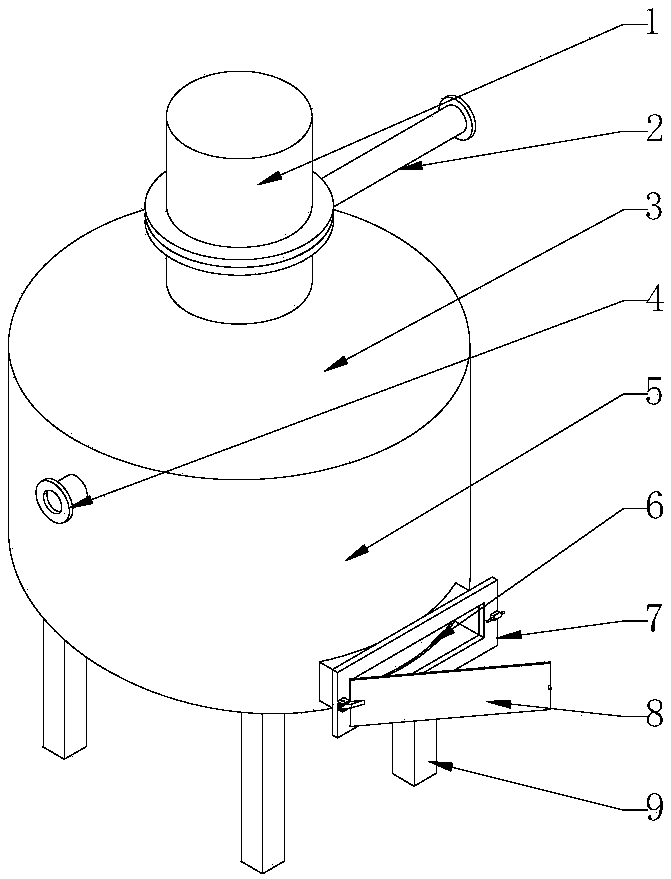

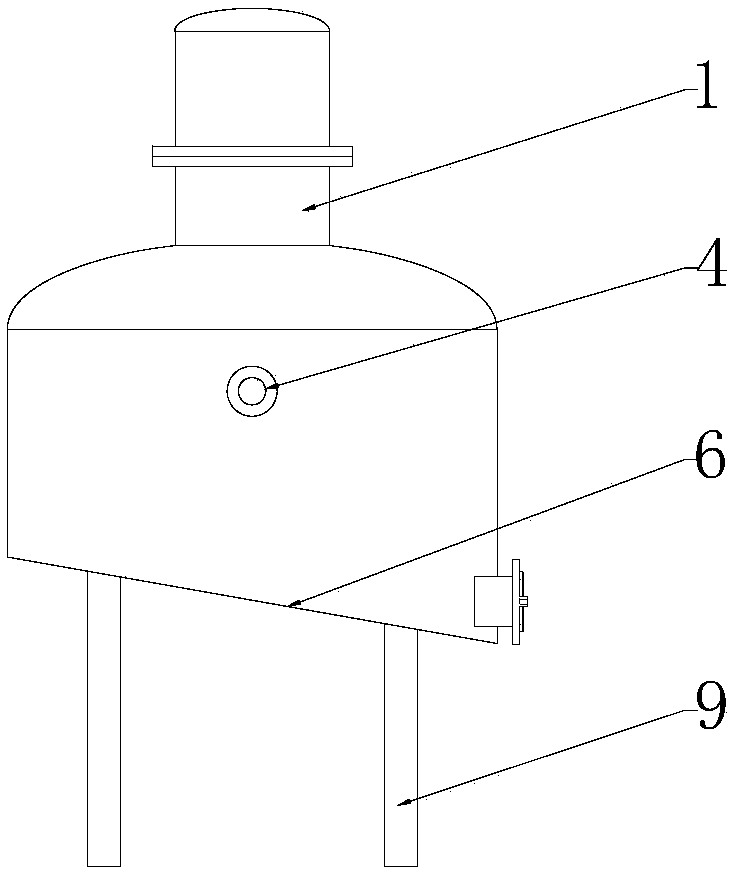

Efficient environment-friendly straw methane tank used in rural areas

InactiveCN102703304AEasy dischargeRealize solid-liquid separationGas production bioreactorsWaste based fuelRural areaProcess engineering

The invention discloses an efficient environment-friendly straw methane tank used in rural areas, which includes a tank body, a charging tank and a discharging tank, wherein the charging tank and the discharging tank are respectively mounted on two sides of the tank body; the upper part of the tank body is an acidification tank, and the lower part of the tank is a fermentation tank separated from the acidification tank; a gas outlet of the fermentation tank extends out of the acidification tank and is flush with a tank port of the acidification tank; two sides of the fermentation tank are respectively connected with the discharging tank and the charging tank; a first discharge port is arranged on one side at the bottom part of the acidification tank; the first discharge port is connected with a vacuum pump; and moreover, a second discharge port is mounted at the upper end of vacuum pump and is communicated with the charging tank. According to the invention, the whole tank body is divided into two parts, namely the upper part and the lower part, the upper part is acidification tank while the lower part is the fermentation tank, as a result, solid-liquid separation and acidification-fermentation separation are realized, discharging of the methane tank is facilitated, the age-old problem of difficulty in discharging is solved, and further, the straw methane tank solves the problems of difficult management and the like in case of multi-day gas usage stop because the movable cover of the methane tank is opened due to large-volume of discharge in two seasons every year.

Owner:泗阳县新能源服务站

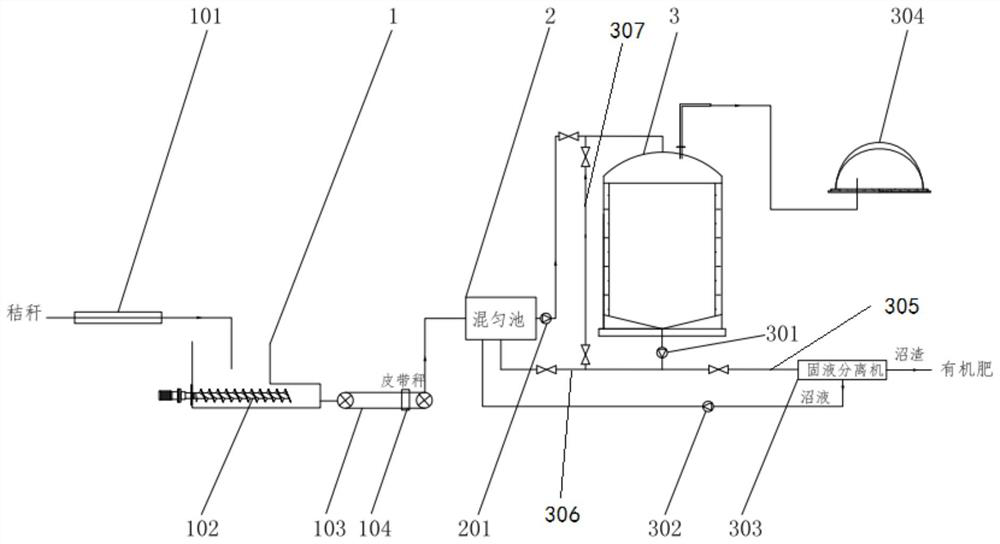

Straw anaerobic fermentation system and method

InactiveCN111662813AIncrease raw material throughputIncrease contactBioreactor/fermenter combinationsBiological substance pretreatmentsBiogasProcess engineering

The invention discloses a straw anaerobic fermentation system which comprises a mixing mechanism, a feeding mechanism, a fermentation tank, a circulating mechanism, a gas storage film and a backflow mechanism. The invention also discloses a straw anaerobic fermentation process, so that raw material treatment capacity can be improved, material circulation in the fermentation tank is realized, and the problems of difficult straw feeding and difficult straw discharging are solved. In addition, all biogas slurry is recycled, so that straw can be fully fermented, biogas can be continuously and stably produced, and the method is suitable for large-scale straw fermentation biogas production engineering.

Owner:北京长信绿源节能科技有限公司

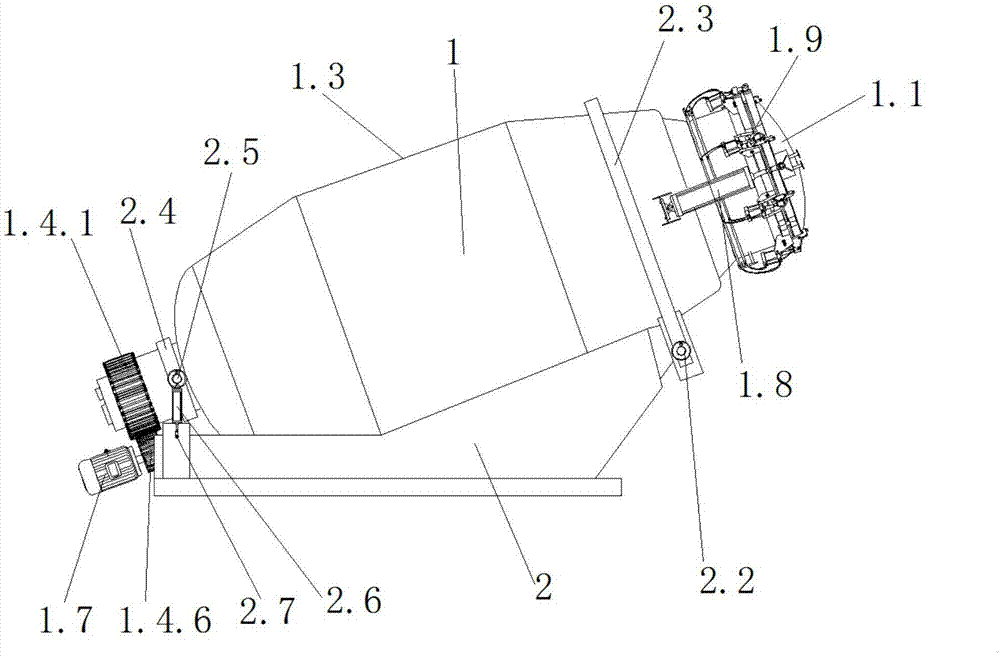

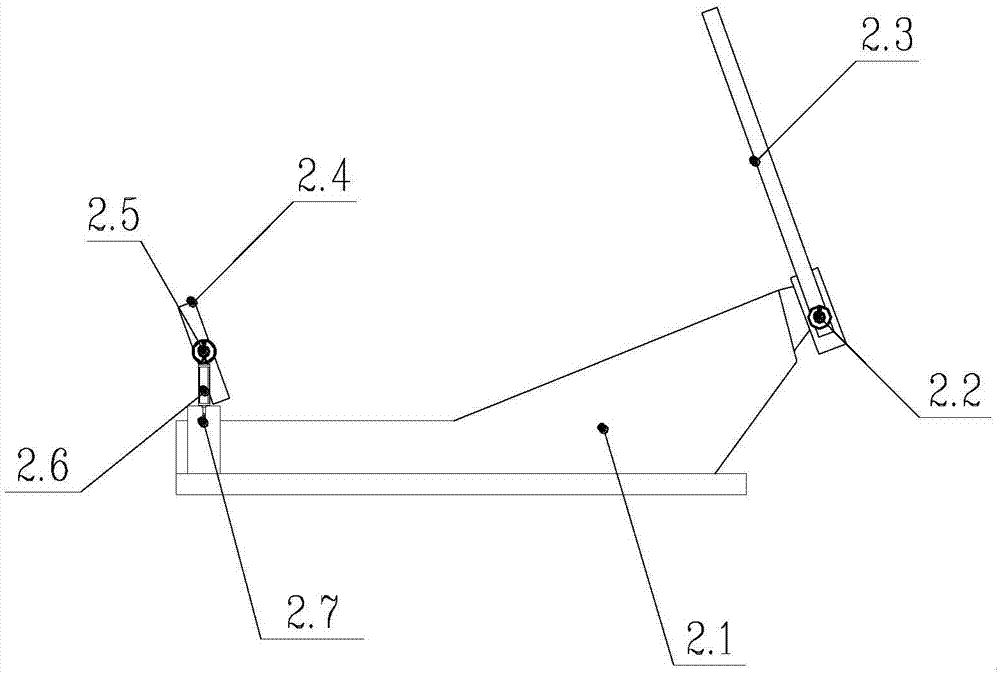

Novel solid material dissolving and extracting device

InactiveCN107050920AAddressing Dissolution Uniformity EffectsSolve uneven heatingRotating receptacle mixersTransportation and packagingWaste managementSolid material

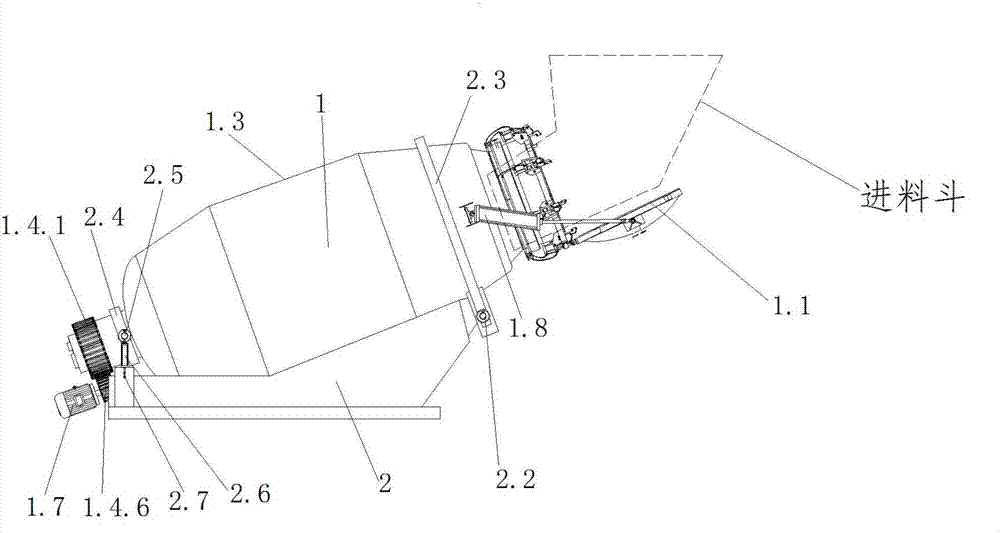

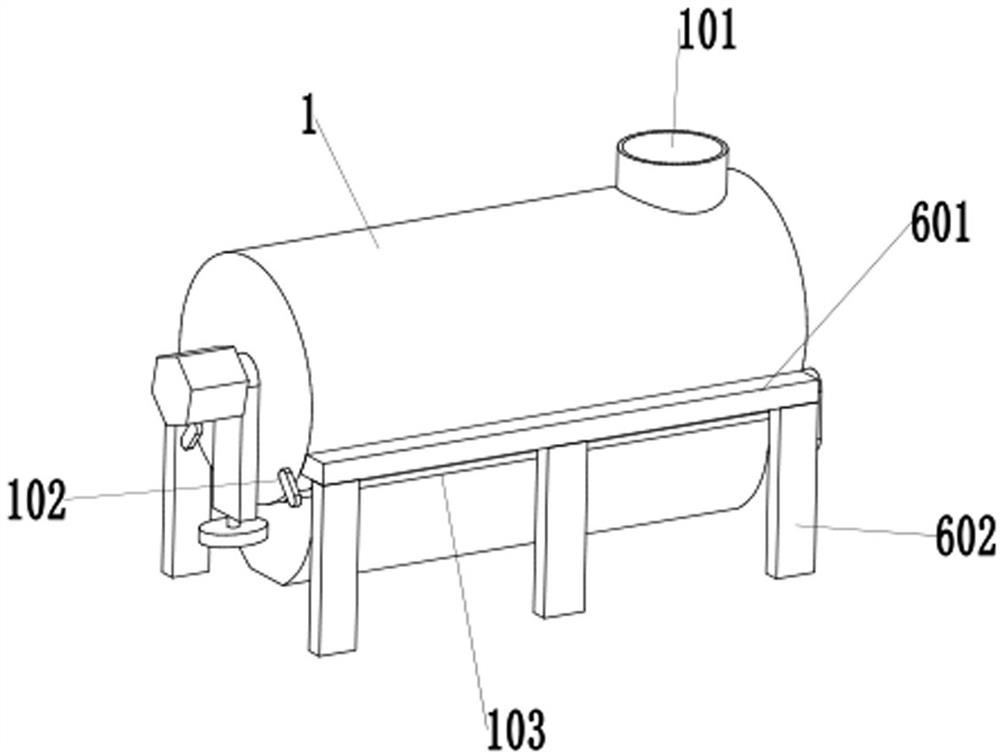

The invention relates to a novel solid material dissolving and extracting device. The device comprises an extraction tank and an extraction tank support, wherein the extraction tank support can control the tail part of the extraction tank to be lifted or lowered when materials are input into or output from the extraction tank, the extraction tank rotates in the extraction process, and a power device providing power for the extraction tank is located at the tail part or the side wall of the extraction tank; the extraction tank comprises a tank cover, a tank body, a tank cover opening cylinder and tank cover clamps, the tank cover opening cylinder is movably connected with the tank body and the tank cover, the edge of the tank cover is movably connected with the tank body, and the tank body can be sealed through the tank cover clamps; a heating jacket is arranged on the surface of the tank body. With the adoption of the novel solid material dissolving and extracting device, the problems about the dissolving and extracting uniformity of a solid material and difficulty in material discharging in the prior art are solved.

