Patents

Literature

66results about How to "Contact thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

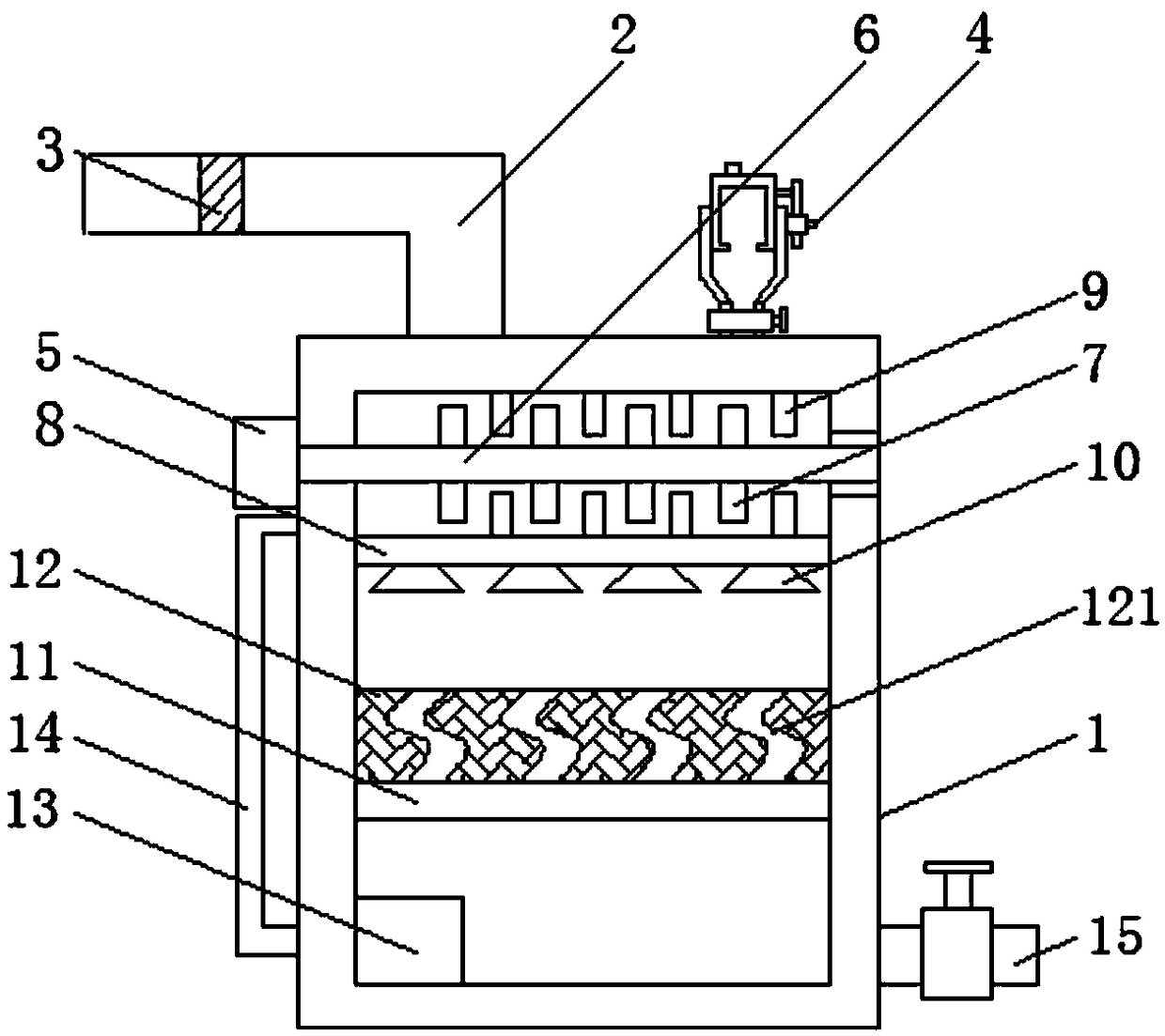

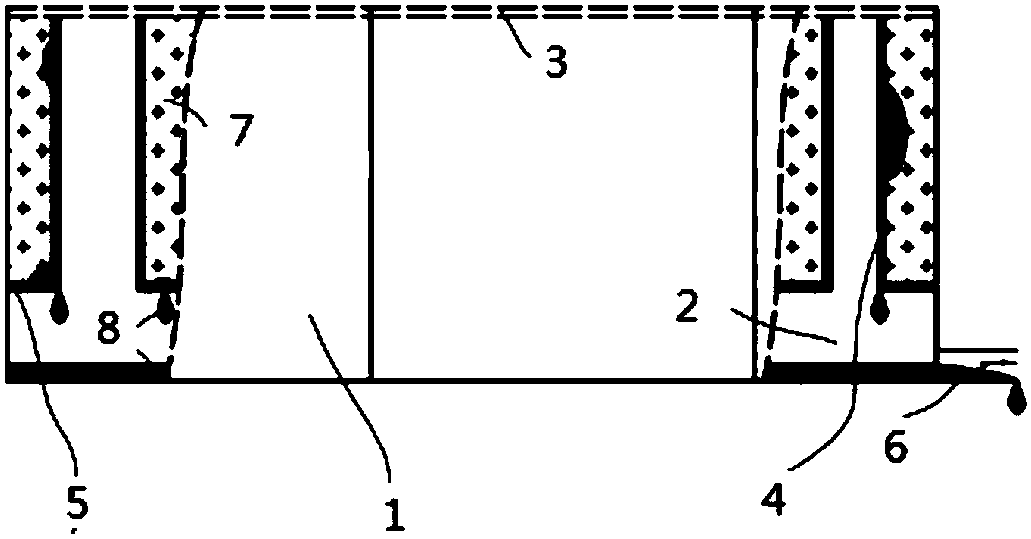

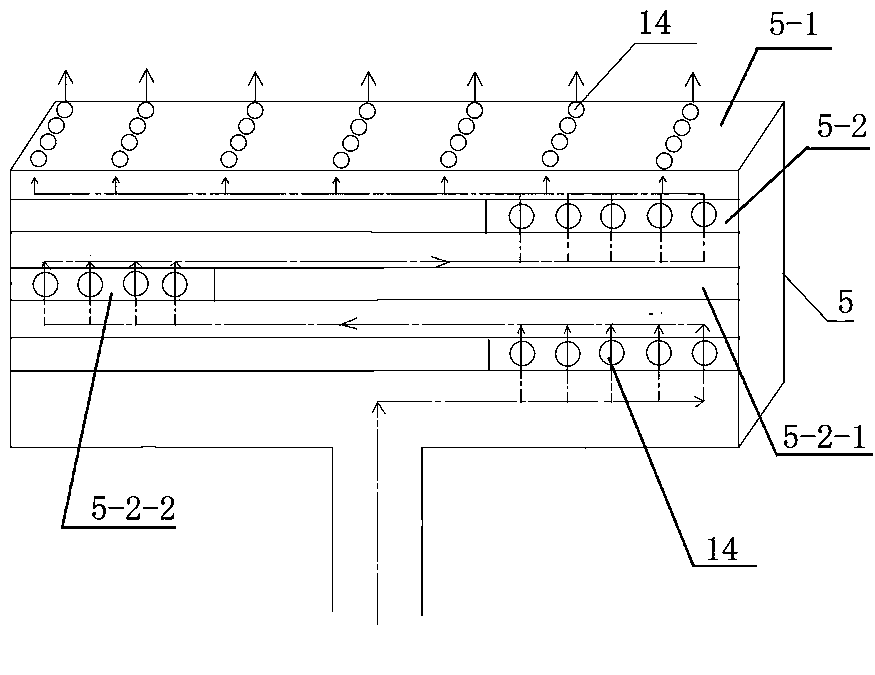

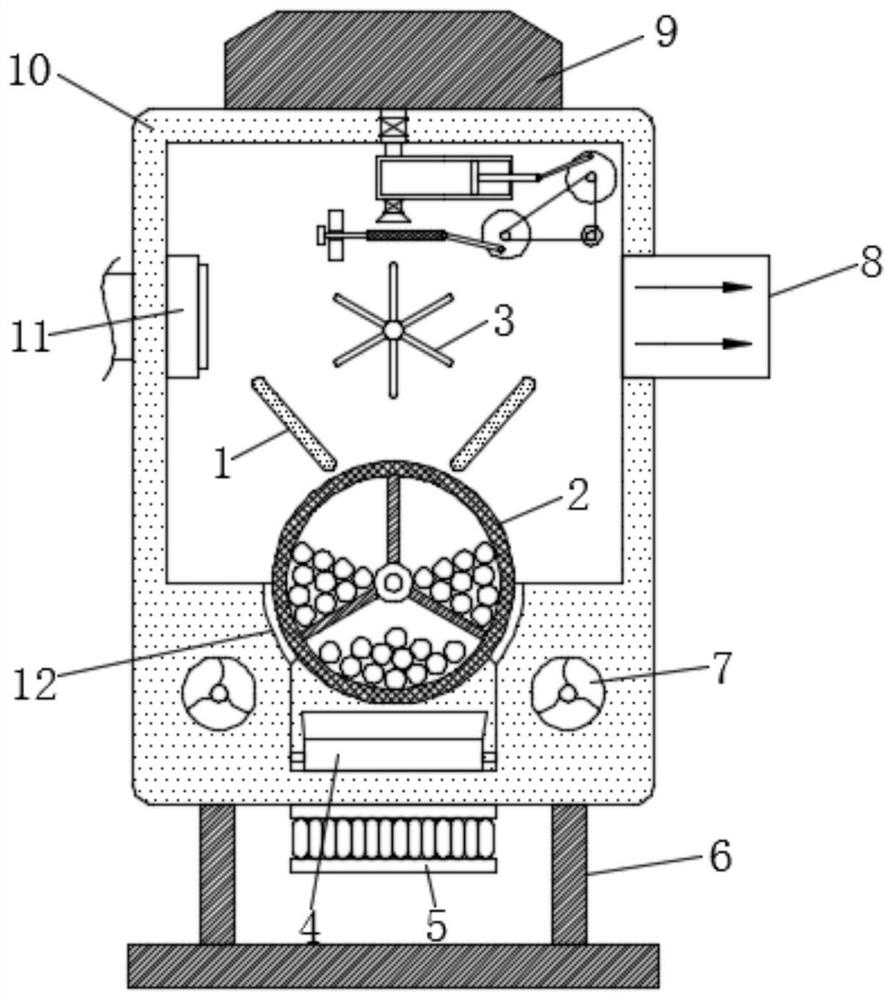

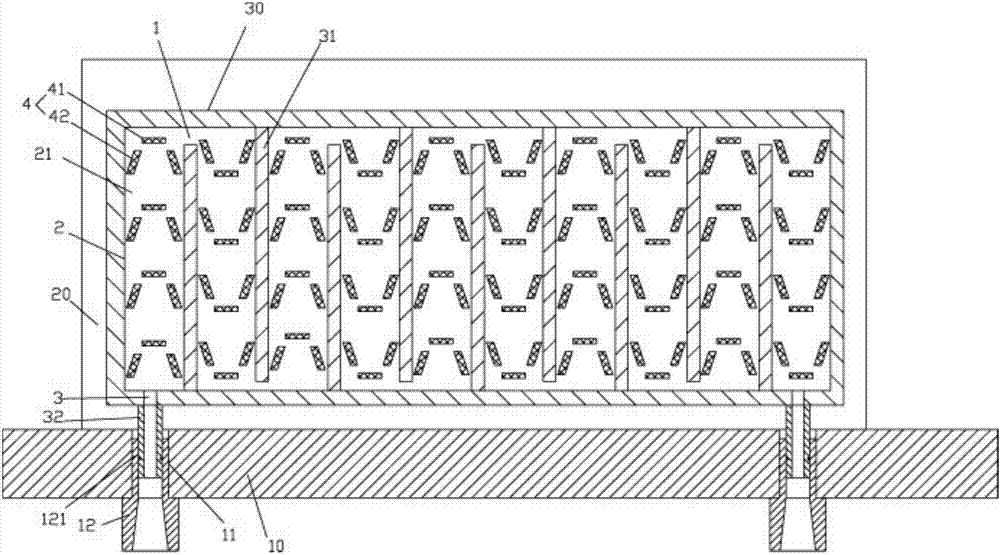

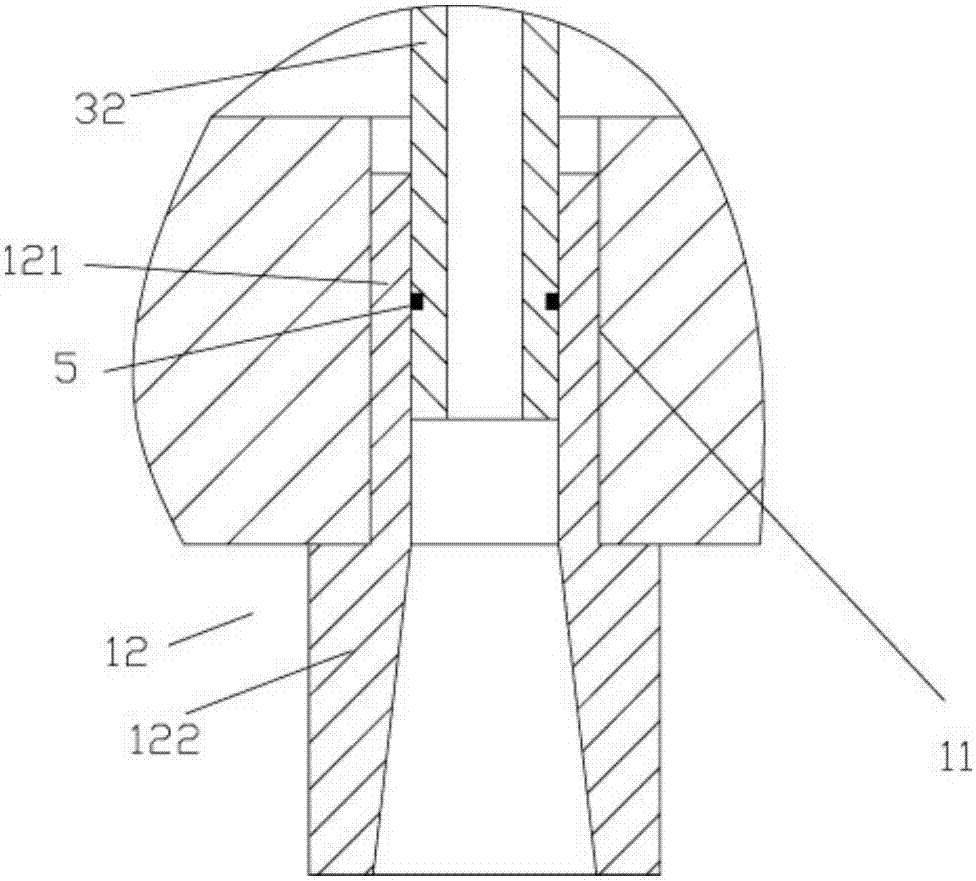

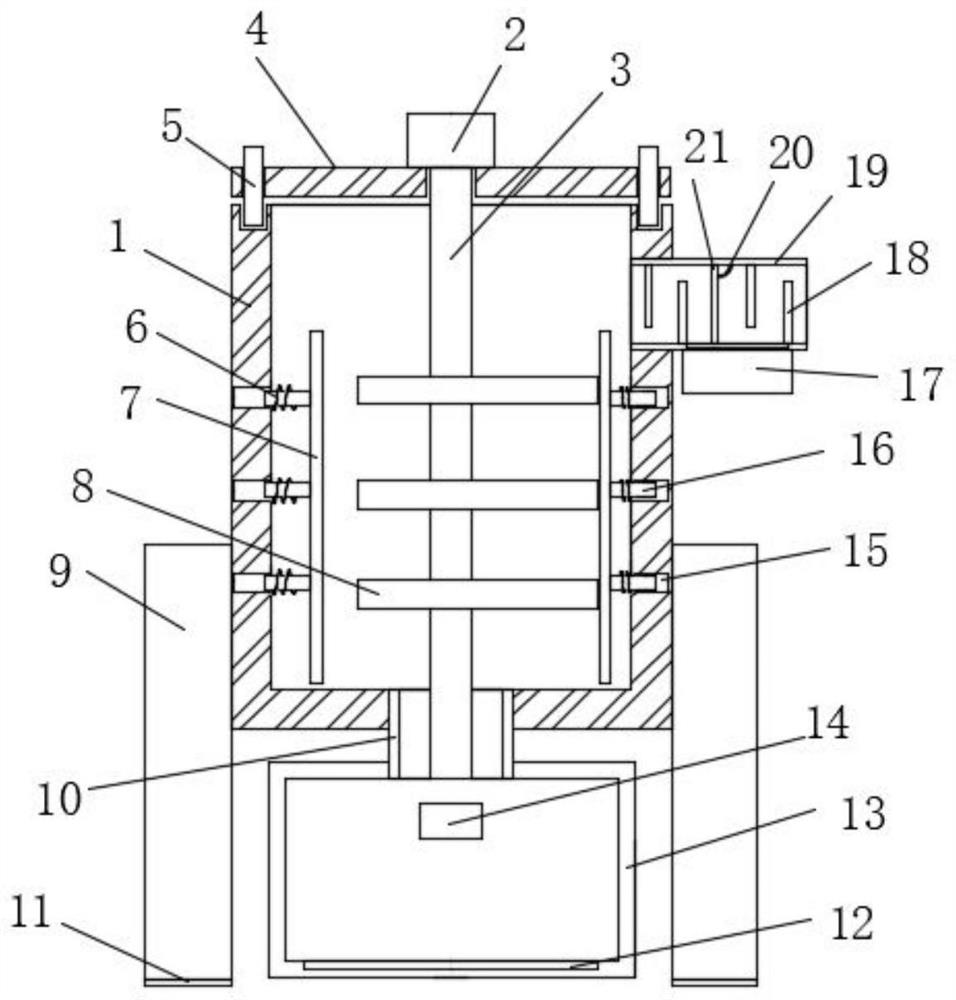

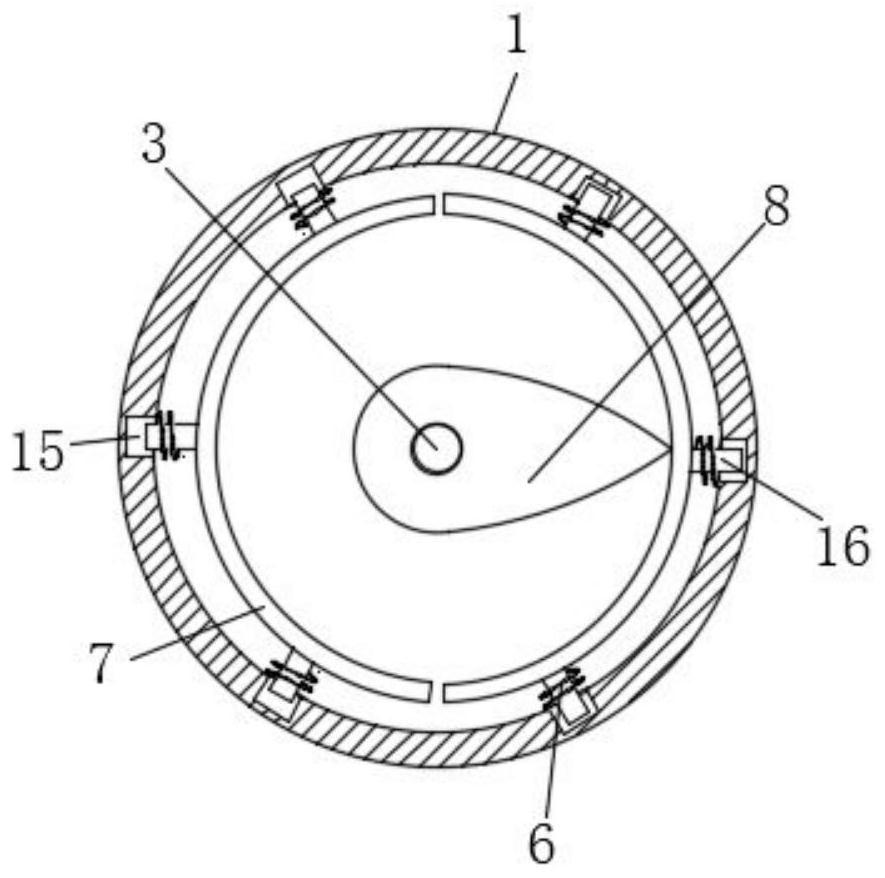

Floating bed catalytic ozonation reactor and method therewith for treating waste water

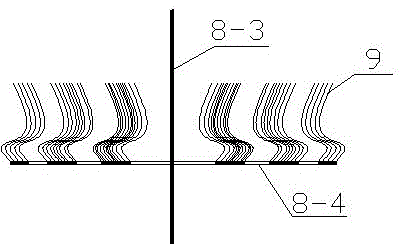

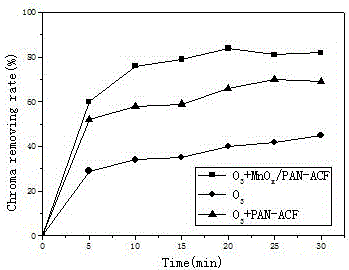

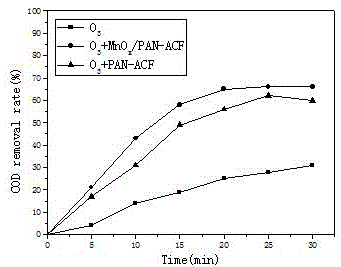

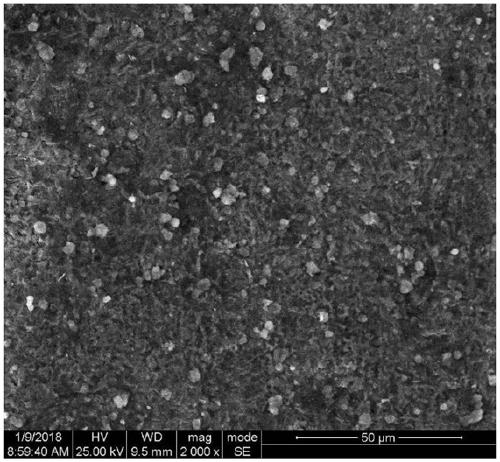

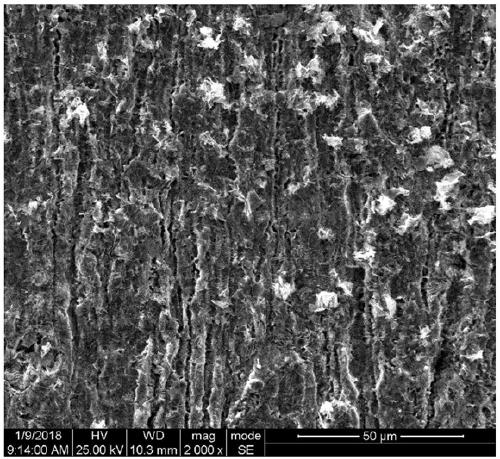

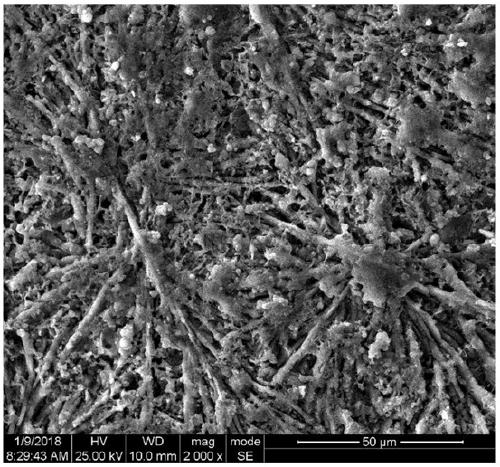

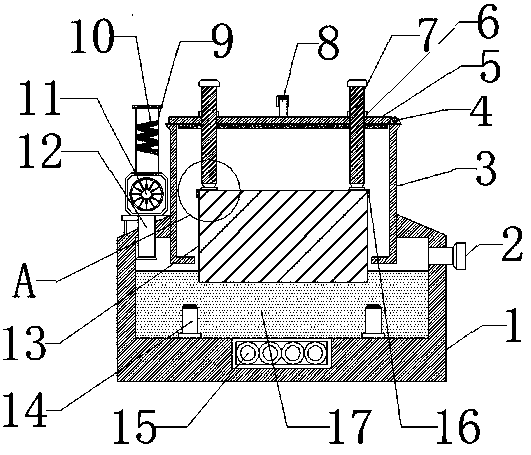

ActiveCN105129965ASimple structureModerate densityWater/sewage treatment by oxidationPtru catalystCatalytic ozonation

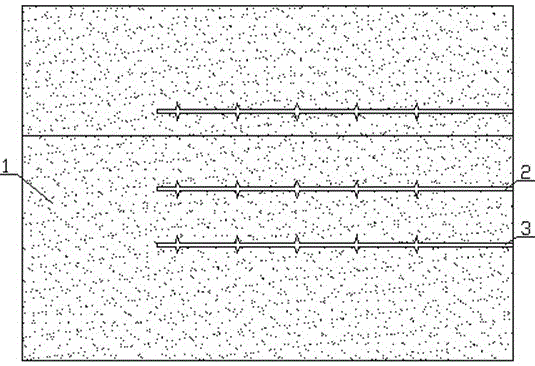

The invention relates to a floating bed catalytic ozonation reactor and a method therewith for treating waste water. A floating catalyst bed assembly is installed in the reactor and is formed by an upper fixing frame, a lower fixing frame and a hanging rope. A porous annular plate is arranged on the hanging rope. One end of a flexible floating catalyst is fixed on the porous annular plate. A water distributing device is arranged above the reactor and is used for uniformly distributing waste water to all parts. An air inlet pipe and a water distributor are arranged under the reactor and are used for uniformly diffusing gas. In the invention, by means of the light-weight flexible fiber-like catalyst arranged on the floating bed, the catalyst is uniformly distributed in the space of the reactor, and with disturbance of ozone bubbles, the reactor is improved in gas-solid-liquid mass transfer efficiency and ozone utilization rate, is reduced in system resistance, and can decompose and mineralize refractory organic substances in waste water effectively.

