Crystal back preparation method of ultrathin chip

An ultra-thin chip, chip technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of unevenness, small contact area, thin thickness, etc., to achieve easy progress control, uniform cracks, and increased resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

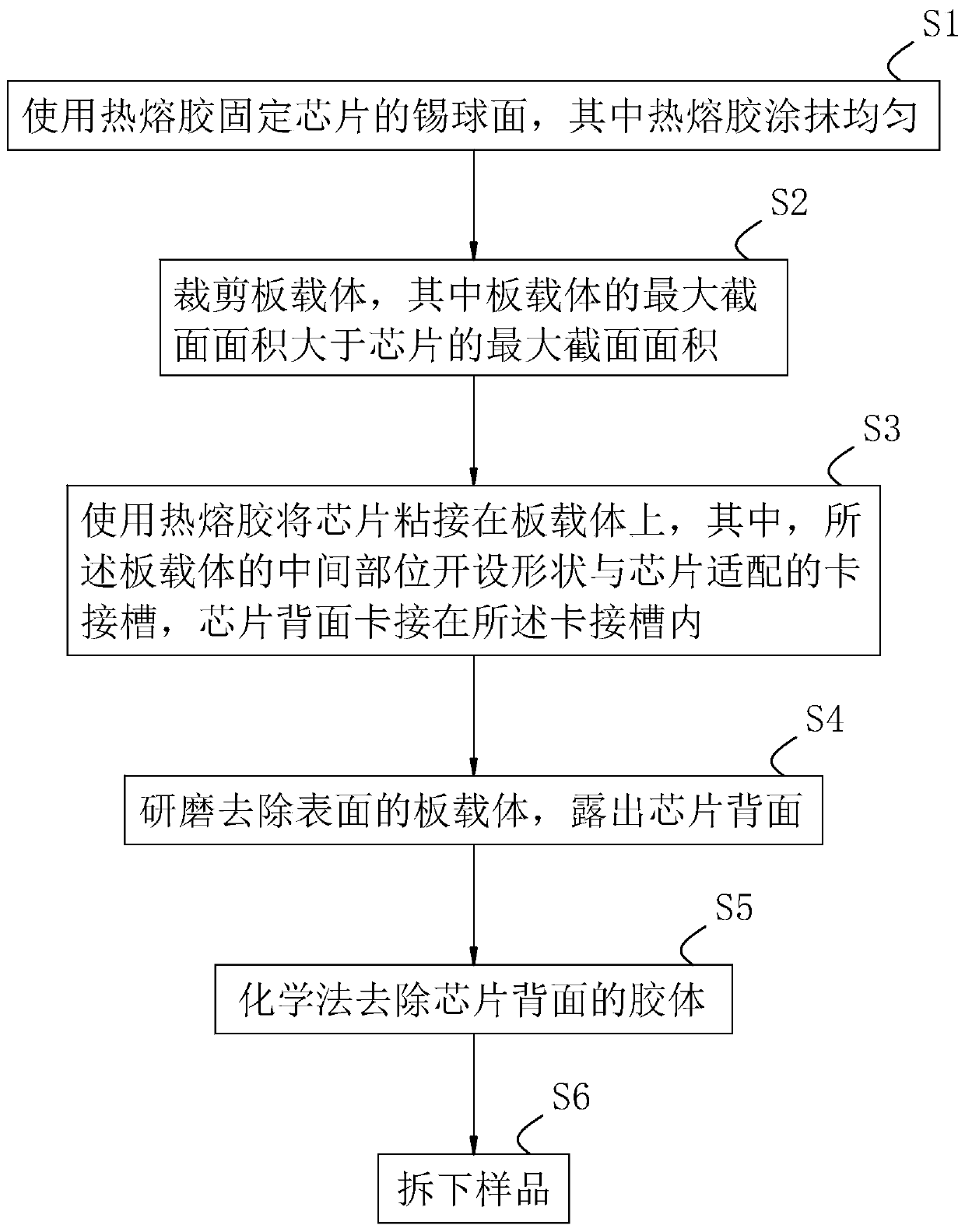

[0038] A method for preparing the crystal back of an ultra-thin chip, such as figure 1 shown, including the following steps:

