Cross-flow filtration oil-water separation device

An oil-water separation device and a technology of cross-flow filtration, which are applied in the directions of filtering and thickening suspension liquid separation, liquid separation, separation methods, etc., to achieve the effects of improving separation efficiency, simple operation and increasing contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

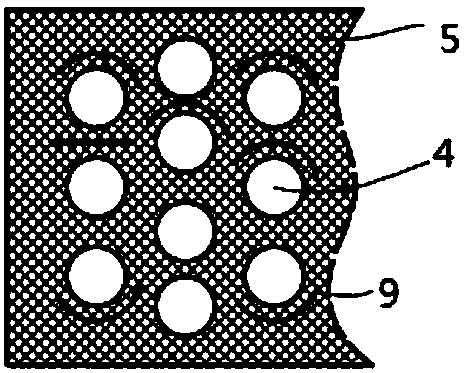

[0024] In this example, a stainless steel metal filter with a pore diameter of 30 μm is selected as the base material, and low surface energy materials such as hydrophobic silica and methyl MQ resin are selected to carry out surface hydrophobization modification treatment on the base material, and the hydrophobic silica Particles and MQ resin with low surface energy were fully dispersed in alcohol to obtain an alcohol mixed solution with a mass fraction of 1%. Soak the filter material in the mixed solution for 30 minutes, take it out and dry it in a vacuum oven at 100°C.

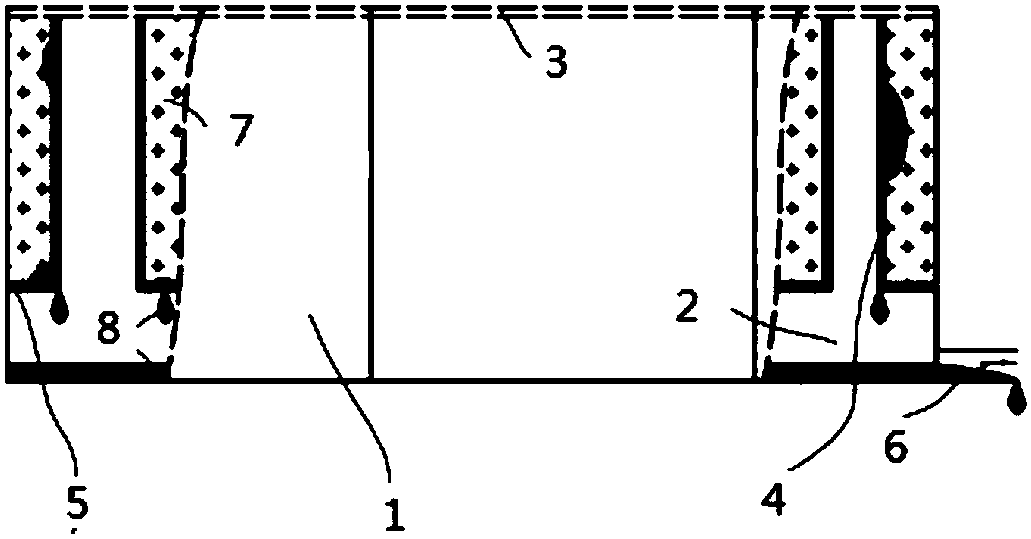

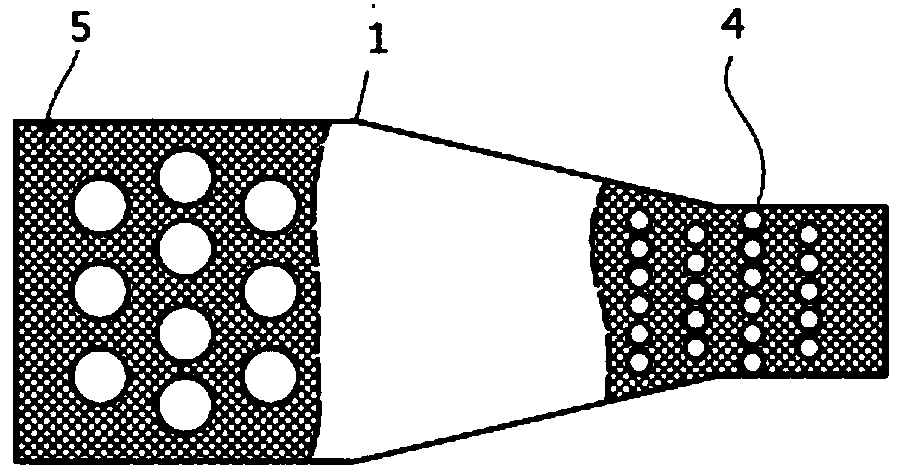

[0025] The overall length of the filter channel is 200mm, the width of the inlet is 50mm, the length of the converging part is 30mm, the width of the narrowest part of the converging part is 20mm, the width of the outlet is also 20mm, and the number of filter cartridges forming the microchannel is 20. The overall length of the cross-flow filter oil-water separation device is 200mm, the height is 60mm, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com