Owner:HARBIN INST OF TECH AT WEIHAI

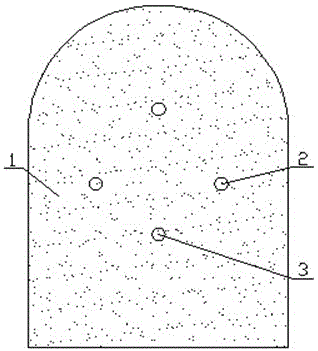

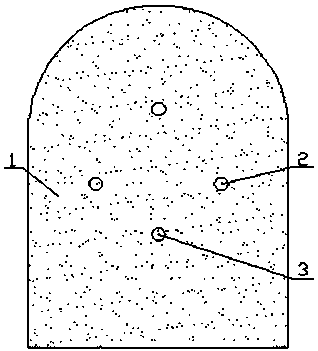

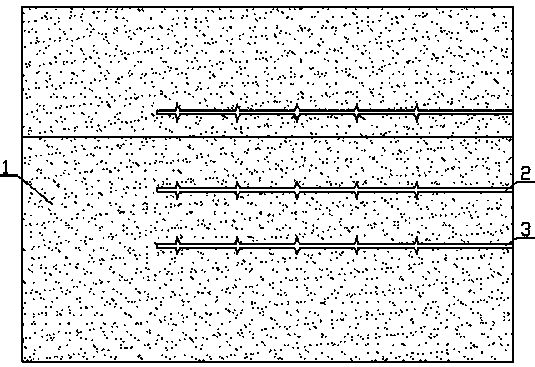

Method of filling fast excavation tunnel with hydrofracturing chemical expanding agent

InactiveCN106089174AFast cleft developmentSafe and efficient tunnelingFluid removalSealing/packingStress concentrationRock engineering

The invention relates to a method of filling a fast excavation tunnel with a hydrofracturing chemical expanding agent. In normal production of underground rock engineering, water detecting boreholes bored in front to learn forward geological conditions are used, and related regulations of water detecting are strictly abided before boring. The boreholes are arranged in a fan shape, and the other is located in the middle. Multiple wedge-shaped grooves are formed in all the boreholes with a grooving drill, then water is injected at high pressure, and stress of water pressure in the wedge-shaped grooves acts in a concentrated mode to break integrity of surrounding rock. The characteristic that the size is increased when the expanding agent is coagulated is used, and a coagulator is injected after hydrofracturing, and cracks in the boreholes grown more completely. A related chemical solution is prepared according to chemical components of rock and is injected into the boreholes. Chemical reaction of the chemical solution and the surrounding rock can reduce mechanical strength of the rock. The boreholes needed by water detecting are used and combined with chemical and physical methods during practical application, and the purpose of fast excavation face pushing can be achieved.

