Preparation method of modified activated carbon nanosheet and separation column thereof

A separation column and activated carbon technology, which is applied in the direction of separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of narrow operating range and small adsorption capacity, and achieve obvious effects, increase adsorption capacity, and increase contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

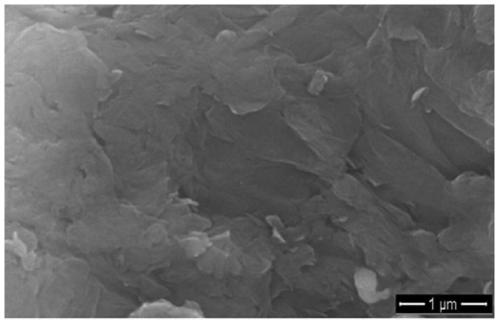

[0033] S1: Disperse 3g of activated carbon in a mixed solvent of 90g of water and 45g of ethanol, perform ultrasonic separation at 2°C for 80 minutes, then perform centrifugation, collect the solid part and wash it with distilled water to obtain activated carbon nanosheet materials;

[0034] S2: Disperse the 0.6g activated carbon nanosheet material in 48g, 1N nitric acid solution, stir at 60°C for 20min, add 138g of distilled water, stir for 5min, filter, collect the filter residue for washing, adjust the pH value to 5, and dry get solid;

[0035] S3: passing water vapor into the solid, and treating at 250° C. for 1 hour to obtain modified activated carbon nanosheets.

[0036] S4: Put the prepared modified activated carbon nanosheets into a vacuum drying oven at 80°C, activate them for 20 hours under the condition of 5 μmHg, and remove the water and solvent to obtain a method for effectively separating CO in flue gas according to the present invention. 2 modified activated ca...

Embodiment 2

[0040] S1: Disperse 3g of activated carbon in a mixed solvent of 100g of water and 50g of ethanol, perform ultrasonic separation at 5°C for 90 minutes, then perform centrifugation, collect the solid part and wash with distilled water to obtain activated carbon nanosheet materials;

[0041] S2: Disperse the 0.8g activated carbon nanosheet material in 68g, 2N hydrochloric acid solution, stir at 65°C for 30min, add 200g of distilled water, stir for 8min, filter, collect the filter residue for washing, adjust the pH value to 6, and dry get solid;

[0042] S3: passing water vapor into the solid, and treating at 300° C. for 1.5 h to obtain modified activated carbon nanosheets.

[0043] S4: Put the prepared modified activated carbon nanosheet into a vacuum drying oven at 80°C, activate it for 24 hours under the condition of 5 μmHg, and remove the water and solvent to obtain a method for effectively separating CO in flue gas according to the present invention. 2 modified activated ca...

Embodiment 6

[0067] S1: Disperse 3g of activated carbon in a mixed solvent of 120g of water and 60g of ethanol, perform ultrasonic separation at 8°C for 100 minutes, then perform centrifugation, collect the solid part and wash it with distilled water to obtain activated carbon nanosheet materials;

[0068] S2: Disperse the 1.2g activated carbon nanosheet material in 105g, 3N sulfuric acid solution, stir at 80°C for 40min, add 300g of distilled water, stir for 15min, filter, collect the filter residue for washing, adjust the pH value to 7, and dry get solid;

[0069] S3: passing water vapor into the solid, and treating at 400° C. for 2 hours to obtain modified activated carbon nanosheets.

[0070] S4: Put the prepared modified activated carbon nanosheets into a vacuum drying oven at 80°C, activate them for 30 hours under the condition of 5 μmHg, and remove the water and solvent to obtain a method for effectively separating CO in flue gas according to the present invention. 2 modified activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com