Owner:TIANJIN YINUO PHARMA IND DESIGN CO LTD

Potassium tripolyphosphate preparation method

ActiveCN1799997ASolve the difficulty of mixing and dischargingPrevent stickingPhosphorus compoundsPhosphoric acidChemistry

The invention discloses a making method of potassium tripolyphosphate, which comprises the following steps: proceeding one-step potassium tripolyphosphate synthetic process through high temperature of peroxyphosphoric acid and anhydrous potassium carbonate; producing the needed potassium tripolyphosphate through mixing, neutralizing, drying, grinding, sintering and disintegrating by twin-screw plodder. The invention simplifies the flow path and saves the equipment investment, which improves the conversion rate and quality.

Owner:YUNNAN CHEM RES INST

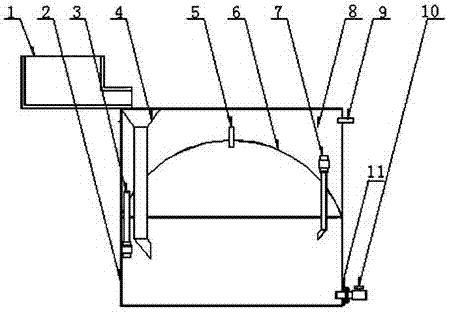

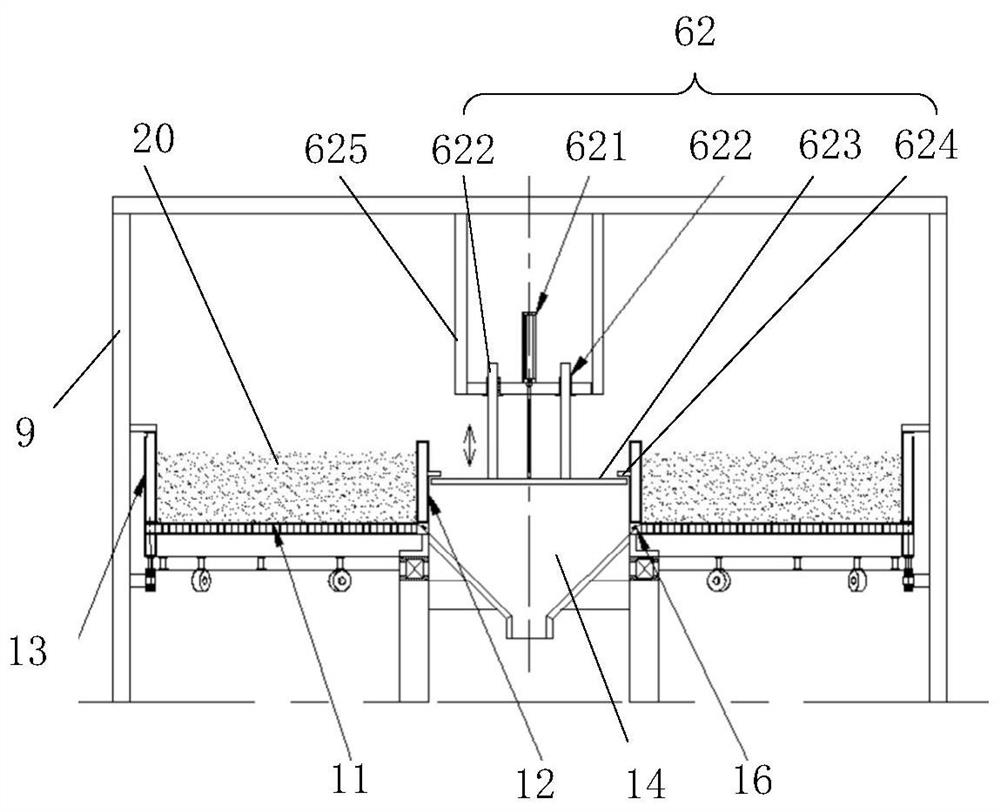

Automatic hydraulic turnover type OAR (Organics Aerobic Oxidation Resources) treatment device

ActiveCN104177135AReduce space consumptionImprove capacity utilizationClimate change adaptationOrganic fertiliser preparationAeration systemControl system

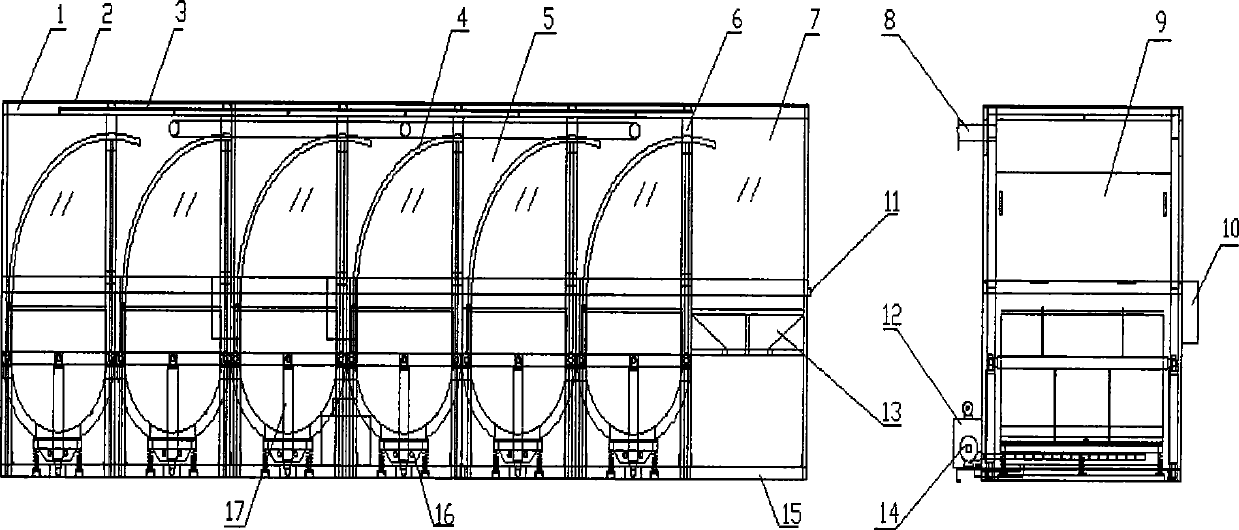

The invention provides an automatic hydraulic turnover type OAR (Organics Aerobic Oxidation Resources) treatment device and belongs to the field of solid waste organic matter resource utilization technology and equipment. The device comprises a frame, a fermentation tank, an aeration system, an automatic hydraulic overturning system, a fermentation control system, a spraying system and an air exhaust system, wherein the frame is used for fixing each component; the fermentation tank is connected with an oil cylinder in the automatic hydraulic overturning system, the bottom of the oil cylinder is connected with a base, a pump station is arranged on the back surface of the frame, and a control cabinet is positioned in the front surface of the frame; the aeration system is positioned on the lower side of the fermentation tank and is fixedly arranged on the base of the frame by virtue of a lifting aeration groove; the fermentation control system is arranged on the side surface of the fermentation tank; the spraying system is arranged in a framework at the top of the frame and is connected with a tap water pipe; the air exhaust pipe is arranged at the rear side part of the frame and is connected with a deodorizing machine. The device provided by the invention is low in energy consumption, high in efficiency, simple in structure and small in floor area, is simple and easy to operate, can not cause secondary pollution, and is suitable for the treatment of production and living organic garbage.

Owner:北京圣海林生态环境科技股份有限公司 +2

Microbial fermentation deodorization device applied to kitchen waste treatment

PendingCN112552085AEasy dischargeEliminate Pollution PotentialBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringWaste treatment

The invention discloses a microbial fermentation deodorization device applied to kitchen waste treatment, which belongs to the technical field of kitchen waste treatment and comprises a low-speed motor, a fermentation kettle, supporting legs and a deodorization box, the motor is fixedly arranged on the supporting legs through a bracket, the deodorization box is fixedly arranged on the side edges of the supporting legs, and the fermentation kettle is fixedly arranged at the upper ends of the supporting legs, and comprises a feeding mechanism, a fermentation mechanism, a material returning mechanism, a water removal mechanism, a deodorization mechanism and a transmission mechanism, the feeding mechanism is fixedly arranged at the front end of the fermentation mechanism, the fermentation mechanism is rotatably connected to the upper ends of supporting legs through a plurality of rotating wheels, the supporting legs are fixedly arranged on the ground, and the water removal mechanism is fixedly arranged at the front ends of the supporting legs, the deodorization mechanism is fixedly arranged on the two ends of the fermentation kettle, the transmission mechanism is fixedly arranged on the edge of the upper end of the supporting leg, and the problems that an existing kitchen garbage disposal machine can emit foul irritant gas in the kitchen garbage disposal process, discharging is difficult, and feeding and cleaning cannot be continued are solved.

Owner:西安网浪互联网科技有限公司

Dry stirring ball mill capable of relieving paste milling phenomenon

The invention relates to the technical field of stirring ball mills, and discloses a dry stirring ball mill capable of relieving a paste milling phenomenon. The ball mill comprises a cushion table, wherein a main shaft is installed on the cushion table, a ball milling cylinder is connected to the middle of the main shaft, a main gear is connected to the left side of the ball milling cylinder, an air draft device is connected to the top of the left side of the main shaft, an air outlet pipeline is connected to the left side of the bottom of the air draft device, an air inlet pipeline is installed on the right side of the air outlet pipeline, a second gear is installed in the air inlet pipeline, a third gear is installed on the left side of the second gear, and a fan is connected to the center of the third gear. According to the dry stirring ball mill capable of relieving the paste milling phenomenon, the main gear, the first gear, the second gear and the third gear move in a matched mode, so that the fan rotates to conduct air draft, air circulation in the ball mill cylinder is increased, the paste milling phenomenon can be reduced to a certain extent, and materials attached to a sieve plate are washed through the air draft device, so that the problem that discharging is difficult due to the fact that the sieve plate is blocked by the materials is solved.

Owner:博士爱玩具有限公司

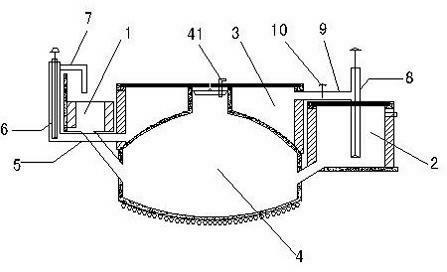

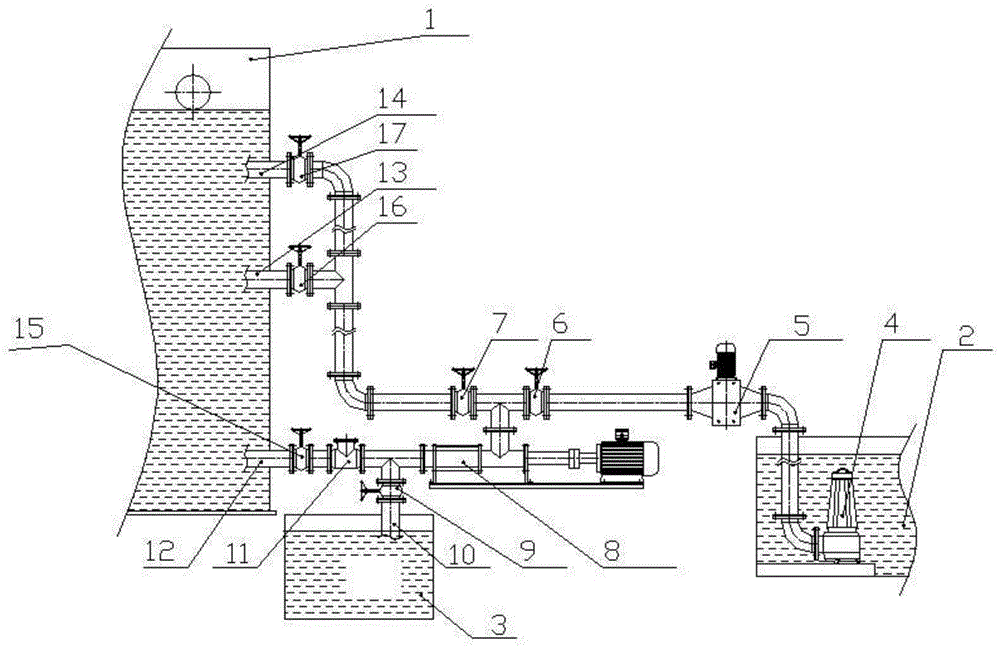

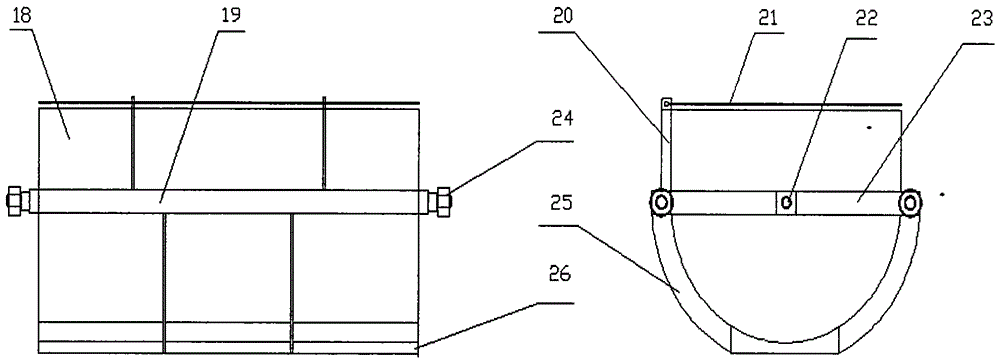

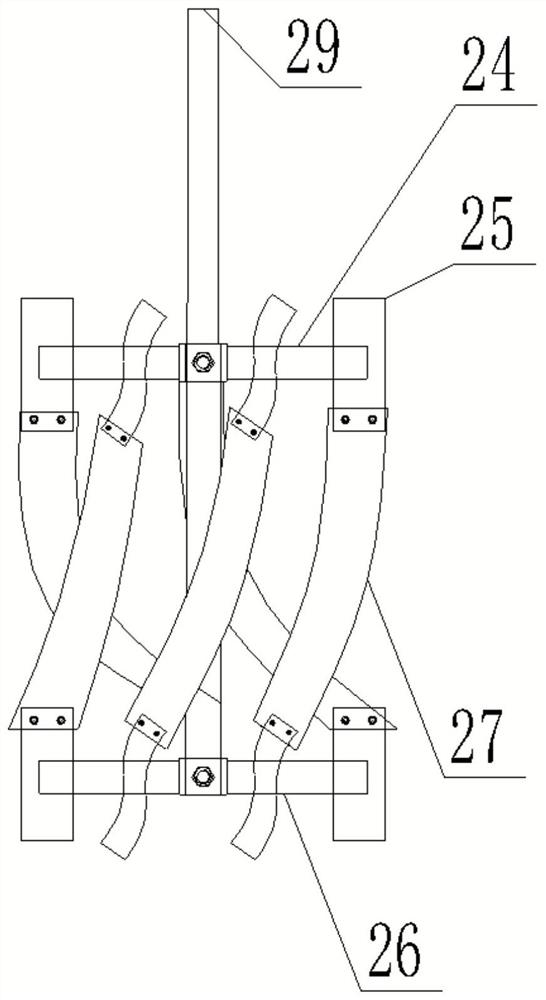

FRP (fiber reinforced plastic) biogas digester for treating rural organic waste

InactiveCN107267371ASolve the difficulty of dischargingIncrease collection rateBioreactor/fermenter combinationsBiological substance pretreatmentsFiberPulp and paper industry

An embodiment of the invention discloses an FRP (fiber reinforced plastic) biogas digester for treating rural organic waste. The FRP biogas digester comprises a pretreatment pool and a fermentation pool body, wherein the fermentation pool body is connected with an outlet of the pretreatment pool through a feeding pipe extending out of the pool body, and a hydraulic pressure chamber is formed above the fermentation pool body; the hydraulic pressure chamber is provided with an overflow pipe, and a one-way return pipe and a one-way drainage pipe are arranged between the hydraulic pressure chamber and the fermentation pool body; a liquid in the fermentation pool body is discharged to the hydraulic pressure chamber by the one-way drainage pipe, the liquid in the hydraulic pressure chamber flows back to the fermentation pool body by the one-way return pipe, and a gas guiding pipe is arranged at the top of the fermentation pool body.