Owner:TAIYUAN UNIV OF TECH

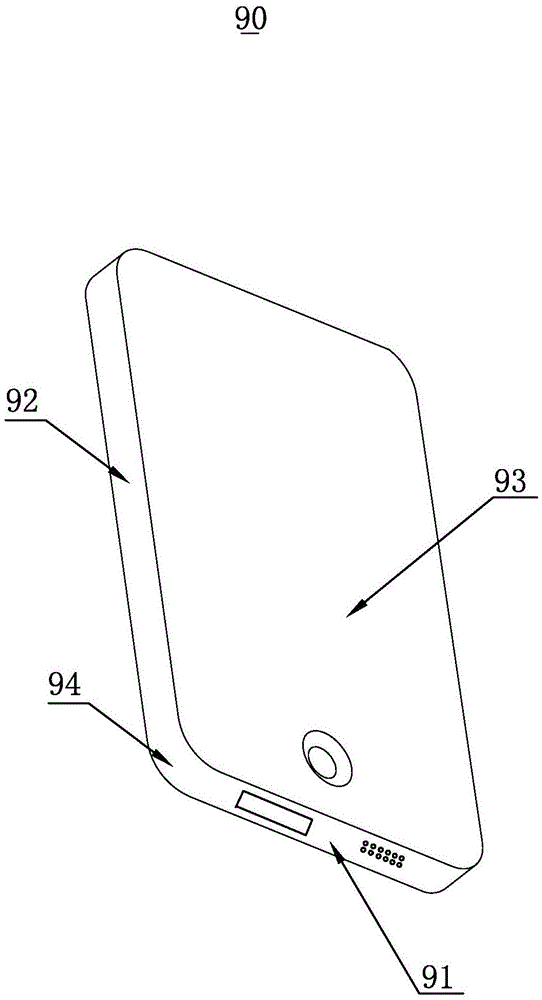

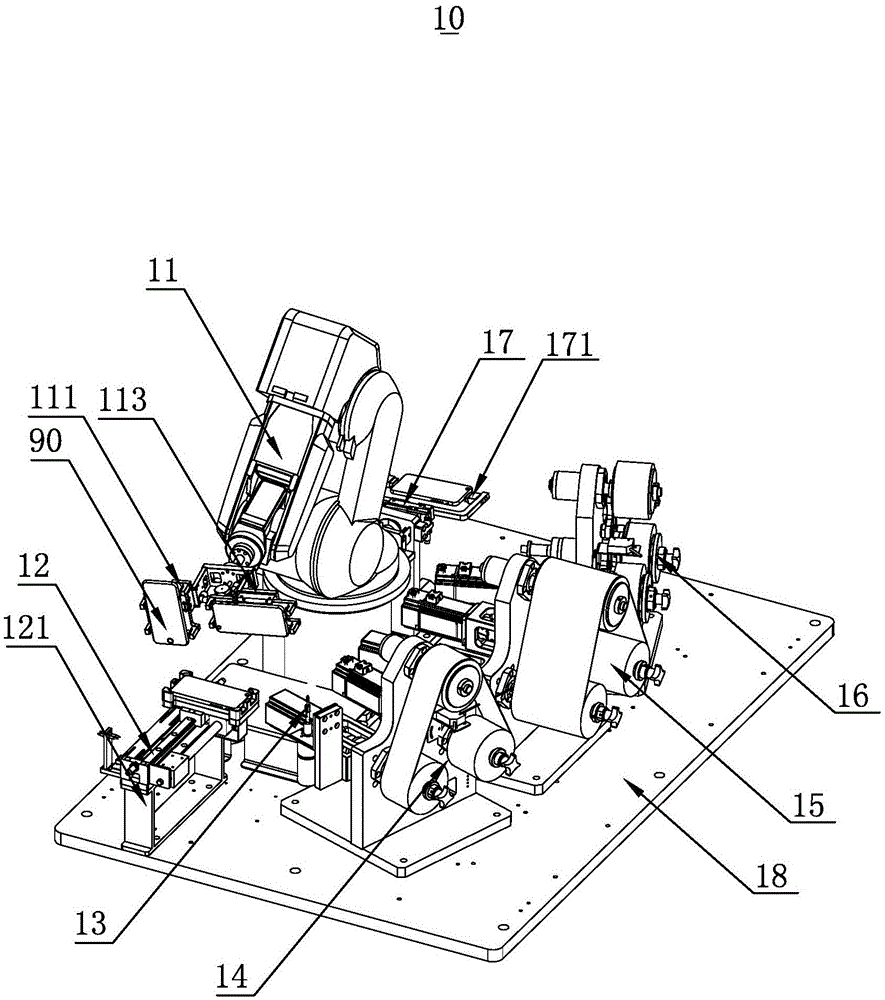

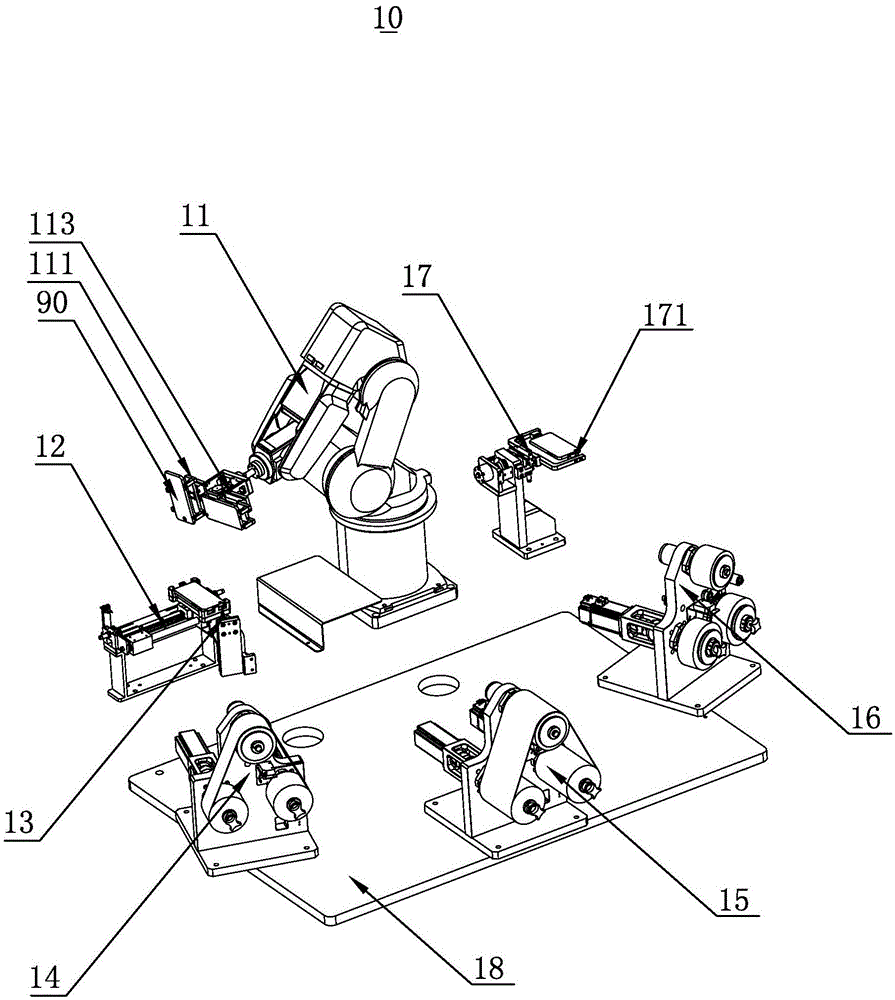

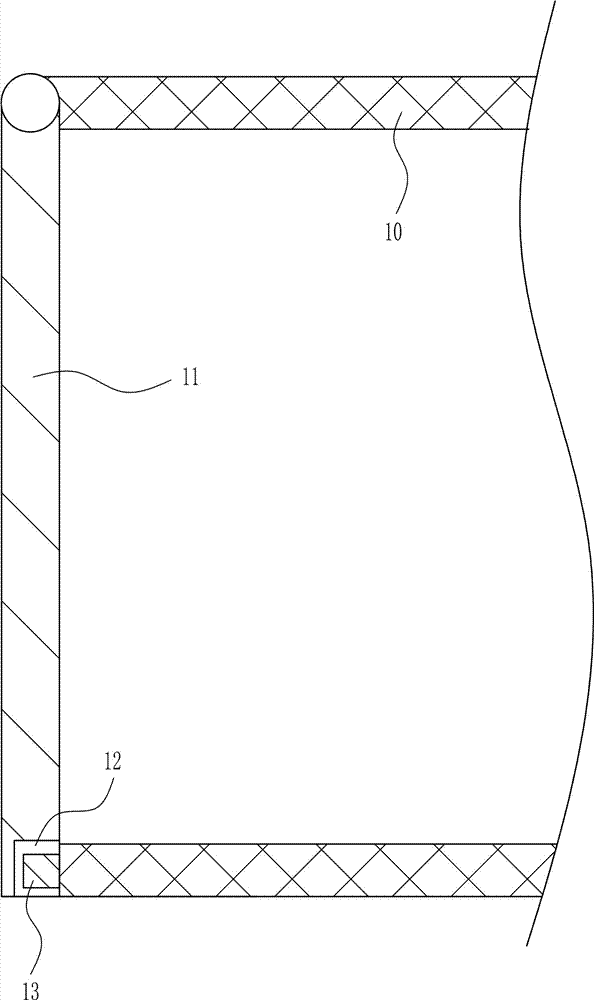

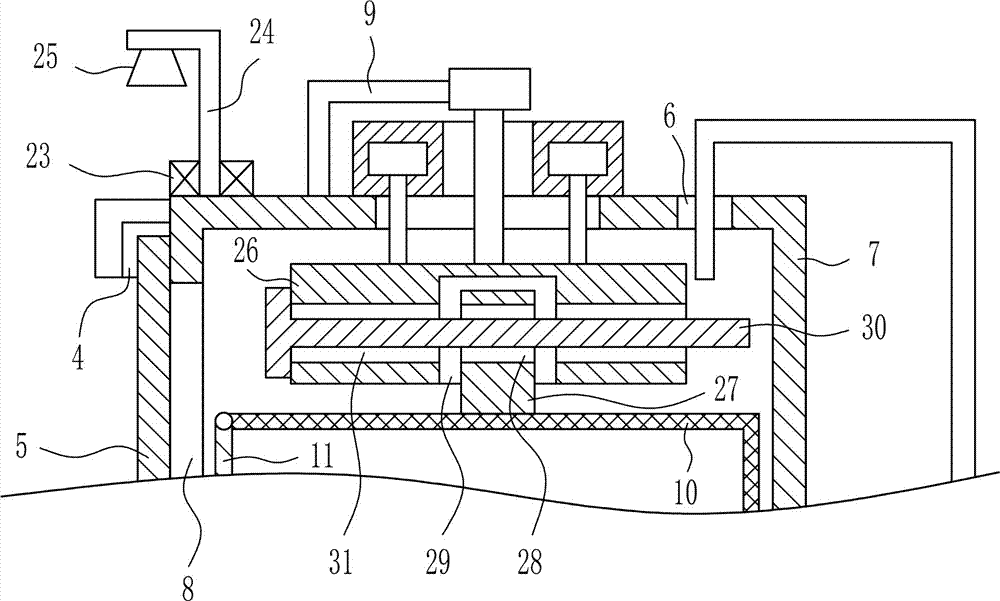

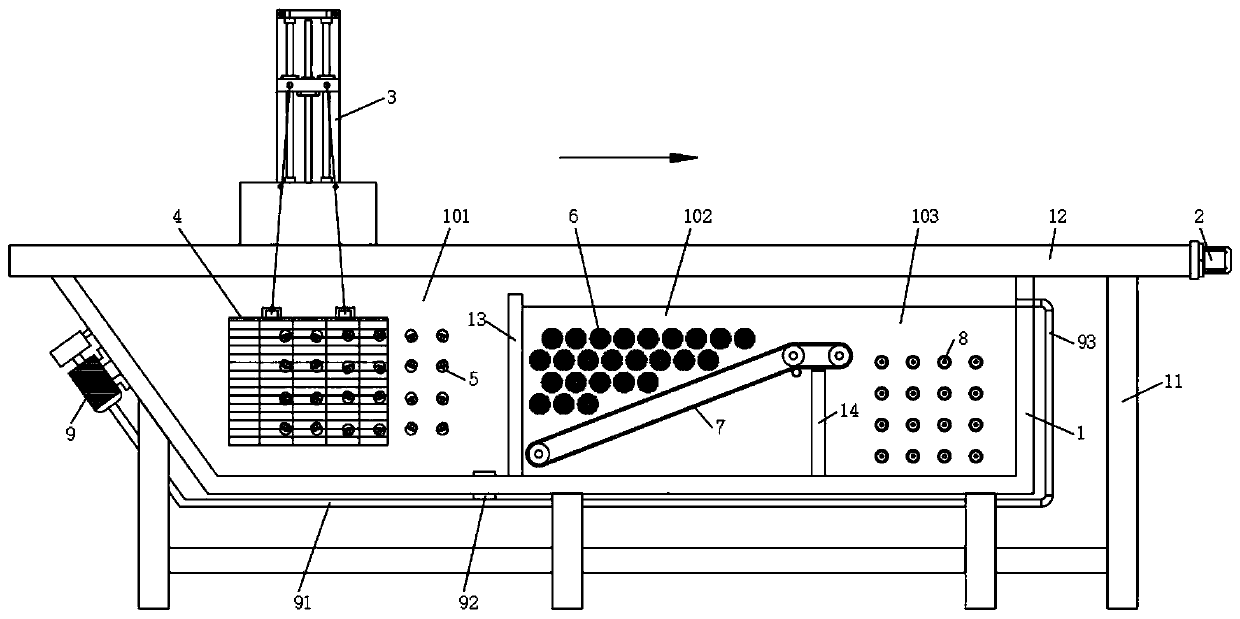

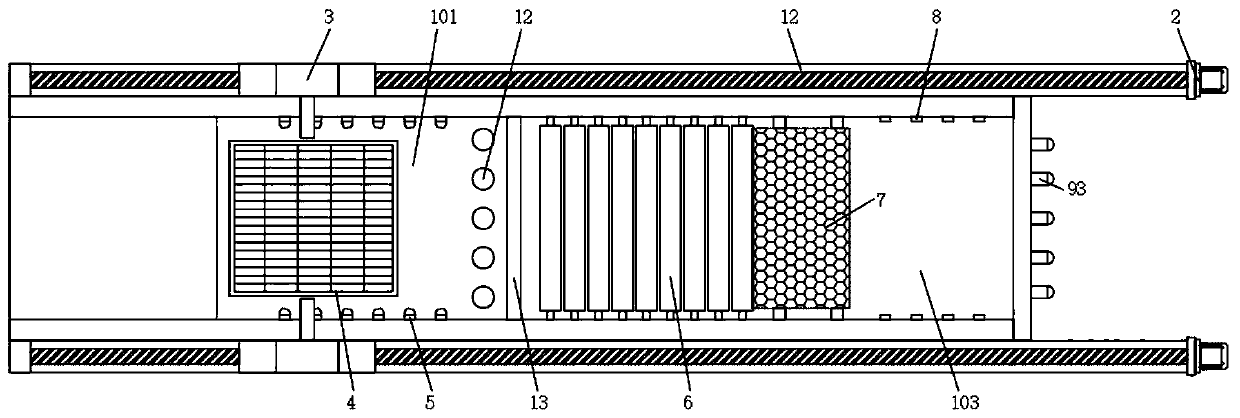

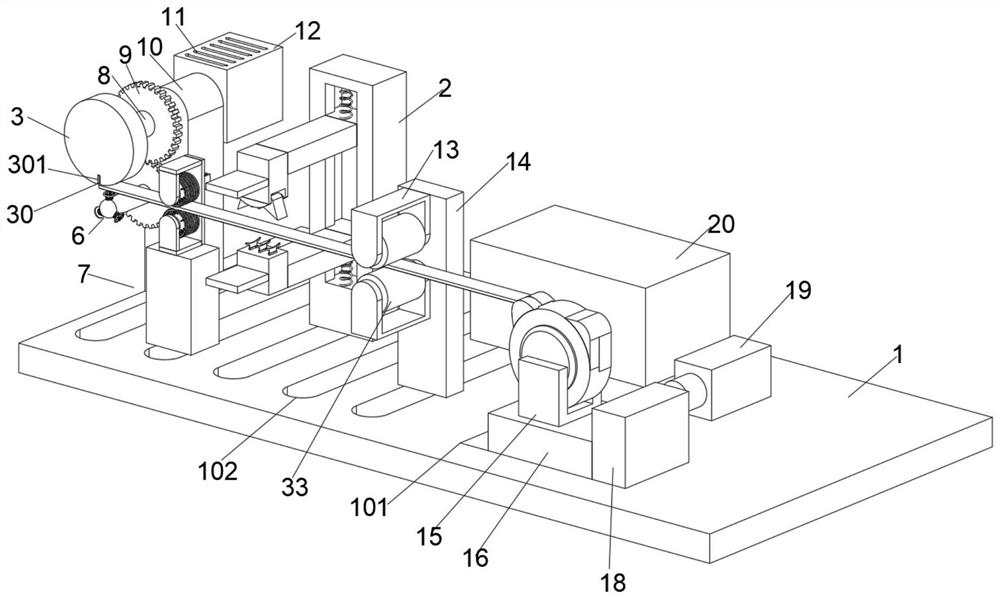

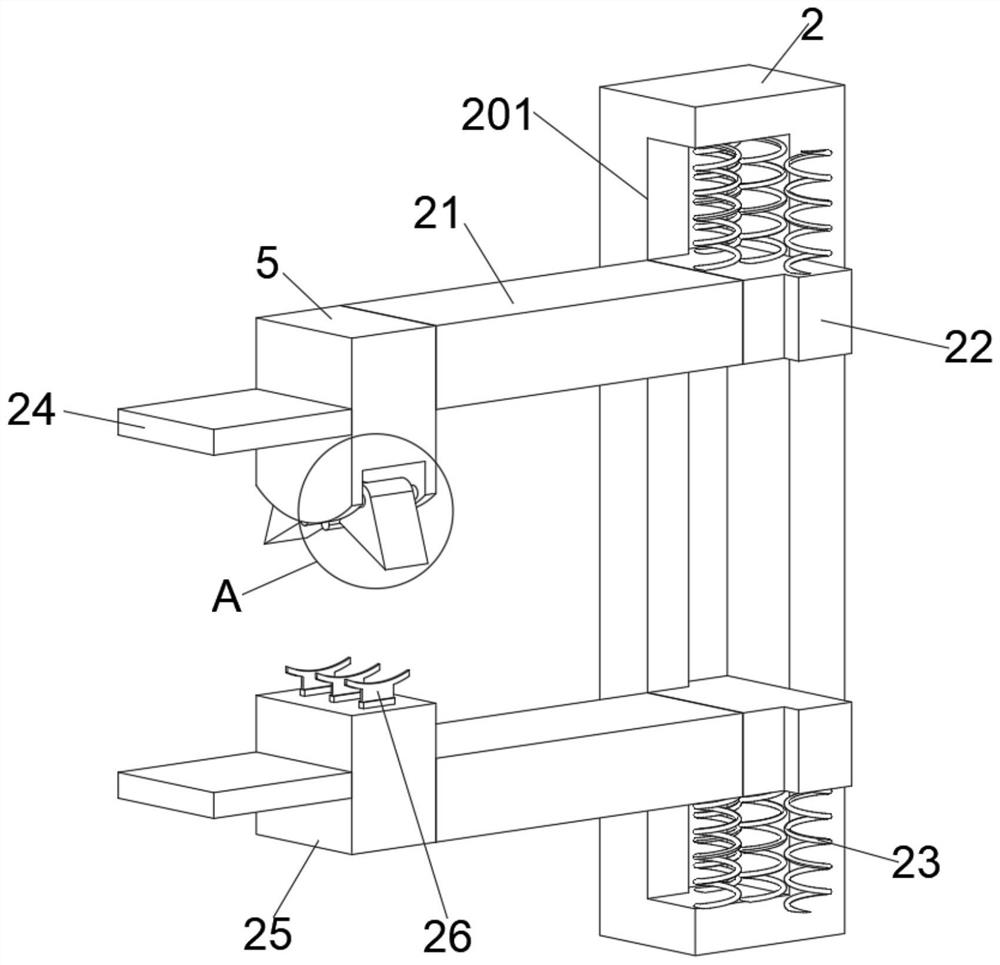

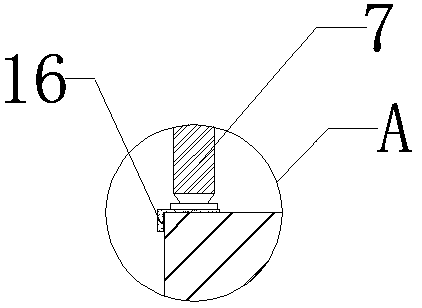

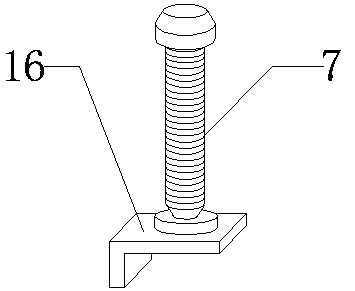

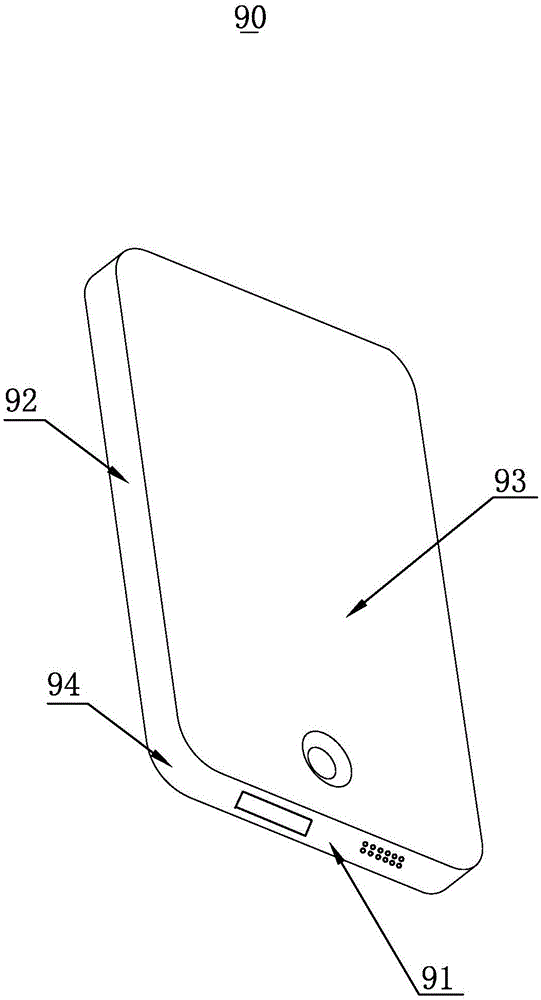

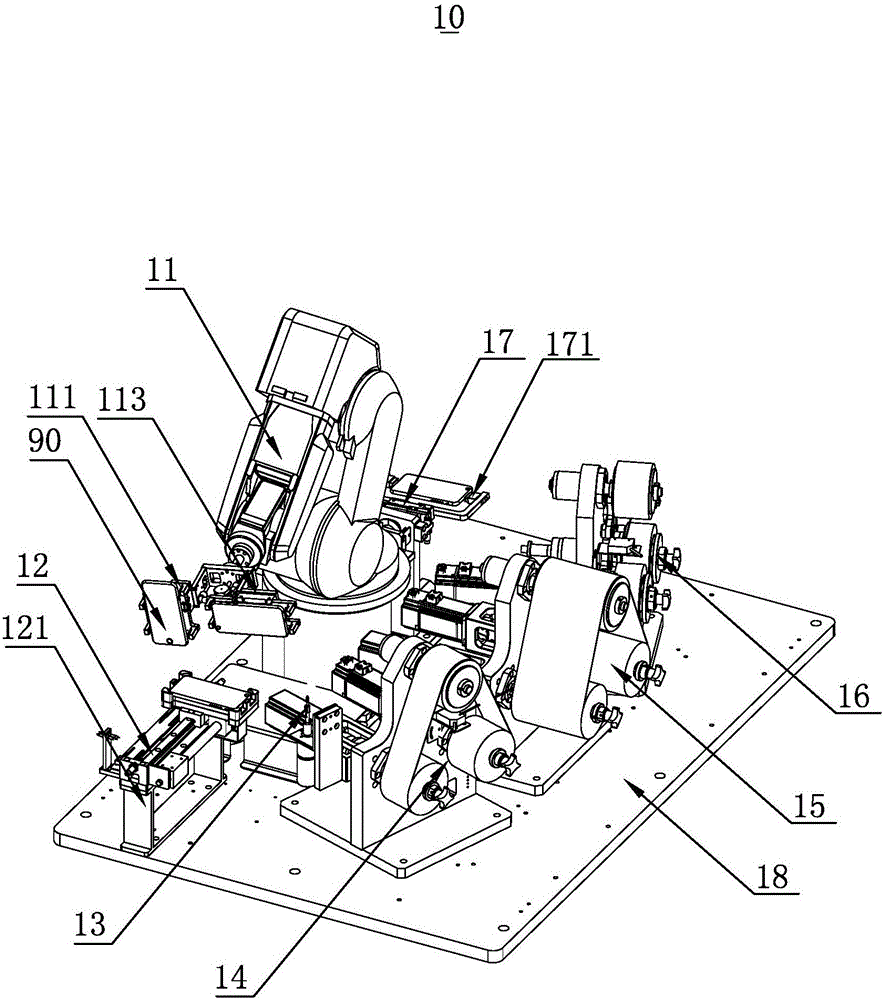

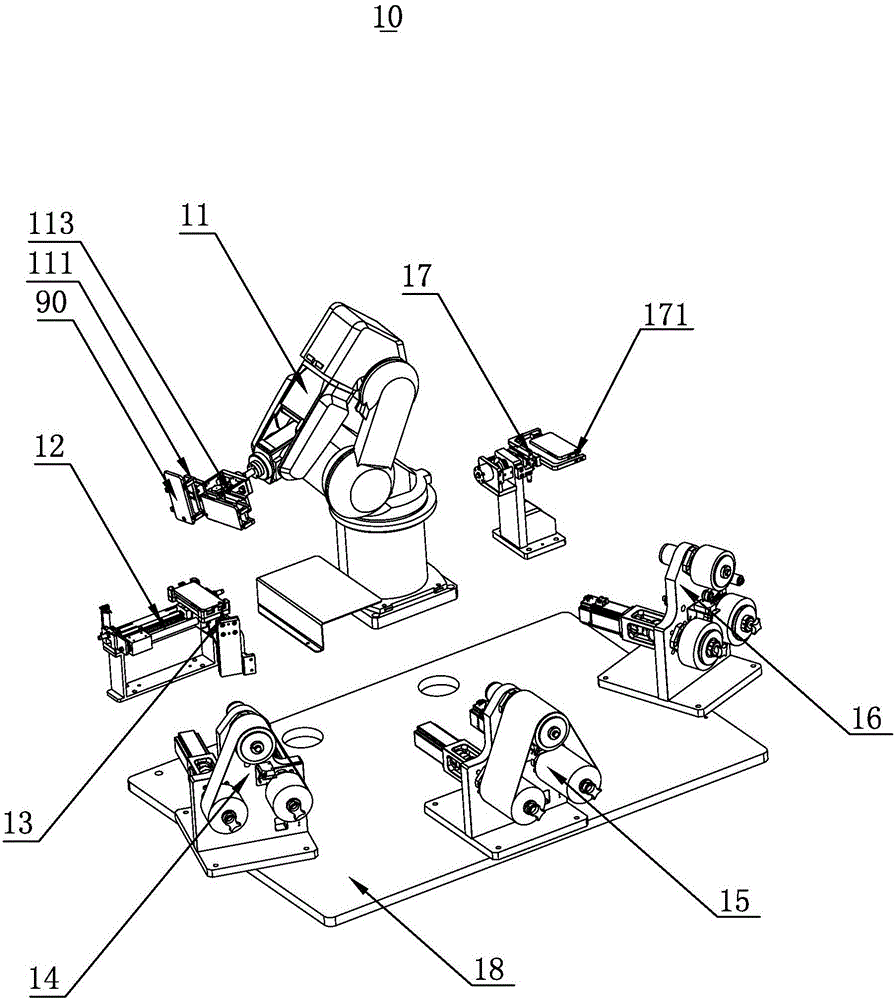

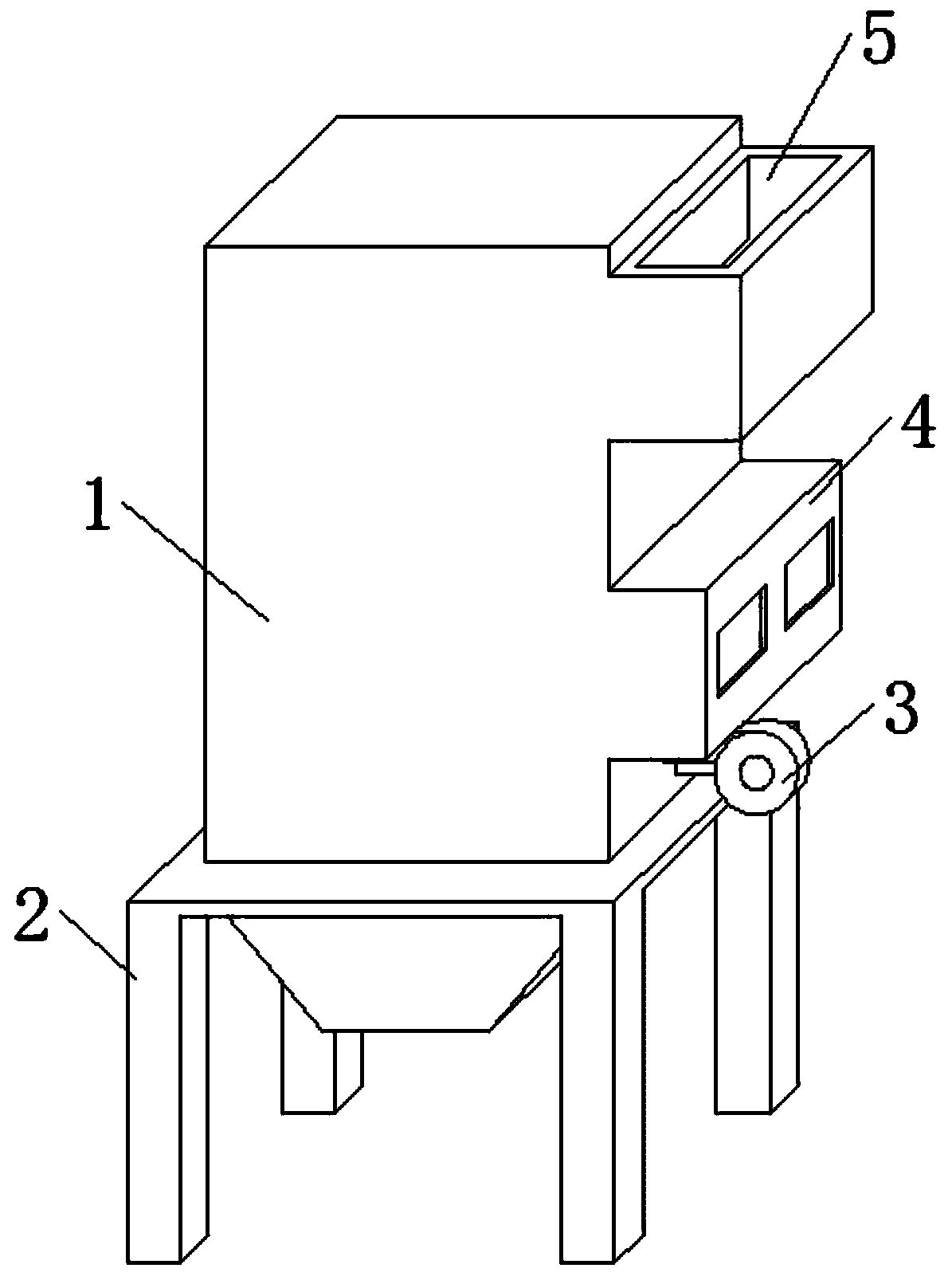

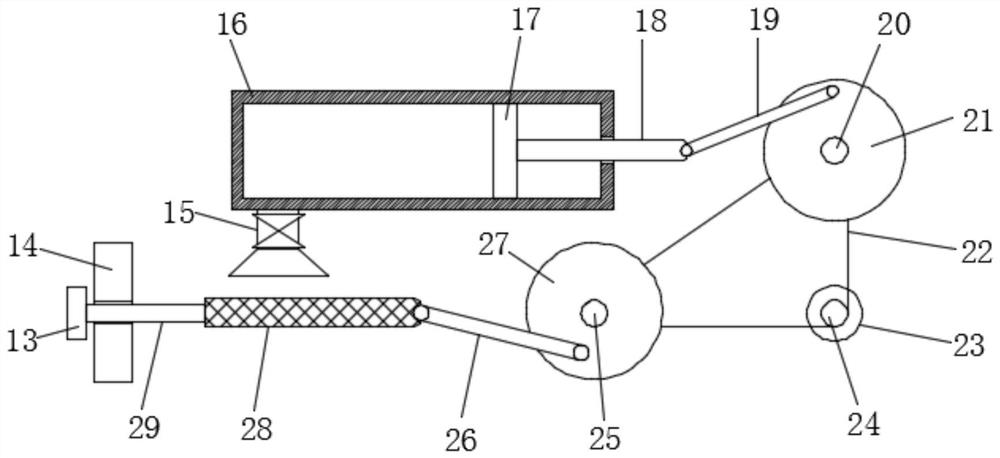

Automatic cleaning machine and automatic cleaning method

ActiveCN106269591AClean thoroughlyOptimizing cleaning programsCleaning using toolsAutomotive engineeringCleaning methods

The invention provides an automatic cleaning machine used for cleaning the surface of an electronic product. The automatic cleaning machine is sequentially provided with at least one cleaning mechanism and a gluing mechanism. The cleaning mechanisms are used for wiping the surface of the electronic product. The gluing mechanism is used for gluing the surface of the electronic product. The invention further provides an automatic cleaning method. According to the automatic cleaning method, the surface of the electronic product is cleaned through the automatic cleaning machine. The automatic cleaning method comprises the steps that step S0, the electronic product is provided; step S1, the surface of the electronic product is wiped; and step S2, the surface of the electronic product is glued. By the adoption of the automatic cleaning machine and the automatic cleaning method, the electronic product is cleaned thoroughly, operation is easy, convenient and fast, a cleaning program is optimized, a mechanical structure is most simplified, the cleaning efficiency is improved effectively, the equipment cost is lowered, and the automatic cleaning machine and the automatic cleaning method have very broad application prospects.

Owner:SHENZHEN FUYUNDI TECH

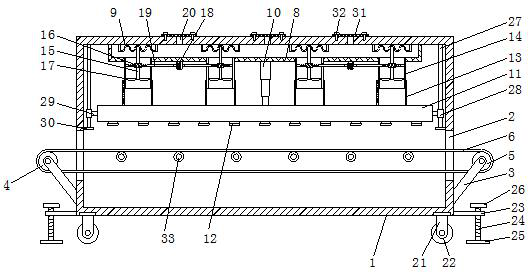

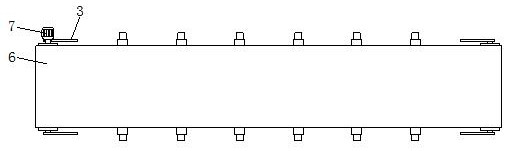

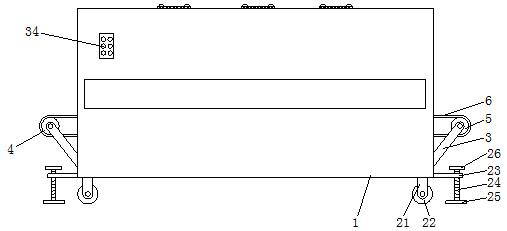

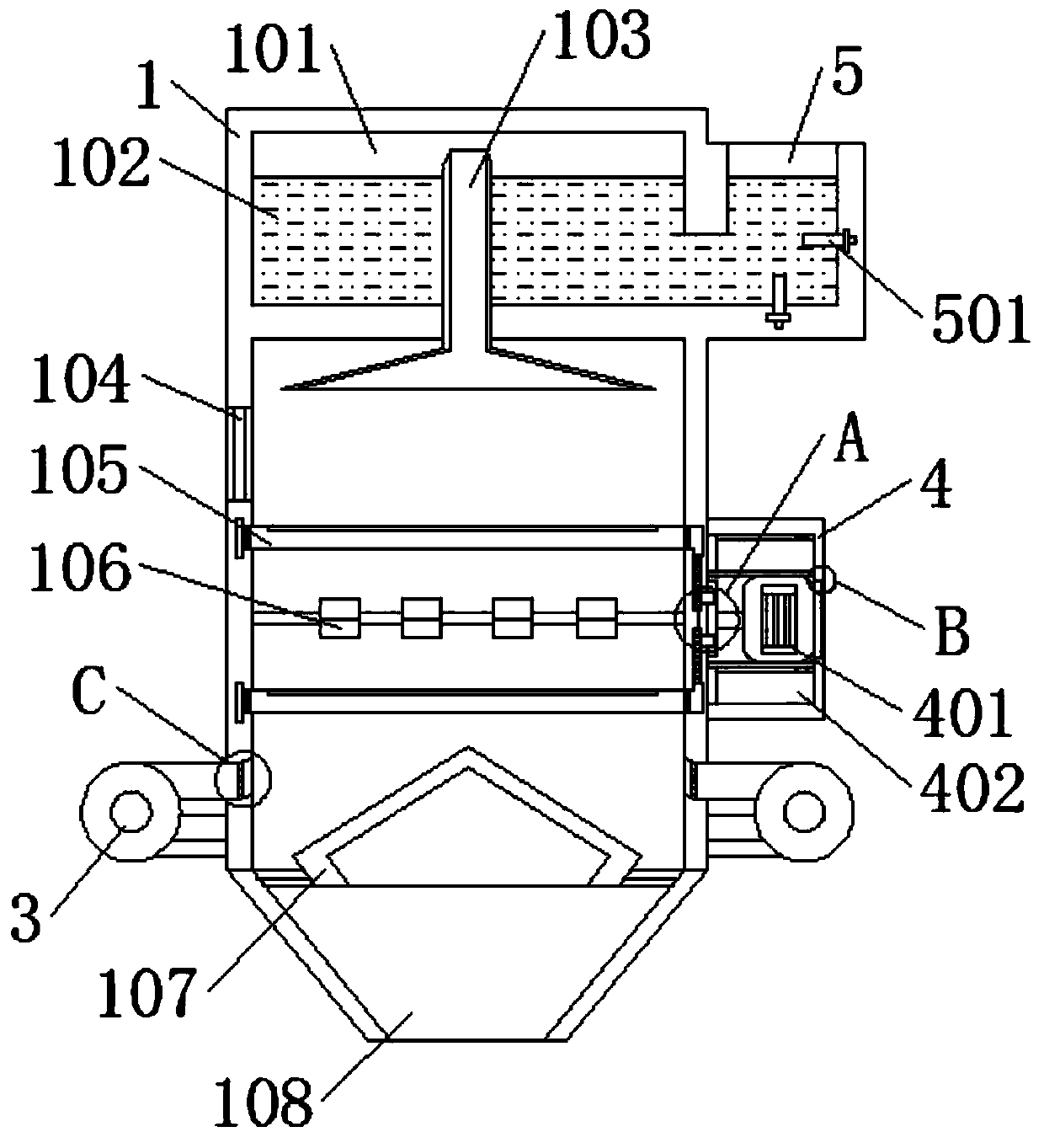

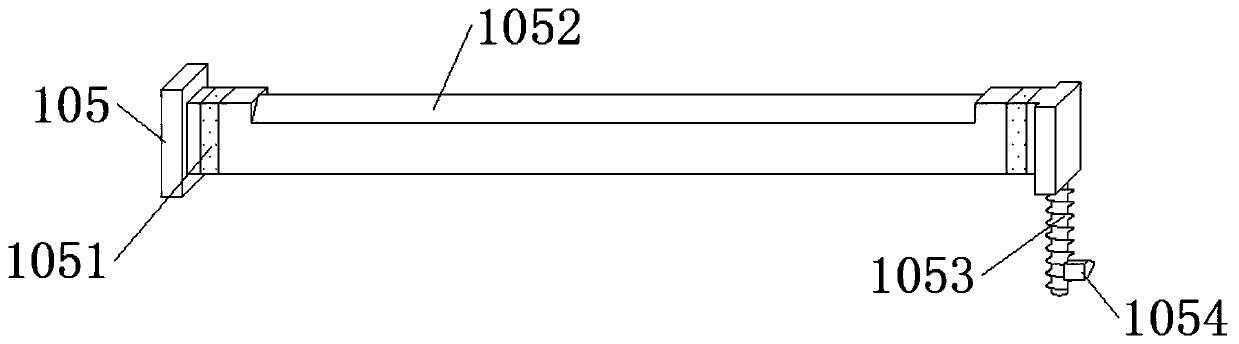

Tableware disinfection equipment for catering

InactiveCN107050480ATo achieve the purpose of immersion disinfectionNo wasteLavatory sanitoryChemicalsEngineeringLeft wall

The invention relates to disinfection equipment, in particular to tableware disinfection equipment for catering, and solves the technical problem of providing the tableware disinfection equipment for the catering, which is short in disinfection time and capable of replacing a screen frame for disinfection. In order to solve the technical problem, the invention provides the tableware disinfection equipment for catering, which comprises a worktable, a disinfection mechanism, a fixing block, a second baffle plate, a disinfection box, a driving mechanism and the like; the disinfection mechanism is arranged at the bottom of the worktable, the disinfection box is connected at the top of the worktable, a first through hole is formed in the right side of the top of the disinfection box, a second through hole is formed in the upper side of the left wall of the disinfection box, the driving mechanism is arranged at the top of the disinfection box, and the screen frame is connected on the driving mechanism and located in the disinfection box. The invention designs the tableware disinfection equipment for catering, a first motor is arranged to drive the screen frame to rotate stably and rapidly, and the screen frame drives tableware to rotate, thereby being beneficial to the contact between a disinfection solution and the tableware.