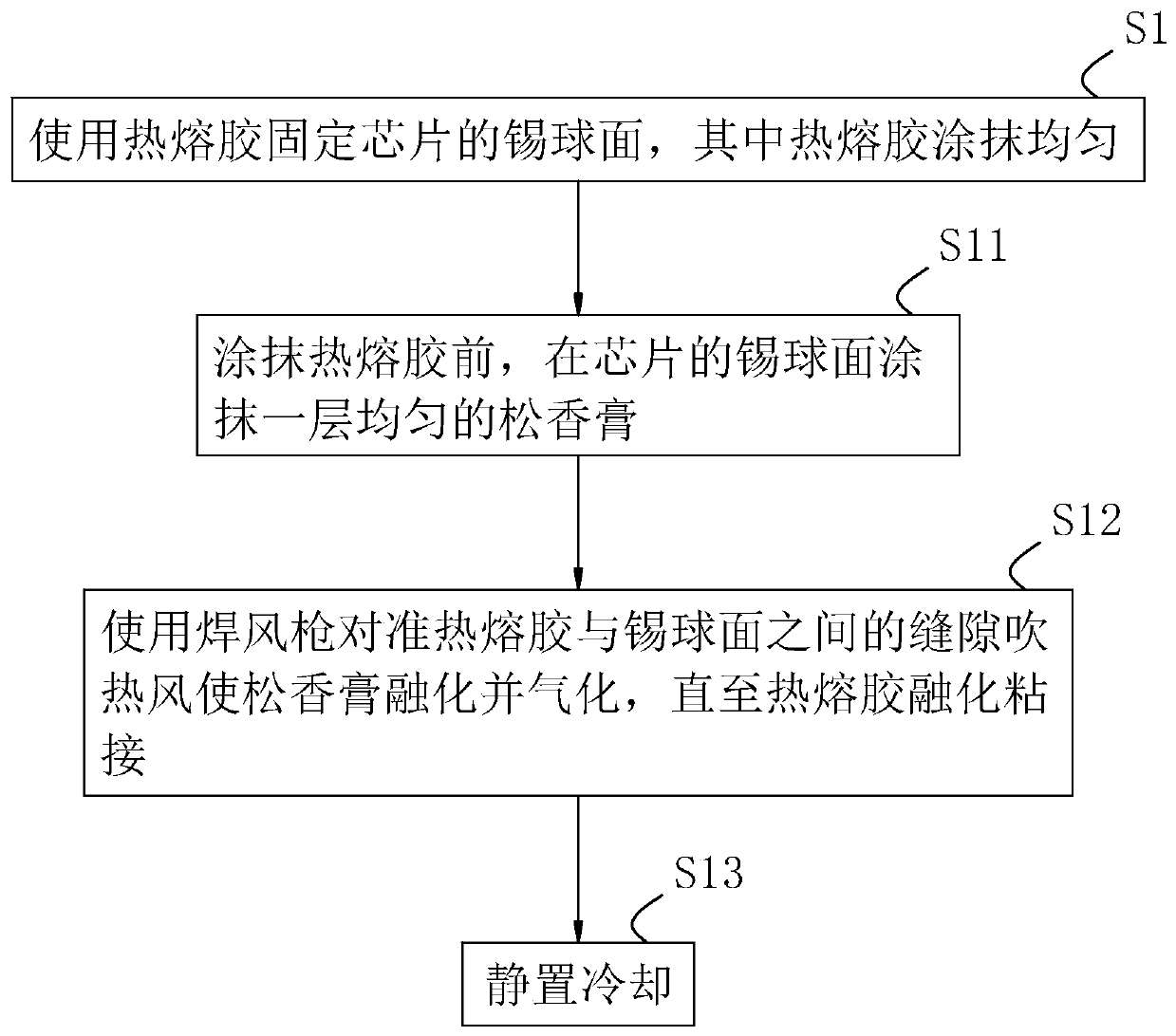

[0039] S1: Use hot melt adhesive to fix the solder spherical surface of the chip, and the hot melt adhesive is evenly applied. Such as figure 2 As shown, S1 also includes: S11: Before applying hot melt adhesive, apply a layer of rosin paste evenly on the solder ball surface of the chip. S12: Use a welding air gun to blow hot air at the gap between the hot melt adhesive and the solder ball surface to melt and vaporize the rosin paste until the hot melt adhesive is melted and bonded. S13: Stand to cool.

