Reaction device for interesterification and polycondensation reaction

A technology of reaction device and polycondensation reaction, which is applied in the field of reaction device, can solve problems such as uneven heating, easy overheating, and inability to discharge materials, and achieve the effects of uniform molecular weight, narrow molecular weight distribution, and high technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

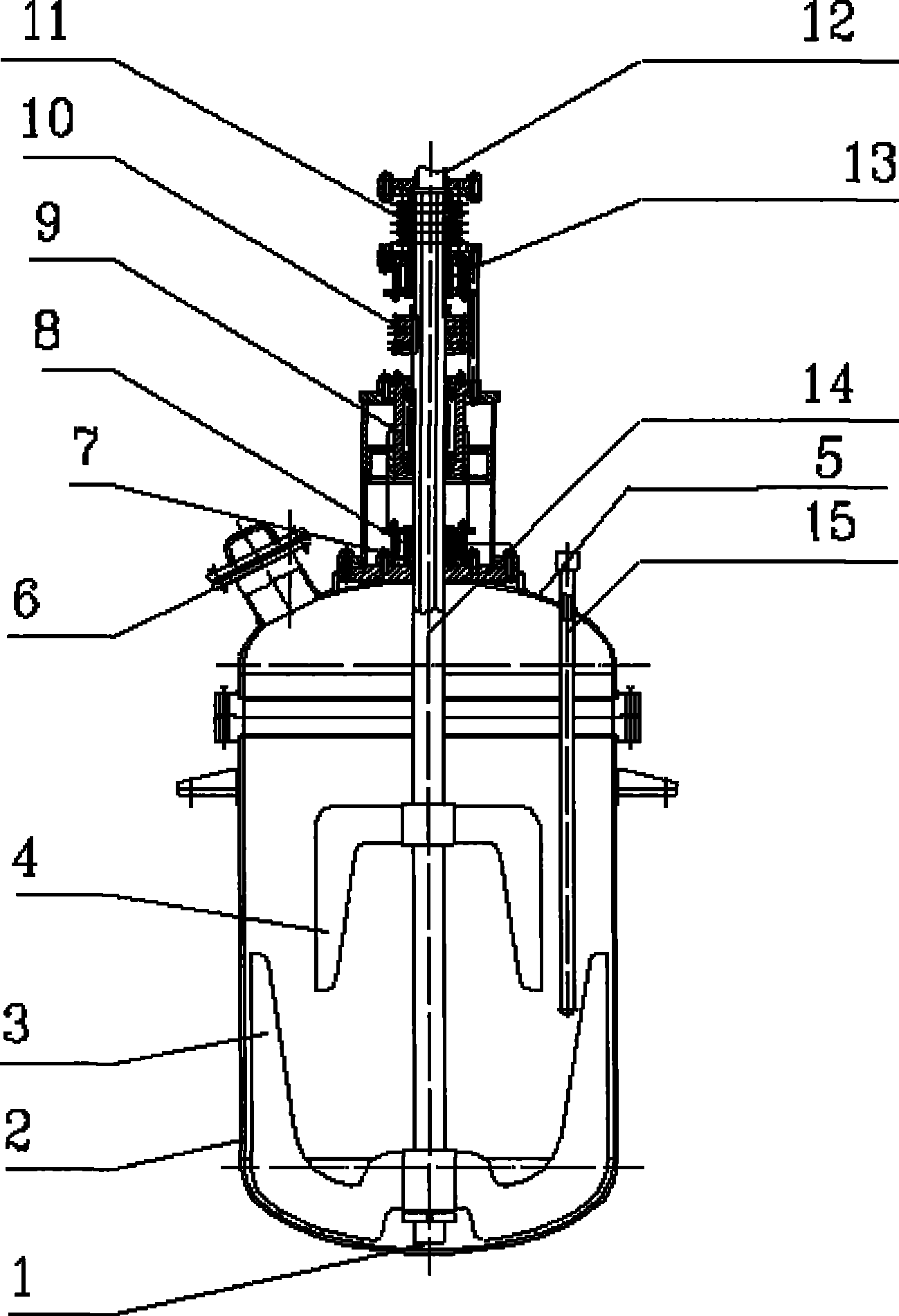

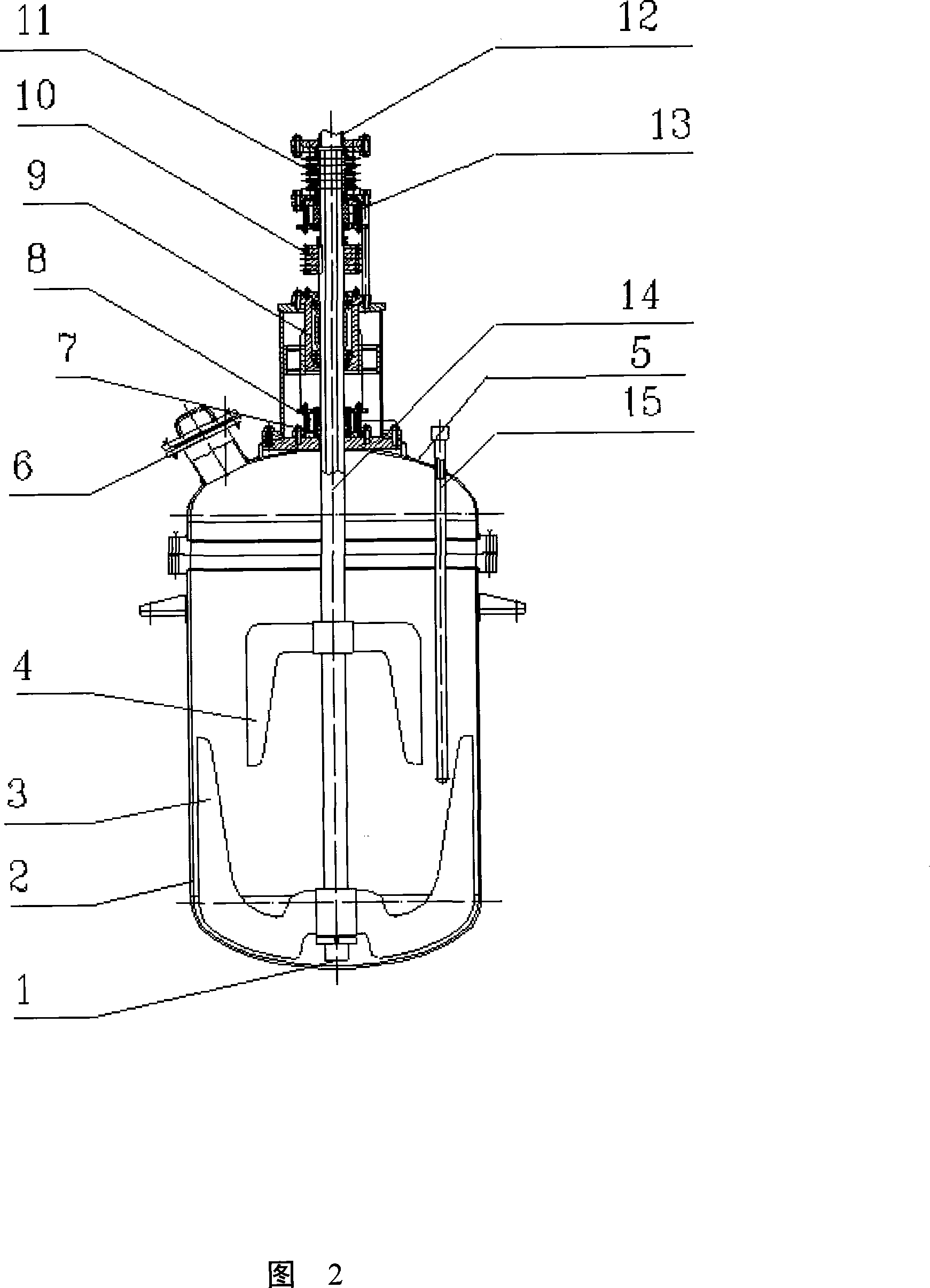

[0033] The reaction device of the transesterification and polycondensation reaction of the present embodiment comprises a still body 2 with a still cover 5, and a central shaft 14 is installed on the still cover 5 at the center of the still body 2, and the central shaft 14 is hollow. One end of the hollow shaft 14 stretches to the inside of the kettle body 2, and the other end is outside the kettle body 2.

[0034] On the central axis 14, be connected with " U " shape downside down anchor 3 and upside down downside down anchor 4 of " U " shape, the two are relatively installed. The "U" shaped openings of the upper inverted anchor 4 and the lower inverted anchor 3 are partially overlapped, as shown in Fig. 2 .

[0035] During installation, the gap between the outer wall of the lower inverted anchor 3 and the inner wall of the kettle body 2 is 15-20mm, and the gap between the outer bottom wall of the lower inverted anchor 3 and the inner bottom wall of the kettle body 2 is 150-2...