Owner:广西北海跃达玻璃钢制品有限公司

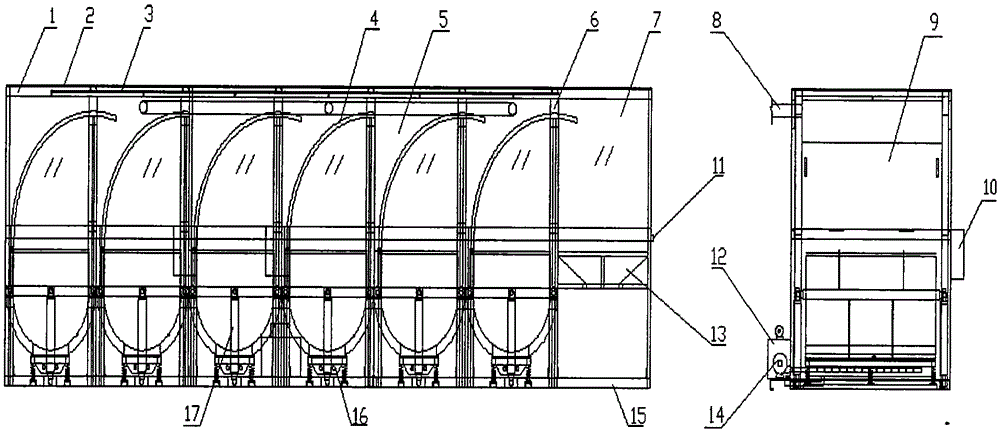

Straw mixed raw material fermentation charging and discharging blocking resisting method

InactiveCN104087618AIncrease CODcr concentrationReduced risk of cloggingGas production bioreactorsFermentationModular compositionFailure rate

The invention discloses a straw mixed raw material fermentation charging and discharging blocking resisting method. The method comprises the following steps: preprocessing straws, sending the preprocessed straws into a fermentation tank (1) through a forced charging and discharging system, carrying out biogas slurry self-stirring fermentation, and pumping out a fermented material from the fermentation tank (1) through the forced charging and discharging system. The preprocessing of the straws improves the gas yield, improves the CODcr concentration of a feed liquor, alleviates the crusting of straw mixed raw material fermentation floating residues, and substantially reduces the straw mixed raw material fermentation charging and discharging blocking risk. The forced discharging system adopting modular combination integration has the advantages of easy installation, simple operation, no need of grasping of professional technologies by users, instant grasping of the operation technology after simple training, convenient maintenance, low failure rate, good reliability, high safety, and complete avoiding of the straw mixed raw material fermentation charging and discharging blocking problem.