Owner:陈涛

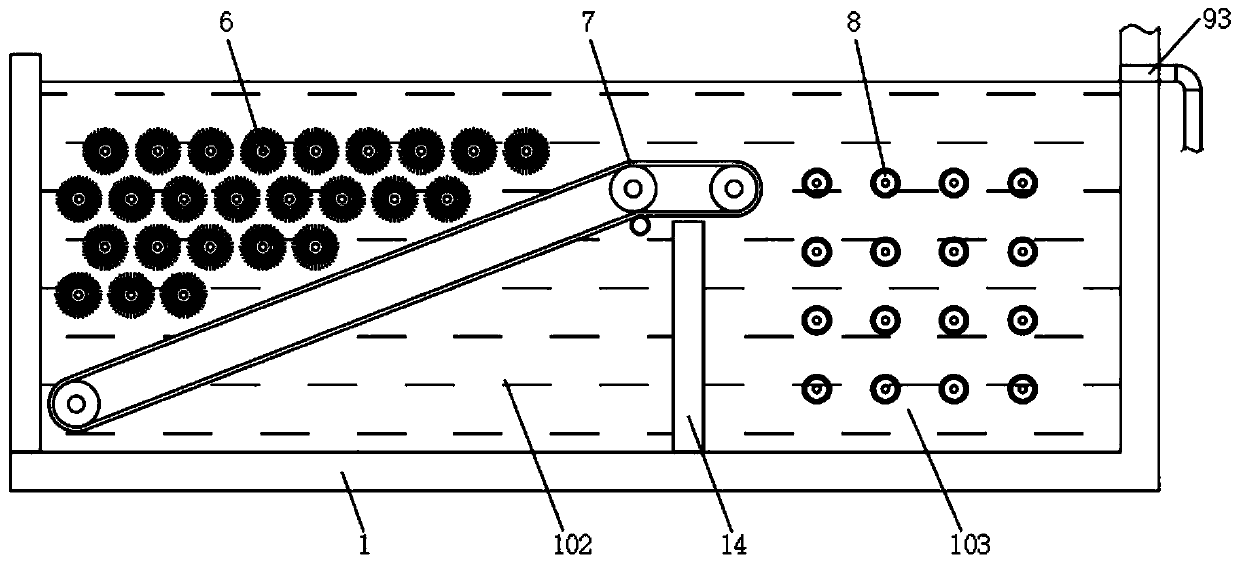

Oil removing and degreasing device and method for heat treatment production line

InactiveCN111001603ARemove completelyGuaranteed cleanlinessCleaning using toolsCleaning using liquidsOil and greaseMegasonic cleaning

The invention belongs to the technical field of heat treatment and particularly relates to an oil removing and degreasing device and method for a heat treatment production line. The device comprises adegreasing tank and a plurality of supporting legs fixed to the bottom of the degreasing tank, wherein a first partition plate and a second partition plate are fixedly arranged in the degreasing tank, and the interior of the degreasing tank is divided into a flushing tank, a scrubbing tank and an ultrasonic cleaning tank by the first partition plate and the second partition plate. The flushing tank, the scrubbing tank and the ultrasonic cleaning tank are arranged in the degreasing tank, a workpiece is washed in the washing tank, relatively obvious grease attached to a surface is removed, through a plurality of layers of roller brushes, the workpiece surface is carefully cleaned and brushed, the workpiece surface can make full contact with a complex surface, then the workpiece is conveyedinto the ultrasonic cleaning tank after being brushed and is cleaned through ultrasonic waves in cooperation with grease removing liquid, the grease on the workpiece surface can be removed more thoroughly, the cleaning liquid is used in a classified mode, the cleaning degree of the cleaning liquid is guaranteed, and waste of the cleaning liquid is reduced.

Owner:嘉兴兴欣环保科技股份有限公司

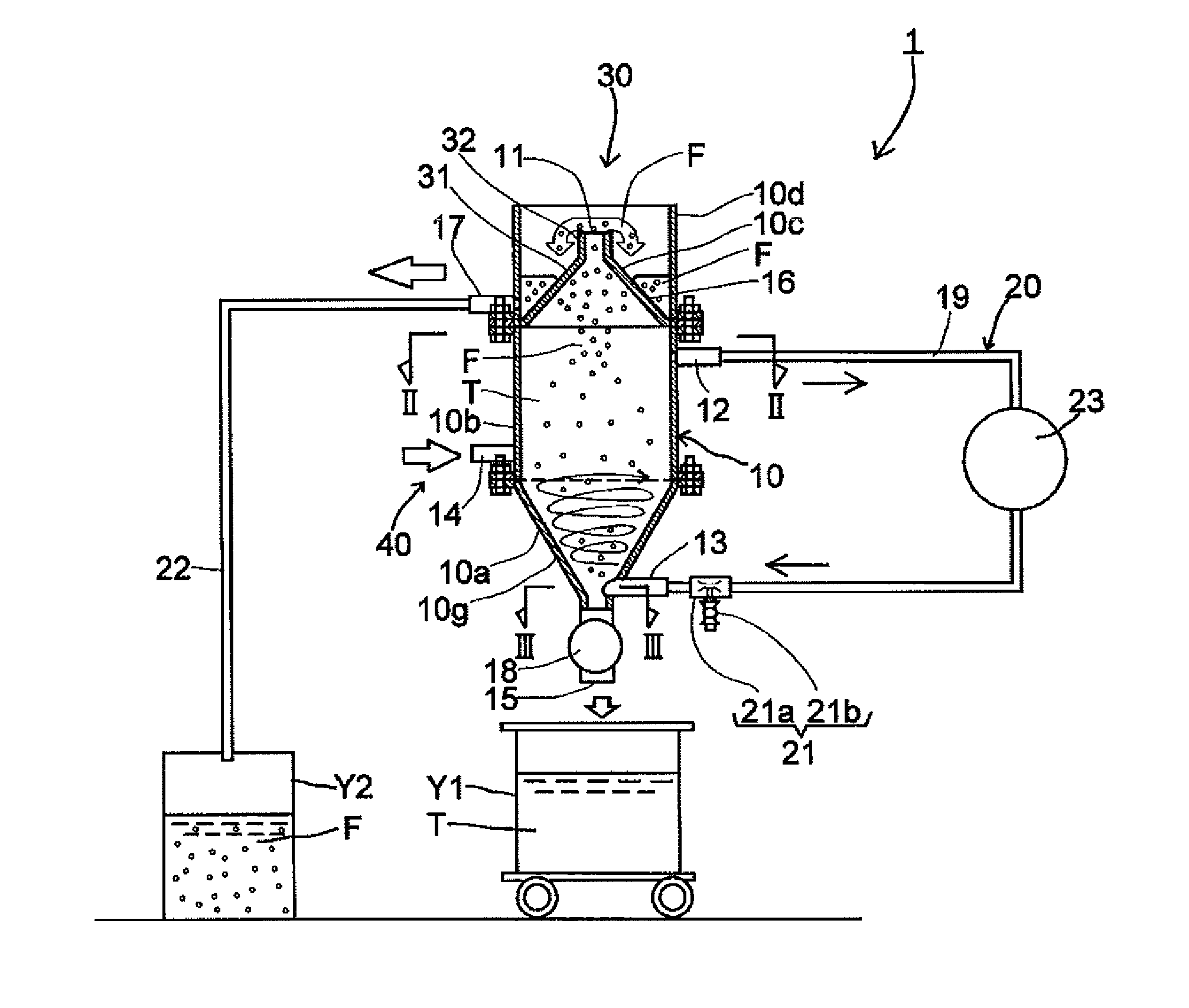

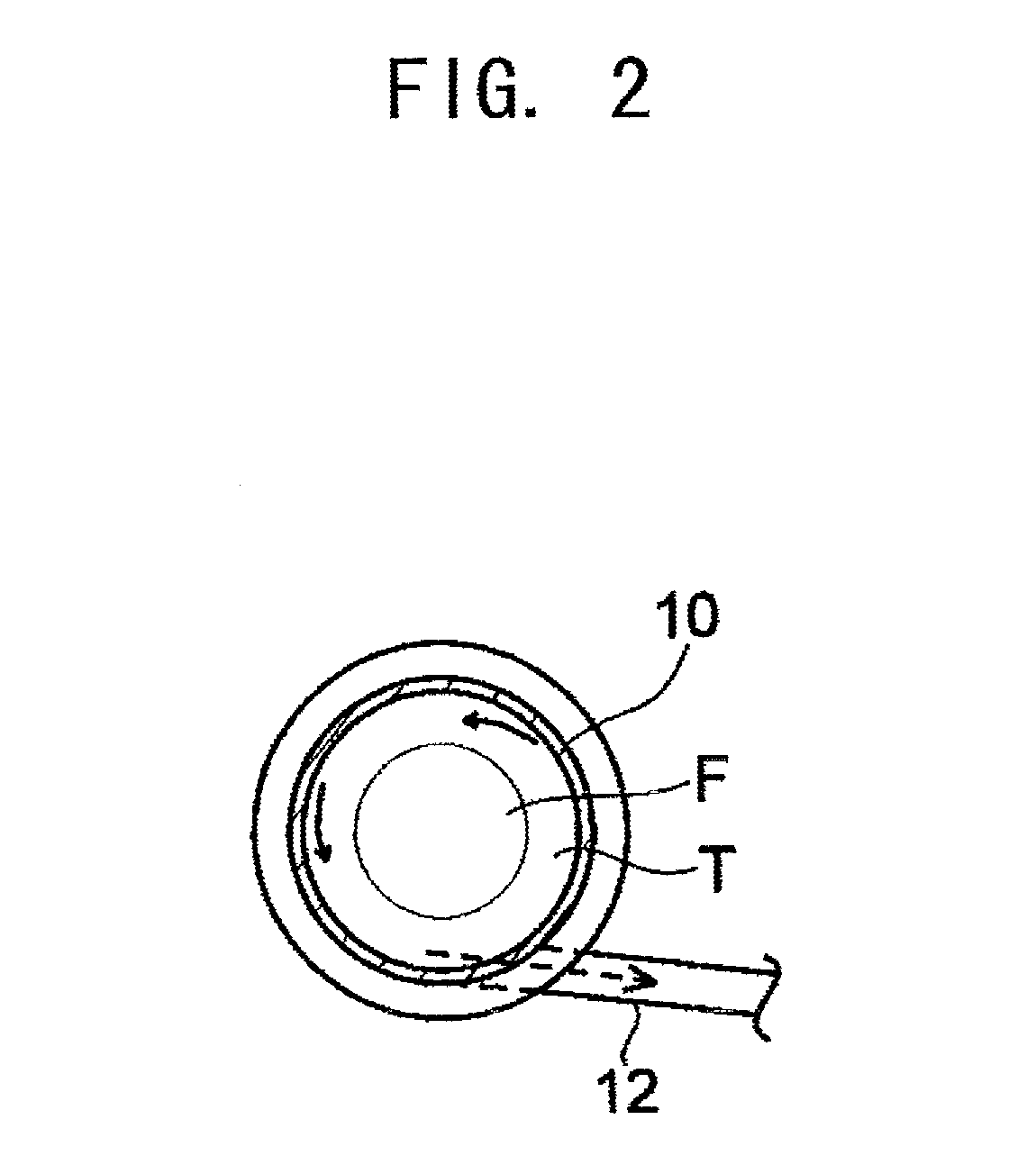

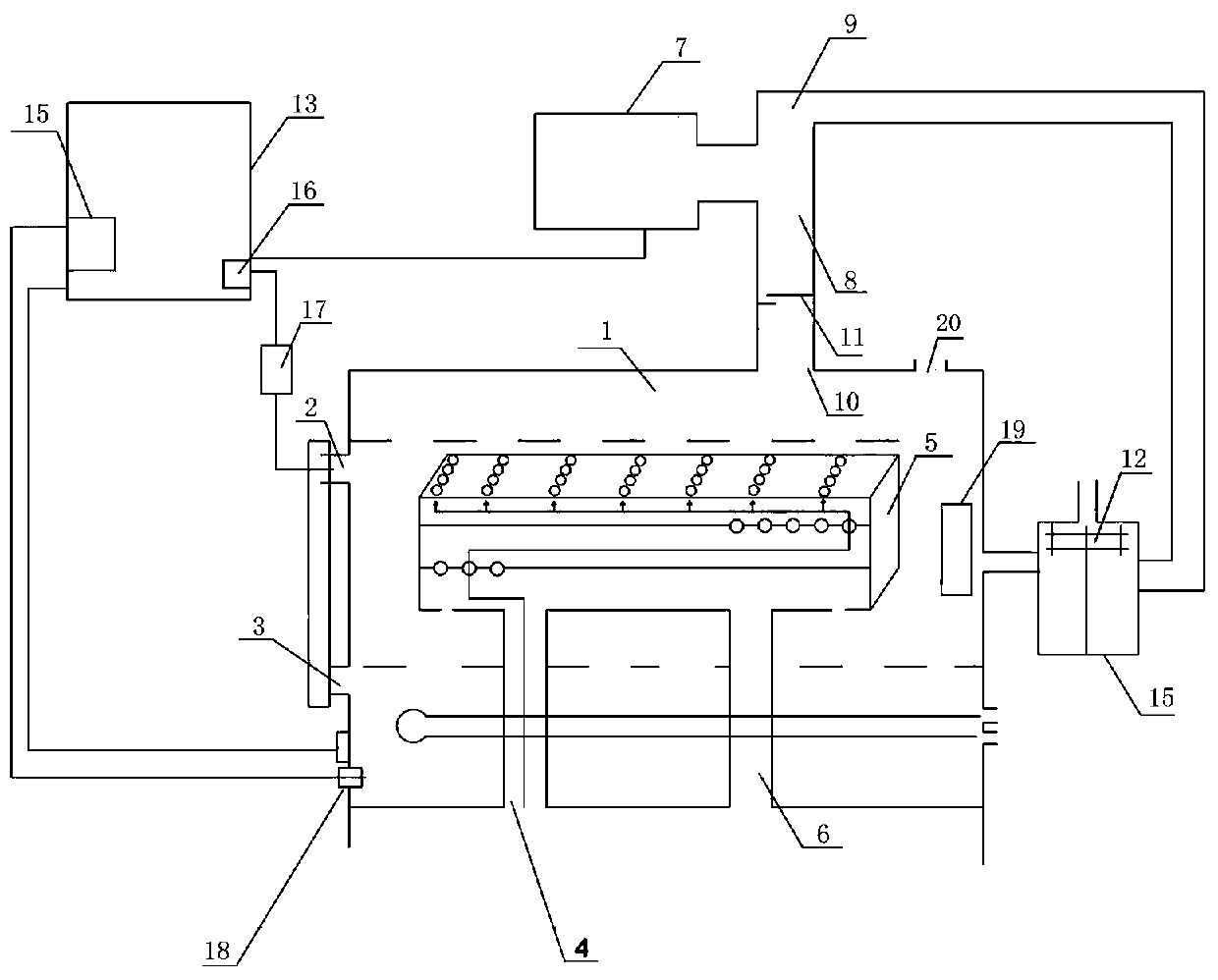

Floatation separation apparatus, method of floatation separation, and method of manufacturing products using the same

InactiveUS9174856B2Simple structureWidely distributedSolid waste managementFlotationEngineeringLiquid circulation

Owner:UNIVERSITY OF KITAKYUSHU

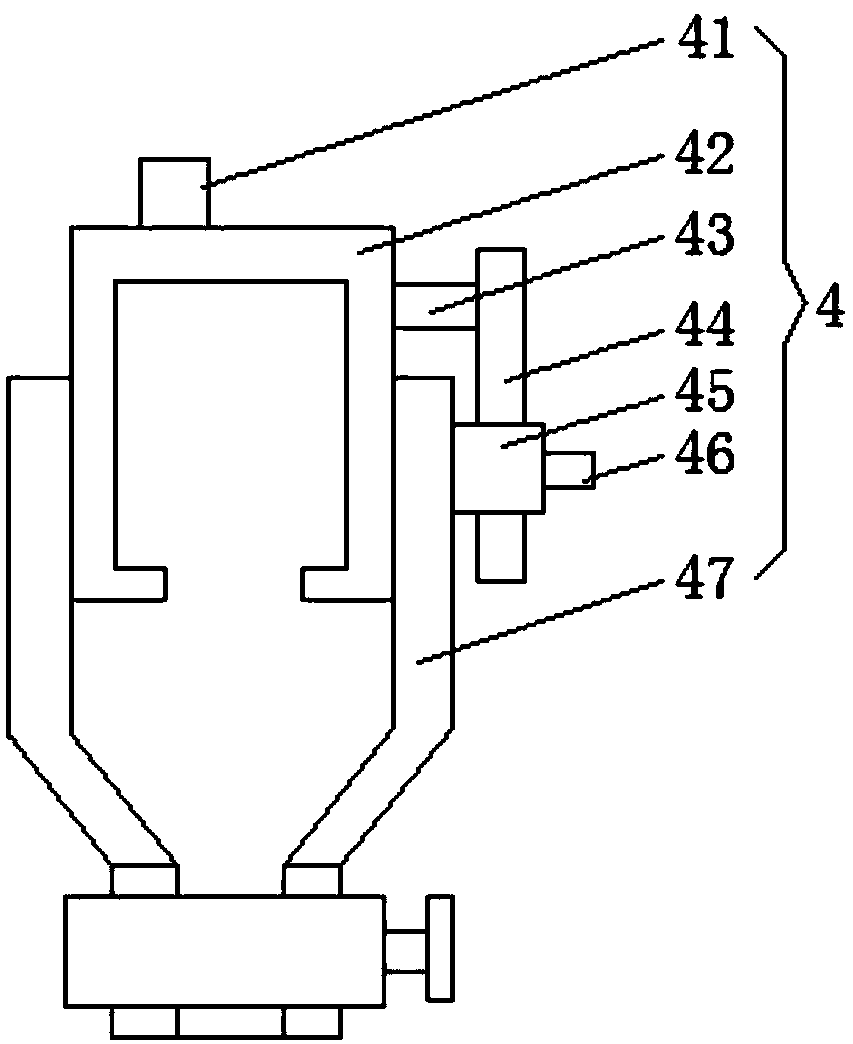

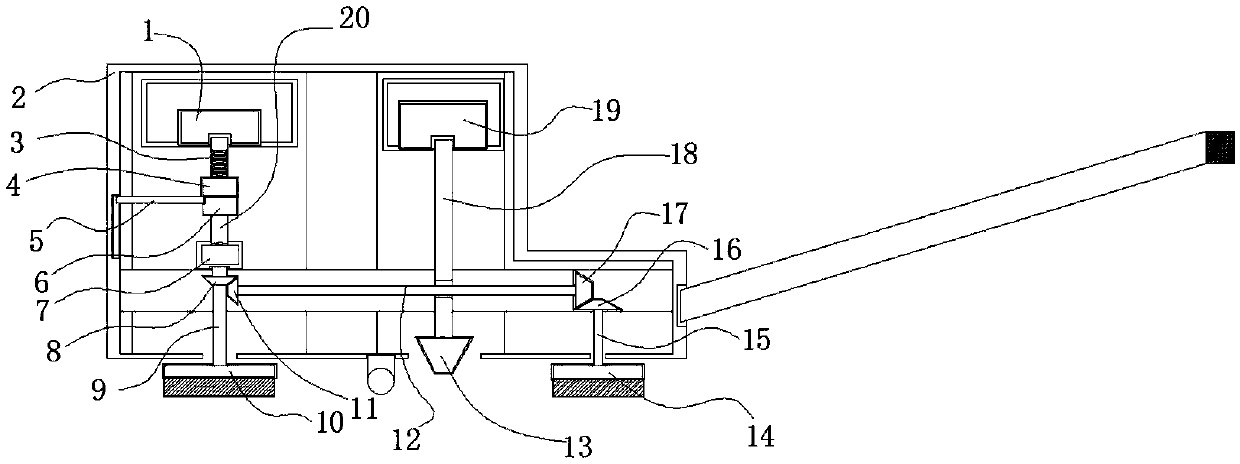

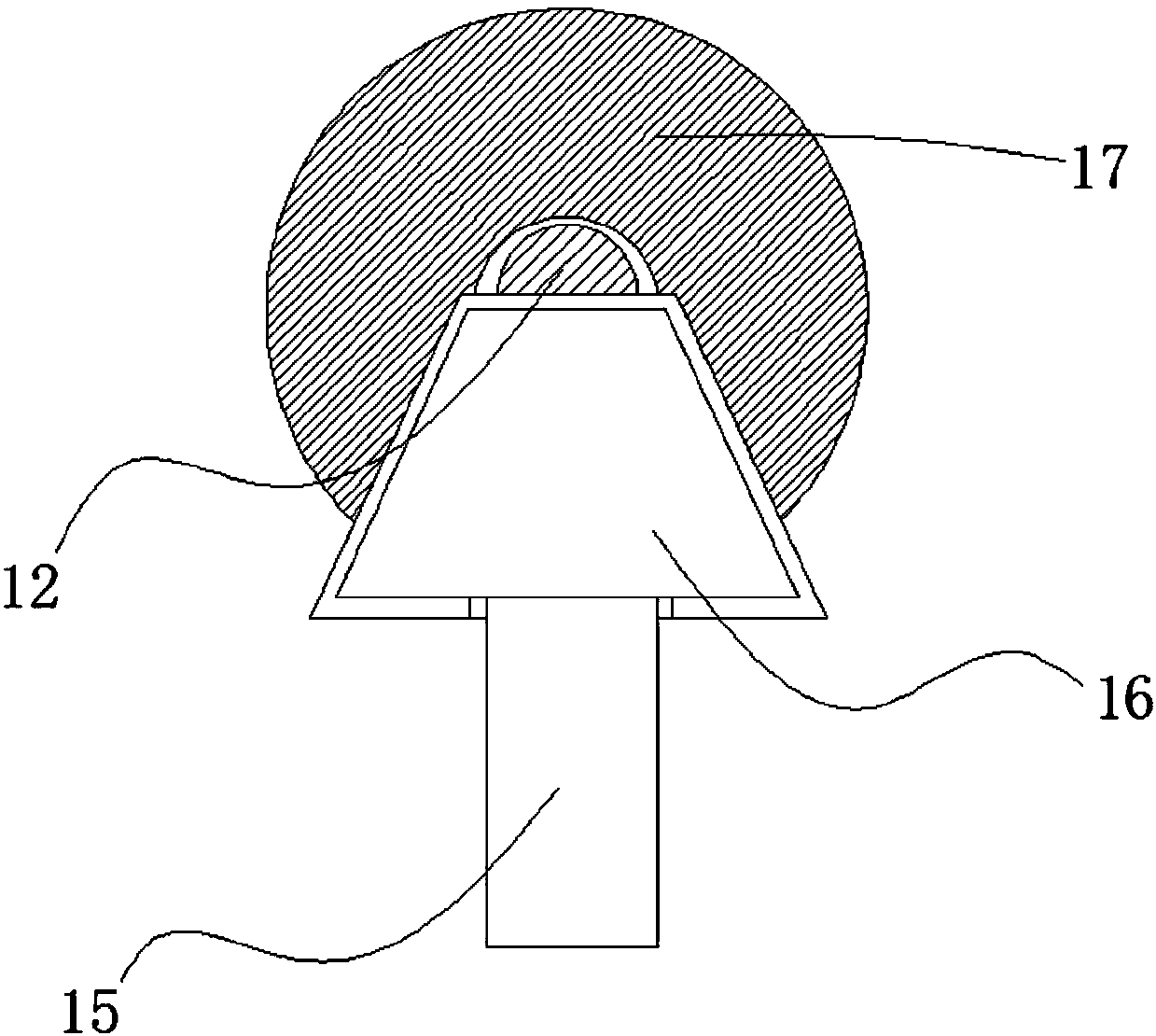

Energy-saving and environment-friendly flue gas denitrification device and method

PendingCN108704477AAvoid affecting the emission effectMaintain the ecological environmentGas treatmentDispersed particle filtrationFlue gasSpray nozzle

The invention discloses an energy-saving and environment-friendly flue gas denitrification device and belongs to the technical field of flue gas denitrification. The energy-saving and environment-friendly flue gas denitrification device comprises a body, wherein a gas inlet pipe is arranged at the left side of the top of the body; a filtering layer is arranged in an inner cavity of the gas inlet pipe; spraying nozzles are uniformly arranged at the bottom of a liquid collection box; a catalysis layer is located just below the spraying nozzles; S-shaped circulation pipelines are uniformly formedin the inner cavity of the catalysis layer; a liquid suction pump is arranged at the left side of the bottom of an inner cavity of the body; a left-side outlet of the liquid suction pump extends to aleft-side outer wall of the body and is connected with a refluxing pipe; a discharging opening is formed in a right-side outer wall of the body; a valve is mounted on the discharging opening; flue gas is filtered through the filtering layer in the device and a condition that the device is blocked when large-particle dust enters the device is avoided; a reactant and flue gas are mixed completely through rotating a stirring blade, and the S-shaped circulation pipelines arranged in the inner cavity of the catalysis layer enable a mixture and the catalysis layer to be in contact for longer time,and furthermore, the flue gas denitrification efficiency is improved.