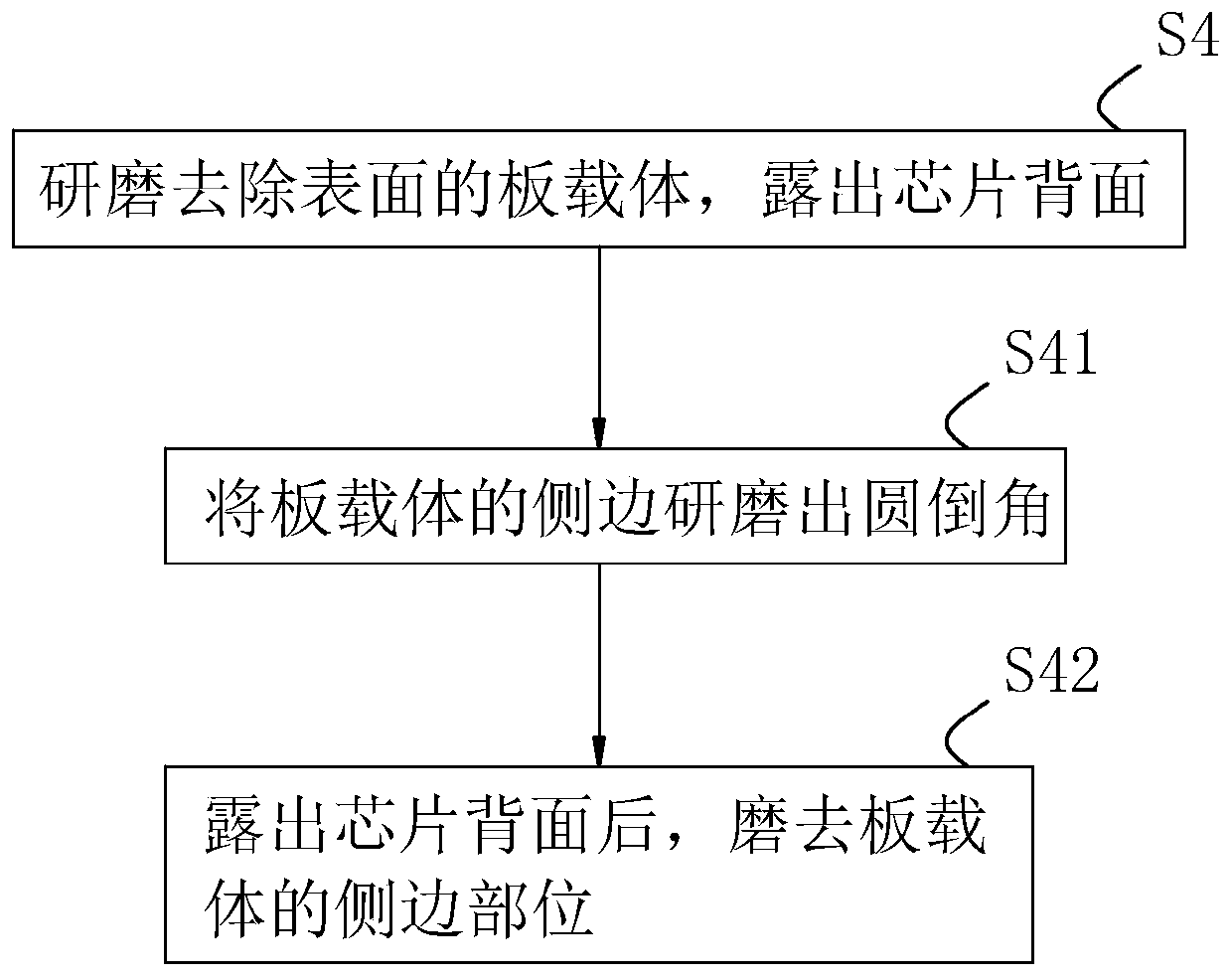

[0040] back to figure 1 , S2: Cutting the board carrier, wherein the maximum cross-sectional area of the board carrier is larger than the maximum cross-sectional area of the chip. The board carrier can use a PCB boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com