Owner:CHONGQING ACAD OF AGRI SCI +1

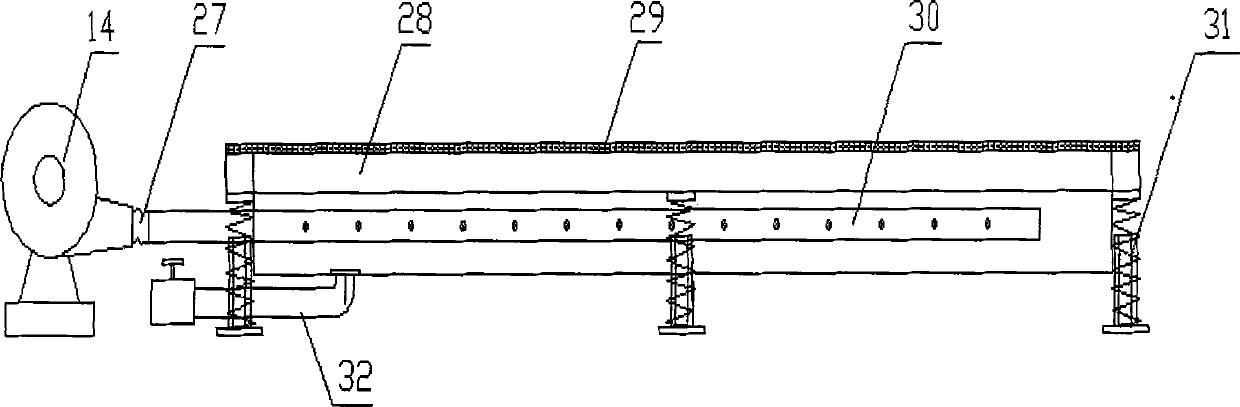

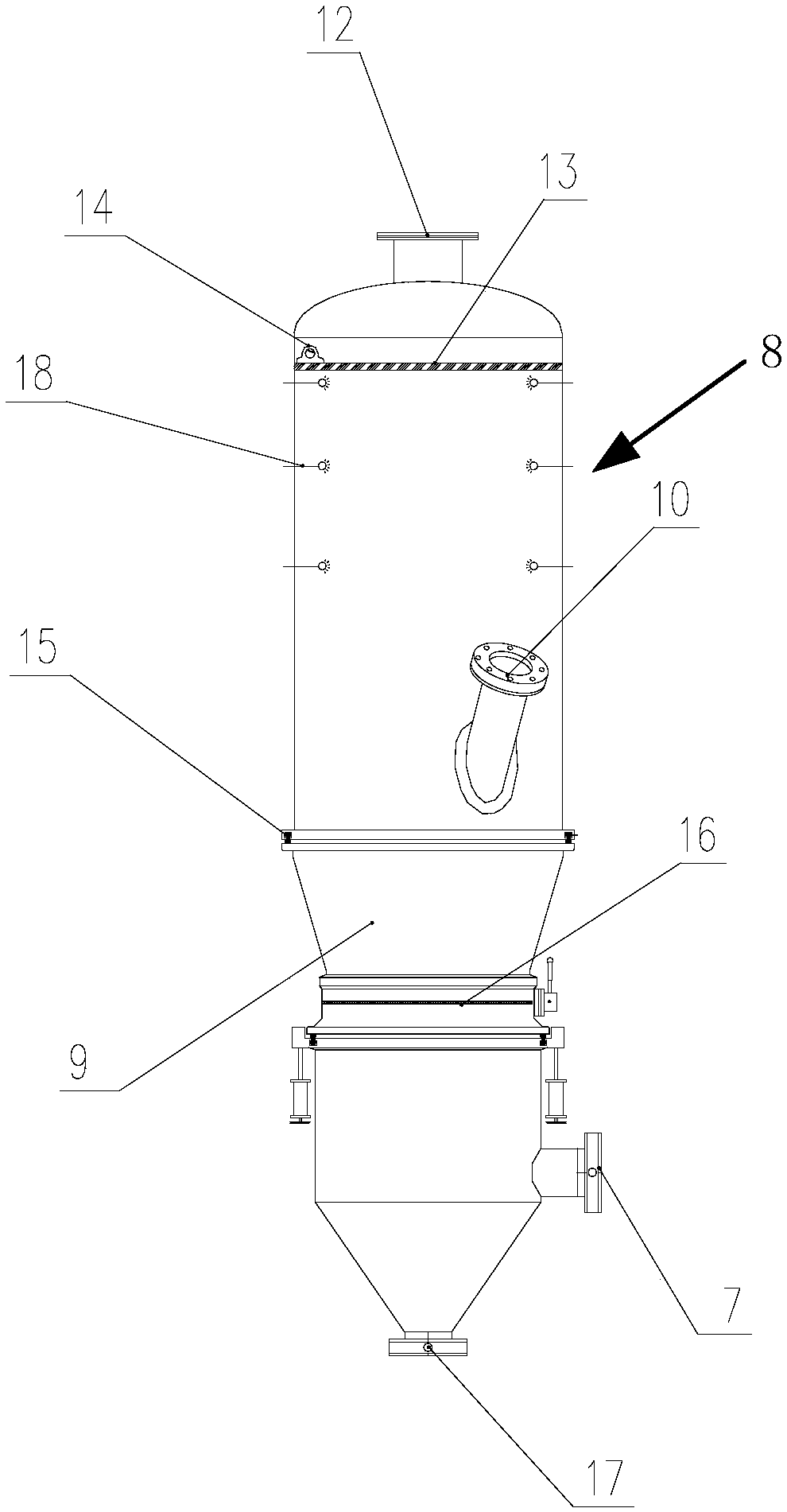

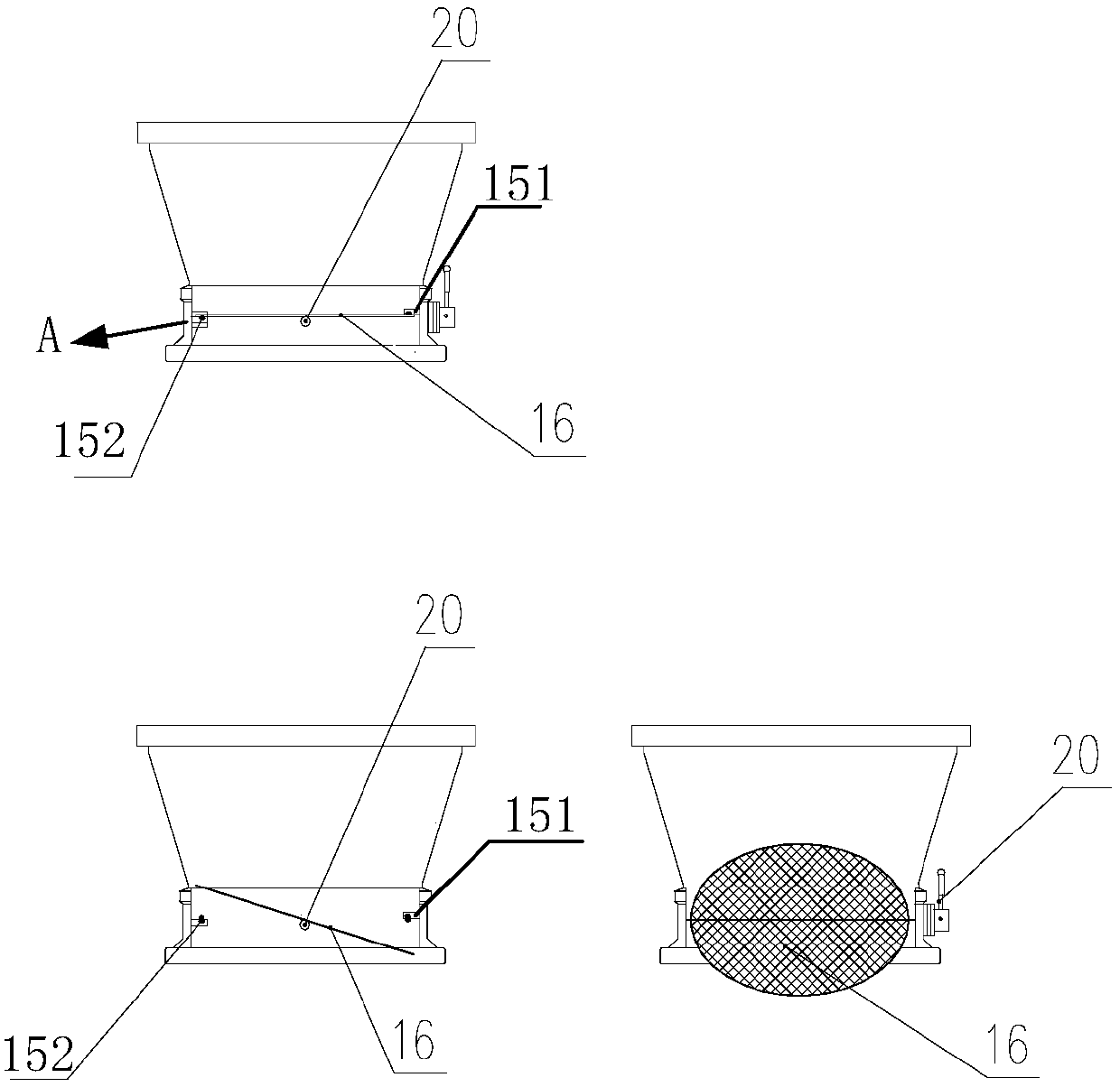

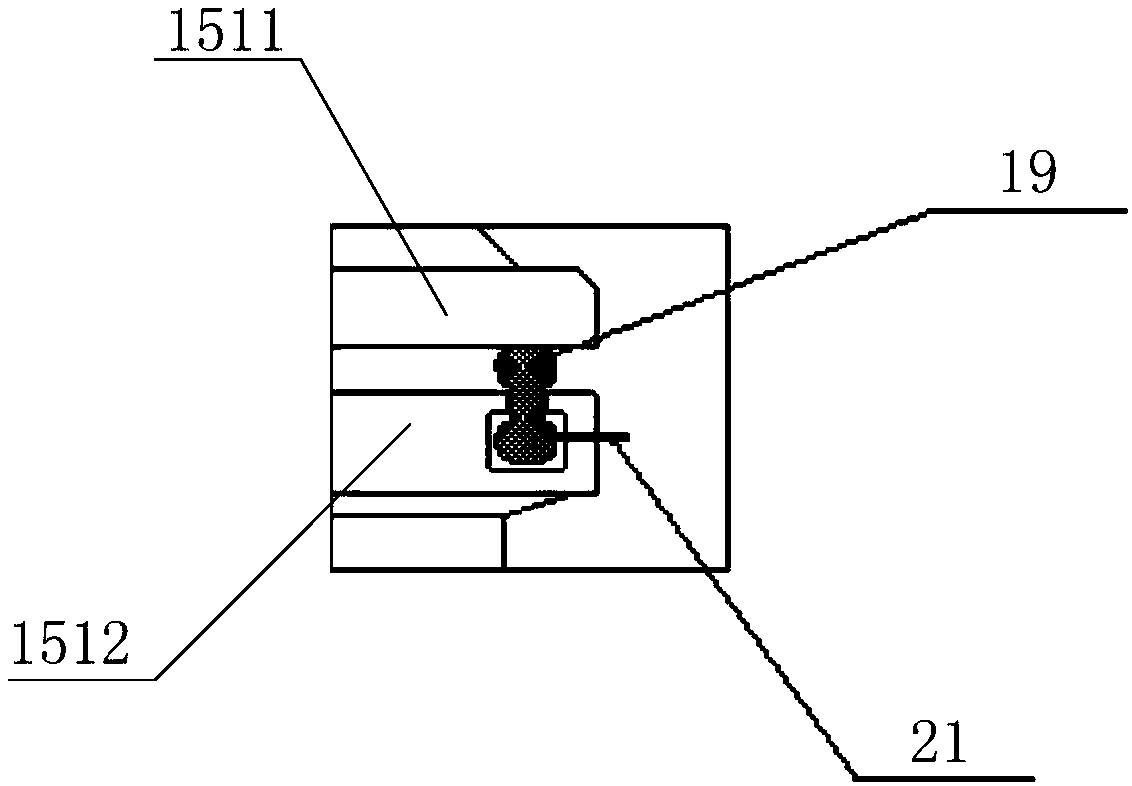

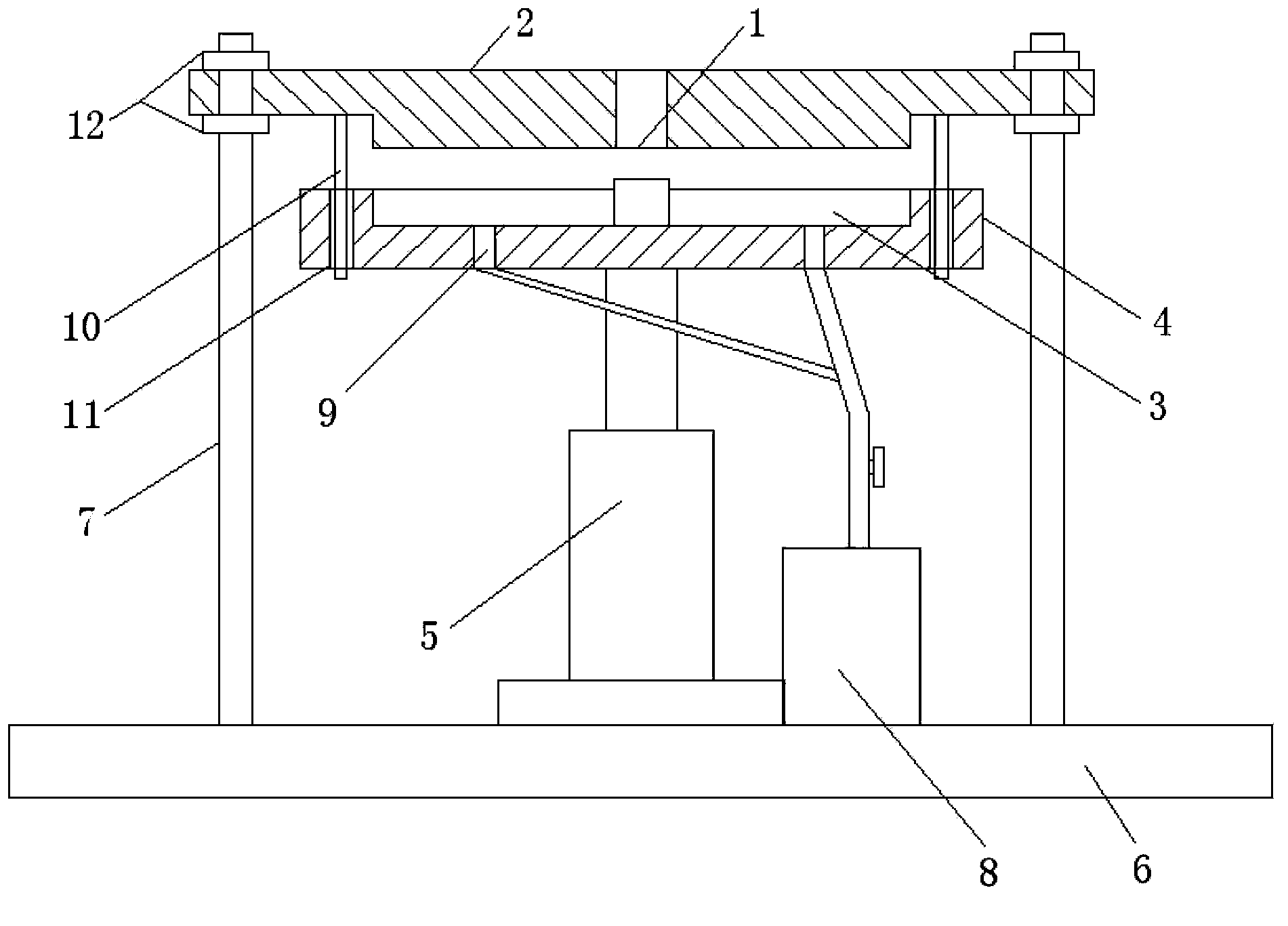

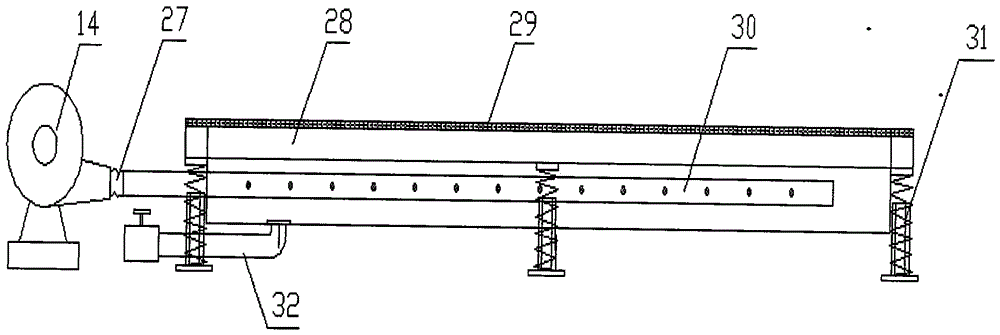

Circulating fluidized bed and circulating fluidized bed system

PendingCN107606878ASolve the difficulty of dischargingDrying solid materials with heatDrying gas arrangementsFluidized bedEngineering

The invention provides a circulating fluidized bed and a circulating fluidized bed system, and relates to the technical field of material drying. The circulating fluidized bed comprises a feeding anddischarging section. The feeding and discharging section comprises a sieving plate, a rotating shaft and a sealing assembly. The rotating shaft is arranged on the tube wall of the feeding and discharging section in a rotatable mode. The sieving plate is arranged on the rotating shaft so that the rotating shaft can drive the sieving plate to rotate. The sealing assembly is arranged inside the tubewall of the feeding and discharging section. The edge of the sieving plate abuts against the sealing assembly. The technical problems that the filtering section of a circulating fluidized bed in the prior art is high in position, the fluidized state section is insufficient in space, the material drying effect is poor, the distance between a filter screen and the fluidized state section is small and filtering pressure is large are solved.

Owner:TIANJIN YINUO PHARMA IND DESIGN CO LTD

Punching belt rubber piece device capable of realizing automatic material returning

InactiveCN104249389APrecision mold clampingSolve the difficulty of dischargingMetal working apparatusPunchingEngineering

The invention relates to a punching belt rubber piece device capable of realizing automatic material returning. The punching belt rubber piece device comprises an upper mold and a lower mold, wherein the lower end surface of the upper mold is provided with an upper die cavity, the upper end surface of the lower mold is provided with a lower die cavity, after the upper mold and the lower mold are combined, the upper die cavity and the lower die cavity are combined into a complete die cavity, an ascending and descending mechanism is arranged at the lower end surface of the lower mold, the lower end of the ascending and descending mechanism is fixedly arranged on a base, at least two support rods are arranged on the base, the upper ends of the two support rods are respectively arranged on the upper mold, an automatic material returning device is arranged on the lower mold, the automatic material returning device comprises an air supply device arranged on the base, a material jacking hole is formed in the lower mold and is communicated with the lower die cavity of the lower mold, the air supply end of the air supply device is arranged in the material jacking hole, after the punching process is completed, the air supply device is started, and the air supply end of the air supply device conveys high-pressure air into the material jacking hole, so rubber pieces in the lower die cavity are ejected out from the lower die cavity through high-pressure air, the problem of difficult manual material discharging is solved, and the work efficiency is improved.

Owner:CHANGZHOU LIWEI KNIFE

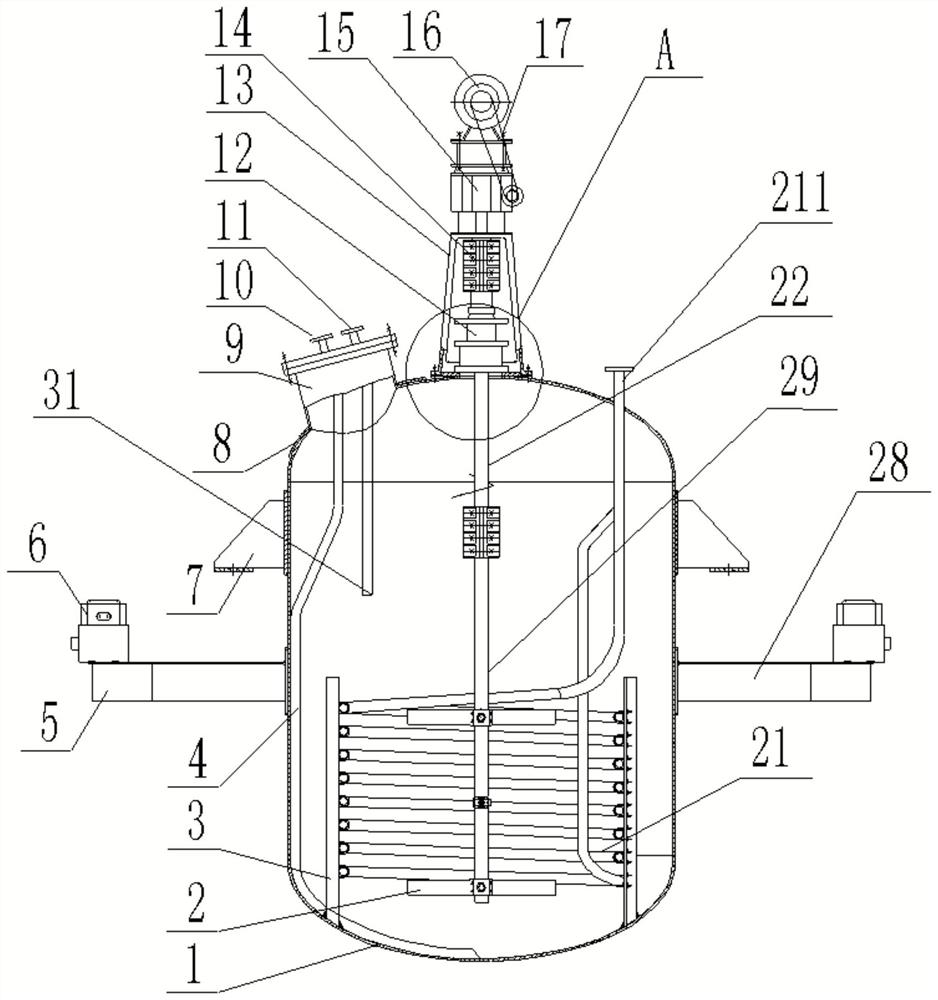

Straw hydrolytic acidification pre-treatment reaction device

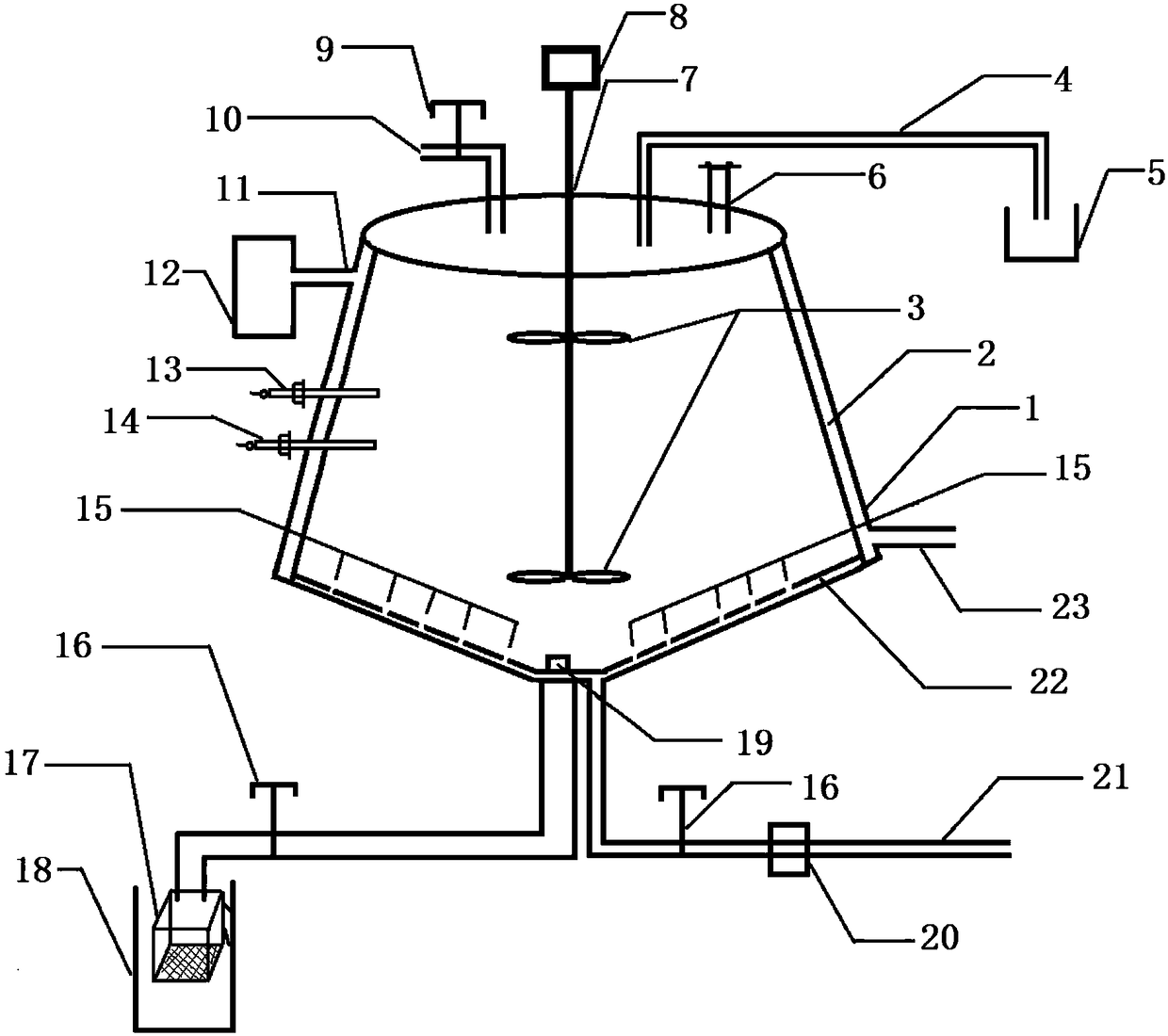

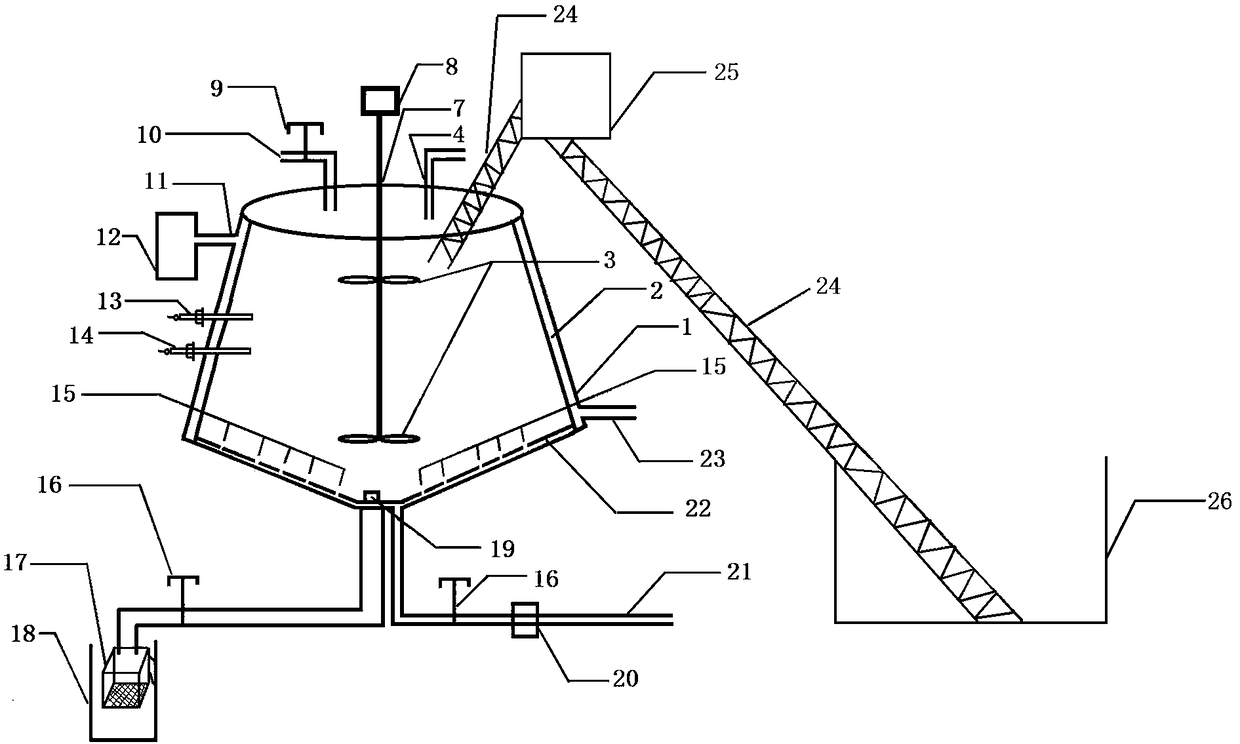

InactiveCN108384706AParameter control is stableReduce operating energy consumptionBioreactor/fermenter combinationsBiological substance pretreatmentsTemperature controlAeration system