Owner:张燕

Drying device for carton printing and using method

The invention discloses a drying device for carton printing and a using method. The drying device comprises a box body, wherein square holes are formed in the bottoms of the two sides of the box bodycorrespondingly, supporting plates are fixedly connected to the bottoms of the two sides of the box body correspondingly, a first rolling shaft is movably connected to the left side of the box body through the supporting plate, and the right side of the box body is movably connected with a second rolling shaft through the supporting plate. The drying device has the beneficial effects that the distance between an air outlet pipe and a carton can be adjusted, printed matter on the surface of the carton can be better dried, drying is thorough, hot air makes thorough contact with the carton, the drying efficiency is high, the problems that an existing carton drying device conducts drying by blowing hot air to the carton conveyed on a conveying belt, contact time of the carton and hot air is short, thorough drying of the printed matter on the surface of the carton is not facilitated, and meanwhile, the distance between the air outlet pipe and the carton cannot be adjusted, the carton can beexcessively dried and damaged when the distance is short, drying is not thorough when the distance is long, and using by people is inconvenient are solved.

Owner:祥恒(嘉善)包装有限公司

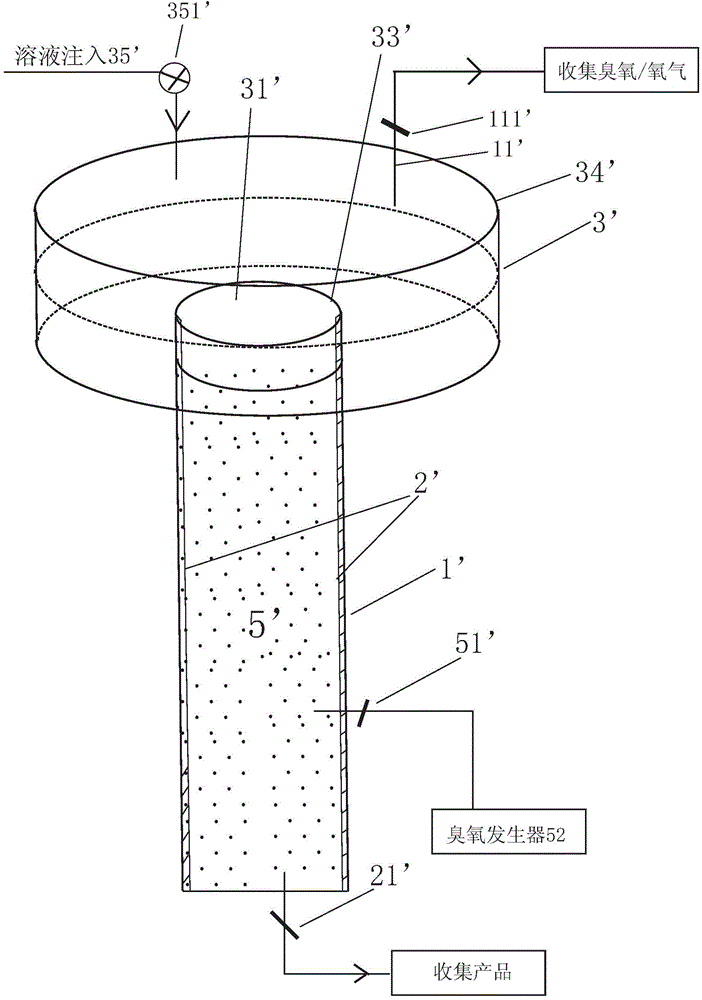

Preparation method for synthesizing indigotin through continuous oxidation

InactiveCN101591476ALower conversion rateImprove conversion rateBis-indole indigosAcetic acidLiquid metal

The invention discloses a preparation method for synthesizing indigotin through continuous oxidation, which comprises the following steps: introducing ammonia gas into liquid sodium metal, and performing reaction in an ammonia-sodium synthesizing tower to generate sodium amide; adding the sodium amide into alkali according to certain proportion, and adding the mixture into a material-mixing reactor continuously or at intervals; at certain temperature and pressure, using the alkali as a solvent and the sodium amide as a condensating agent, and adding anilino-acetate continuously to cyclize the anilino-acetate into hydroxy indole phenolate; discharging the materials continuously and diluting the materials with water, and then adding 3 to 20 percent w / w of indole phenolate solution into an oxidation reaction tower continuously from the upper part of the tower; introducing air into the tower from the lower part of the tower at a temperature of between 60 and 80 DEG C; after the continuous cyclic oxidations by an oxidation tower and oxidation reaction devices, sending the materials oxidized to the end point to post-processing from the bottom of the tower; and obtaining the indigotin through filtering, washing and drying. The preparation method improves the reaction yield and the product quality, shortens the reaction period, and greatly reduces the energy consumption.

Owner:JIANGSU TAIFENG CHEM

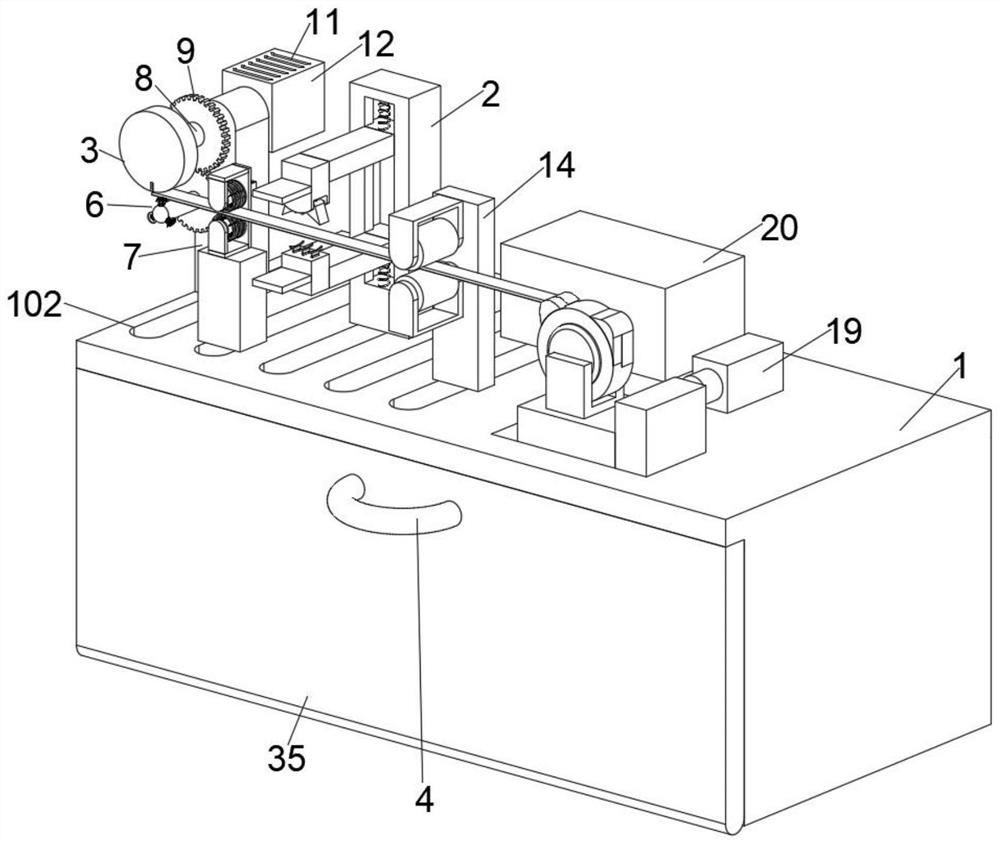

Hand-held steel ruler cleaning device for engineering cost

PendingCN113231365AExtended service lifeImprove cleaning effectDirt cleaningCleaning using toolsElectric machineryManufacturing engineering

The invention discloses a hand-held steel ruler cleaning device for engineering cost, and belongs to the technical field of equipment for engineering cost. The hand-held steel ruler cleaning device for construction cost comprises a fixed box body, wherein a bearing block is arranged on the top face of the fixed box body; a first motor is arranged in a first motor box; a spindle is arranged at the end of an output shaft of the first motor; a reel is arranged at the front end of the spindle; a wiping component is arranged at the right side of the reel; the circumferential outer wall of the spindle is sleeved with a first gear; an oscillation component is arranged at the lower side of the first gear; two triangular push blocks are arranged on the lower portion of a rotating frame; and a plurality of arc-shaped scrapers are arranged on the top face of a movable block. Through the cooperation of the triangular push blocks arranged on the lower portion of the rotating frame, the arc-shaped scrapers on the top face of the movable block and a sponge roller in the middle of a U-shaped fixing frame, when a worker cleans a steel tape, the steel tape does not need to be washed with water, the situation that the steel tape is damaged due to water residues is prevented, and the service life of the steel tape is prolonged.

Owner:马海威

Alkyl glycoside refining bleaching method and equipment

ActiveCN104418923AIncrease contact areaFully contactedSugar derivativesSugar derivatives preparationActive agentSurface-active agents

An alkyl glycoside refining bleaching method is as follows: a dealcoholized alkyl polyglycoside crude product is prepared into a water solution with certain concentration, then at a certain temperature and under a certain operation pressure, a liquid film with a certain thickness is formed by the alkyl polyglucoside water solution, gas-liquid two-phase membrane contact of the liquid film and an oxidative gas is performed, the oxidative gas is a bleaching agent, under the effect of the bleaching agent, color groups in the alkyl polyglucoside water solution are oxidized to achieve the purpose of bleaching. The method adopts gas-liquid two-phase membrane contact, so that contact area is large, the contact is more full, the bleaching more thorough, and bleaching time is shortened; to be more important, the to-be-bleached alkyl polyglucoside water solution flows down along an overflow wall, so that the content of the gas dissolving in the alkyl polyglycoside water solution can be reduced, internal molecular collision and liquid agitation effect of the alkyl polyglycoside water solution can be reduced, and no a lot of bubbles are produced. The alkyl polyglycoside which is a surface active agent has a very important significance to reduce the generation of foams.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

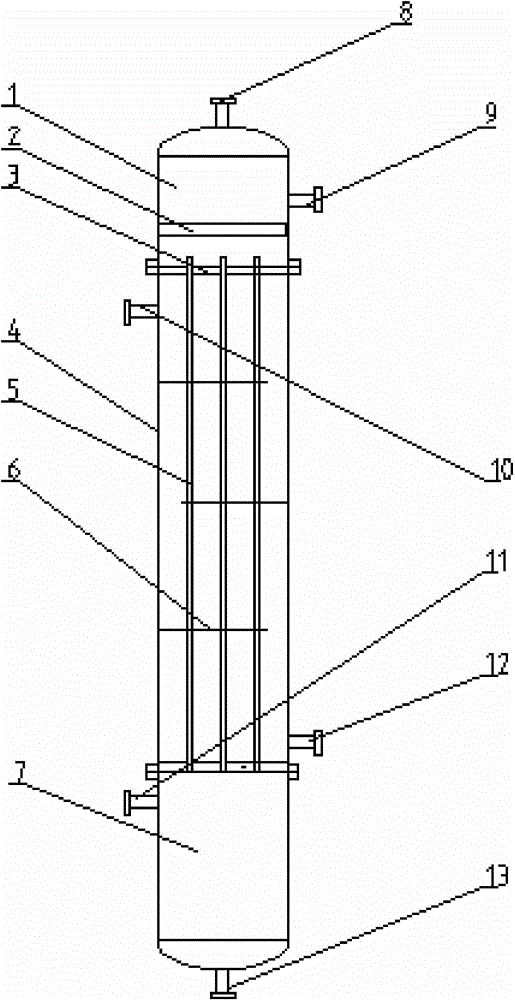

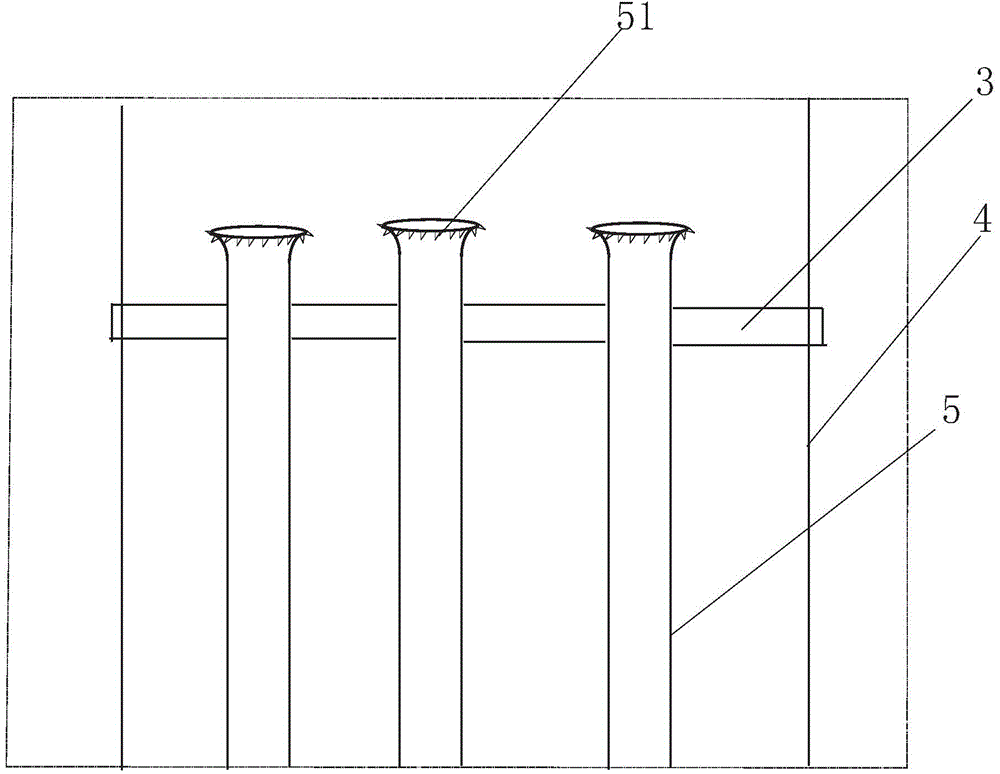

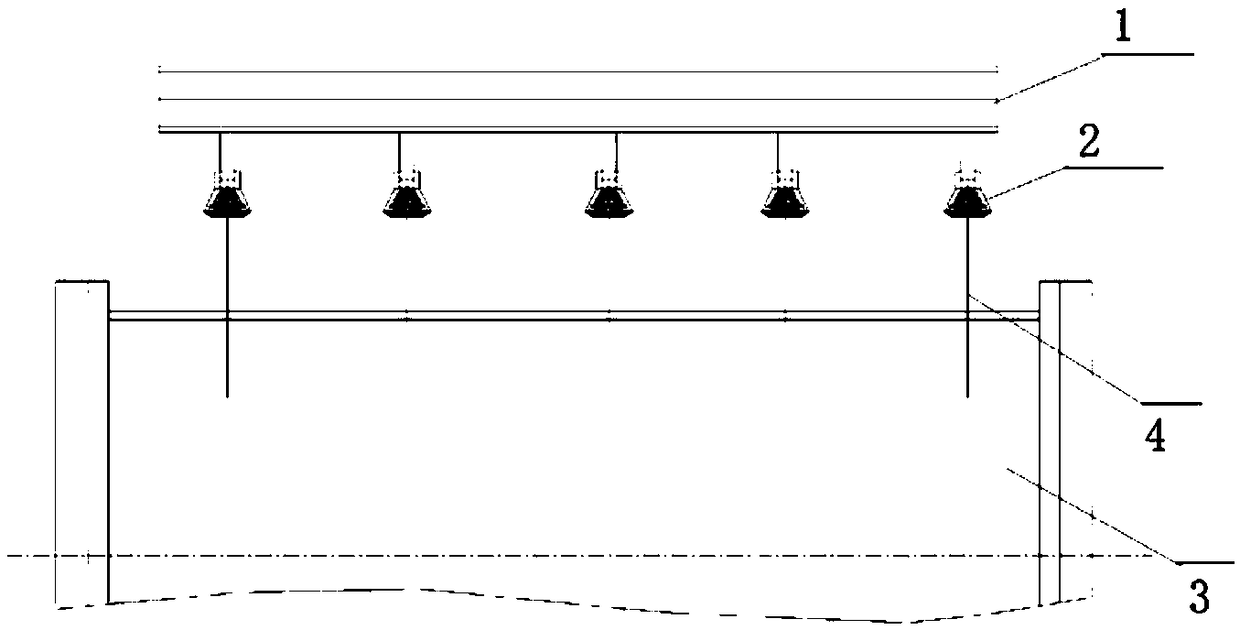

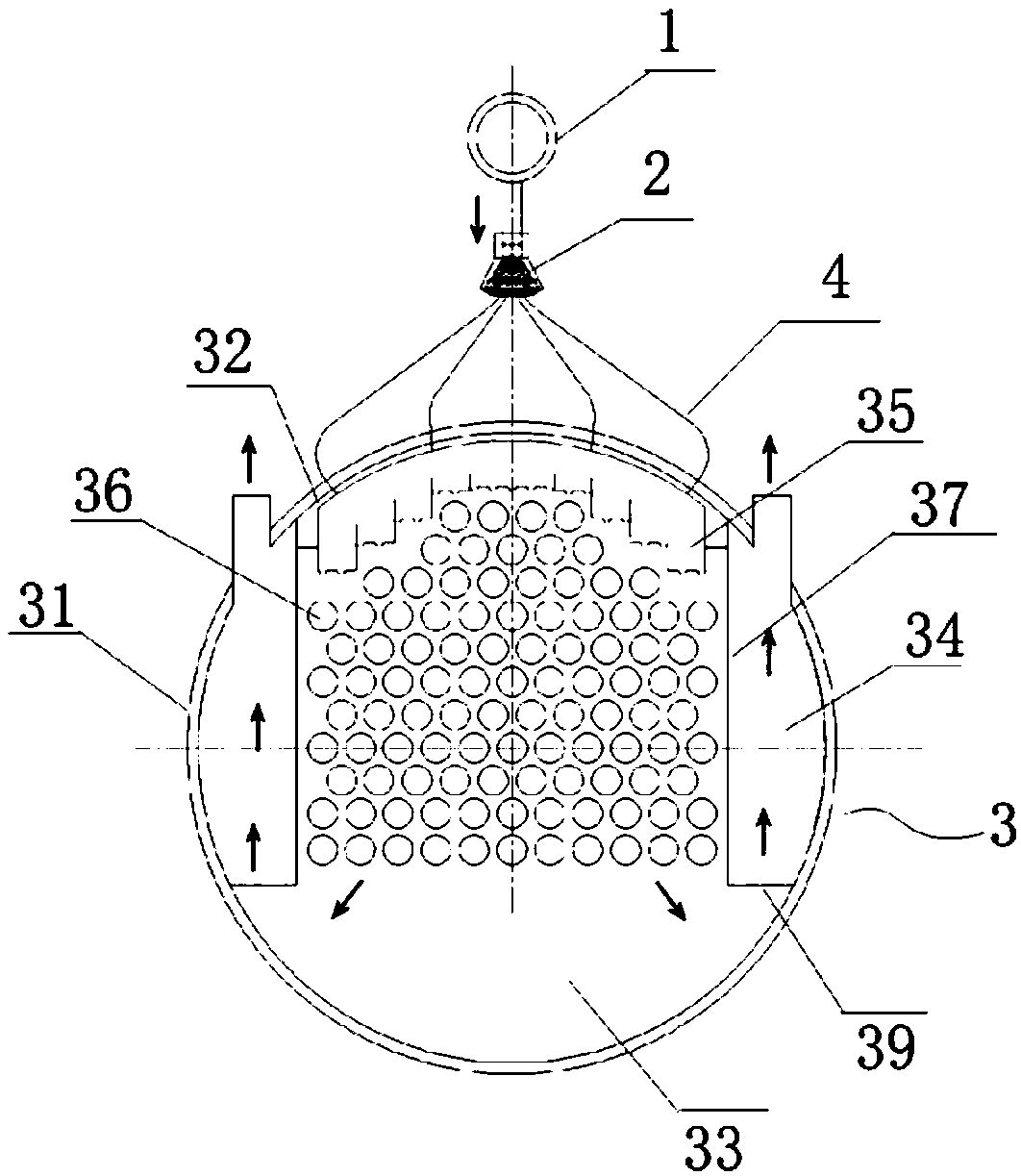

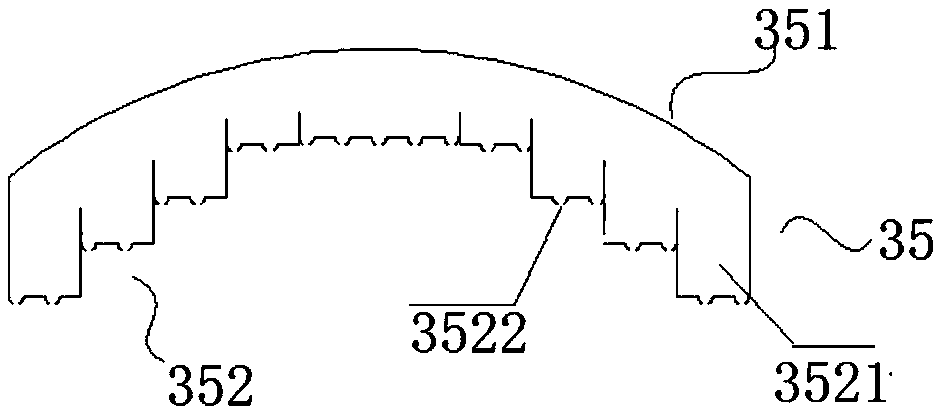

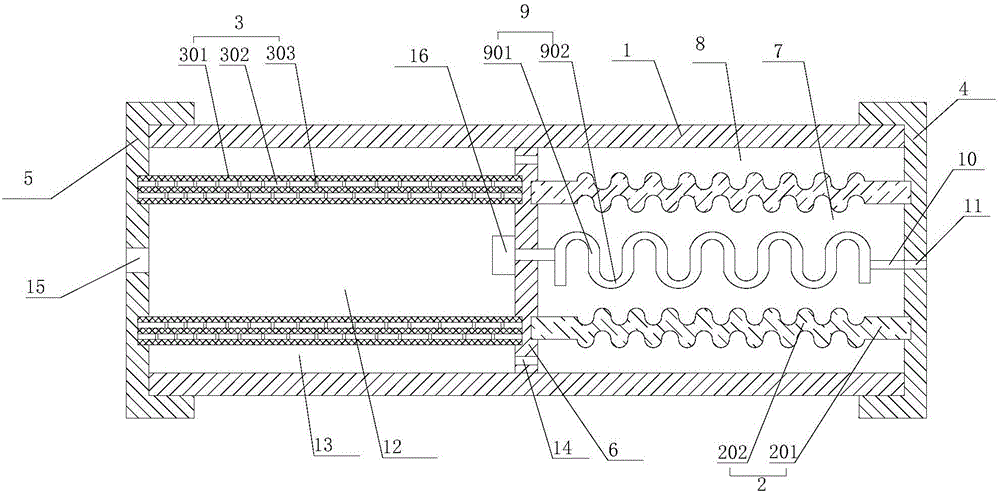

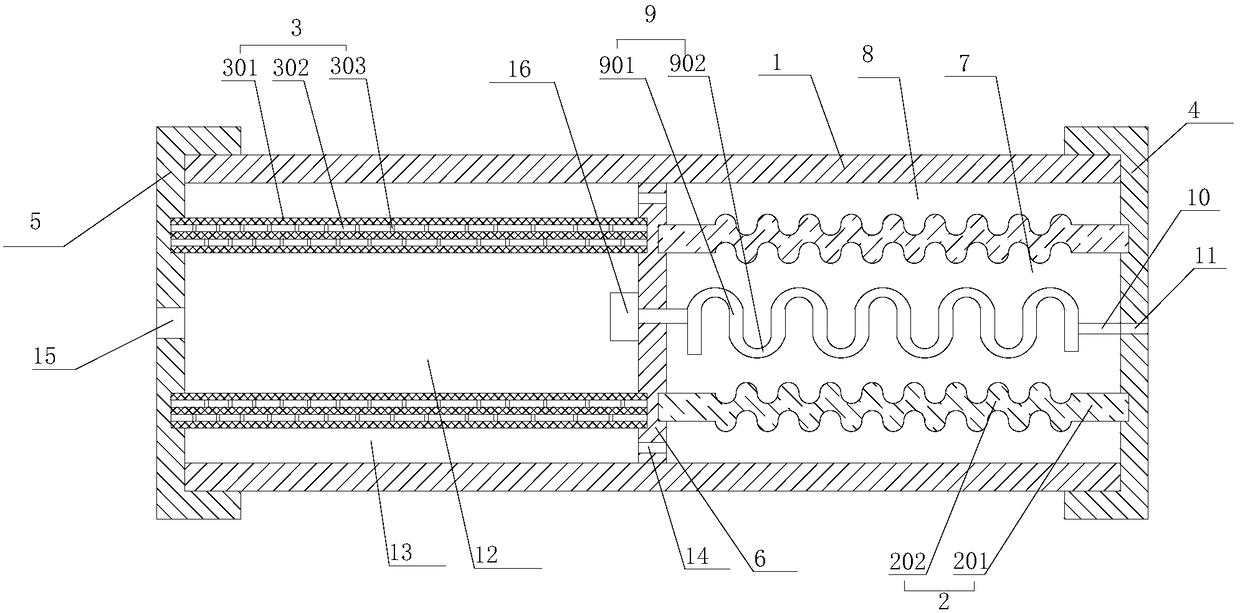

Falling film type evaporator

ActiveCN109140835AImprove space utilizationFlexible installation positionEvaporators/condensersEngineeringDistributor

