Floating bed catalytic ozonation reactor and method therewith for treating waste water

A technology of ozone catalytic oxidation and floating catalyst, applied in the direction of oxidized water/sewage treatment, etc., can solve the problems of poor gas-liquid-solid three-phase mass transfer efficiency, large system pressure loss, low ozone utilization rate, etc., and achieve good floating state, The effect of saving floor space and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0020] Specific implementation mode two: The gas passed into the reactor in this embodiment is air that has not passed through the ozone generator. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: The catalyst of this embodiment is activated carbon fiber filament (PAN-ACF). Others are the same as in the first embodiment.

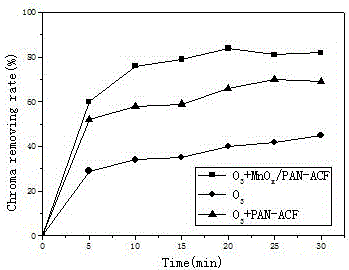

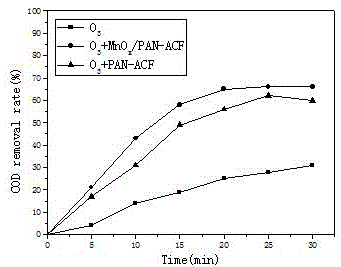

[0022] In order to detect the reactor of the present invention and method to the treatment effect of waste water, adopt fibrous flexible floating catalyst catalyst PAN-ACF and catalyst MnOx / PAN-ACF respectively, use figure 1 The reactor shown is used for the advanced treatment test of refractory cationic printing and dyeing wastewater. The waste water is the biochemical secondary effluent of a printing and dyeing factory with a chroma of 130-160 times and a COD of 140-160mg / L, and the dosage of the catalyst is 1.0g / L. The wastewater is treated by the method of Embodiment 1, samples are taken at regular intervals, and the chromaticity and COD value of the water samples are measured. Experimental results such as image 3 and Figure 4 shown.

[0023] in, image 3Middle - □ - represents the graph of chro...

specific Embodiment approach 4

[0025] Specific implementation mode four: The reactor and catalyzer used in this embodiment are the same as Embodiment 1 (see figure 1 , figure 2 ), the difference is that the actual wastewater is treated continuously.

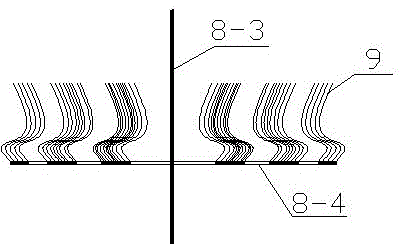

[0026] This embodiment is mainly divided into the following steps: 1. On the porous ring plate (8-4), fix the catalyst (PAN- ACF / MnOx); 2. The wastewater storage tank is connected to the water inlet pipe (2) through the water pump, and the residence time of the wastewater in the reactor is controlled by adjusting the flow rate of the water pump; 3. The ozone mixed gas generated by the ozone generator passes through the ozone inlet pipe (6) Pass in and disperse the ozone mixed gas into uniform and tiny bubbles through the microporous gas diffusion plate (7). A large number of small bubbles and wastewater flow upward, driving the light, fibrous, flexible floating catalyst to float in the wastewater And float up and down to form a three-phase floating bed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com