The invention discloses a straw hydrolytic acidification pre-treatment reaction device. The straw hydrolytic acidification pre-treatment reaction device comprises a temperature control system, a stirring system, a feeding system, a discharging system, an aeration system, an overflowing system and a monitoring feedback system, wherein the inner part of the reaction device is a reverse tapered tankbottom; the center of the tank bottom is downward connected with a discharging pipeline and an aeration ventilation pipe; an upper end opening of the discharging pipeline is connected with a discharging motor through a motor bracket; the discharging pipeline is provided with a valve; after straw hydrolytic acidification pre-treatment reaction is finished, material liquid is sufficiently dischargedout of a tank body through the discharging motor communicated with the reverse tapered bottom, and a mixture of hydrolytic dreg and hydrolysate is filtered through a filtering strainer, so that solids and liquid are separated; the solid hydrolytic dreg is remained in the filtering strainer and the hydrolysate flows into a hydrolysate collection tank. By adopting the straw hydrolytic acidificationpre-treatment reaction device, the problems of a straw hydrolytic acidification pre-treatment process of crusting and non-uniform aeration are solved; the straw hydrolytic acidification pre-treatmentreaction device has the advantages of capability of continuously feeding and discharging materials, stable parameter control and low operation energy consumption, and has a wide application prospect.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

Pulverizer for desulfurization catalyst production

InactiveCN113117854ASmooth dischargeSolve the difficulty of dischargingGrain treatmentsPtru catalystElectric machinery

The invention relates to a pulverizer for desulfurization catalyst production. The pulverizer comprises a crushing barrel, a shaking device, a discharging barrel, an extruding device and a support, wherein the crushing barrel is transversely arranged, a feeding port is formed in the side wall of the crushing barrel and faces upwards, a screening plate is arranged on the side wall of the bottom of the crushing barrel, the bottom of the crushing barrel is arranged on the discharging barrel, one end of the crushing barrel is provided with the shaking device connected with the discharging barrel, the other end of the crushing barrel is provided with the extruding device connected with the discharging barrel, one end of the shaking device is provided with a motor, the motor is connected with a rotating shaft, the rotating shaft is arranged in the crushing barrel, and the rotating shaft is provided with a crushing arm. According to the pulverizer, the screening plate is directly arranged at the bottom of the crushing barrel for discharging, crushed materials are directly discharged, meanwhile, smooth discharging of the materials is achieved under rotation of the crushing arm, the problem that discharging of an existing transverse crushing barrel is difficult and not thorough is solved, and the discharging efficiency is improved.

Owner:湖南玉伟新材料有限公司

Water-pressure separation type methane-generating tank

InactiveCN105255708ASolve the difficulty of dischargingBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringSlag

The invention relates to a water-pressure separation type methane-generating tank. The water-pressure separation type methane-generating tank is characterized in that a tank body is provided with a cover plate; the cover plate is provided with a water-pressure tank and a methane opening higher than the water-pressure tank; a baffle plate is arranged at the bottom part of the tank body and separates the tank body into a solid area and a liquid area with non-communicated bottom parts; a slag feeding pipe and a slag discharging pipe are inserted into the solid area; a liquid feeding pipe is inserted into the liquid area; the lower end part of the liquid feeding pipe is lower than the top part of the baffle plate; the upper end part of the slag discharging pipe is higher than the top part of the water-pressure tank; floating devices are arranged on the slag feeding pipe and the liquid feeding pipe and are positioned in the water-pressure tank. The water-pressure separation type methane-generating tank has the advantages that solid slag is introduced into the solid area by the slag feeding pipe, liquid materials are introduced into the liquid area by the liquid feeding pipe, and the solid slag in the solid area is positioned at the bottom part and can not enter the liquid area; after fermentation, since the solid slag is not completely utilized, the liquid materials are pumped out by the liquid feeding pipe, the solid slag is remained, and new liquid materials are introduced for repeated fermentation, so that the utilization rate of the solid slag can be increased, solid and liquid can be effectively separated and pumped, and the utilization rate can be increased.

Owner:CHONGQING BAIJIASI BIOGAS EQUIP

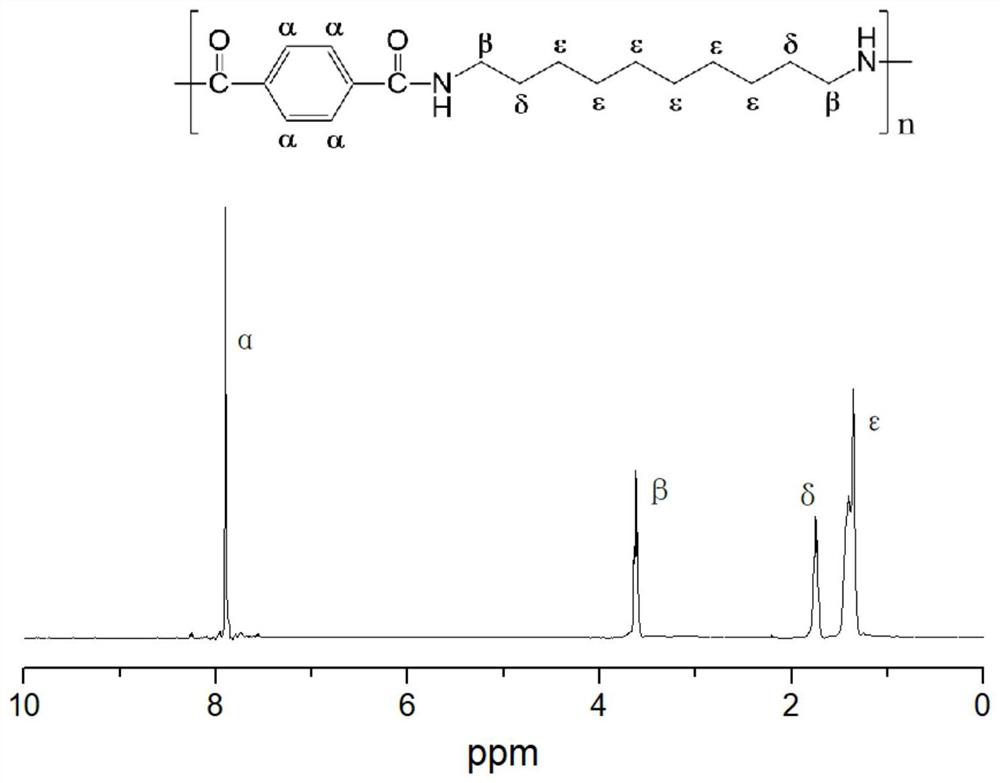

A kind of preparation method of semi-aromatic polyamide

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

A dry stirring ball mill capable of alleviating paste milling

ActiveCN112156859BAlleviate stickinessIncrease air circulationSievingScreeningAir cycleThermodynamics

The invention relates to the technical field of agitating ball mills, and discloses a dry-process agitating ball mill capable of alleviating paste milling. The main gear is connected, the left top of the main shaft is connected with an exhaust device, the left side of the bottom of the exhaust device is connected with an air outlet pipe, the right side of the air outlet pipe is installed with an air inlet pipe, and the inside of the air inlet pipe is installed with gear 2, gear The left side of two is equipped with gear three, and the center position of gear three is connected with fan. The dry agitating ball mill that can reduce the sticky grinding phenomenon, through the cooperative movement of the main gear, the first gear, the second gear and the third gear, the fan is rotated to draw air, which increases the air circulation inside the ball mill cylinder, and can reduce the stickiness to a certain extent. The grinding phenomenon is eliminated, and the material attached to the sieve plate is washed away by the ventilation device, which solves the problem of difficult discharge caused by the blockage of the sieve plate by the material.