The invention discloses a falling film type evaporator. The falling film type evaporator comprises a liquid distribution main pipe, a plurality of distributors communicated with the liquid distribution main pipe, a heat exchanger and a liquid distribution pipe which is used for communicating the distributors with the heat exchanger; the heat exchanger comprises a shell, a liquid inlet cavity, a heat exchange cavity and an gas outlet cavity communicated with the heat exchange cavity, the heat exchange cavity is located at the lower end of the liquid inlet cavity, the gas outlet cavities are located on the two sides of the heat exchange cavity; and a liquid equalizing assembly is arranged at the joint of the liquid inlet cavity and the heat exchange cavity, a plurality of heat exchange pipesare arranged in the heat exchange cavity, and a gas baffle plate is arranged at the joint of the heat exchange cavity and the gas inlet cavity. According to the falling film type evaporator, the distributor is arranged outside the heat exchanger, so that the volume of the evaporator cylinder is reduced, the design is reasonable, the structure is simple, the control is convenient, the unit cold capacity can be improved under the refrigerating working condition, and the user requirements are met.

Owner:南京恒标斯瑞冷冻机械制造有限公司

Stripping agent for pickling undrawn wire as well as preparation and using methods of stripping agent

The invention aims at solving the problems that an overcorrosion phenomenon easily appears on the surface of a traditional wire pickled by using sulfuric acid, an occasional fracture phenomenon appears in a wire drawing process, a film layer is nonuniform after the wire is phosphated and the treatment cost of waste acids is high, provides a stripping agent for pickling an undrawn wire as well as preparation and using methods of the stripping agent and belongs to the technical field of metal surface treatment. The stripping agent disclosed by the invention is composed of the following components in percentage by mass: 5-50% of concentrated phosphoric acid, 1.0-20% of compound organic acid, 0.2-10% of a compound corrosion inhibitor, 0.5-5% of an accelerant, 0.05-3% of a compound surfactant and the balance of water. The stripping agent disclosed by the invention is mainly prepared from the phosphoric acid and the compound organic acid and is remarkable in pickling effect, and an effluentcan be recycled after being regenerated, so that not only is the requirement for environment protection met, but also the production cost is greatly reduced.

Owner:ANSHAN FALAN STEEL STRIP CO LTD

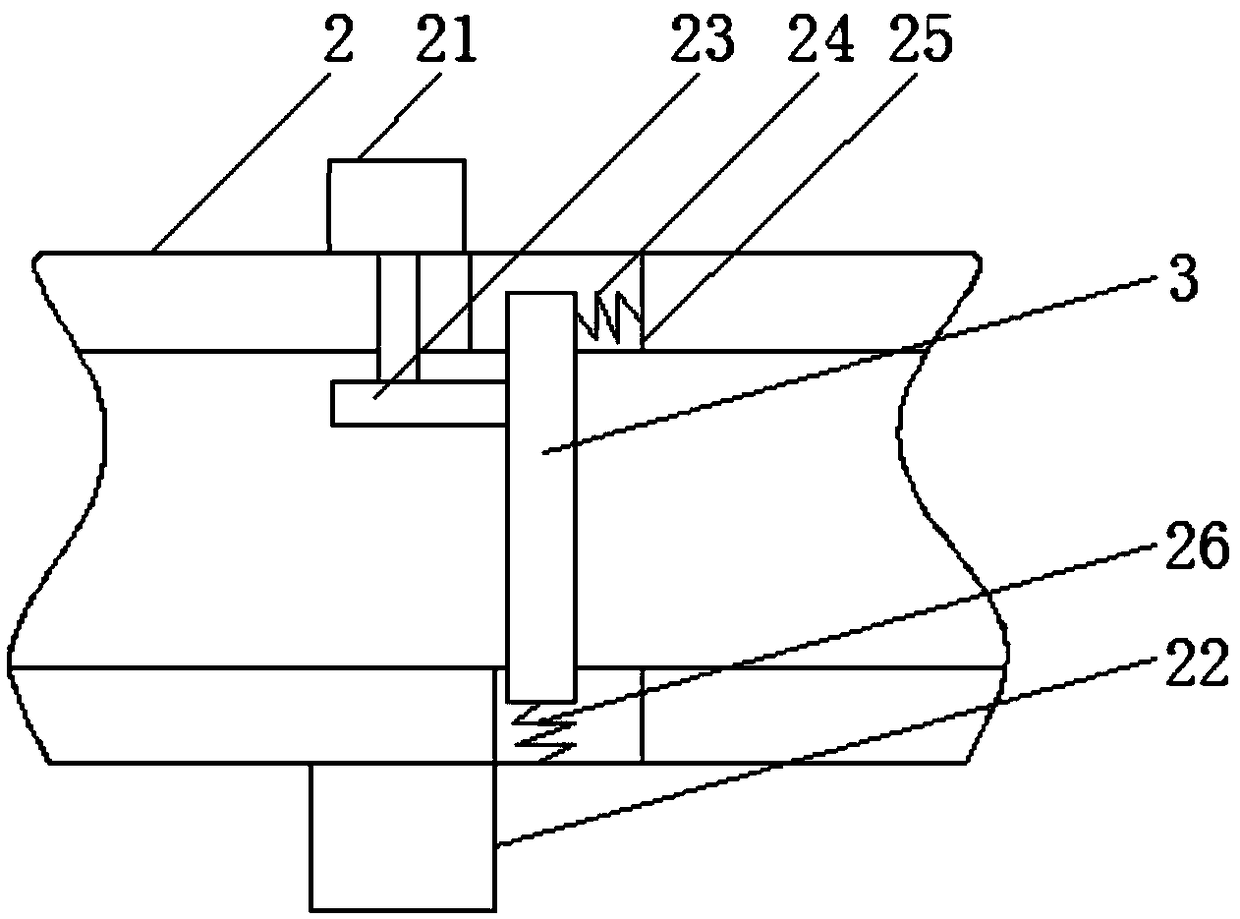

Electrolytic cell for nickel mineral wet metallurgy

PendingCN109837560AImprove work efficiencyDamage to healthPhotography auxillary processesElectrolysis componentsCarbon nanotubeHydrometallurgy

The invention discloses an electrolytic cell for nickel mineral wet metallurgy. The electrolytic cell for nickel mineral wet metallurgy comprises an electrolytic cell body, a liquid inlet pipe is arranged at the upper part position of one side of the electrolytic cell body in a penetrating mode, an anode chamber is connected to the middle position of the top of the electrolytic cell body, and a movable cover plate is connected to the position of one side of the top of the anode chamber through a hinge. A screw hole and a handle are separately arranged at the top of the movable cover plate, ananode bar is arranged on the inner wall of the screw hole, and an anode is connected to the bottom end of the anode bar through a connecting piece. According to the electrolytic cell for nickel mineral wet metallurgy, the screw hole and the anode bar are further arranged simultaneously, the anode bar can be rotated during electrolysis, so that the anode bar moves up and down in the screw hole through a thread on the outer surface, a purpose of adjusting the height of the anode is achieved, thus, the anode is in contact with a electrolyte solution more thoroughly, and the working efficiency ofthe electrolytic cell is greatly improved; and the drainage pipe is filled with waste gas generated in the electrolytic cell absorbed by a carbon nano pipe, and pollution to the environment is avoided.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Cleaning machine and cleaning method thereof

ActiveCN106269592ASave on cleaning materialsEasy to cleanCleaning using toolsCleaning methodsMechanical engineering

The invention provides a cleaning machine used for cleaning surfaces of an electronic product. The surfaces of the electronic product are divided into side surfaces, a front surface and a reverse surface. The cleaning machine is provided with a first cleaning mechanism and a second cleaning mechanism in sequence, wherein the first cleaning mechanism cleans the side surfaces of the electronic product, and the second cleaning mechanism cleans the front surface or the reverse surface of the electronic product. The invention further provides a cleaning method. According to the method, the cleaning machine is adopted for cleaning the surfaces of the electronic product, and the surfaces of the electronic product are divided into the side surfaces, the front surface and the reverse surface. The cleaning method comprises the steps that S1, the side surfaces and corners of the electronic product are cleaned; S2, the front surface or the reverse surface of the electronic product is cleaned. The cleaning machine and the cleaning method thereof have the advantages of being thorough in cleaning effect, high in cleaning efficiency and the like.

Owner:SHENZHEN FUYUNDI TECH

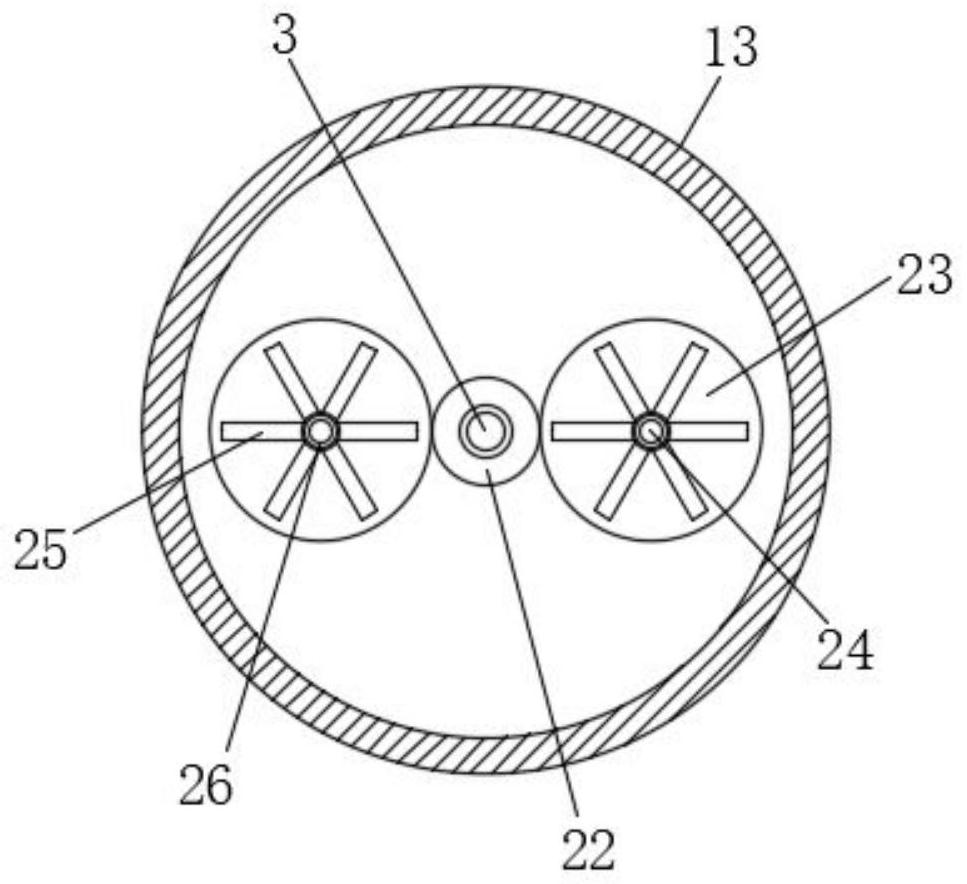

Convenient household sweeper

InactiveCN107752915AShorten the timeContact thoroughlyCarpet cleanersFloor cleanersMotor driveEngineering

The invention discloses a convenient household floor sweeper, which comprises a machine body shell. Several installation cavities are arranged in the body shell, and the two installation cavities are divided into a first installation cavity and a second installation cavity. A placement cavity is provided, and the placement cavity communicates with the first installation cavity and the second installation cavity. The first installation cavity is provided with a first motor, and the driving end of the first motor is connected with a threaded rod, and the thread A slip ring is sleeved on the rod, the bottom of the slip ring is fixedly connected with a rotating tube, the bottom of the rotating tube is fixedly connected with a first connecting rod, and the other end of the first connecting rod is fixedly connected with a second motor, so The driving end of the second motor is provided with a first rotating rod, and the placement cavity is provided with a second rotating rod. In the present invention, sweeping, dust collection and wetland are completed in one step, which saves the user's time. At the same time, the easy-to-disassemble structure also makes the device more environmentally friendly and can be used for a long time.

Owner:陈永

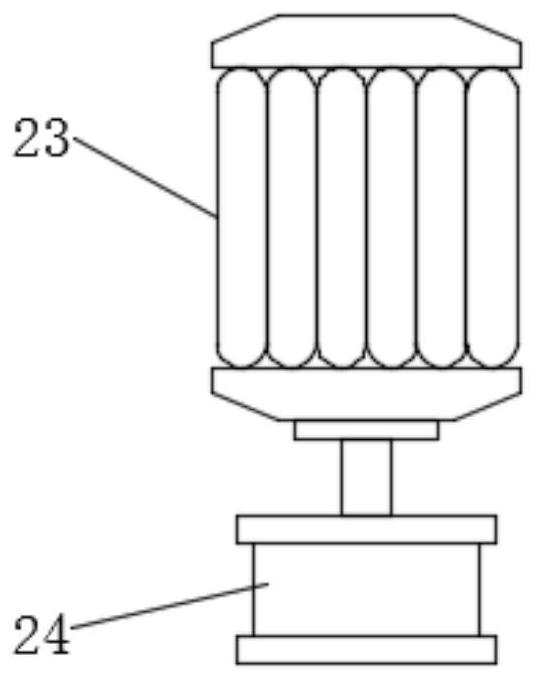

Air filter for automobile engine

InactiveCN106014710AImprove filtration efficiencyIncrease contact areaMachines/enginesAir cleaners for fuelAir filterAutomotive engine

The invention provides an air filter for an automobile engine. The air filter comprises a filter body, a first filter element, a second filter element, a first end cover and a second end cover. A round partition plate is arranged in the filter body. The interior of the filter body is partitioned into a first cavity and a second cavity through the partition plate. The first filter element is arranged in the first cavity. The first cavity is partitioned into a first filter chamber and a second filter chamber through the first filter element. An air guiding pipe is arranged in the first filter chamber. The air guiding pipe comprises multiple U-shaped pipe bodies which are arranged in an equally-spaced manner. Any two adjacent U-shaped pipe bodies are connected through a semicircular bent joint. The U-shaped pipe bodies and the semicircular bent joints are each provided with ventilation holes. The first filter element comprises two cylindrical segments and a corrugated segment connecting the two cylindrical segments. The second filter element is arranged in the second cavity. The second cavity is partitioned into a third filter chamber and a fourth filter chamber through the second filter element. Air guiding holes enabling the second filter chamber to communicate with the fourth filter chamber are formed in the partition plate. According to the air filter, air is filtered through multiple channels; air filtering efficiency and filtering cleanliness are improved; and the air supplying requirement of the engine is met.

Owner:WUHU AOBENMA AUTOMOBILE PARTS

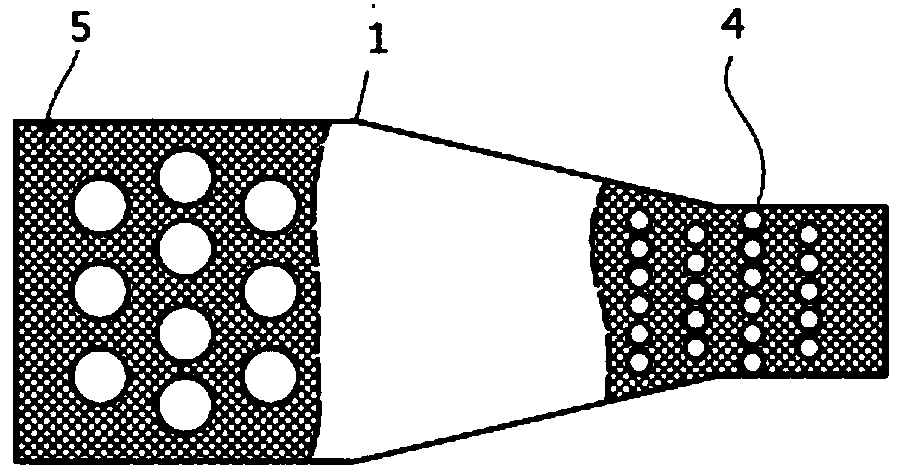

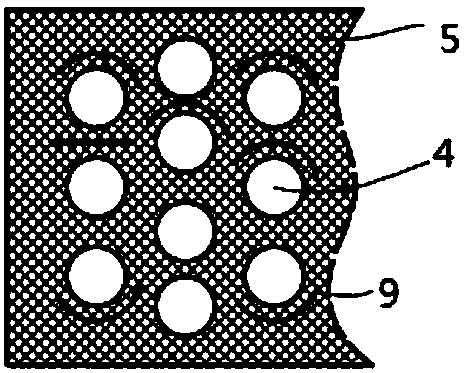

Cross-flow filtration oil-water separation device

PendingCN108046375AIncrease contact areaFully contactedFatty/oily/floating substances removal devicesLiquid suspension thickening by filtrationCross-flow filtrationOil water

The invention discloses a cross-flow filtration oil-water separation device. The cross-flow filtration oil-water separation device comprises a filtering channel, wherein a cover body covers the top ofthe filtering channel; an oil collection groove is communicated with the bottom of the filtering channel; a plurality of filtering cartridges which are as high as the filtering channel are arranged in the filtering channel in a staggered manner; the bottoms of the filtering cartridges are communicated with the inner part of the oil collection groove; filtering screens are arranged at positions, which are not provided with the filtering cartridges, between the bottom of the filtering channel and the oil collection groove; the filtering screens have the performance that only oil can pass through the filtering screens, but water cannot pass through the filtering screens. The filtering channel is divided into a wide part, a converging part and a narrow part along a circulation direction of filtering; one end, close to an inlet, of the filtering channel forms the wide part; one end, close to an outlet, of the filtering channel forms the narrow part; the converging part is between the widepart and the narrow part; the oil collection groove and the cover body are molded in a manner of corresponding to shapes of the wide part, the converging part and the narrow part. According to the cross-flow filtration oil-water separation device disclosed by the invention, oil type substances in an oil-water mixture can rapidly enter the oil collection groove under the adsorption effect of a selective filtering material and the gravity effect, and oil-water separation is finished without the need of an external force effect; the cross-flow filtration oil-water separation device has the advantages of large application range, simple structure, high separation efficiency and wide application prospect.

Owner:北京北方科诚信息技术股份有限公司

The method of hydraulic fracturing chemical expansion agent filling rapid excavation roadway

InactiveCN106089174BFast cleft developmentSafe and efficient tunnelingFluid removalSealing/packingStress concentrationChemical reaction

The invention relates to a method of filling a fast excavation tunnel with a hydrofracturing chemical expanding agent. In normal production of underground rock engineering, water detecting boreholes bored in front to learn forward geological conditions are used, and related regulations of water detecting are strictly abided before boring. The boreholes are arranged in a fan shape, and the other is located in the middle. Multiple wedge-shaped grooves are formed in all the boreholes with a grooving drill, then water is injected at high pressure, and stress of water pressure in the wedge-shaped grooves acts in a concentrated mode to break integrity of surrounding rock. The characteristic that the size is increased when the expanding agent is coagulated is used, and a coagulator is injected after hydrofracturing, and cracks in the boreholes grown more completely. A related chemical solution is prepared according to chemical components of rock and is injected into the boreholes. Chemical reaction of the chemical solution and the surrounding rock can reduce mechanical strength of the rock. The boreholes needed by water detecting are used and combined with chemical and physical methods during practical application, and the purpose of fast excavation face pushing can be achieved.

Owner:TAIYUAN UNIV OF TECH

Gaseous pollutant disposer

The invention belongs to the technical field of treatment of smoke air pollutants and especially relates to a gaseous pollutant disposer. The gaseous pollutant disposer comprises a filtering system, acontrol system and an auxiliary system; the filtering system comprises a water tank treatment device, a gas-absorbing / exhausting device, a box type water tank and a gas distributor arranged in a gaswater treatment layer; the filtering system is characterized in that the gas distributor comprises a top gas plate and N layers of inner gas plates arranged on the lower part of the top gas plate; each layer of inner gas plate includes a solid plate and a porous plate connected with the solid plate; each two adjacent layers of inner gas plates are reversely arranged; a gas-liquid separation systemis connected with an exhaust port of an aspirated engine; an electrostatic precipitation system and an air resistor are arranged on an exhaust pipe of the water tank; a temperature control system anda water level control system are connected with the box type water tank. The gaseous pollutant disposer has a simple structure, has an excellent disposing effect and is easy for maintenance; the disposed and recycled pollutants can generate usable substances during the recycling process; waste is turned into wealth, so that the secondary value is created; the disposing cost is lowered.

