Catalytic device for low-cement self-flowing wear-resistant castable

A catalytic device and castable technology, which is applied in the field of catalysis, can solve the problems of incomplete reaction between oil and raw materials, oil cannot be fully utilized, atomized raw material catalyst contact, etc., to achieve complete reaction, full utilization, and uniform heating Effect

Active Publication Date: 2020-11-03

郑州博达耐火材料有限公司

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] The purpose of the present invention is to solve the problem in the prior art that "the oil is usually columnar during the injection process, and cannot fully contact the atomized raw material and the catalyst, resulting in incomplete reaction between the oil and the raw material, resulting in the oil being unable to be sprayed." Make full use of” defects, thus proposing a catalytic device for low-cement self-flowing wear-resistant castables

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

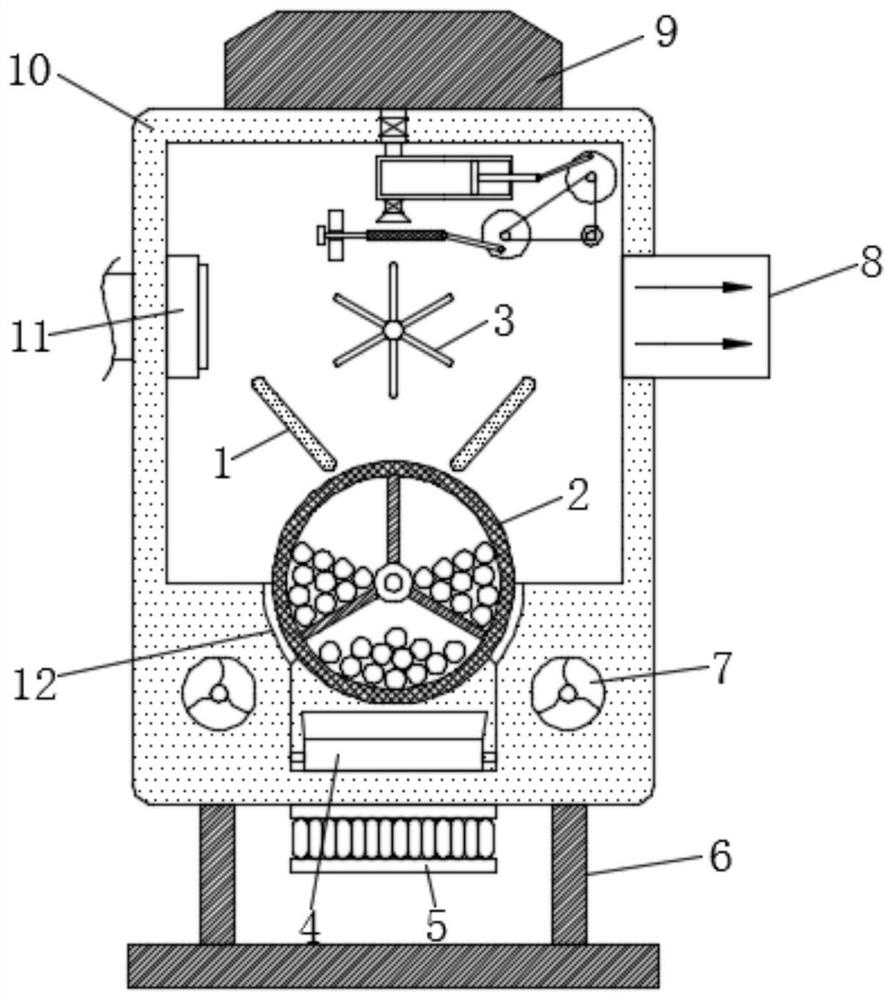

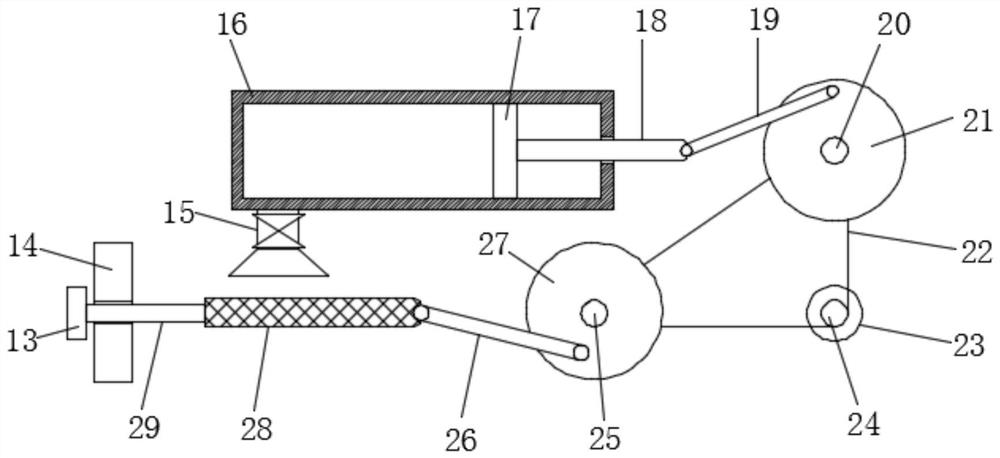

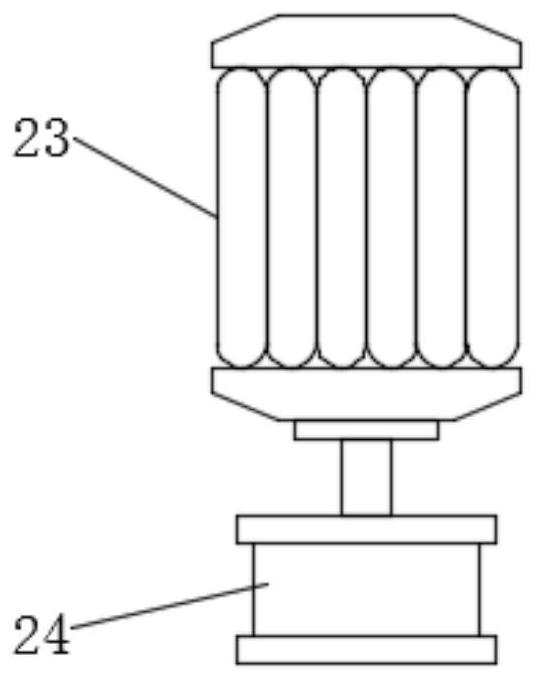

The invention discloses a catalytic device for low-cement self-flowing wear-resistant castable. The device comprises a reaction shell, a reaction cavity is formed in the reaction shell, an oil storagetank is fixedly installed on the upper end face of the reaction shell, an oil inlet mechanism is arranged on the inner wall of the upper portion in the reaction cavity, and an oil outlet mechanism isarranged on the inner wall of the lower portion in the reaction cavity. The oil inlet mechanism comprises an oil pipe, a first rotating disc, a servo motor, a second rotating disc, a dividing net plate and a fixing plate, wherein the oil pipe is fixedly installed on the inner wall of the reaction