Embodiment 2

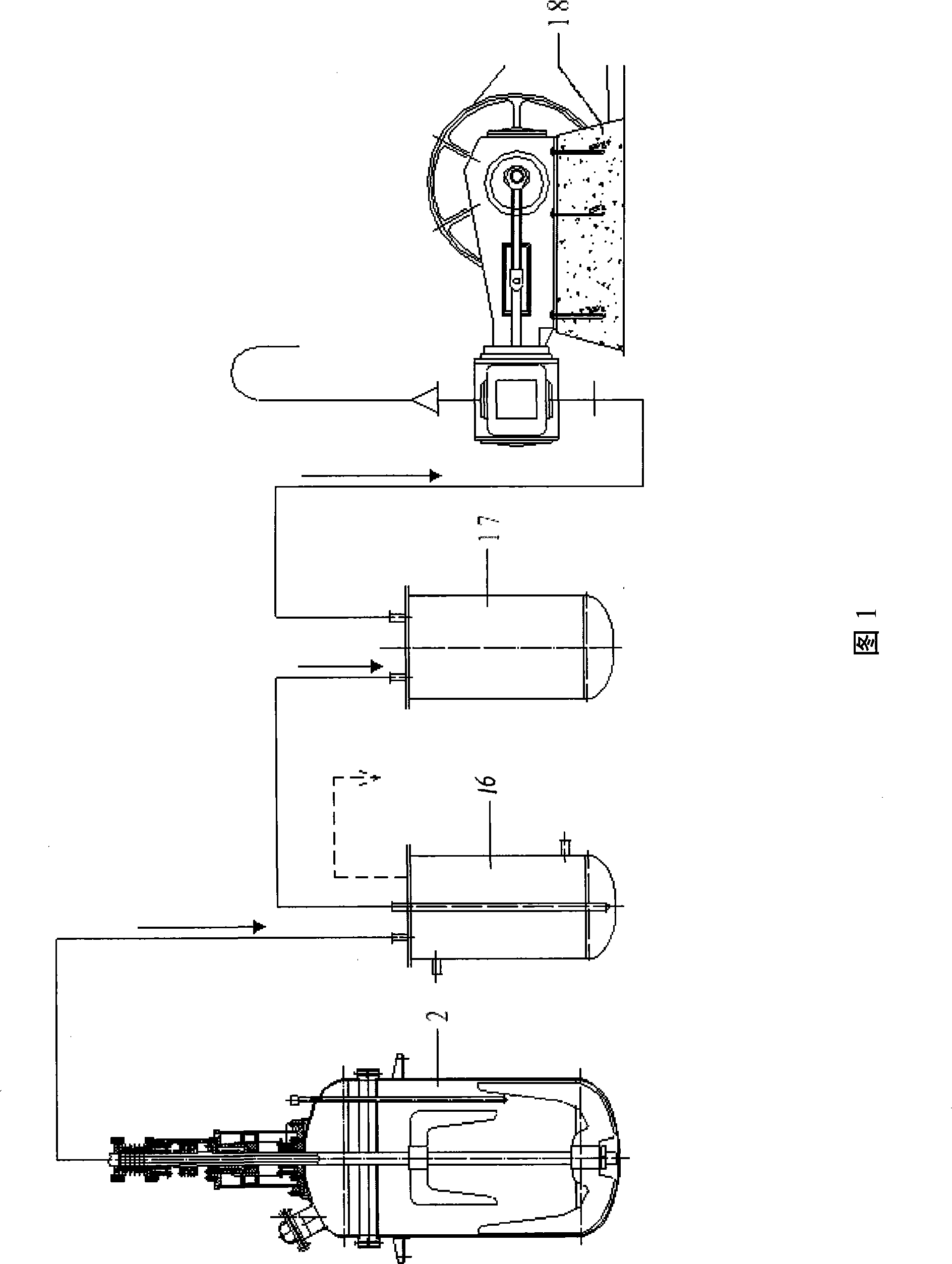

[0042] The device of the invention is used for the transesterification and polycondensation reactions of preparing POB.

[0043] In the transesterification and polycondensation reactor body 2 described in the embodiment 1 of 1000L, 599 kg of raw materials for transesterification and polycondensation are thrown into the reactor body 2 from the feeding port 6 at one time, and the amount of raw material is 1 / 2 of the volume of the reactor body 2 70% to 75%. Connecting terminal 4 is connected with a power supply. Turn on the power supply and heat the kettle body 2 to 63°C through the electric furnace wire 5, and then stop heating. Due to the effect of the insulation layer 24 of the electric heating furnace, the solid components of the above materials can start to melt at 63°C. Generally, it takes 2 ~3h, then turn on the power supply to heat the kettle body 2 through the electric furnace wire 23, raise the temperature to 120°C, and carry out the transesterification reaction, which ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com