Owner:博士爱玩具有限公司

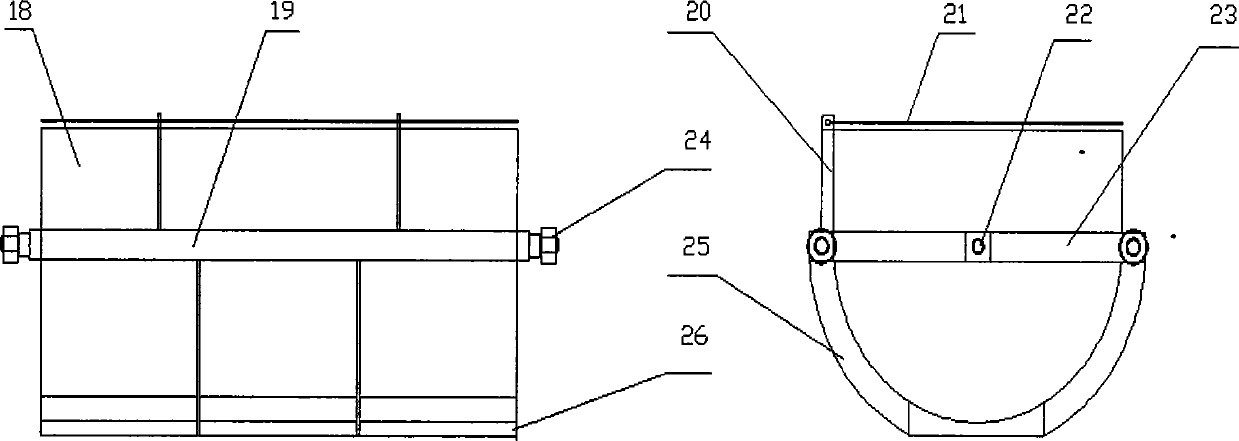

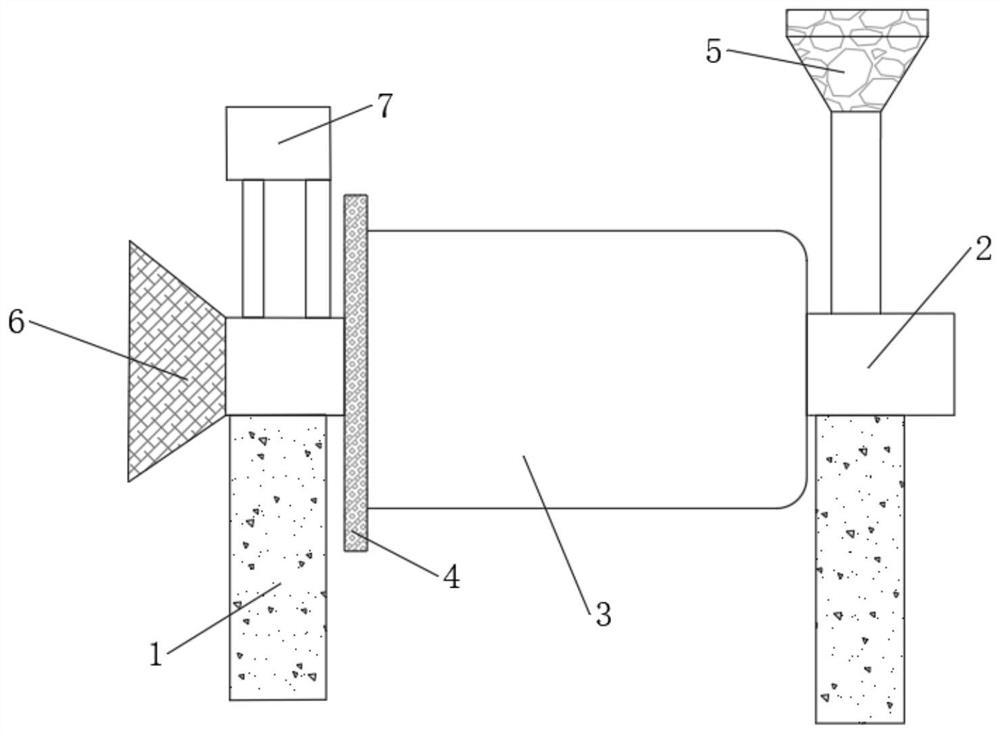

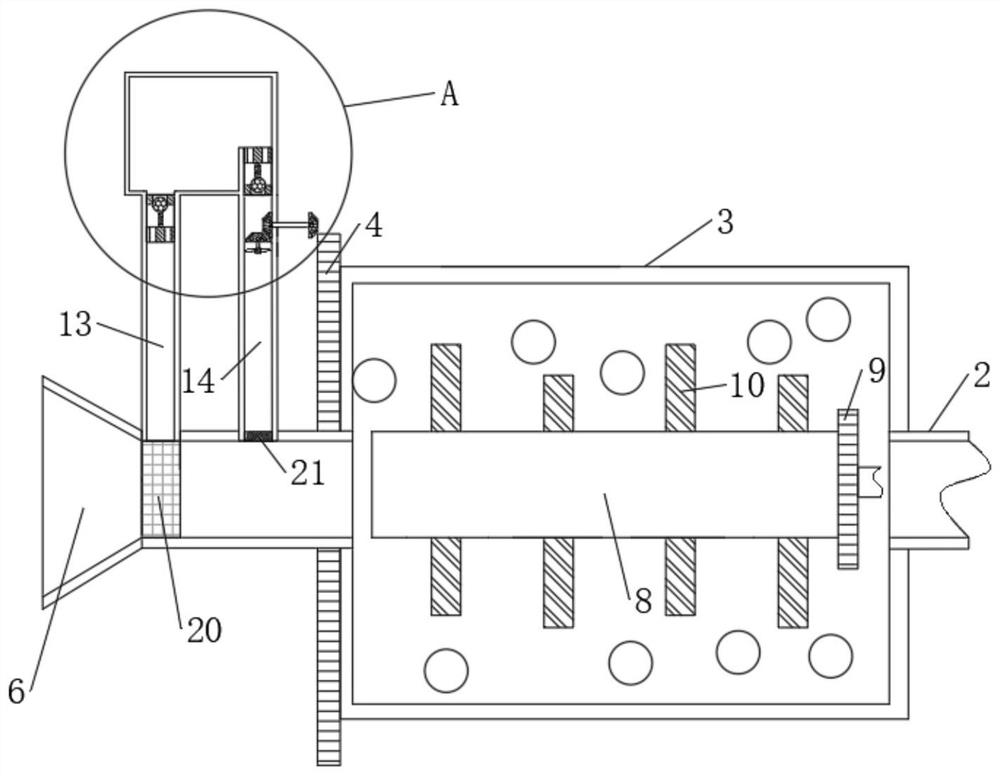

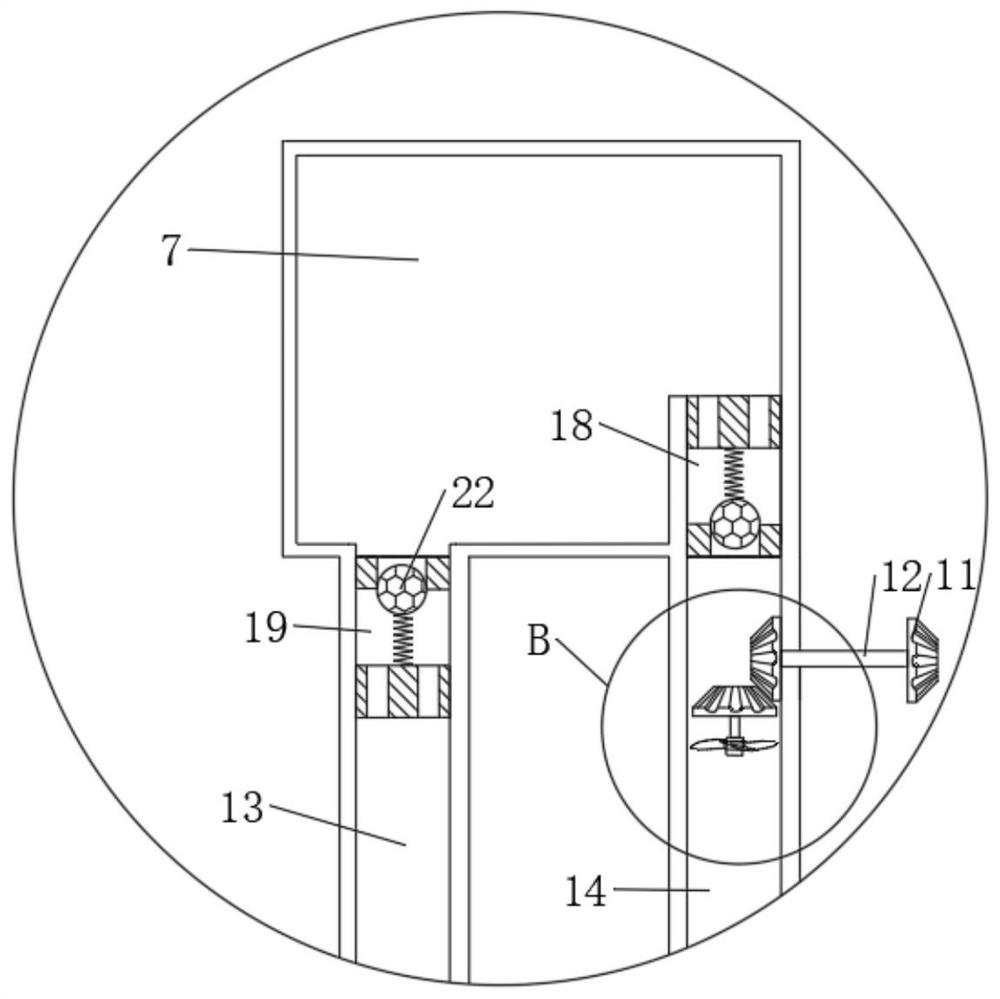

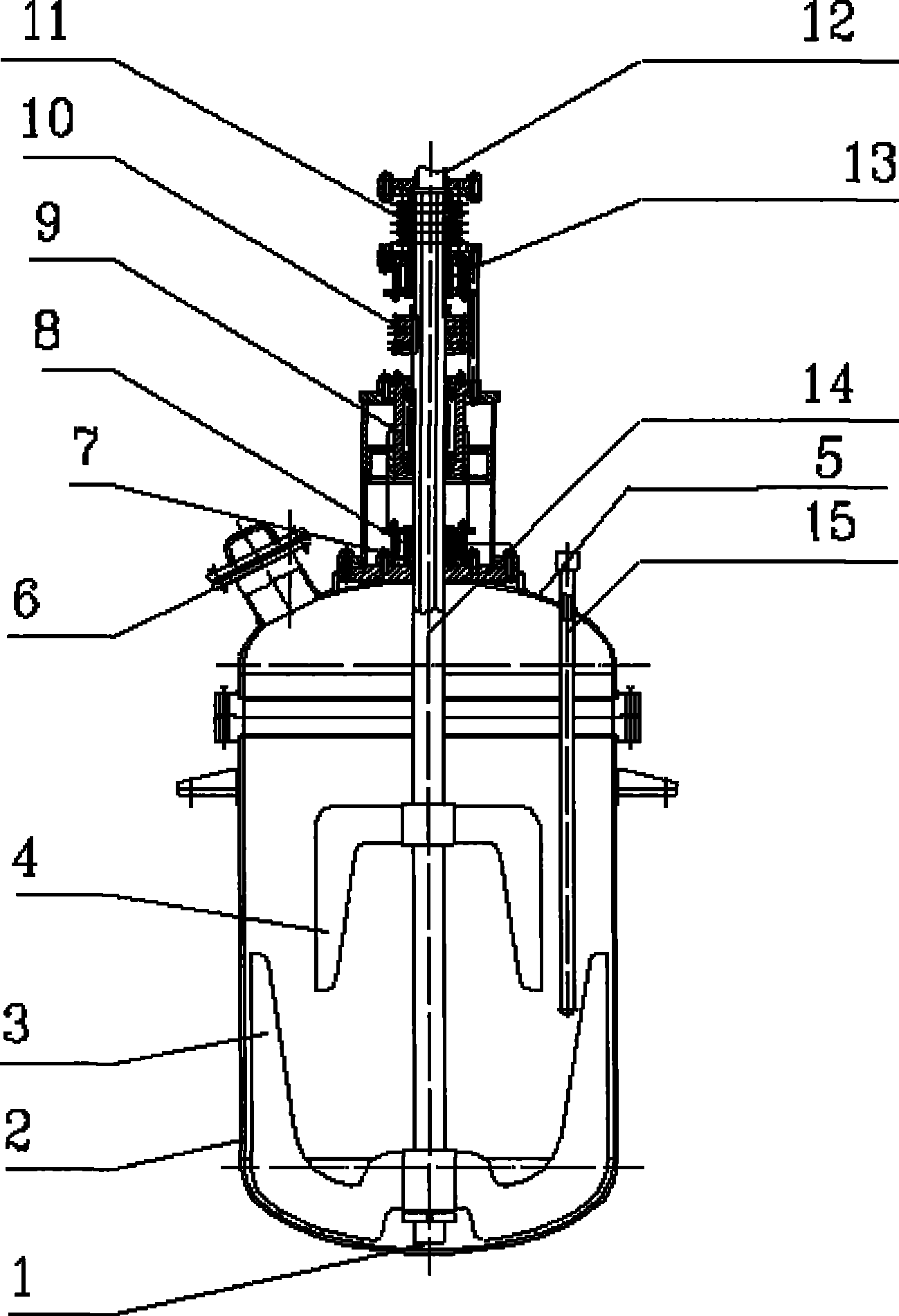

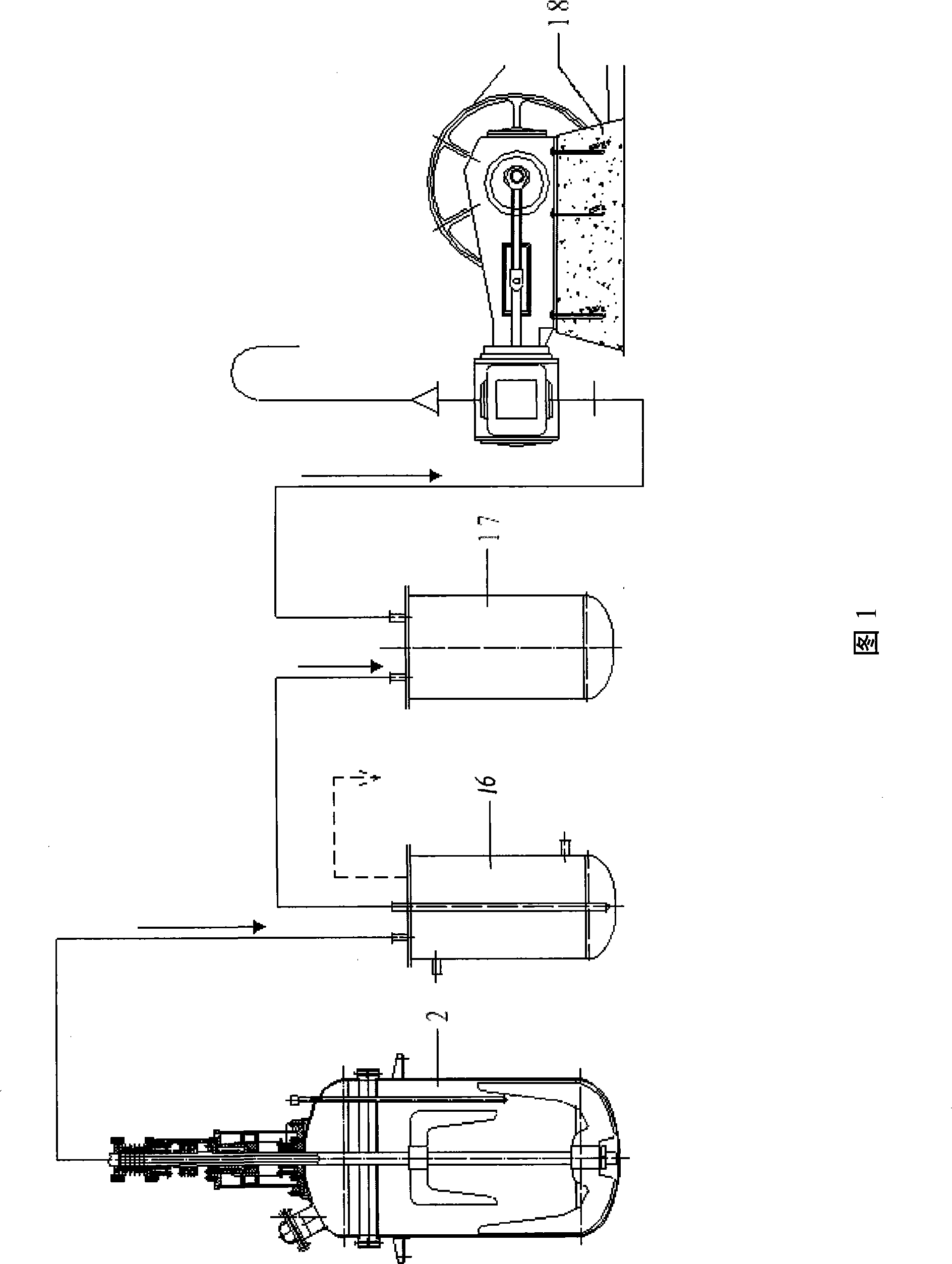

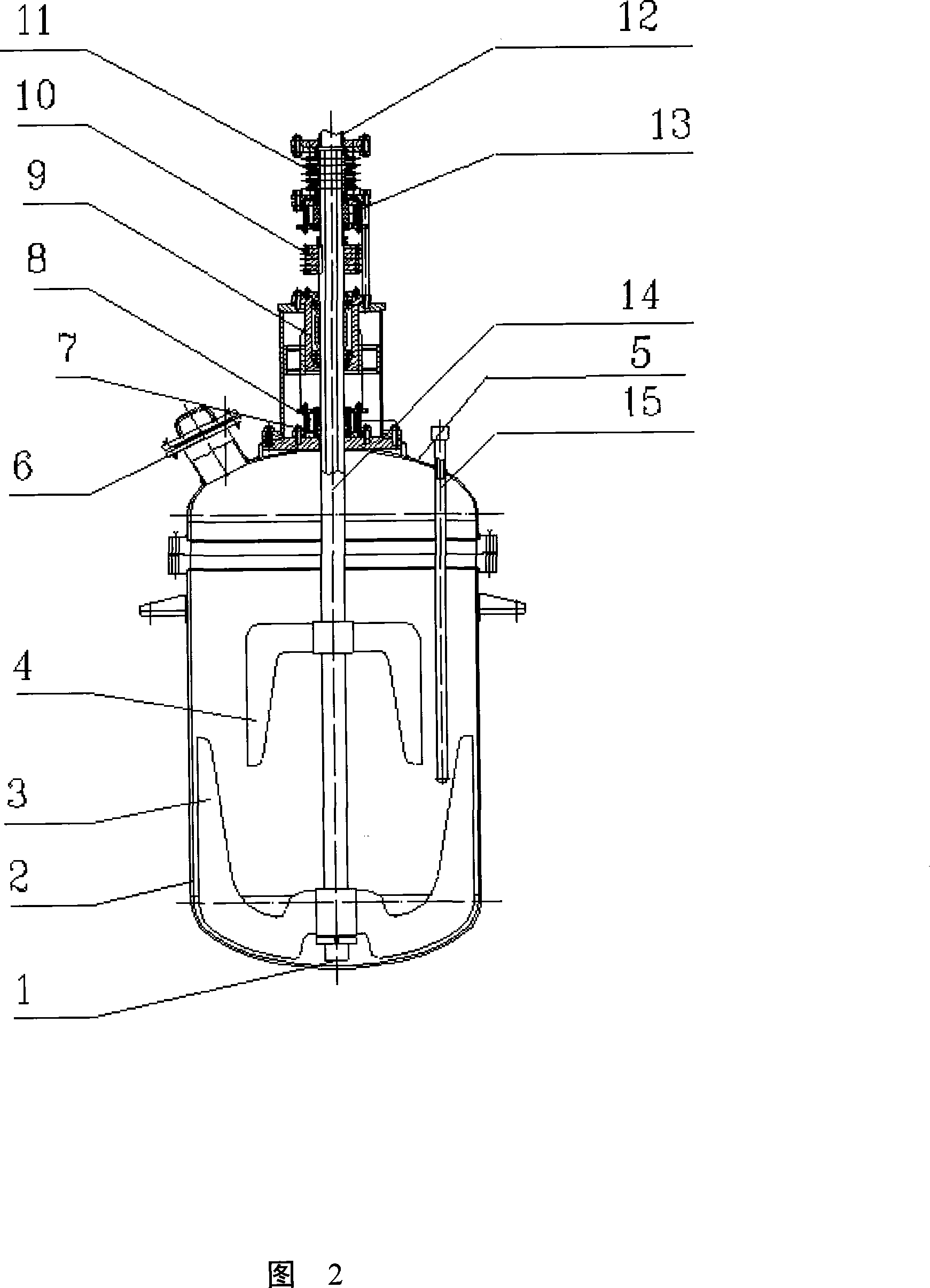

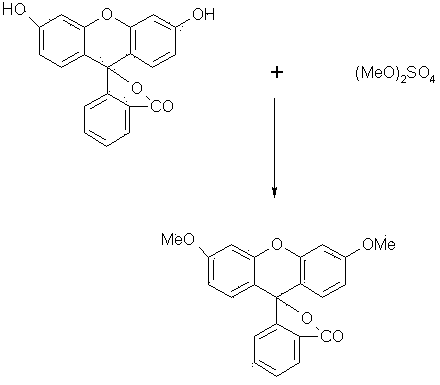

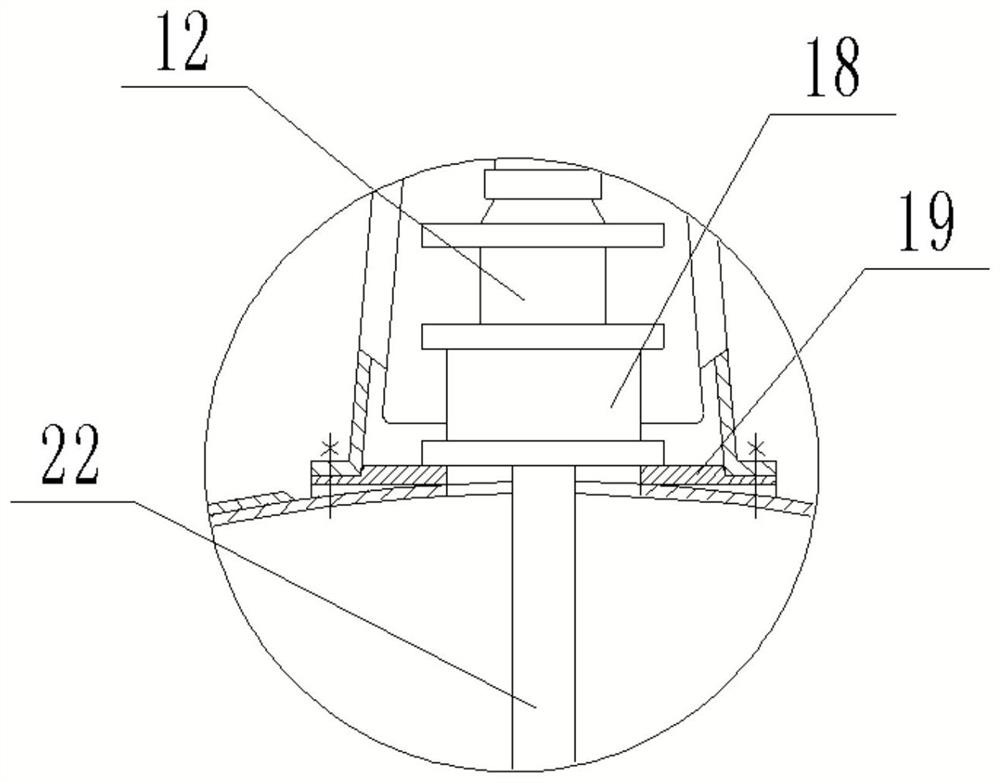

Reaction device for interesterification and polycondensation reaction

The invention provides a reaction device for transesterification and polycondensation, which comprises a kettle 2 with a reactor lid 5, a central axis 14 which is hollow, a heating apparatus and a stirring part connecting with the central axis 14. The stirring part comprises an upper inversed anchor 4 and a lower inversed anchor 3 connecting with the hollow axis 14. The reaction device of the invention can ensure that the transesterification and the polycondensation are carried out at the same time in one reactor, thus being applicable to large scale production and solving the problem of difficult material discharging. By adopting the invention, the polycondensed molecule weight distribution is narrow and the size of the molecule weight is even.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Reverse back-extrusion process of equilateral three-jaw flange sliding sleeve and reverse back-extrusion die

The invention provides an equilateral three-jaw flange sliding sleeve reverse extrusion process, which includes reverse extrusion, and the reverse extrusion is to put the billet-made bar into the mold cavity of the reverse extrusion mold Upsetting and back extrusion are carried out simultaneously in the middle to form a blank with an equilateral three-jaw flange at one end and a cylindrical shape at the other end. The invention utilizes the relative movement of the back-extrusion die and the back-extrusion punch to carry out reverse extrusion, so that the processes of upsetting the flange and the back-extrusion sliding sleeve with equal wall thickness are carried out simultaneously, reducing the process and improving the efficiency. This process solves the problem of The problem of difficult material, there is a thick gap between the back-extrusion punch and the inner wall of the back-extrusion die cavity, the contact area between the back-extrusion punch and the bar is small, the friction force is reduced when the material is returned, and the life of the die is also reduced. Improvement, the process is simple and easy, saves materials, and improves efficiency; and the reverse extrusion die is simple to manufacture, easy to assemble, and has a long service life, saving die cost.

