Air filter for automobile engine

A technology for air filters and automobile engines, which is applied to fuel air filters, engine components, machines/engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

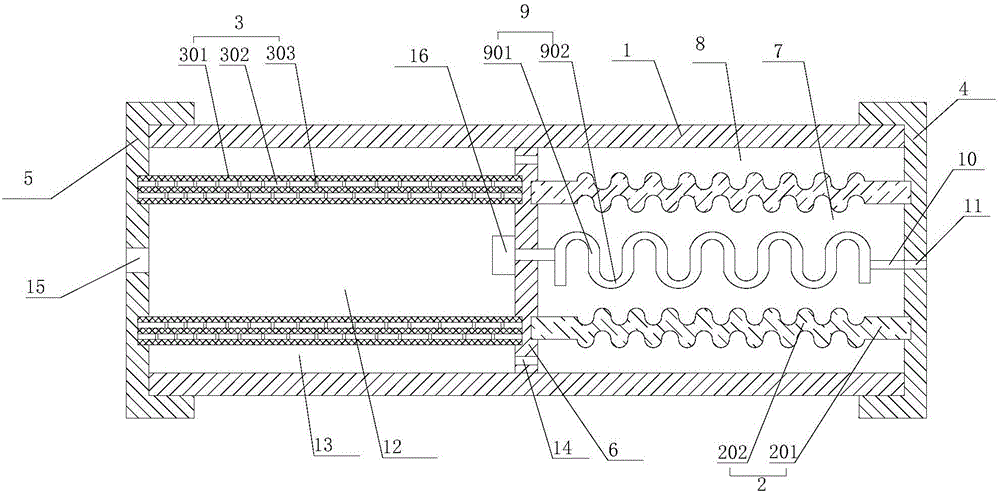

[0018] refer to figure 1 , the present invention proposes an air cleaner for an automobile engine, comprising a filter body 1, a first filter element 2, a second filter element 3, a first end cover 4, a second end cover 5, and a driving mechanism 16, wherein:

[0019] The filter body 1 is a cylinder structure with both ends open, and the two ends of the filter body 1 are respectively screwed with the first end cover 4 and the second end cover 5. The filter body 1 is provided with a circular partition 6, and the center of the partition 6 The axis is collinear with the central axis of the filter body 1, the diameter of the partition 6 is adapted to the inner diameter of the filter body 1, and the partition 6 divides the interior of the filter body 1 into a first cavity and a second cavity.

[0020] The first filter element 2 is arranged in the first cavity, the first filter element 2 is cylindrical and arranged coaxially with the filter body 1, and the side surface of the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com