Owner:祝恩波

Energy-saving and environment-friendly incinerator

The invention provides an energy-saving and environment-friendly incinerator. The energy-saving and environment-friendly incinerator comprises a furnace body, a supporting frame, air blowers, a powercollecting box and a ventilation groove, the outer wall of the bottom end of the furnace body is fixedly connected with the supporting frame, the left side and the right side of the bottom end of thefurnace body are embedded with the air blowers correspondingly, an inclined guide hole is fixedly connected to the inner sides of the air blowers, a first dustproof net is fixedly connected to the inner wall of the inclined guide hole, an electricity collecting box is integrally arranged in the middle of the right side of the furnace body, a motor is arranged in the middle of the inner wall of theelectricity collecting box, a gear is fixedly connected to the left side of the motor, storage batteries are arranged at the upper end and the lower end of the inner wall of the electricity collection box correspondingly, a heat dissipation hole is formed in the middle of the right side of the electricity collection box in an embedded mode, a second dustproof net is fixedly connected to the middle of the heat dissipation hole, a ventilation groove is embedded in the right side of the top end of the furnace body, an electrode is embedded in the middle of the inner wall of the ventilation groove, a gas collecting chamber is embedded in the top end of the inner wall of the furnace body, and an electrolyte is filled in the gas collecting chamber. The energy-saving and environment-friendly incinerator is stable in structure and high in incineration capacity, has good waste gas purification treatment capacity, can convert thermal energy into electric energy and is energy-saving and environment-friendly.

Owner:肖林

Catalytic device for low-cement self-flowing wear-resistant castable

ActiveCN111871340ATake advantage ofThe reaction is evenly heatedCatalytic crackingChemical/physical processesPtru catalystEngineering

The invention discloses a catalytic device for low-cement self-flowing wear-resistant castable. The device comprises a reaction shell, a reaction cavity is formed in the reaction shell, an oil storagetank is fixedly installed on the upper end face of the reaction shell, an oil inlet mechanism is arranged on the inner wall of the upper portion in the reaction cavity, and an oil outlet mechanism isarranged on the inner wall of the lower portion in the reaction cavity. The oil inlet mechanism comprises an oil pipe, a first rotating disc, a servo motor, a second rotating disc, a dividing net plate and a fixing plate, wherein the oil pipe is fixedly installed on the inner wall of the reaction cavity, the upper portion of the left end of the oil pipe penetrates through the upper end face of the reaction shell through a liquid inlet pipe and communicates with an oil storage tank, and a liquid outlet pipe is arranged below the left end of the oil pipe; a piston is slidably connected into theoil pipe, and a push rod is fixedly mounted on the right side wall of the piston. According to the invention, the oil liquid can be in full contact with atomized raw materials and a catalyst, so thatthe oil liquid and the raw materials react more thoroughly, and the oil liquid can be fully utilized.

Owner:郑州博达耐火材料有限公司

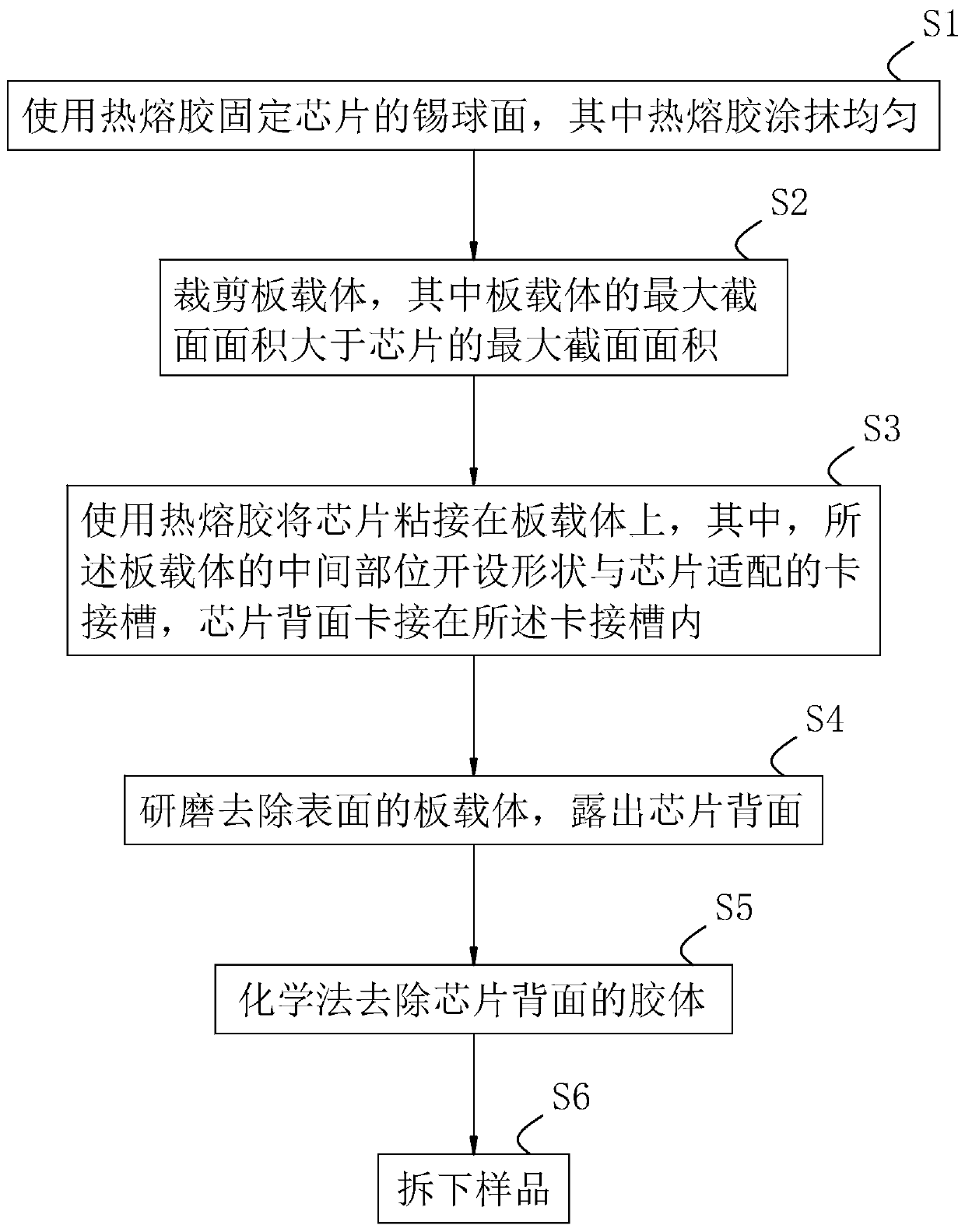

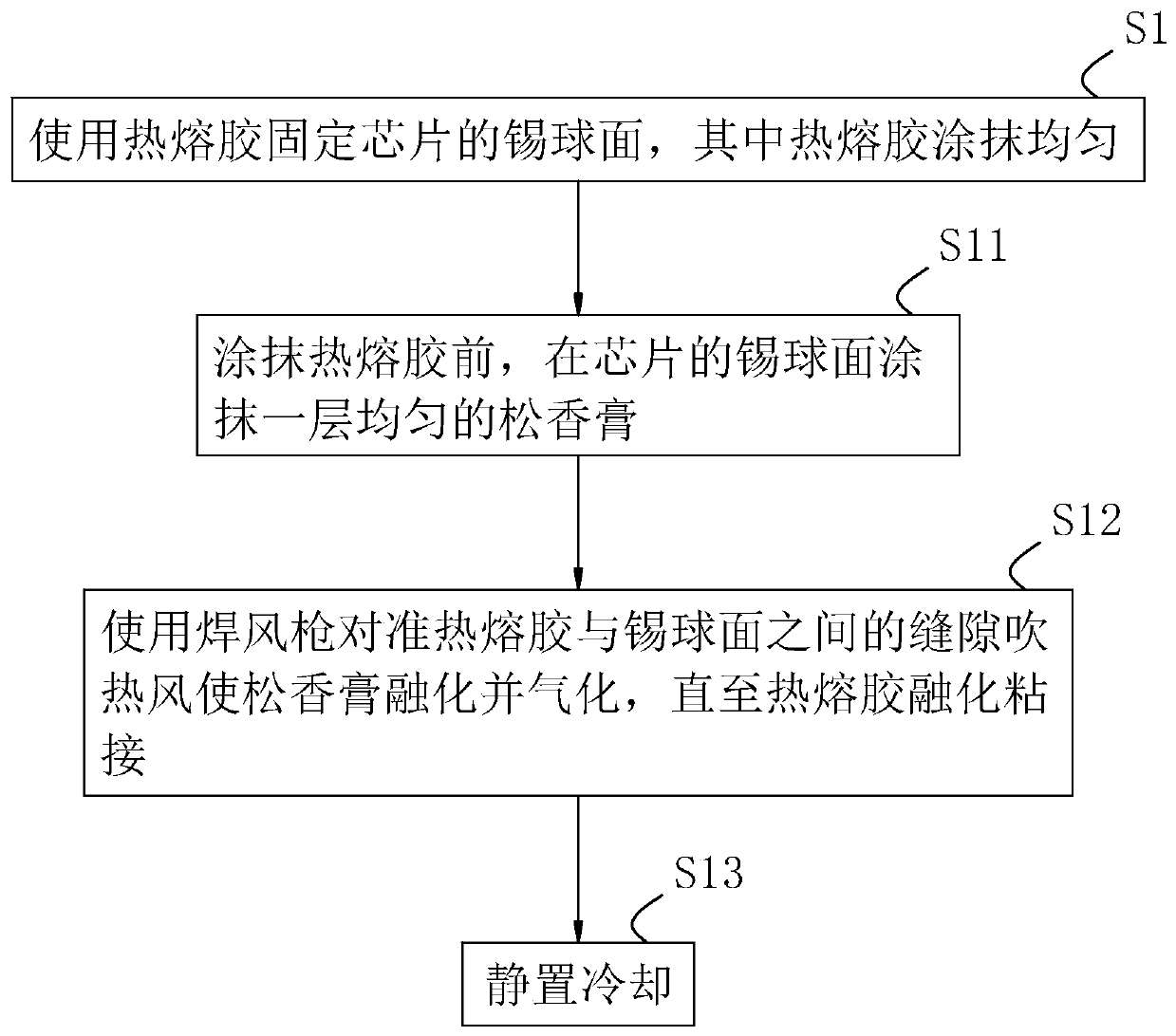

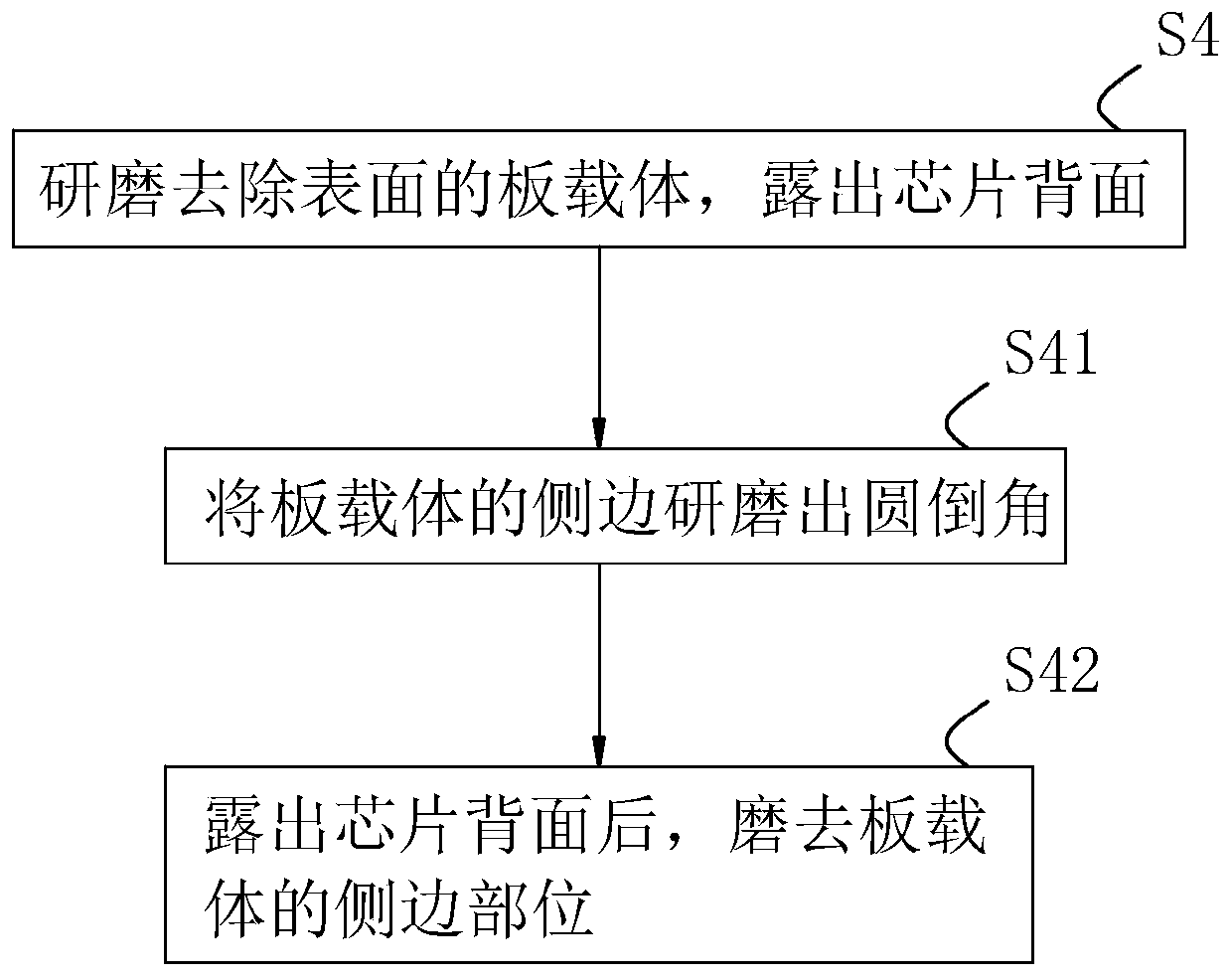

Crystal back preparation method of ultrathin chip

PendingCN111081623APromote infiltrationIncrease resistanceSolid-state devicesSemiconductor/solid-state device manufacturingMicrochip AnalysisEngineering

The invention relates to the technical field of chip analysis and discloses a crystal back preparation method of an ultrathin chip. The method comprises the following steps that: S1, a the tin spherical surface of the chip is fixed by using a hot melt adhesive which is uniformly smeared; S2, a board carrier is cut, wherein the maximum cross-sectional area of the board carrier is greater than the maximum cross-sectional area of the chip; S3, the chip is bonded to the board carrier through the hot melt adhesive, a clamping groove shaped to match with the chip is formed in the middle of the boardcarrier, and the back face of the chip is clamped in the clamping groove; S4, the board carrier on the surface is ground so as to be removed, so that the back surface of the chip can be exposed; S5,the adhesive on the back surface of the chip is removed by a chemical method; and S6, a sample is removed. In the grinding process, borne force can be evenly distributed by the board carrier; meanwhile, the board carrier can increase grinding resistance, and therefore, the progress of the grinding can be more easily controlled when thickness is reduced, grinding uniformity and quality are improved, cracks cannot occur on the back surface of the chip, and the grinding is more uniform.