Owner:江苏理研科技股份有限公司

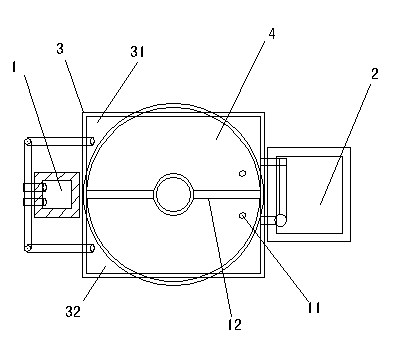

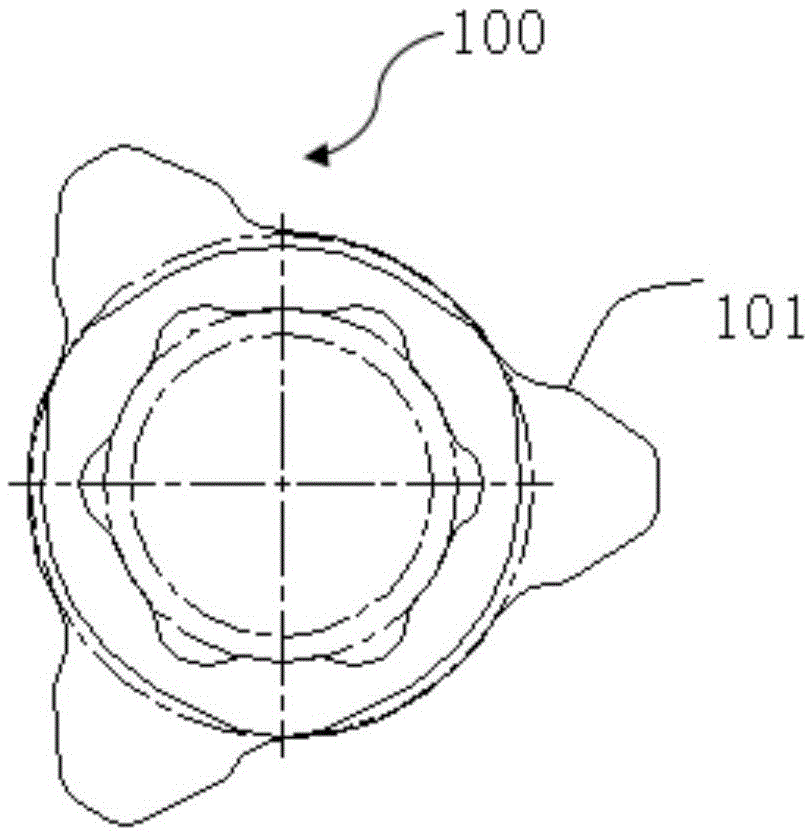

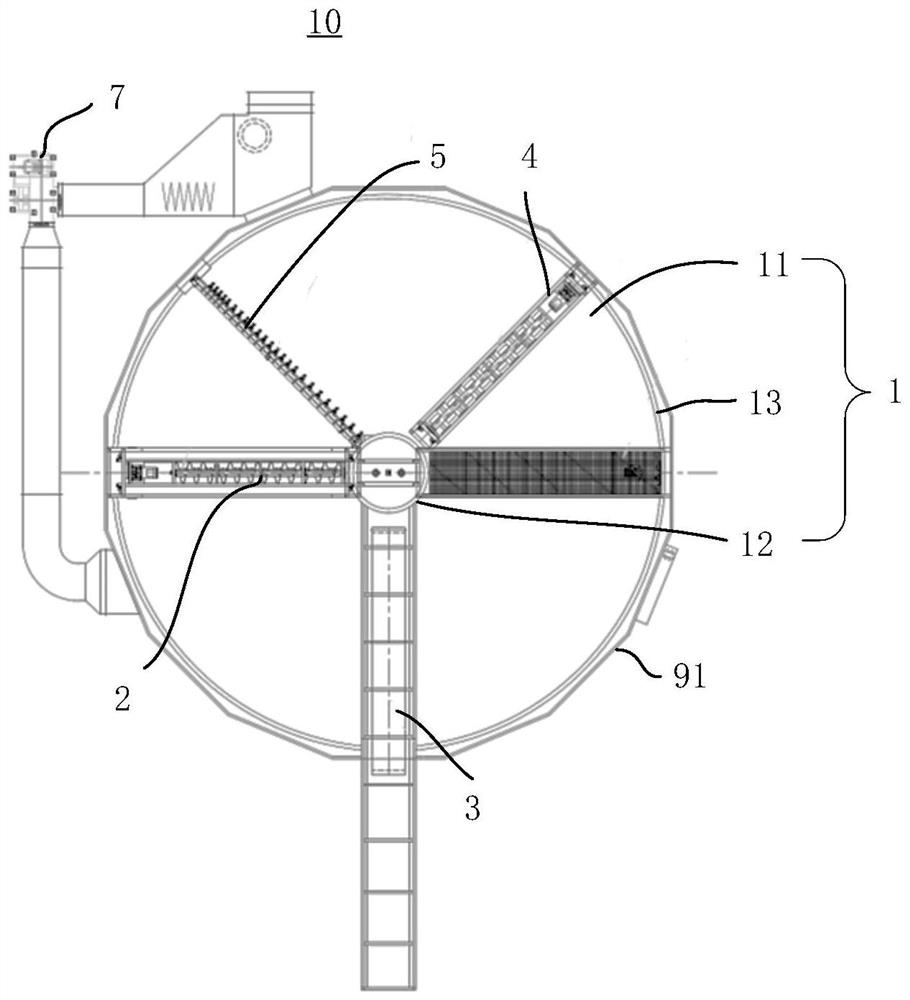

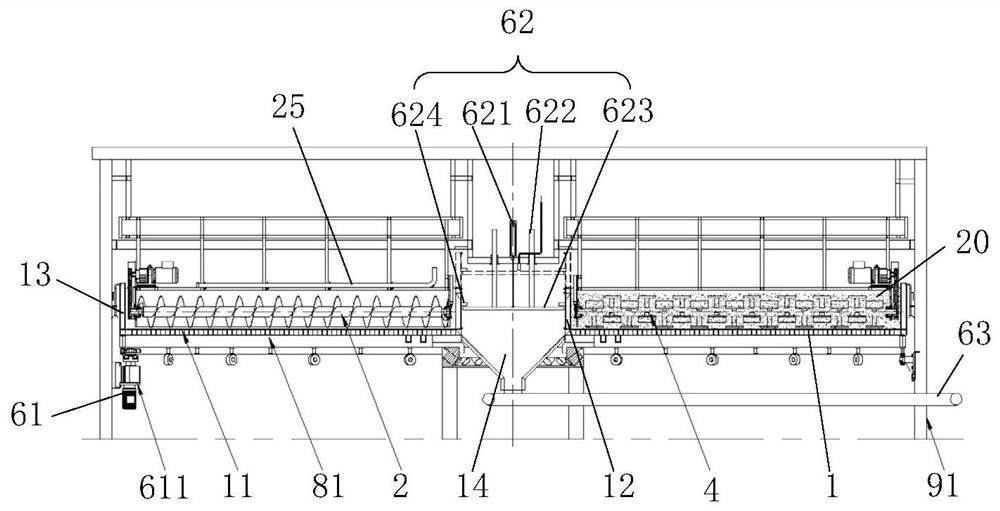

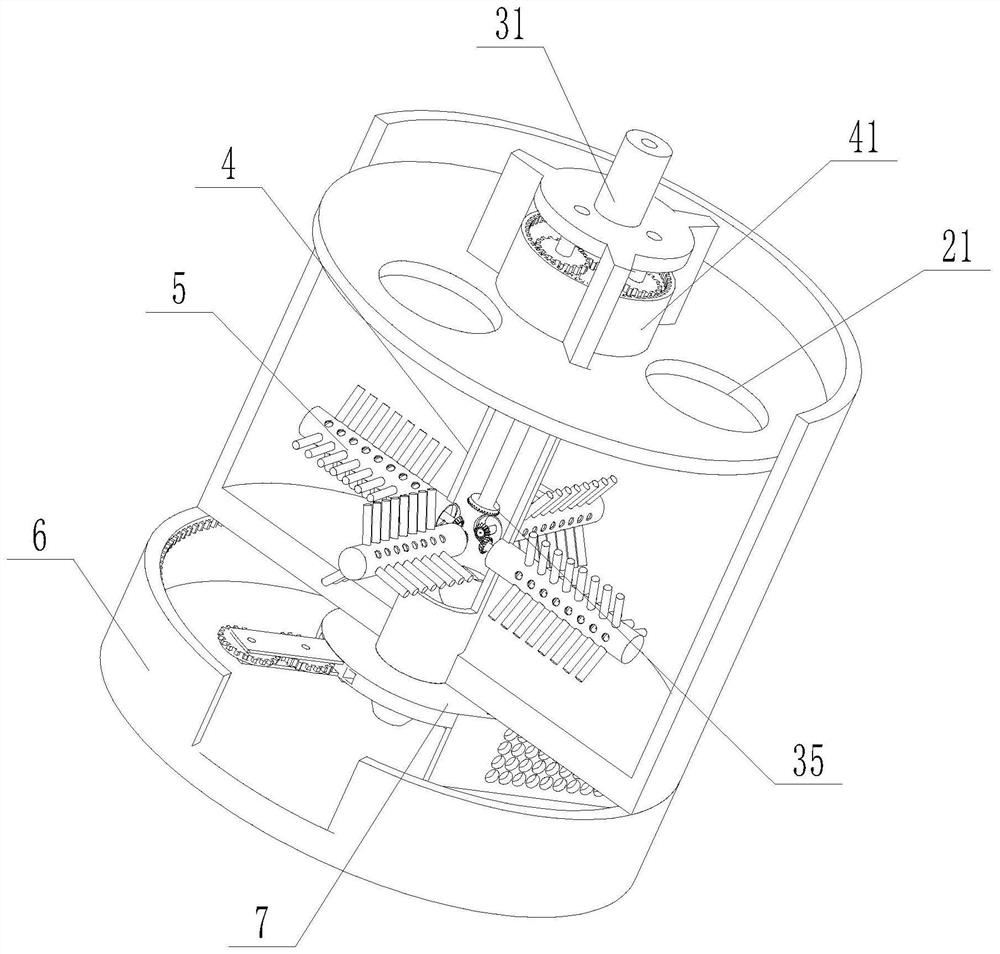

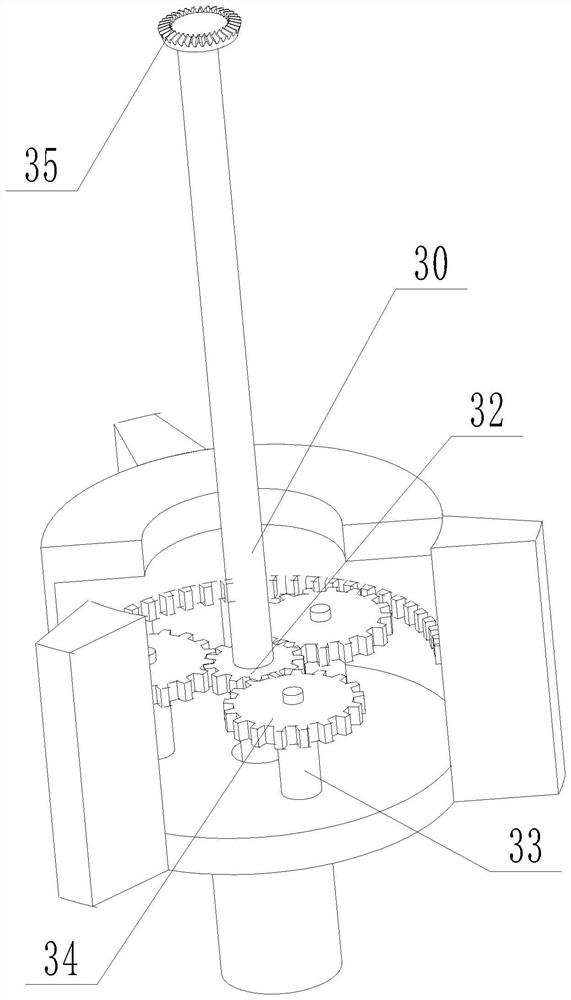

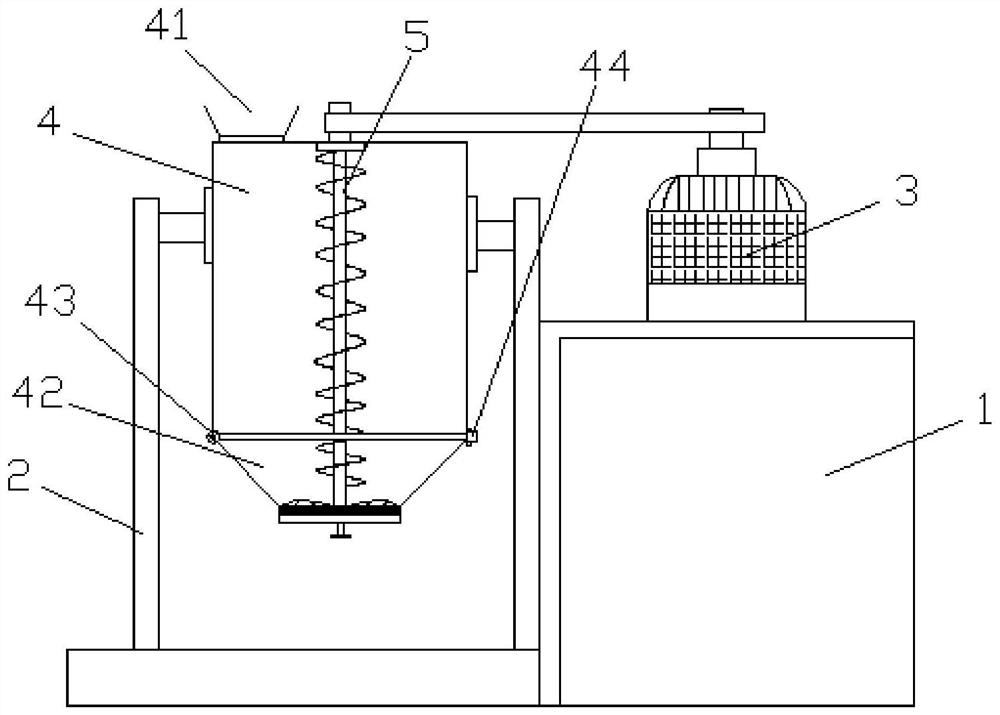

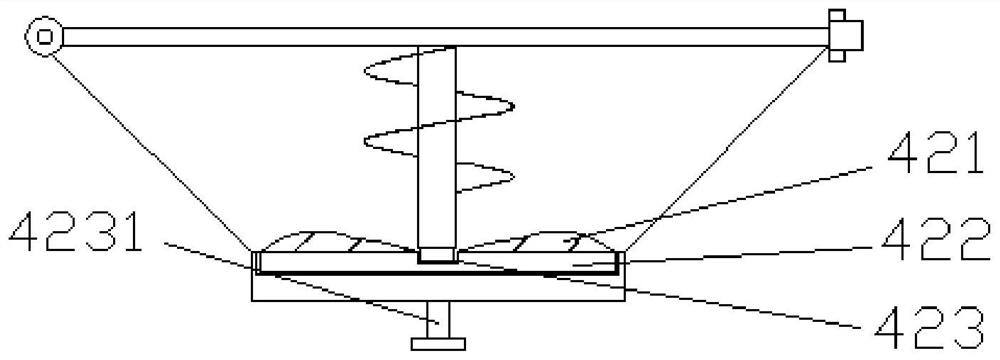

Raw starter maker

PendingCN113697457AEasy dischargeUnblockBioreactor/fermenter combinationsBiological substance pretreatmentsCircular discEngineering

The invention relates to the technical field of fermentation brewing equipment, in particular to a raw starter maker. The raw starter maker comprises a disc and an inner ring driving mechanism, wherein the disc comprises a disc body, an inner ring and an outer ring; the center of the disc body is provided with a discharge port; the inner ring and the outer ring are respectively arranged on the inner ring and the outer ring of the disc body; the inner ring is separably combined with the disc body; and the inner ring driving mechanism is in driving connection with the inner ring and controls the inner ring to be separated from or combined with the disc body by driving the inner ring to move. On the basis, the problem that the circular groove-shaped disc is difficult to discharge can be effectively solved, and discharging of the raw starter maker is facilitated.

