Waste gas treatment equipment for industrial environmental protection

A kind of waste gas treatment equipment, environmental protection technology, applied in lighting and heating equipment, dispersed particle separation, direct contact heat exchangers and other directions, can solve the problem of dust easily inhaled by people, harmful to health, unable to remove waste gas dust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

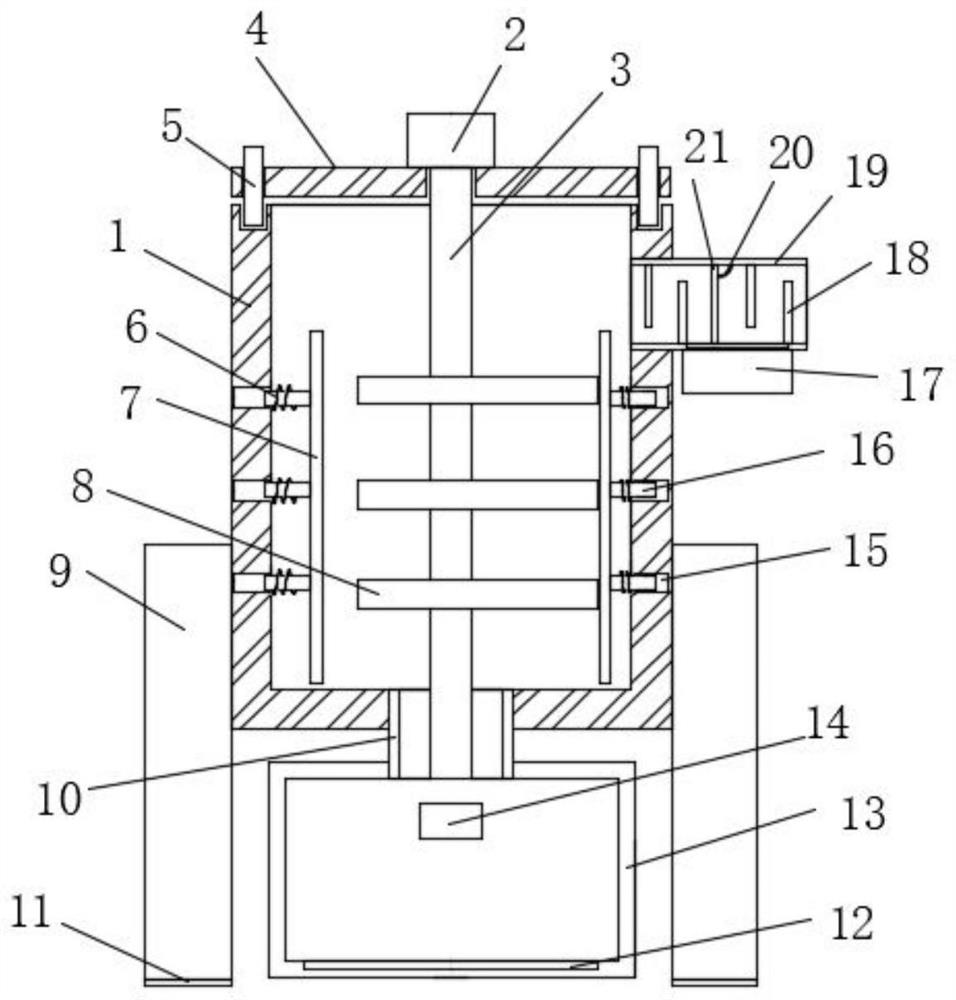

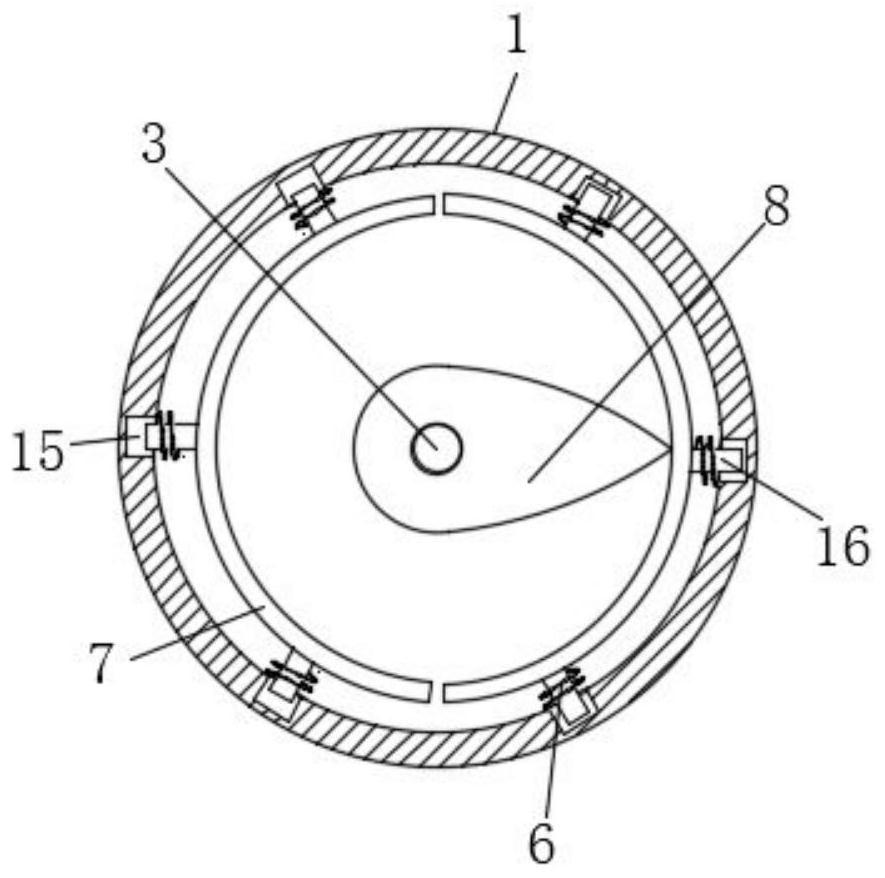

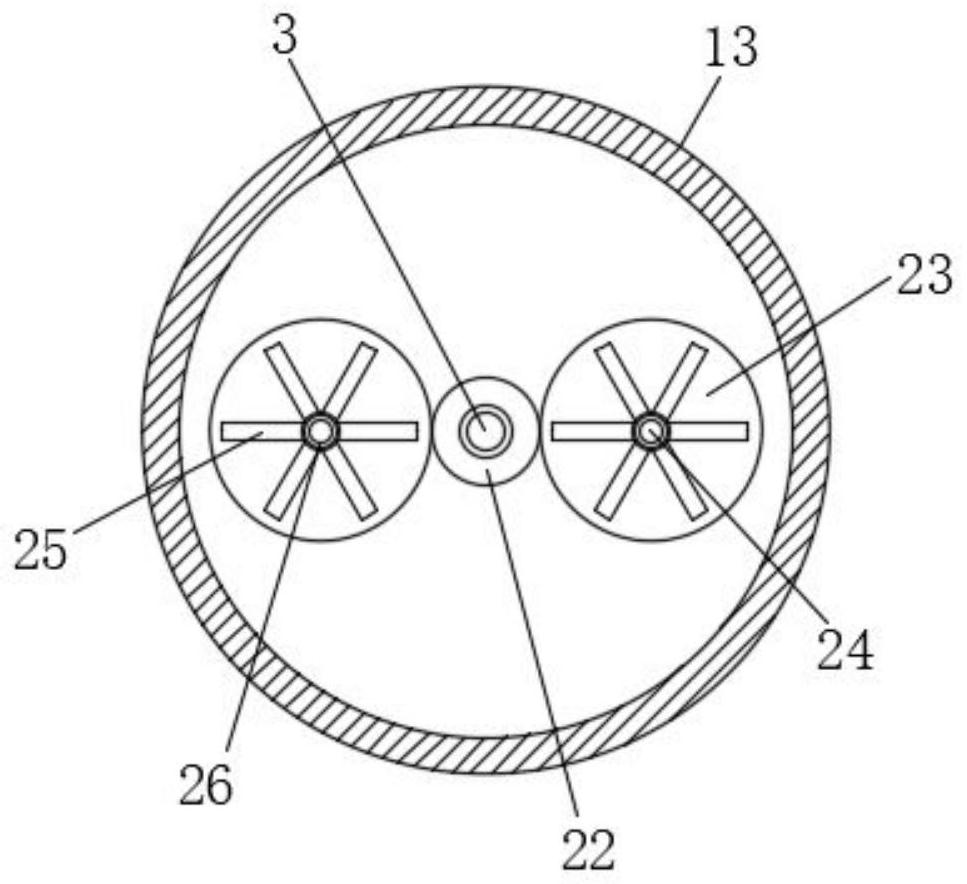

[0027] refer to Figure 1-4 , an exhaust gas treatment device for industrial environmental protection, including a housing 1 and a housing cover 4, the housing 1 is provided with a limit shaft 5 for connecting with the housing cover 4, and the housing 1 and the housing cover 4 pass through the limiting shaft 5 connection, by taking out the limit shaft 5, the shell 1 and the shell cover 4 can be separated, and it is more convenient to clean the inside of the shell 1. The side of the shell 1 is provided with an intake pipe 19 for conveying exhaust gas, and the intake pipe 19 A plurality of baffles 18 for settling dust are provided inside, and a storage box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com