Owner:闳康技术检测(上海)有限公司

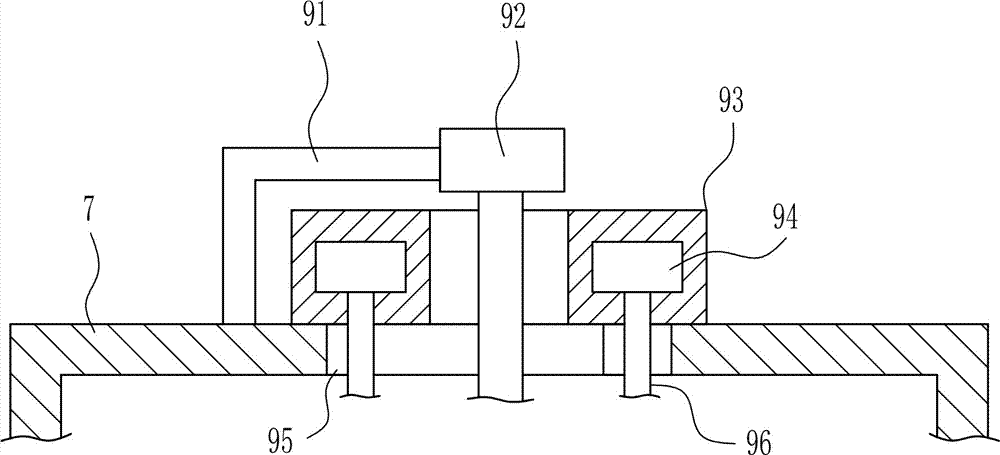

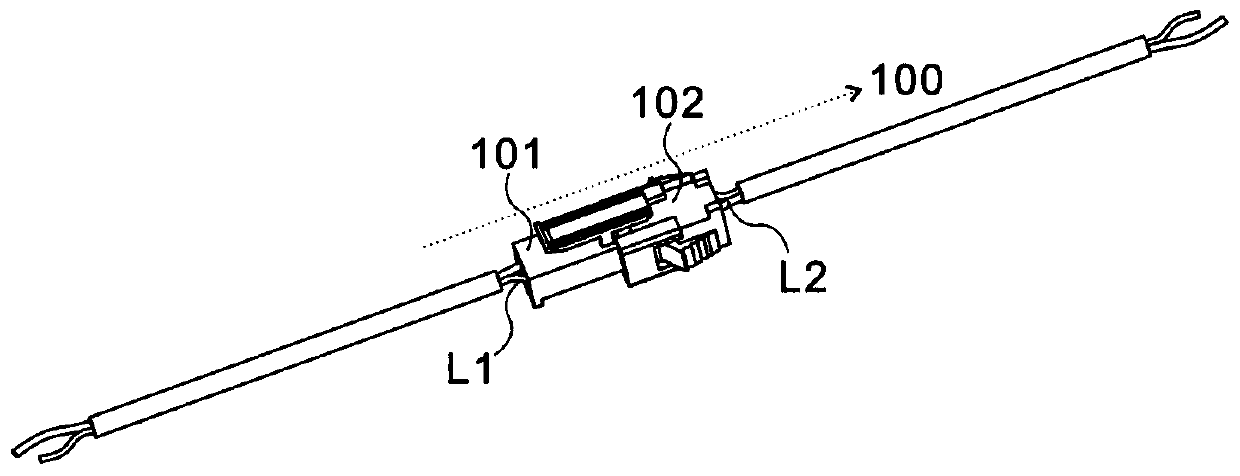

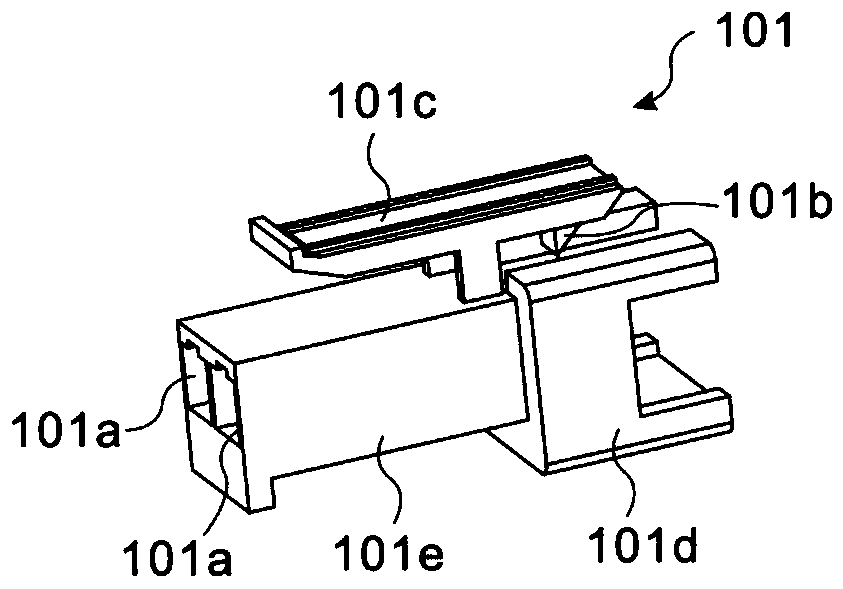

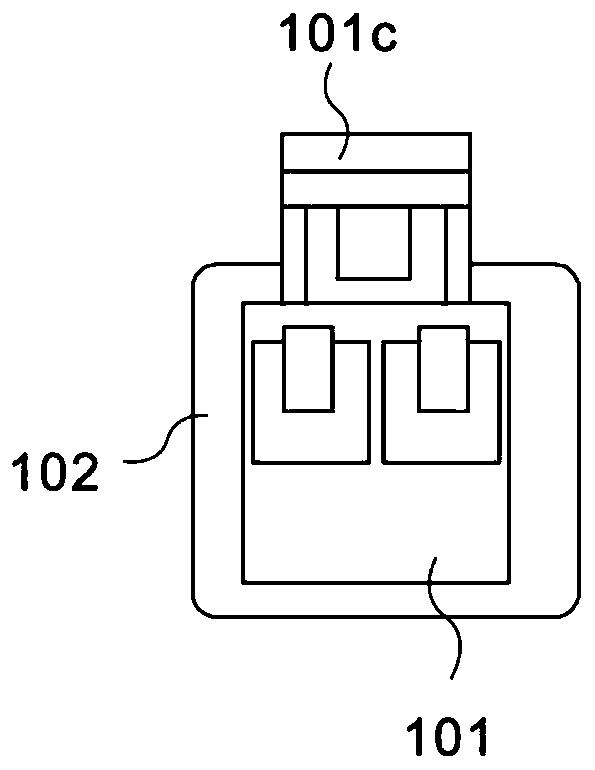

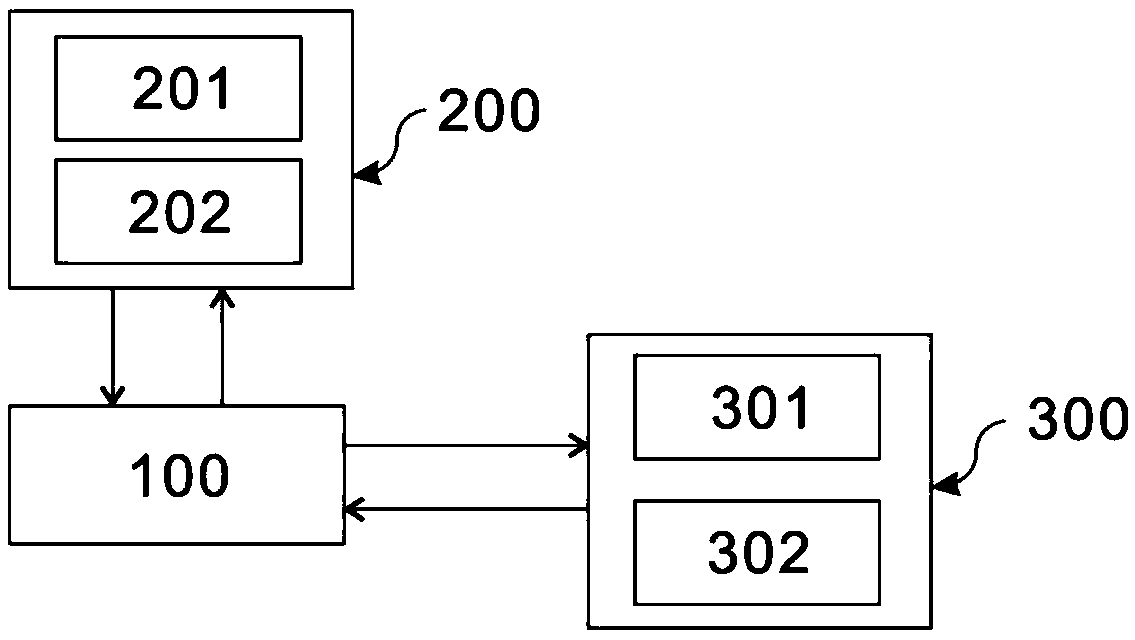

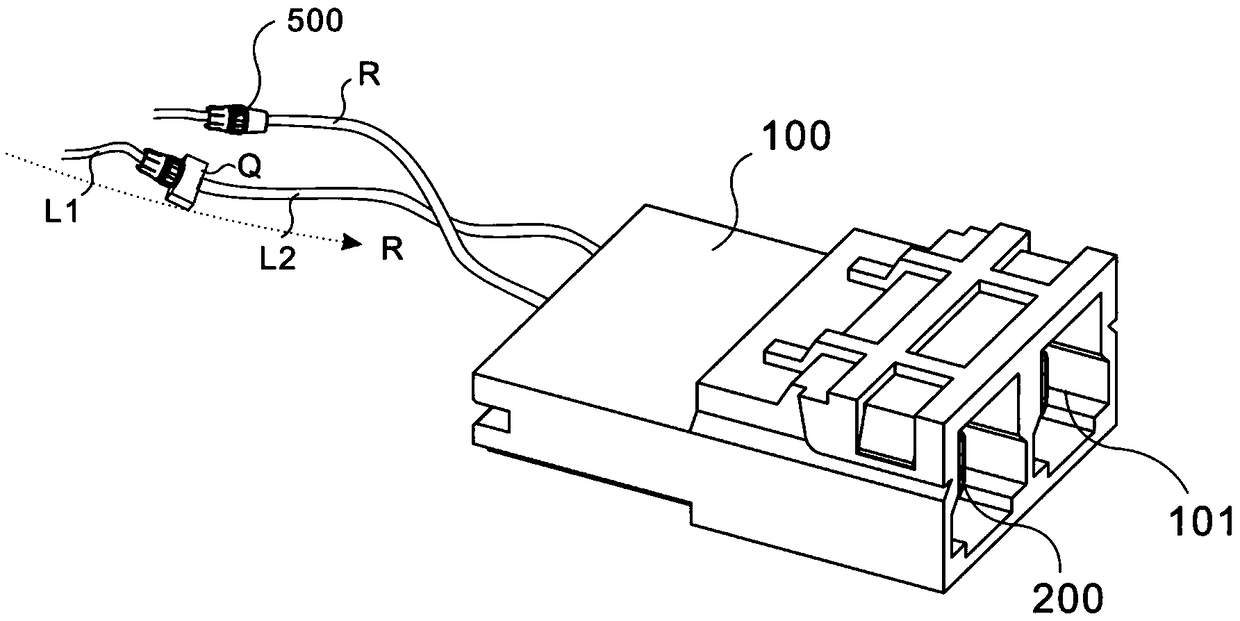

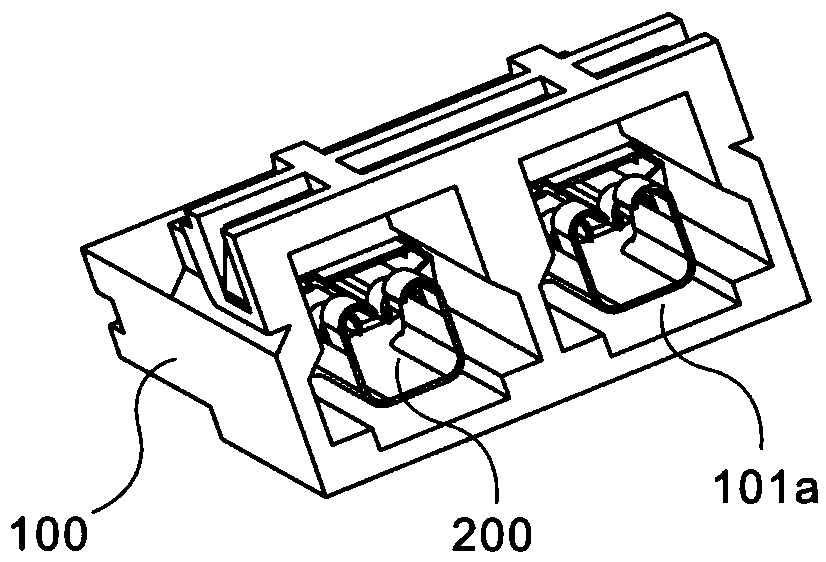

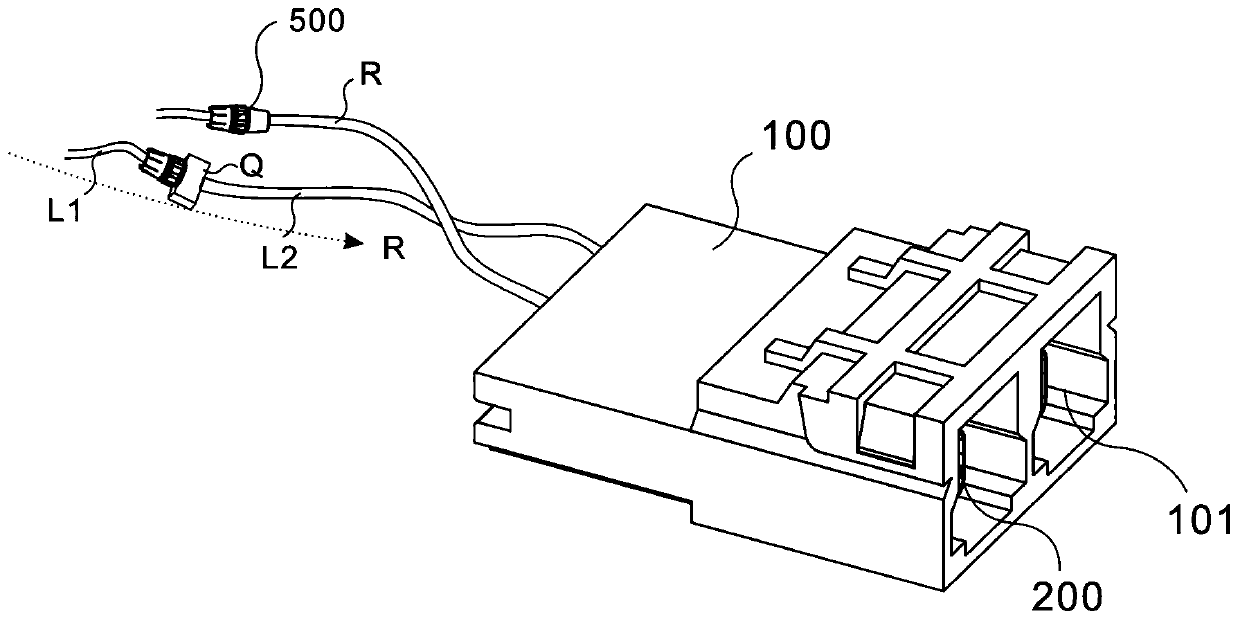

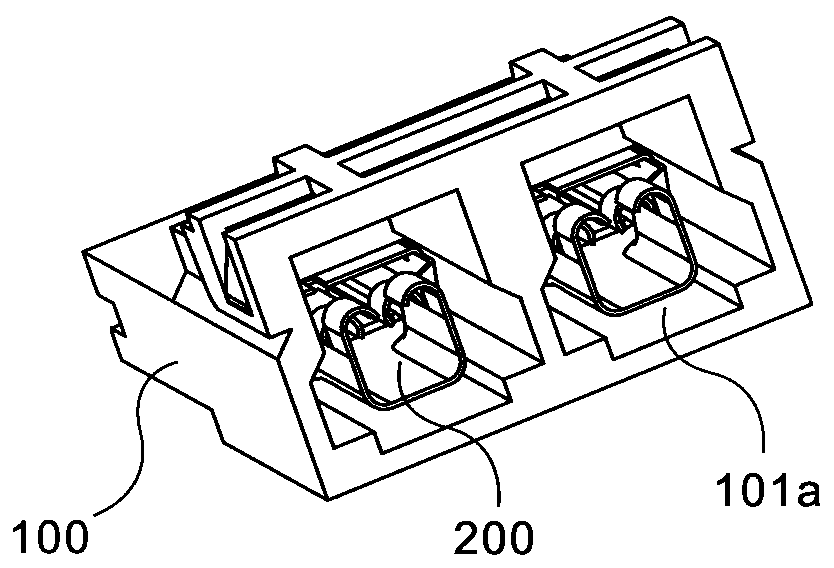

An electronic circuit connection device

ActiveCN108879268BEasy to move and disassembleContact thoroughlyCouplings bases/casesElectric wireElectronic circuit

The invention discloses an electronic circuit connecting device. The electronic circuit connecting device comprises a first fitting assembly. The first fitting assembly comprises an occlusion member and a clamping member, wherein the occlusion member comprises a first through hole and an occlusion protruding block, the clamping member comprises a second through hole and a clamping protruding block, the first through hole communicates with the second through hole, and the occlusion protruding block is matched with the clamping protruding block. A first electric wire penetrates through the firstthrough hole and is connected with the occlusion member, a second electric wire penetrates through the second through hole and is connected with the clamping member, and the occlusion member is connected with the clamping member, so that the first electric wire and the second electric wire are connected. According to the electronic circuit connecting device, the sealing performance of the connection position is realized when the wires are connected, the contact of the connection between the two wires are more thorough in the extrusion process, the situation of poor contact is avoided, and after the electronic circuit connecting device is used in large machinery, wires on the machinery are convenient to carry and disassemble.

Owner:JIANGNAN UNIV

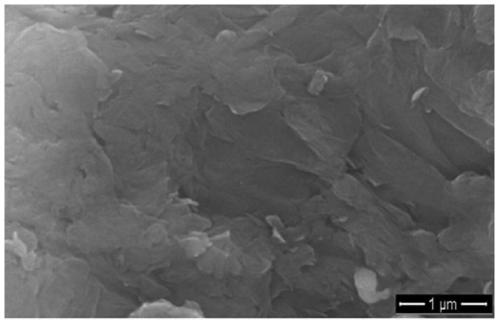

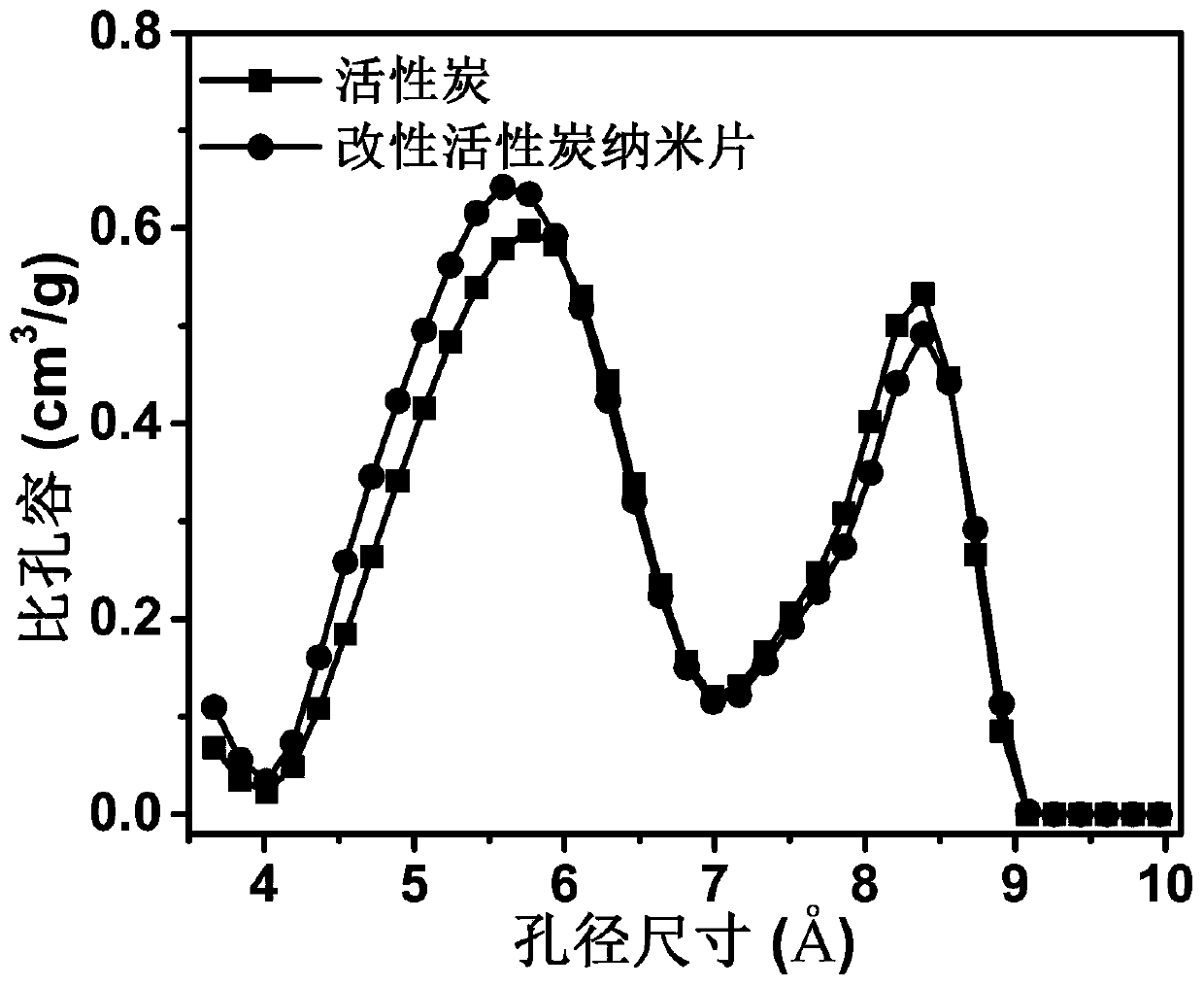

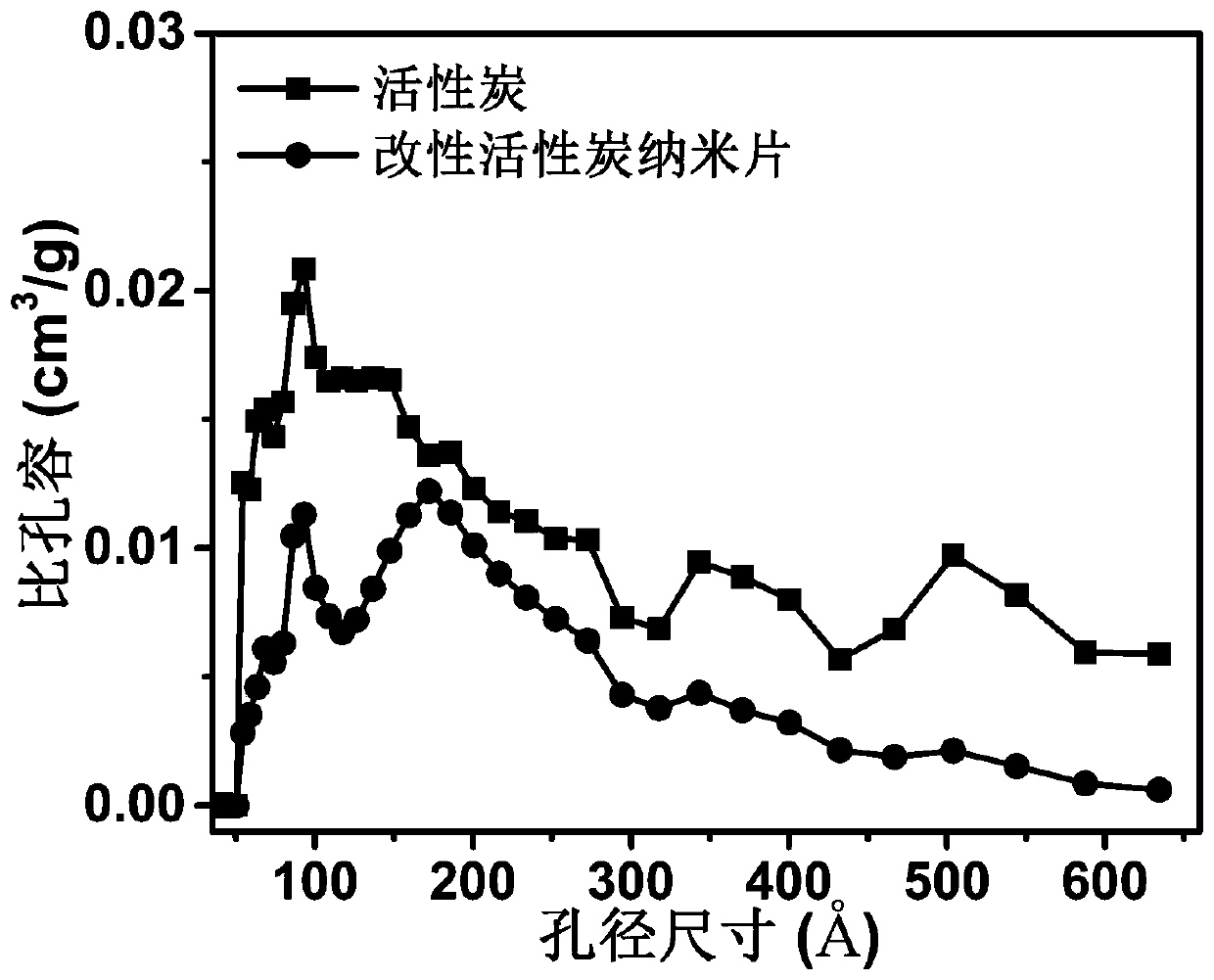

Preparation method of modified activated carbon nanosheet and separation column thereof

InactiveCN107213869BIncrease contactIncrease contact areaGas treatmentOther chemical processesActivated carbonFlue gas

The invention belongs to the technical field of gas separation, and particularly relates to a method for effectively separating CO2 in flue gas by a modified activated carbon nanosheet. An ultrasonic peeling method is mainly adopted to obtain an activated carbon nanosheet; then, an acid solution is used for carrying out oxidative modification; finally, a breakthrough experiment indicates that the separation volume of a modified activated carbon nanosheet material subjected to vacuum activation at a temperature of 80DEG C for CO2 / N2 mixed gas (v to v=15 to 85, and total flow is 20mL / min) at room temperature is 15.79cm<3>g, and separation selectivity is 4.37. The modified activated carbon nanosheet can be used as a solid adsorbent material for effectively separating the CO2 in the flue gas.

Owner:FUJIAN NORMAL UNIV

High-power energy-saving heat dissipation box

InactiveCN107246811AContact thoroughlyImprove heat transfer effectStationary conduit assembliesVertical barIntermediate heat exchanger

The invention discloses a high-power energy-saving heat dissipation box, which comprises a mounting base, a vertical heat exchange main board is fixed on the top surface of the installation base, an intermediate heat exchange box body is fixed on the wall of the vertical heat exchange main board, and the intermediate heat exchange The inner cavity of the box is provided with a plurality of vertical partitions, and the top and bottom surfaces of all the vertical partitions are fixed on the top and bottom of the inner cavity of the intermediate heat exchange box, and the adjacent two vertical There is a water flow channel between the front end of one of the vertical partitions and the front inner wall of the inner cavity of the intermediate heat exchange box, and the rear end of the other vertical partition is connected to the inner wall of the intermediate heat exchange box. There is a water flow channel between the rear inner side walls of the cavity, and an S-shaped water flow channel is formed between all the vertical partitions and the inner cavity of the intermediate heat exchange box. The invention makes the liquid contact thoroughly with the wall surface of the intermediate heat exchange box body, greatly improving its heat exchange and heat dissipation effects.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Convenient-to-disassemble anti-seepage cable connection system

ActiveCN108832366AEasy to move and disassembleContact thoroughlyCoupling contact membersCouplings bases/casesEngineeringComputer module

The invention discloses a convenient-to-disassemble anti-seepage cable connection system, which comprises a shell, an inner sleeve assembly, a cable, a control module, a monitoring module and an alarming module, wherein the cable is divided to a first wire and a second wire; the first wire and the second wire are connected through an embedding assembly; the embedding assembly comprises a positioning assembly and a locking assembly; the positioning assembly is tightened through the locking assembly; a monitoring unit is arranged outside the locking assembly; the monitoring unit comprises the control module, the monitoring module and the alarming module; the alarming module comprises a buzzer and a warning lamp; and if liquid falls in a range value, the warning lamp operates, and if lower than the maximum value of the range value, the buzzer operates. When connection between wires is realized, sealing performance of the connection place is ensured; during a squeezing process, the contactbetween the two in the case of connection is more thorough, and poor contact is avoided; and when the device is used on a large machinery, a line on the machinery can be transported and disassembledconveniently.

Owner:JIANGNAN UNIV

Air filter for automobile engine

InactiveCN106014710BImprove filtration efficiencyIncrease contact areaMachines/enginesAir cleaners for fuelAir filterAutomotive engine

The invention provides an air filter for an automobile engine. The air filter comprises a filter body, a first filter element, a second filter element, a first end cover and a second end cover. A round partition plate is arranged in the filter body. The interior of the filter body is partitioned into a first cavity and a second cavity through the partition plate. The first filter element is arranged in the first cavity. The first cavity is partitioned into a first filter chamber and a second filter chamber through the first filter element. An air guiding pipe is arranged in the first filter chamber. The air guiding pipe comprises multiple U-shaped pipe bodies which are arranged in an equally-spaced manner. Any two adjacent U-shaped pipe bodies are connected through a semicircular bent joint. The U-shaped pipe bodies and the semicircular bent joints are each provided with ventilation holes. The first filter element comprises two cylindrical segments and a corrugated segment connecting the two cylindrical segments. The second filter element is arranged in the second cavity. The second cavity is partitioned into a third filter chamber and a fourth filter chamber through the second filter element. Air guiding holes enabling the second filter chamber to communicate with the fourth filter chamber are formed in the partition plate. According to the air filter, air is filtered through multiple channels; air filtering efficiency and filtering cleanliness are improved; and the air supplying requirement of the engine is met.

Owner:WUHU AOBENMA AUTOMOBILE PARTS

Waste gas treatment equipment for industrial environmental protection

InactiveCN111841233AIncrease temperatureReduce the temperatureCombination devicesDirect contact heat exchangersDust controlEnvironmental engineering

The invention discloses waste gas treatment equipment for industrial environmental protection. The waste gas treatment equipment comprises a shell and a shell cover, a gas inlet pipe used for conveying waste gas is arranged on one side of the shell. A turnover mechanism for discharging dust in the gas inlet pipe is arranged in the gas inlet pipe; a rotating shaft is vertically arranged in the shell; a servo motor used for driving the rotating shaft to rotate is arranged over the shell cover. A shaking mechanism is arranged in the shell; the rotating shaft is provided with a plurality of cams used in cooperation with the shaking mechanism. A collecting box is arranged below the shell; the liquid becomes steam after being volatilized, so that dust sedimentation is facilitated, the temperature of waste gas; and a rotating sheet rotates in the liquid, so that volatilization of the liquid and contact between the waste gas and the liquid are facilitated, dust is settled more thoroughly, thewaste gas subjected to dust removal can be exhausted from the exhaust pipe, dust is prevented from entering the external environment, the environment is prevented from being polluted, and the body health of people is facilitated.

Owner:北京鼎翰建筑有限公司

A system of easy-to-detach water-proof cable connections

ActiveCN108832366BEasy to move and disassembleContact thoroughlyCoupling contact membersCouplings bases/casesControl engineeringElectric wire

The invention discloses a convenient-to-disassemble anti-seepage cable connection system, which comprises a shell, an inner sleeve assembly, a cable, a control module, a monitoring module and an alarming module, wherein the cable is divided to a first wire and a second wire; the first wire and the second wire are connected through an embedding assembly; the embedding assembly comprises a positioning assembly and a locking assembly; the positioning assembly is tightened through the locking assembly; a monitoring unit is arranged outside the locking assembly; the monitoring unit comprises the control module, the monitoring module and the alarming module; the alarming module comprises a buzzer and a warning lamp; and if liquid falls in a range value, the warning lamp operates, and if lower than the maximum value of the range value, the buzzer operates. When connection between wires is realized, sealing performance of the connection place is ensured; during a squeezing process, the contactbetween the two in the case of connection is more thorough, and poor contact is avoided; and when the device is used on a large machinery, a line on the machinery can be transported and disassembledconveniently.

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com