Owner:GUANGDONG TIANNIANG INTELLIGENT EQUIP CO LTD

Automatic hydraulic flip oar processing device

ActiveCN104177135BReduce space consumptionImprove capacity utilizationClimate change adaptationOrganic fertiliser preparationAeration systemResource utilization

The invention provides an automatic hydraulic turnover type OAR (Organics Aerobic Oxidation Resources) treatment device and belongs to the field of solid waste organic matter resource utilization technology and equipment. The device comprises a frame, a fermentation tank, an aeration system, an automatic hydraulic overturning system, a fermentation control system, a spraying system and an air exhaust system, wherein the frame is used for fixing each component; the fermentation tank is connected with an oil cylinder in the automatic hydraulic overturning system, the bottom of the oil cylinder is connected with a base, a pump station is arranged on the back surface of the frame, and a control cabinet is positioned in the front surface of the frame; the aeration system is positioned on the lower side of the fermentation tank and is fixedly arranged on the base of the frame by virtue of a lifting aeration groove; the fermentation control system is arranged on the side surface of the fermentation tank; the spraying system is arranged in a framework at the top of the frame and is connected with a tap water pipe; the air exhaust pipe is arranged at the rear side part of the frame and is connected with a deodorizing machine. The device provided by the invention is low in energy consumption, high in efficiency, simple in structure and small in floor area, is simple and easy to operate, can not cause secondary pollution, and is suitable for the treatment of production and living organic garbage.

Owner:北京圣海林生态环境科技股份有限公司 +2

Potassium tripolyphosphate preparation method

ActiveCN100358801CSolve the difficulty of dischargingAvoid wall stickingPhosphorus compoundsPhosphoric acidPOTASSIUM TRIPOLYPHOSPHATE

The invention discloses a making method of potassium tripolyphosphate, which comprises the following steps: proceeding one-step potassium tripolyphosphate synthetic process through high temperature of peroxyphosphoric acid and anhydrous potassium carbonate; producing the needed potassium tripolyphosphate through mixing, neutralizing, drying, grinding, sintering and disintegrating by twin-screw plodder. The invention simplifies the flow path and saves the equipment investment, which improves the conversion rate and quality.

Owner:YUNNAN CHEM RES INST

Rapid raw material mixing and stirring device and operation method thereof

PendingCN114405397AImprove the mixing effectSolve the difficulty of dischargingRotary stirring mixersTransportation and packagingEngineeringMechanical engineering

The invention discloses a rapid raw material mixing and stirring device and an operation method thereof, and belongs to the field of candy stirring devices. Comprising a stirring barrel, a first rotating pipe is arranged in the stirring barrel, a first stirring rod is movably mounted on the first rotating pipe, second stirring rods distributed circumferentially are arranged in the first rotating pipe and on the first stirring rod, a first material conveying hole is formed in the first stirring rod, and first through holes distributed circumferentially are formed in the first material conveying hole; a first rotating shaft is installed in the first through hole, a first feeding screw is arranged on the first rotating shaft, the first material conveying hole is communicated with an inner cavity of the first rotating pipe, a storage bin is arranged below the stirring barrel, a discharging head is arranged below the first rotating pipe, and the discharging head is connected with an inner cavity of the storage bin, so that the problem that discharging is difficult after stirring can be solved.

Owner:广东创辉食品有限公司

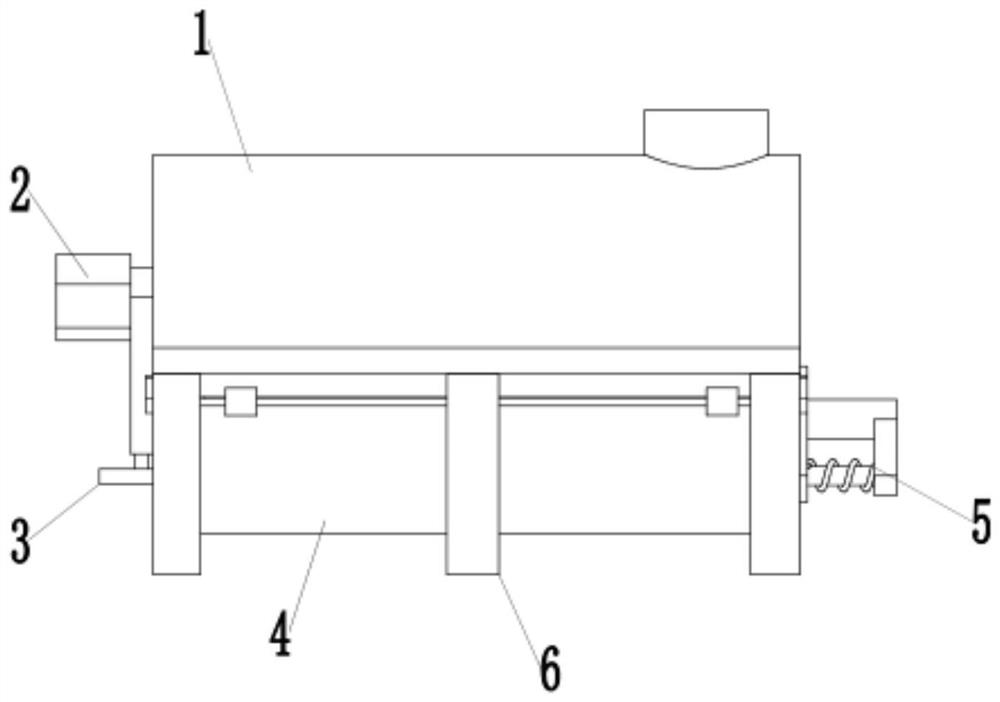

Pulverizer for industrial basic zinc carbonate production

InactiveCN112844621ASmooth dischargeSolve the difficulty of dischargingGrain treatmentsElectric machineryStructural engineering

The invention discloses a pulverizer for industrial basic zinc carbonate production. The pulverizer comprises a crushing barrel, a shaking device, a discharge barrel, an extrusion device and a support, wherein the crushing barrel is transversely arranged, a feed inlet is formed in the side wall of the crushing barrel, the feed inlet is arranged upwards, a screening plate is arranged on the side wall of the bottom of the crushing barrel, the bottom of the crushing barrel is arranged on the discharge barrel, one end of the crushing barrel is provided with the shaking device connected with the discharged barrel, the other end of the crushing barrel is provided with the extrusion device connected with the discharged barrel, one end of the shaking device is provided with a motor, the motor is connected with a rotating shaft, the rotating shaft is arranged in the crushing barrel, and the rotating shaft is provided with a crushing arm. The screening plate is directly arranged at the bottom of the crushing barrel for discharging, crushed materials are directly discharged, meanwhile, smooth discharging of the materials is achieved under rotation of the crushing arm, the problem that discharging of an existing transverse crushing barrel is difficult and not thorough is solved, and the discharging efficiency is improved.

Owner:衡阳市坤泰化工实业有限公司

Spiral stirrer for agricultural product processing and using method

InactiveCN111841381ASimple structureExtended service lifeRotary stirring mixersTransportation and packagingElectric machineAgricultural engineering

The invention discloses a spiral stirrer for agricultural product processing and a using method. The spiral stirrer is mainly formed by combining a base, a bracket, a driving motor, a stirring cylinder and a stirring shaft, wherein the base is arranged on one side of the bracket, the driving motor is arranged on the base, the stirring cylinder is arranged on the bracket, one end of the stirring shaft is arranged in the stirring cylinder, and the other end of the stirring shaft is arranged outside the top wall of the stirring cylinder and is connected with the driving motor through a belt; thespiral stirrer is simple in structure; long service life, an openable end cover is arranged at the bottom and used for discharging, and a turntable and stirring fan blades are arranged in the end cover and drive the turntable and the stirring fan blades at the bottom of the end cover to rotate through the stirring shaft, so that the spiral stirrer solves the problems that bottom materials cannot be fully stirred and discharging is difficult at the same time, the practicability is remarkably improved, and the market prospect is good.

Owner:怀化聚农轩农业科技有限公司

High performance solar methane generator

InactiveCN100352911CCreativeIncrease gas production rateGas production bioreactorsWaste based fuelEngineeringFlap valve

The provided new solar methane generator comprises a regenerator with solar energy, a sealed feeding port, a fermentor, a cycle stirring system, a gas storage and feed system, an outlet hydraulic chamber, a pressure flap valve for discharge, and a discharge pond. Compared with prior art, this invention improves creating-gas ratio greatly, and overcomes air impermeability problem.

Owner:HEBEI AGRICULTURAL UNIV.

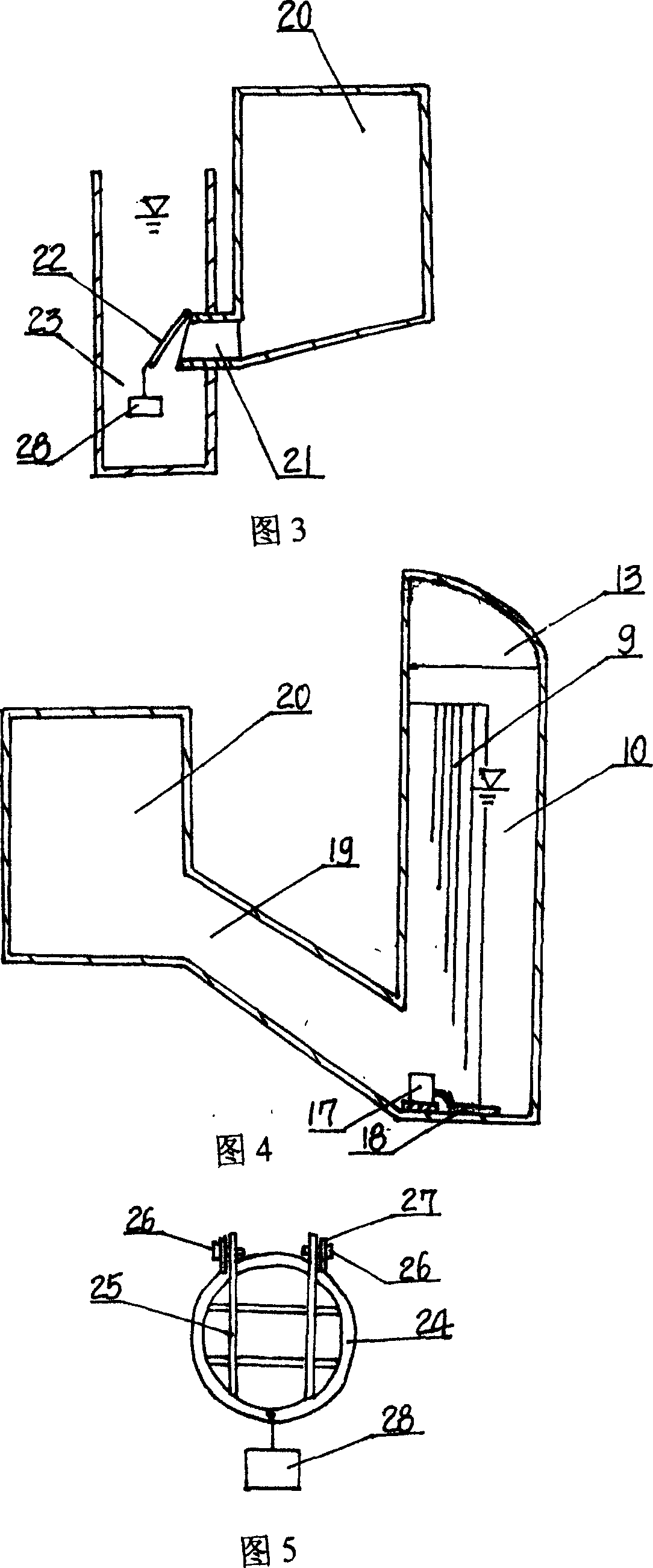

A kind of preparation method of 3',6'-dimethoxyfluoran yellow thermosensitive dye

Owner:沈阳感光化工研究院有限公司

Multifunctional microwave heating wet-process variable-pressure metallurgical reaction device

PendingCN113337708AEven contactContact thoroughlyProcess efficiency improvementEngineeringMaterials science

The invention discloses a multifunctional microwave heating wet-process variable-pressure metallurgical reaction device. The device comprises a stirring device, a pressure container, a cooling device, a microwave generating device, a feeding and discharging device and an air intake and exhaust device. The stirring device comprises a stirring mechanism arranged in the pressure container and a driving mechanism arranged outside the pressure container, and the cooling device is circumferentially arranged on the outer side of the stirring mechanism. The microwave generating device is circumferentially arranged on the outer side of the pressure container, and the feeding and discharging device is arranged at the top of the pressure container. The air intake and exhaust device is arranged at the top of the pressure container. According to the multifunctional microwave heating wet-process variable-pressure metallurgical reaction device, continuous heating in the reaction process can be achieved through microwaves, materials can be evenly heated, and reactants can be in full contact and react by optimizing the stirring mechanism.

Owner:KUNMING UNIV OF SCI & TECH

Recycling tank for bauxite sewage

PendingCN107758766ASolve the difficulty of dischargingWaste water treatment from quariesTreatment involving filtrationSewageMechanical engineering

The invention discloses a recycling tank for bauxite sewage. The recycling tank comprises a tank body, a liquid inlet pipe positioned on the tank body, and a discharging port; a stirrer is mounted inthe tank body; the tank body comprises a bottom plate, a sealing cover and an enclosing wall for connecting the bottom plate with the sealing cover; the liquid inlet pipe is positioned at the upper part of the sealing cover, and a liquid outlet pipe is arranged on the enclosing wall on one side opposite to the liquid inlet pipe; and the bottom plate is an obliquely-arranged elliptical plate, the shape of the elliptical plate is matched with that of the enclosing wall, the discharging port is formed in the side wall at the contact lowest point between the enclosing wall and the elliptical plate, and a sealing door for sealing the discharging port is arranged outside the discharging port. The recycling tank disclosed by the invention has the benefits that crystals only can be discharged after supernatant liquid is extracted; and through arranging the oblique elliptical plate and the discharging port in the side edge, the friction force of the crystals and the dead angles of the tank bodyare reduced, so that the crystals are convenient and quick to clean.

Owner:遵义汇恒环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com