cavity, the upper portion of the left end of the oil pipe penetrates through the upper end face of the reaction shell through a liquid inlet pipe and communicates with an oil storage tank, and a liquid outlet pipe is arranged below the left end of the oil pipe; a piston is slidably connected into theoil pipe, and a push rod is fixedly mounted on the right side wall of the piston. According to the invention, the oil liquid can be in full contact with atomized raw materials and a catalyst, so thatthe oil liquid and the raw materials react more thoroughly, and the oil liquid can be fully utilized.

Description

technical field [0001] The invention relates to the technical field of catalysis, in particular to a catalysis device for low-cement self-flowing wear-resistant castables. Background technique [0002] The catalytic device is a secondary processing device for oil refining. It uses heavy distillate oil as raw material, under a certain temperature and pressure, uses molecular sieve catalyst as carrier, and adopts fluidization technology. When the raw material oil contacts with the high-temperature catalyst, a series of chemical reactions occur. Reaction, so as to convert raw materials into light oil production and processing technology. The main products are gasoline, light diesel oil and liquefied petroleum gas. 80% of my country's motor gasoline consumption is produced by catalytic units. Catalytic cracking units are usually composed of three major parts, namely, reaction regeneration system, fractionation system and absorption stabilization system. The reaction temperature...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J8/08B01J8/10C10G11/02

CPCB01J8/085B01J8/10C10G11/02C10G2300/70C10G2300/4006C10G2400/06

Inventor 宫军州

Owner 郑州博达耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com